Home » CNC Machining Materials: Metals and Plastics » Aluminum: Custom Aluminum CNC Machining Supplier in China

Custom Aluminum CNC Machining Supplier In China

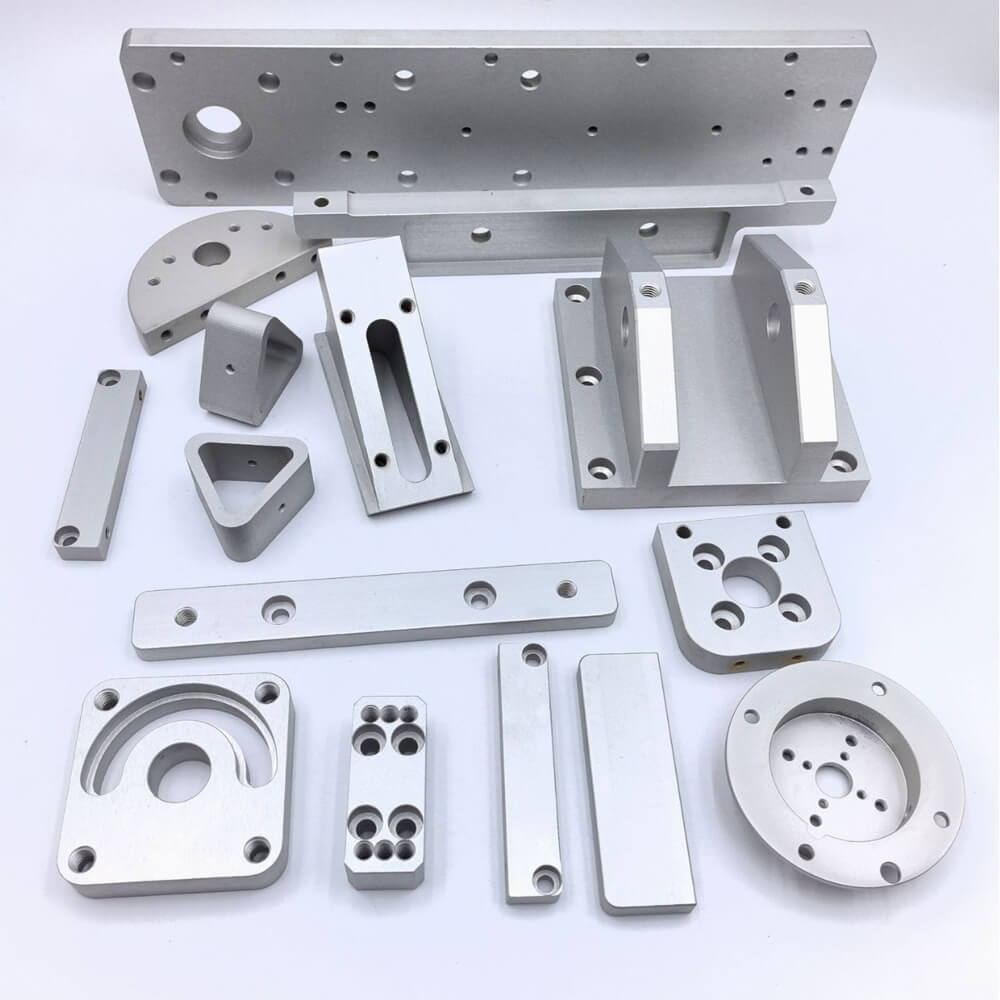

As a leading CNC machining supplier in China, Celerity Precision specializes in the rapid production of high-precision custom aluminum parts. We leverage our advanced 3, 4, and 5-axis CNC machining centers and a deep understanding of aluminum’s unique properties to transform your designs into tangible, high-quality components. Our ISO 9001-certified facility is optimized for machining a wide range of aluminum alloys, from the versatile 6061 to the high-strength 7075, ensuring we can meet the specific demands of any project with speed, accuracy, and cost-effectiveness.

