Applications: Machining, Fabrication, Casting, and Surface Finish Services

Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services

We don’t just make parts; we also offer solutions that are made to fit the needs and problems of your industry with great accuracy.

Industries We Served

Aerospace & Aviation

Manufacturing mission-critical components where failure is not an option.

Automotive

Delivering durable parts for everything from high-performance racing to electric vehicle systems.

Medical & Healthcare

Machining biocompatible and sterilizable components to the highest standards of quality.

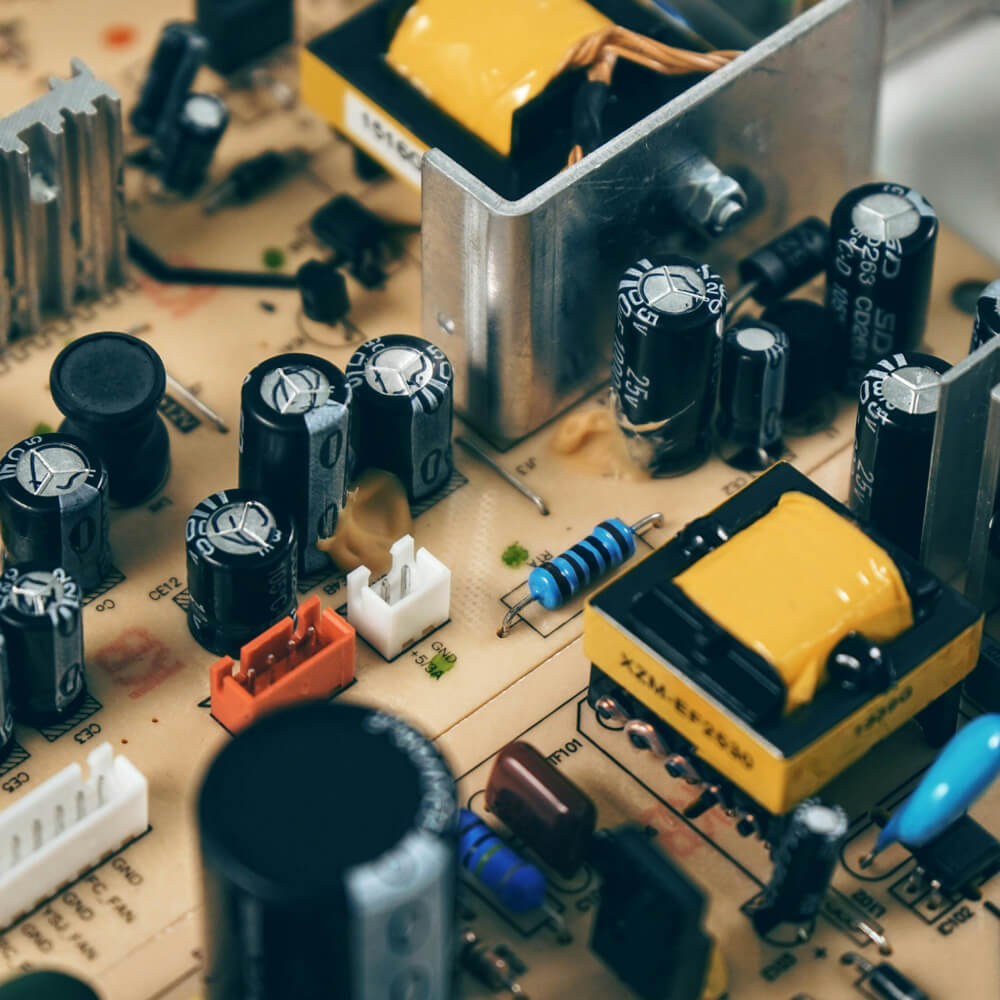

Consumer Electronics

Creating sleek, durable, and precise housings and components for the latest devices.

Robotics & Automation

Building the lightweight, strong, and precise components that power the future of automation.

Industrial Machinery

Producing robust gears, fixtures, and structural parts that withstand the toughest factory floors.

Marine

Fabricating corrosion-resistant hardware and components designed to survive in harsh saltwater environments.

Energy & Power

Manufacturing reliable components for the traditional and renewable energy sectors.

Defense & Military

Delivering rugged, mission-ready components that meet stringent military specifications.

Semiconductor

Machining ultra-high-performance materials for wafer handling and processing equipment.

Scientific Instruments

Creating custom, high-precision components for laboratory and research equipment.

Drones & UAVs

Specializing in the ultra-lightweight and strong components essential for unmanned aerial vehicles.

Why Partner With Us for Your Industry?

A Partner Who Speaks Your Language

Industry-Specific Compliance

We know how to meet the strict quality standards in your field, from AS9100 for aerospace to ISO 13485-ready processes for medical.

