Home » Material

CNC Machining Materials

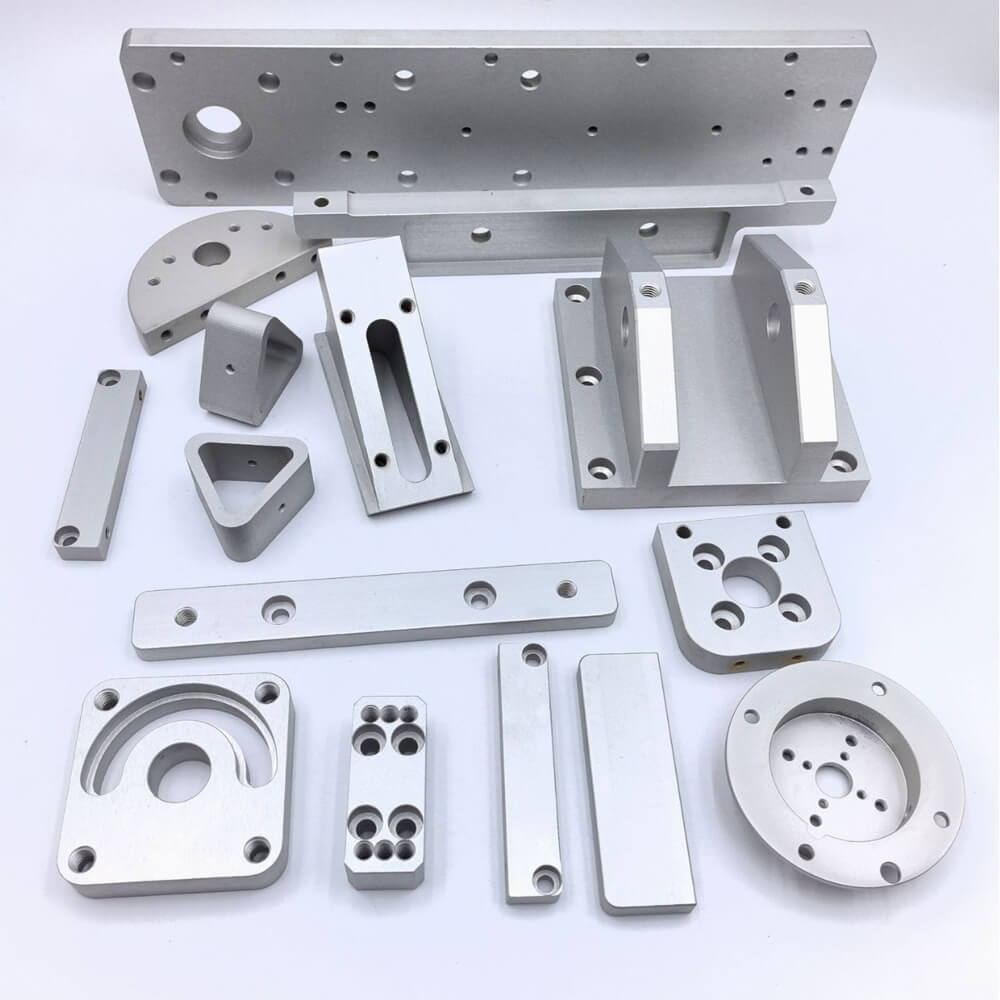

Explore our extensive in-stock inventory of metals and engineering plastics. We have the right material to meet the specific demands of your project, from lightweight aluminum to high-performance PEEK.

The Right Material for Every Application

Selecting the right material is one of the most critical decisions in the manufacturing process. It directly impacts a part’s strength, weight, durability, chemical resistance, and cost. At Celerity Precision, we not only stock a comprehensive range of the most common metals and plastics but also have the deep expertise to help you choose the perfect material for your specific performance and budget requirements.

Explore Our Material Library

Metals

A selection of our most commonly machined metals, chosen for their excellent mechanical properties and versatility.

Aluminum

A lightweight, versatile metal with an excellent strength-to-weight ratio.

Stainless Steel

Offers exceptional corrosion resistance, high strength, and a premium finish.