- 3, 4, and 5-axis milling and turning for complex geometries.

- In-stock inventory of the most common aluminum grades.

- Complete in-house solutions from machining to anodizing.

- Optimized processes for both low and high-volume runs.

- ISO 9001 certified quality management for guaranteed results.

Aluminum in CNC Machining

Aluminum is one of the most popular materials in CNC machining due to its outstanding combination of properties, making it an ideal choice for a vast array of applications across numerous industries. Its excellent machinability allows for high-speed cutting, which translates to faster production times and lower costs. At Celerity Precision, we have honed our techniques for machining aluminum to minimize burrs, achieve superior surface finishes, and hold tight tolerances, ensuring we capitalize on all the advantages this versatile material has to offer.

- Allows for high cutting speeds, reducing cycle times and cost.

- Provides the strength of steel at roughly one-third of the weight.

- Forms a protective oxide layer, which can be enhanced by finishing.

- An excellent conductor of both heat and electricity.

- Aluminum is 100% recyclable without any loss of its natural qualities.

- Perfectly suited for a wide range of finishes like anodizing and powder coating.

Aluminum 6061

A highly versatile and popular alloy known for its good mechanical properties, excellent weldability, and corrosion resistance.

Tensile Strength, Yield (MPa) | 124 MPa |

Fatigue Strength (MPa) | 62 MPa |

Elongation at Break (%) | 25-30% |

Hardness (Brinnell) | 30 |

Density (g/cm³) | 2.70 |

Aluminum 2024

A high-strength “aircraft” alloy, valued for its excellent strength-to-weight ratio and fatigue resistance, though with lower corrosion resistance.

Tensile Strength, Yield (MPa) | 186 MPa |

Fatigue Strength (MPa) | 138 MPa |

Elongation at Break (%) | 20% |

Hardness (Brinnell) | 47 |

Density (g/cm³) | 2.78 |

Aluminum 5052

An alloy with excellent corrosion resistance, especially in marine environments, and good formability, making it the strongest non-heat-treatable grade.

Tensile Strength, Yield (MPa) | 228 MPa |

Fatigue Strength (MPa) | 117 MPa |

Elongation at Break (%) | 12-25% |

Hardness (Brinnell) | 60 |

Density (g/cm³) | 2.68 |

Aluminum 5083

Known for its exceptional performance in extreme environments, offering the highest strength of any non-heat-treatable alloy and superior corrosion resistance.

Tensile Strength, Yield (MPa) | 275-350 MPa |

Fatigue Strength (MPa) | 150 MPa |

Elongation at Break (%) | 12-22% |

Hardness (Brinnell) | 80 |

Density (g/cm³) | 2.66 |

Aluminum 6061-T6

The T6 temper significantly increases the strength of 6061 through precipitation hardening, making it the most common general-purpose aluminum alloy.

Tensile Strength, Yield (MPa) | 310 MPa |

Fatigue Strength (MPa) | 96.5 MPa |

Elongation at Break (%) | 12-17% |

Hardness (Brinnell) | 95 |

Density (g/cm³) | 2.70 |

Aluminum 6063

Often called “architectural aluminum,” it has a superior surface finish, good corrosion resistance, and is ideal for extrusion, though with lower strength than 6061.

Tensile Strength, Yield (MPa) | 241 MPa |

Fatigue Strength (MPa) | 69 MPa |

Elongation at Break (%) | 12% |

Hardness (Brinnell) | 73 |

Density (g/cm³) | 2.70 |

Aluminum 6082

A structural alloy with the highest strength of the 6000 series, often used as a substitute for 6061 in higher-stress applications.

Tensile Strength, Yield (MPa) | 310 MPa |

Fatigue Strength (MPa) | 95 MPa |

Elongation at Break (%) | 10-12% |

Hardness (Brinnell) | 95 |

Density (g/cm³) | 2.70 |

Aluminum 7075

A premium zinc-based alloy known for its extremely high strength, comparable to many steels, making it a top choice for high-stress aerospace applications.