Full Material Traceability

We know how important it is to certify materials, and we can trace all of the alloys and plastics used in your project back to their source.

Scalable Production

We can help you with every step of your product's life cycle, from making prototypes in the beginning to running full-scale, high-volume production runs.

Confidentiality & IP Protection

We have strict NDAs in place and promise to keep your intellectual property safe during the whole manufacturing process.

Applications of Machining, Fabrication, Casting, and Surface Finish Services - Celerity Precision

We at Celerity Precision understand how important accuracy and dependability are in making things. For CNC machining, sheet metal fabrication, and more, we’re the place to go.

We also offer services for casting and finishing surfaces. This means that we give our clients exactly what they want, when they want it. We make everything from quick prototypes to a lot of products, and they are all of the highest quality and meet your standards.

We know a lot about different manufacturing services. We want to help you reach your project goals. Do you need precise machining or complicated fabrication? We can deal with it.

Key Takeaways

- Celerity Precision does a lot of different kinds of manufacturing work.

- We offer CNC machining and sheet metal fabrication as part of our services.

- We offer services for casting and finishing surfaces.

- We can make everything from quick prototypes to large-scale production.

- We want to be the manufacturing partner you can trust.

Celerity Precision's Services

Machining

Definition:

Machining is a type of manufacturing that takes away material from a solid piece (metal, plastic, composite) using cutting tools (drilling, milling, turning, grinding, etc.) until the desired shape, size, and surface finish are reached.

Key points: Machining include CNC Machining, CNC Milling, and CNC Turning. In CNC the tools that are controlled by a program can make very precise, repeatable, and complex shapes. The choice of tools, coolant, and lubrication, as well as how they are set up, all matter.

Why it matters:

-

Allows for tight tolerances and a high-quality surface.

-

Works with many different kinds of materials.

-

Good for low to medium volumes, making prototypes, and making parts with high precision.

Common uses:

-

Shafts, housings, brackets, implants, and electronics enclosures are all examples of precision parts.

-

When geometry calls for it, or when casting or forging can’t meet the required tolerances or finish.

Pros and cons:

- High accuracy, a good surface finish, and the ability to work with a variety of materials.

-

Waste of materials because of the subtractive nature; longer cycle times for large volumes; size and fixture limits.

Fabrication

Definition:

Fabrication usually means making parts or assemblies by cutting, shaping, joining (welding, bolting, riveting), bending, or forming sheet or plate metal or structural parts. It’s more about putting things together and building them up than just shaping a part from a block.

Key points: Sheet metal fabrication, welding, forming, laser cutting, water jetting, bending, and putting things together.

Why it matters:

Fabrication lets you make structural frames, enclosures, support systems, and welded assemblies instead of separate machined parts.

Gives you the freedom to make custom or large assemblies.

Common uses:

Frames and supports for machinery, aerospace airframes, automotive chassis sub-components, large enclosures, robotics frames, and ship structural elements.

Often used with machining or casting to make parts that fit with the structure that was made.

Pros and cons:

- Good for custom shapes, large-scale or structural assemblies, and bulk structural work at a lower cost.

Not always as accurate as machining for tight tolerances; welding and fabrication can cause distortions and require skilled workers and inspections.

Casting

Definition:

Casting is a way to shape things by pouring molten material (usually metal or an alloy) into a mold or cavity, letting it cool and harden, and then taking it out and often finishing or machining it.

Some examples are sand casting, die casting, and investment (precision) casting. The mold can hold complicated shapes, holes inside, and more.

Why it matters:

Good for making parts with complicated shapes, internal cavities, large volumes, or large sizes where machining alone would be slow or wasteful.

Often used for near-net-shape: cast roughly, then machine or finish to get the right tolerances.Often used for near-net-shape: cast roughly, then machine or finish to get the right tolerances.

Common uses:

Brackets, pump bodies, turbine housings, engine blocks, structural castings, and more.

In fields where the cost/performance trade-off and the complexity of the geometry are important.

Pros and cons:

- Ability to make big, complicated parts, less waste of materials (especially for big orders), and fast production rates.

- Often less precise as‐cast: surface finish, dimensional tolerance, porosity/defects may require machining/finishing.

Surface Finish

Definition:

Surface finishing is a group of treatments that are done after the main shape/forming is done. They are meant to make the surface better in terms of smoothness, appearance, corrosion resistance, wear resistance, assembly fit, and other things. Some examples are polishing, grinding, coating (anodizing, plating), blasting, chemical film, and passivation.

Some specialized finishes use more advanced methods, like magnetic-field-assisted finishing.

Why it matters:

Roughness on the surface can have a big effect on friction, fatigue life, sealing, looks, and corrosion resistance.

