Home » CNC Machining Materials: Metals and Plastics » PTFE: Custom PTFE CNC Machining Material Supplier in China

Custom PTFE (Teflon™) CNC Machining Services in China

Machining the Ultimate Low-Friction, Chemically Inert Polymer for High-Performance Seals, Gaskets, and Insulators.

- ISO 9001 Certified

- Lowest Coefficient of Friction

- Unmatched Chemical Resistance

Your Expert Partner for PTFE Machining

Celerity Precision is a specialized manufacturer in China offering expert CNC machining of PTFE (Polytetrafluoroethylene), universally known by its DuPont trade name, Teflon™. PTFE is a unique fluoropolymer with a combination of properties unmatched by any other material. It is renowned for having the lowest coefficient of friction of any solid, making it exceptionally slippery, and it is almost completely inert, resisting attack from the most aggressive chemicals. From high-performance seals and gaskets in chemical plants to high-frequency insulators in the electronics industry, machining PTFE is a specialized skill due to its softness and thermal sensitivity. Our facility is expertly equipped to machine PTFE, delivering precision components for the most demanding applications.

Why Choose PTFE for Your Machined Parts?

PTFE is the definitive material for applications demanding extreme chemical resistance and the lowest possible friction. Its molecules are so stable that virtually nothing sticks to it or reacts with it. This makes it an essential material for seals, liners, and components in the chemical processing, medical, and semiconductor industries. While its softness, high thermal expansion, and tendency to “creep” present significant machining challenges, Celerity Precision has mastered the required techniques. We use extremely sharp, dedicated tooling, specialized workholding, and a deep understanding of the material’s properties to produce dimensionally accurate and functional PTFE parts.

Lowest Coefficient of Friction

The most "slippery" solid material known, ideal for non-stick surfaces and low-friction seals.

Unparalleled Chemical Resistance

Virtually inert to almost all industrial chemicals, acids, and solvents.

Wide Temperature Range

Can be used continuously at temperatures from cryogenic levels up to 260°C (500°F).