Steel

The workhorse of industry, offering high strength and durability at a low cost.

Titanium

The ultimate high-performance metal with unmatched strength-to-weight and biocompatibility.

Brass

An easy-to-machine alloy with a natural gold-like appearance and low friction.

Copper

The standard for electrical and thermal conductivity, ideal for heat sinks and busbars.

Bronze

A tough, wear-resistant alloy with superior bearing properties for industrial use.

Magnesium

The lightest of all structural metals, for applications where every gram counts.

Plastic

From general-purpose prototypes to high-performance engineering components, we machine a full spectrum of polymers.

ABS

A tough, cost-effective plastic ideal for durable prototypes and housings.

PC (Polycarbonate)

A shatter-resistant, transparent plastic ideal for strong, clear components.

PLA

A low-cost, biodegradable plastic perfect for rapid concept models.

PMMA (Acrylic)

An optically clear plastic with a glass-like finish, perfect for lenses and light pipes.

POM (Delrin/Acetal)

A stiff, low-friction engineering plastic perfect for precision mechanical parts.

PA (Nylon)

An exceptionally tough and wear-resistant plastic for gears, rollers, and wear pads.

PE (Polyethylene)

A durable and chemically resistant plastic available in LDPE, HDPE, and UHMW grades.

PEEK

An ultra-high-performance polymer for extreme temperature and chemical environments.

PP (Polypropylene)

PP (Polypropylene) A lightweight and tough plastic with superior chemical resistance.

HIPS

A low-cost, impact-resistant plastic ideal for pre-production prototypes.

PBT

A stiff, stable engineering plastic with excellent electrical insulating properties.

PPA

A high-performance polyamide that retains strength at high temperatures.

PAI (Torlon®)

The pinnacle of performance plastics with extreme strength and heat resistance.

PET

A strong, stable, and wear-resistant plastic ideal for food-grade applications.

PPS

A high-performance polymer with unmatched chemical and thermal resistance.

PS (Polystyrene)

A low-cost, clear plastic perfect for non-functional concept models.

PVC

A durable, cost-effective plastic with outstanding chemical and corrosion resistance.

PTFE (Teflon™)

The ultimate non-stick, chemically inert material for seals and insulators.

Bakelite

A hard, heat-resistant thermoset with excellent electrical insulating properties.

FR-4

A glass-epoxy composite with high strength and superb electrical insulation.

From Material to Masterpiece: Our Capabilities

Once you’ve chosen your material, our state-of-the-art facility is ready to transform it into your finished part. We offer a full suite of integrated manufacturing services to bring your design to life.

- CNC Machining: Precision milling and turning for complex components.

- Sheet Metal Fabrication: Laser cutting, bending, and welding for enclosures and brackets.

- Die Casting: High-volume production of complex aluminum and zinc parts.

- Precision Casting: Investment casting for intricate, near-net-shape metal parts.

A Perfect Finish for Every Material

The final step in creating a production-ready part is applying the right finish. We offer a comprehensive range of treatments to enhance performance and aesthetics—from durable Anodizing for aluminum and critical Passivation for stainless steel to cosmetic Powder Coating and Painting for nearly any material. Our integrated process ensures your parts are perfectly prepared and finished to the highest standard.

Materials in Action: Industries We Serve

We have deep experience in providing components for the world’s most demanding industries, where material selection is critical to success. From the high strength-to-weight ratios required in Aerospace and the biocompatibility needed in Medical devices to the durability demanded by the Automotive sector, we understand the unique material challenges of your field.

More Than Just a Material Supplier

Extensive In-Stock Inventory

We maintain a large inventory of the most common materials and grades, allowing us to start your project immediately and reduce lead times.

Expert Engineering Guidance

Unsure which alloy or polymer is best? Our engineering team can provide expert recommendations based on your application, stress requirements, and budget.

Full Material Traceability

We source our materials from certified, reputable suppliers and can provide full material certifications (MTRs) for your project, ensuring quality and compliance.

Specialized Sourcing

If your project requires an exotic or specialized material not listed, our expert sourcing team can procure it for you through our established supply chain.