Tensile Strength, Yield (MPa) | 228 MPa |

Fatigue Strength (MPa) | 159 MPa |

Elongation at Break (%) | 17% |

Hardness (Brinnell) | 60 |

Density (g/cm³) | 2.81 |

Aluminum 7075-T6

The T6 temper elevates 7075 to its peak strength, creating one of the strongest and hardest aluminum alloys available for CNC machining.

Tensile Strength, Yield (MPa) | 572 MPa |

Fatigue Strength (MPa) | 159 MPa |

Elongation at Break (%) | 11% |

Hardness (Brinnell) | 150 |

Density (g/cm³) | 2.81 |

Aluminum ADC12 (A380)

A common die-casting alloy with excellent castability and good mechanical properties, suitable for machining secondary features on cast blanks.

Tensile Strength, Yield (MPa) | 317 MPa |

Fatigue Strength (MPa) | 138 MPa |

Elongation at Break (%) | 3.5% |

Hardness (Brinnell) | 80 |

Density (g/cm³) | 2.71 |

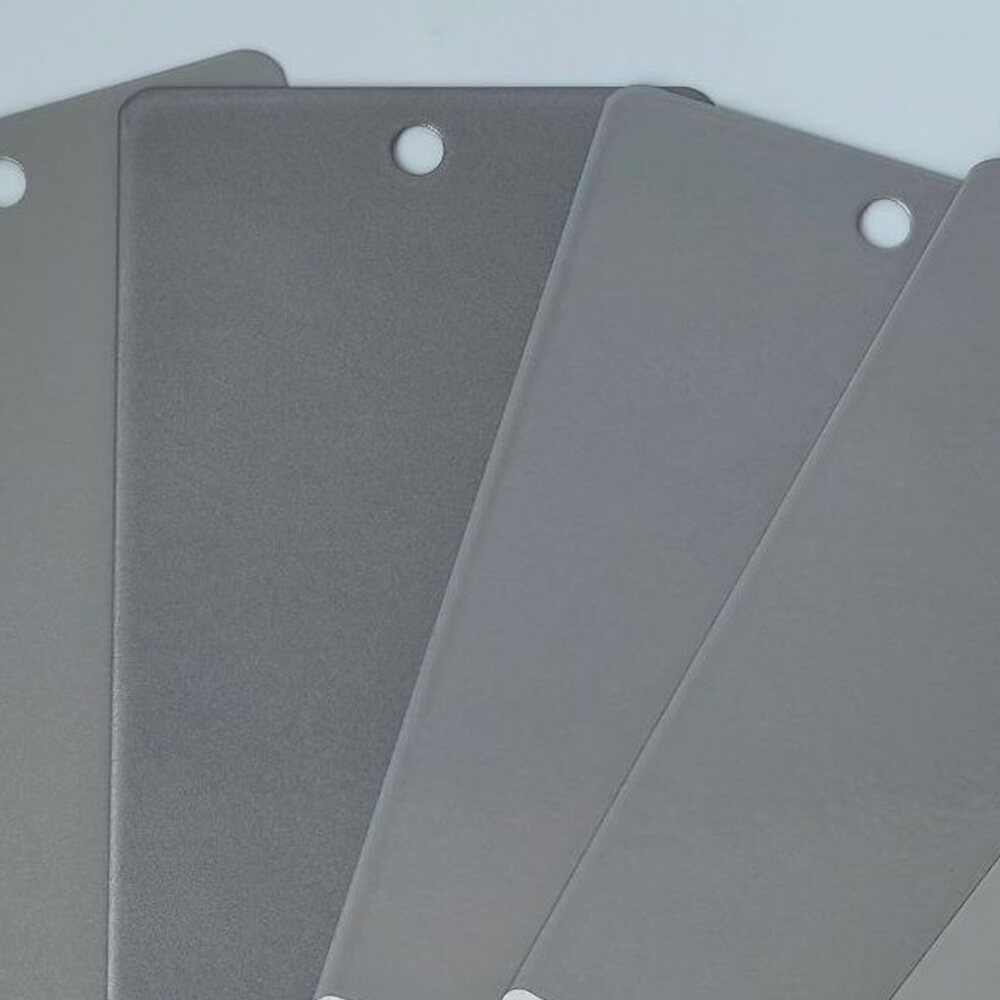

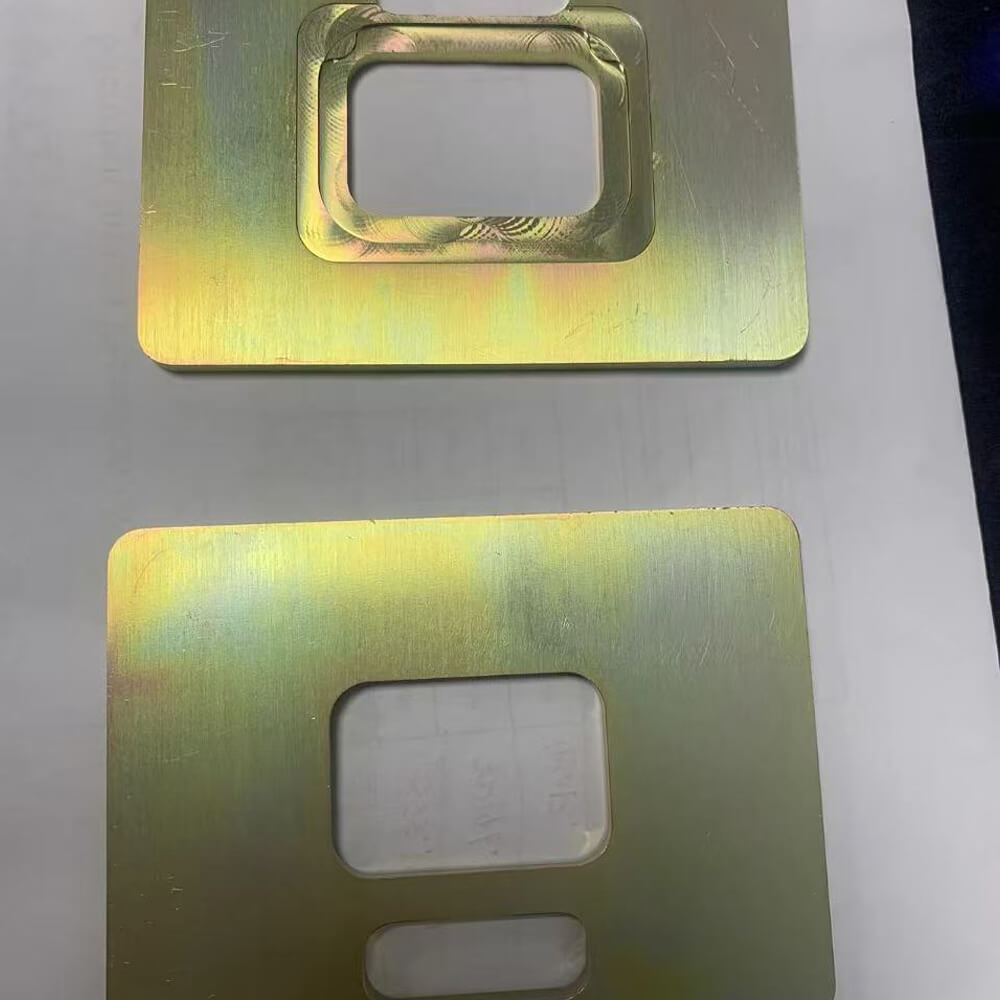

Aluminum CNC Machining Surface Finishes

We offer a complete range of in-house surface finishing options to enhance the cosmetic appearance, corrosion resistance, and wear resistance of your machined aluminum parts.