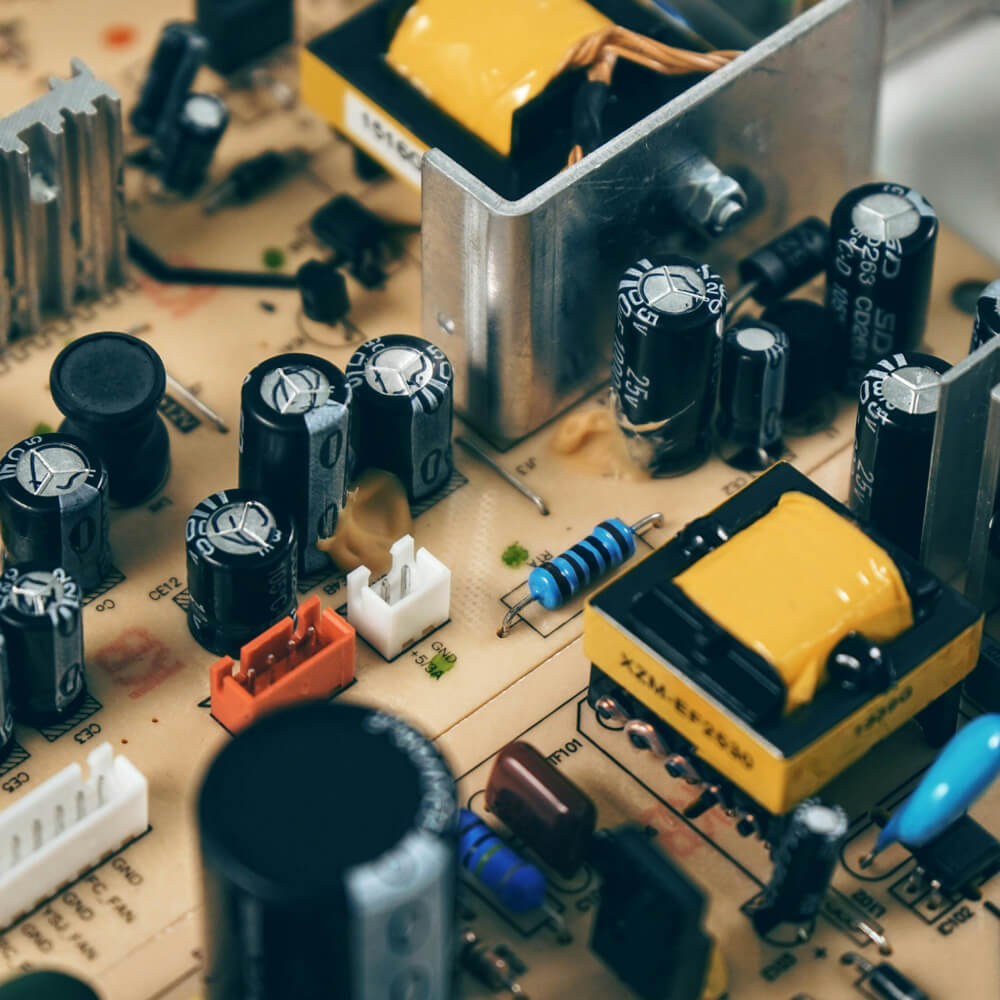

Excellent Electrical Insulator

One of the best electrical insulators, with a very high dielectric strength that is stable across a wide range of frequencies.

Hydrophobic

Repels water and absorbs virtually no moisture.

FDA Compliant

Virgin PTFE is non-toxic and compliant with FDA regulations for food contact.

Virgin (Unfilled) PTFE

This is the pure, standard grade of PTFE. It offers the best chemical resistance, the lowest coefficient of friction, and is FDA compliant. It is relatively soft and has the highest thermal expansion. It is typically a bright, opaque white.

| Tensile Strength, Yield (MPa) | 25 MPa |

| Elongation at Break (%) | 300% |

| Hardness (Shore D) | 55 |

| Density (g/cm³) | 2.15 |

Filled Grades (Glass, Carbon, Bronze)

Fillers are added to PTFE to improve its mechanical properties.

- Glass-Filled: Increases wear resistance and compressive strength.

- Carbon-Filled: Increases hardness, wear resistance, and provides electrical conductivity.

- Bronze-Filled: Increases wear resistance and thermal conductivity.

Surface Finishing Options for PTFE

Due to its extreme chemical inertness and non-stick surface, PTFE cannot be finished in any traditional way.

As Machined

This is the only finish available. PTFE machines to a very smooth, soft, and waxy surface. The quality of the finish is highly dependent on the sharpness of the cutting tools used.

Pros and Cons of PTFE CNC Machining

Pros

- Ultimate Non-Stick Surface: Nothing sticks to it, making it perfect for seals, gaskets, and low-friction bearings.

- Total Chemical Inertness: Can be used with the most aggressive chemicals without degrading.

- Performs in Extreme Temperatures: Stable across a very wide temperature range, from very cold to very hot.

- Superior Electrical Insulator: The top choice for high-frequency and high-voltage electrical applications.

Cons

- Difficult to Machine: Its softness, flexibility, and high thermal expansion make it very challenging to hold tight tolerances.

- Low Mechanical Strength: It is a very soft material with poor strength and stiffness.

- Susceptible to "Creep": Under a constant load, the material will slowly deform or "flow" over time.

- Cannot Be Glued or Painted: Its non-stick surface means that virtually no adhesives or paints will stick to it without specialized and costly chemical etching.