As Machined

The most cost-effective finish with visible tool marks, ideal for functional prototypes.

Anodizing

The most popular finish, creating a hard, durable, corrosion-resistant, and decorative colored surface.

Powder Coating

Provides a very tough, thick, and durable decorative finish in a wide range of colors.

Sand Blasting

Creates a uniform, non-reflective matte texture, ideal for hiding fingerprints and improving paint adhesion.

Alodine

Provides excellent corrosion protection and a primer for paint while maintaining the aluminum's electrical conductivity.

Black Oxidize

Not applicable; this is a chemical process specifically for ferrous metals like steel.

Brushed Finish

Creates a premium, decorative satin finish with a unidirectional grain for a high-end aesthetic.

Electroless Plating

Applies a very uniform, hard, and wear-resistant nickel coating to all surfaces, including complex internal features.

Electrophoresis

Deposits a highly uniform and durable organic coating (typically black) with complete coverage, ideal for complex aluminum assemblies.

Electropolishing

Not commonly used or effective on aluminum; Anodizing and chemical brightening are the preferred methods for a bright finish.

Painting

Offers an unlimited range of colors and a durable protective layer when applied over a suitable primer.

Passivation

Not applicable; this is a cleaning process specifically for stainless steel to enhance its corrosion resistance.

Teflon Coating

Applies a non-stick, low-friction, and chemically resistant surface, typically over a conversion coating primer.

Tumbling

A cost-effective mass-finishing method to deburr sharp edges and create a smooth, uniform, semi-lustrous finish on batches of smaller aluminum parts.

Pros and Cons of Aluminum CNC Machining

Pros

- High-Speed Machining: Reduces cycle times and lowers production costs.

- Excellent Strength-to-Weight Ratio: Ideal for creating lightweight yet strong parts for aerospace and automotive industries.

- Great Corrosion Resistance: Naturally resistant to rust, making it suitable for a wide range of environments.