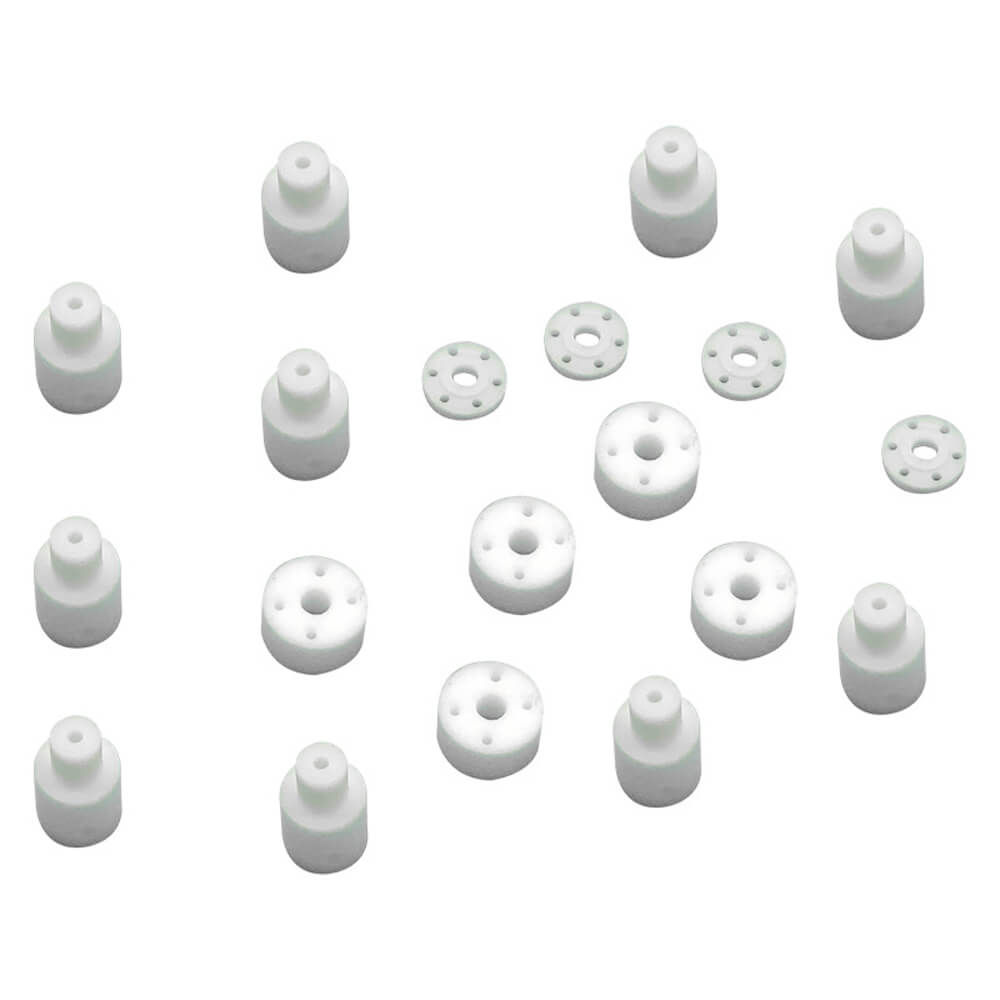

Applications of CNC Machined PTFE Parts

Sealing & Fluid Handling

Gaskets, O-rings, V-rings, and valve seats for the chemical processing industry.

Low-Friction Applications

Bushings, bearings, and slide plates, especially in filled grades.

Electrical & Electronics

High-frequency insulators, connector bodies, and insulating spacers.

Medical & Pharmaceutical

Components for medical devices, pure fluid handling systems, and labware (virgin grade).

Food & Beverage

Non-stick components for food processing and packaging machinery (virgin grade).

Semiconductor

Liners and components for equipment that uses highly corrosive chemicals.

PTFE Machining FAQ

What is the difference between PTFE and Teflon™?

There is no difference in the material. Teflon™ is simply the well-known brand name for the polymer PTFE, originally created by DuPont (now Chemours).

Why is PTFE so difficult to machine accurately?

PTFE is very soft and flexible, so it can easily deflect away from the cutting tool. It also has a very high coefficient of thermal expansion, so the heat from machining can cause it to expand and result in inaccurate dimensions if not managed properly.

What are "filled" grades of PTFE used for?

Fillers like glass, carbon, or bronze are added to improve PTFE’s poor mechanical properties, especially its resistance to wear and creep (deformation under load). This makes it suitable for bearing and structural applications.

Can you really not glue PTFE?

Not in its natural state. To bond PTFE, one side must be chemically etched. This process uses powerful chemicals to alter the surface, allowing industrial adhesives like two-part epoxies to form a mechanical bond.

Is PTFE a strong material?

No. It is very soft and has low tensile strength. Its value comes from its other unique properties, not its strength.

How do you hold PTFE parts for machining without crushing them?

We use specialized soft jaws and low-clamping-force fixtures to hold the material securely without deforming it. This is a key part of the expertise required to machine PTFE.

Is PTFE safe for food and medical use?

Yes, virgin (unfilled) PTFE is biologically inert and complies with FDA regulations, making it safe for food contact and many medical applications.

Does PTFE absorb water?

No, it is one of the most hydrophobic materials known. Its moisture absorption is effectively zero, making it extremely stable in wet environments.