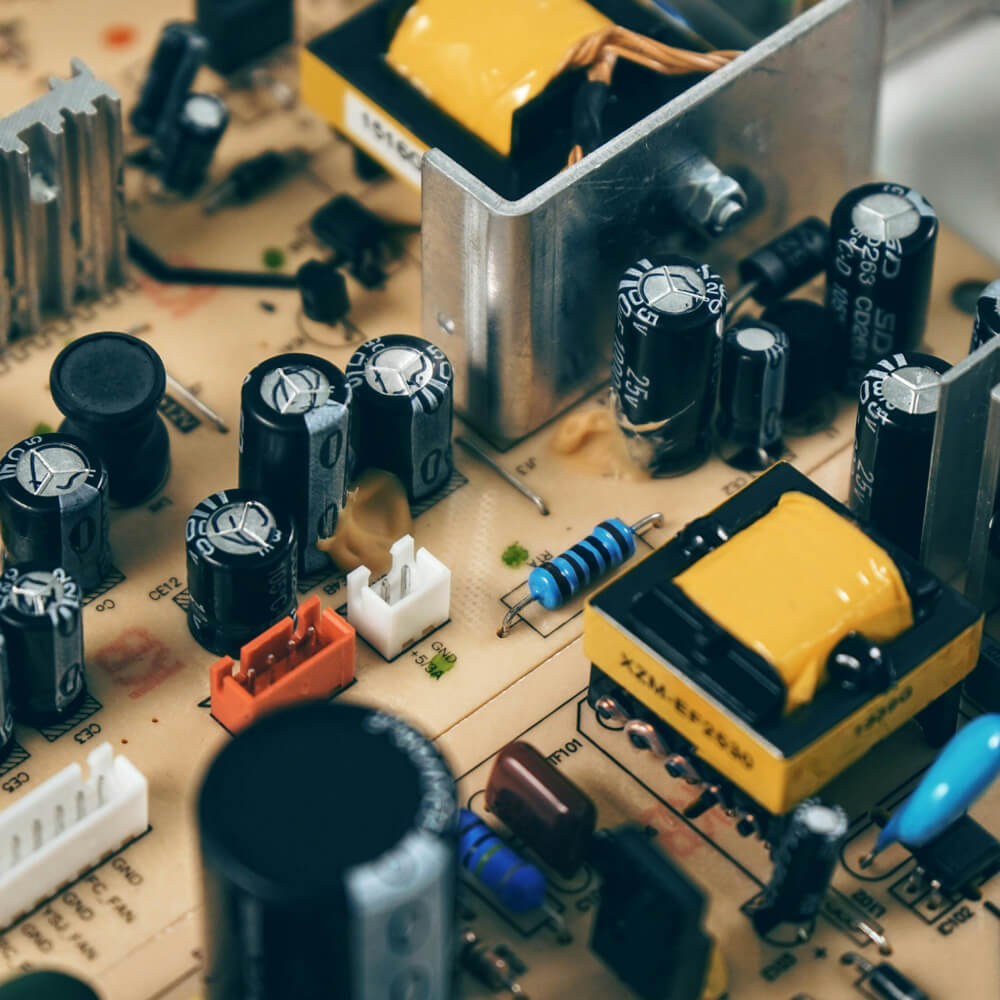

- High Thermal & Electrical Conductivity: Perfect for applications like heat sinks and electronic components.

Cons

- Lower Strength and Hardness vs. Steel: Not suitable for applications requiring extreme strength or wear resistance unless using high-grade alloys like 7075.

- Susceptible to Scratches: Softer than steel and can be easily scratched or dented without a protective finish like anodizing.

- Lower Temperature Resistance: Has a much lower melting point than steel, limiting its use in very high-temperature environments.

- Gummy for some alloys: Some alloys can be "gummy" and require specific tools and techniques to achieve a good surface finish and avoid chip buildup.

Aluminum CNC Machining for Various Industries

Aerospace

Aircraft fittings, structural components, and fuselage parts (7075, 2024).

Automotive

Engine blocks, transmission housings, suspension components, and custom brackets (6061, ADC12).

Consumer Electronics

Smartphone bodies, laptop chassis, and audio equipment enclosures (6063, 6061).

Medical

Surgical instruments, diagnostic equipment housings, and mobility aids.

Industrial Machinery

Jigs, fixtures, machine frames, and robotic components.

Energy

Housings for electrical components, solar panel frames, and heat sinks.

CNC Machining FAQ

Which aluminum alloy is the strongest?

7075-T6 is one of the strongest commercially available aluminum alloys, with strength comparable to many types of steel.

Which aluminum is best for welding?

The 5xxx and 6xxx series alloys, such as 5052 and 6061, are known for their excellent weldability.

Which aluminum is best for corrosion resistance in saltwater?

The 5xxx series alloys, particularly 5052 and 5083, offer the best corrosion resistance in marine environments.

Why is 6061-T6 so popular?

It offers the best all-around combination of strength, corrosion resistance, machinability, and cost-effectiveness, making it the default choice for a huge range of applications.

Do I need to put a finish on my aluminum parts?

While aluminum is naturally corrosion-resistant, a finish like anodizing is highly recommended to protect against scratching and enhance its appearance and durability.

Can you machine very thin walls in aluminum?

Yes, aluminum’s stability allows us to machine very thin walls, but the specific thickness depends on the alloy and part geometry.

Is machining aluminum expensive?

No, aluminum is generally one of the most cost-effective metals to machine due to the high cutting speeds we can achieve, which reduces machine time.

Can you help me choose the right aluminum alloy for my project?

Absolutely. Our engineering team can review your design and application requirements to recommend the best and most cost-effective alloy.