Some industries need high surface finish (like medical implants and aerospace parts) or special coatings (like those that resist corrosion and erosion or are just for looks).

Makes sure that everything is put together correctly, works, and lasts.

Common uses:

Adding the last touch to the look and feel of consumer electronics housings; polishing bores in aerospace; passivating stainless for medical use; anodizing surfaces to protect against corrosion; and so on.

After casting, fabricating, or machining to make sure the final part meets both functional and aesthetic standards.

Pros and cons:

- Improves the performance, look, and lifespan of parts.

Costs more money and time; some finishes need special tools and skills; may need more process controls.

| Service / Industry | Key Role & Requirements |

|---|---|

| Machining | Precision, tight tolerances, complex geometry, many industries from aerospace → electronics |

| Fabrication | Structural assemblies, frames, welded parts, good for large scale or custom build |

| Casting | Complex geometry, large parts, cost effective volume, good for automotive/industrial scale |

| Surface Finish | Critical for function (wear/fatigue), appearance, corrosion/erosion resistance |

Industry-by-Industry Applications of our Services

Now let’s look at how each service (machining, fabrication, casting, and surface finish) is used in each industry and what the most important requirements are.

Aerospace and Aviation

Machining: Parts for planes, like structural brackets, landing gear parts, and engine parts, need very tight tolerances and lightweight alloys like titanium and aluminum. There is a high need for accuracy.

Fabrication: Making the airframe (sheet metal skins, welded frames), structural assemblies, fuselage panels, and support structures.

Casting: Engine housings, turbine blades (sometimes investment casting), large structural castings for landing gear or engine mounts.

Surface Finish: Important for fatigue life, aerodynamic surfaces, and corrosion resistance, especially in harsh conditions. Smooth surfaces lower drag and make sure the seal.

Key requirements: materials that are light, resistant to fatigue, corrosion, and the environment, very reliable, and certified by the government.

Automotive

Machining: engine blocks, parts for transmissions, crankshafts, custom motors, and prototype parts. CNC machining can handle shapes and volumes that are hard to make.

Fabrication: chassis frames, welded assemblies, sheet metal body parts, exhaust systems, and structural sub-assemblies.

Casting: Because of their size and complexity, many car parts, like engine blocks, cylinder heads, and suspension parts, are cast.

Surface Finish: Decorative trims, coatings that protect against rust, smooth surfaces in the cabin and housing, and polished parts in luxury cars.

Key requirements: cost-effectiveness at high volumes, moderate tolerances (compared to aerospace), durability in use, light weight, and crashworthiness.

Medical & Healthcare

Machining: surgical tools, implantable devices, and custom prosthetics. Very tight tolerances, biocompatible materials (like titanium and stainless steel), and small, complicated parts.

Fabrication: frames for equipment, carts, housings for instruments, and maybe even welded assemblies for big devices.

Casting: Investment casting for implants, small parts, or custom devices.

Surface Finish: Very important—smooth surfaces lower the risk of infection, improve biocompatibility, and make sure the product works (for example, polished surfaces in joint implants and passivation of stainless steel).

Key requirements include biocompatibility, sterilizability, traceability, very high quality and certification standards, and often low to medium volume but high complexity.

Consumer Electronics

Machining: making metal frames, housings for high-end devices, prototypes, and custom parts. CNC machining makes it possible to make shapes that are both complex and precise.

Fabrication: putting together sheet metal enclosures, frames, brackets, and other parts.

Casting: For some parts of a house or frame where cost and volume allow, or for parts with complicated shapes.

Surface Finish: Aesthetic finish (polishing, anodizing aluminum, plating), quality of touch and appearance, and coatings to protect against wear and tear.

Main requirements: a lot of volume, cost sensitivity, looks/aesthetics are very important, quick product cycles, and light weight.

Robotics & Automation

Machining: making precise parts like gearboxes, robotic arms, joints, and sensors, as well as modular assemblies with tight tolerances.

Fabrication: Structural frames, welded robotic platform assemblies, gantries, and support structures.

Casting: Some big base parts or housings for robot arms might be cast, especially if they have complicated shapes or channels built in.

Surface Finish: Smooth surfaces for moving parts, protective coatings for strength, and resistance to corrosion in harsh environments.

Key requirements: accuracy, repeatability, long-lastingness, modularity, compatibility with sensors and actuators, and often the ability to combine multiple manufacturing services.

Industrial Machinery

Machining: Shafts, bearings, housings, and other precise parts in big machines.

Fabrication: Making big parts of industrial equipment like frames, supports, platforms, and weldments.

Casting: Big machine bases, pump housings, crusher bodies, and gear cases where shape and volume are important. All Materia

Surface Finish: Surfaces that don’t wear out, protect against rust, and fit together properly for assembly.

Key requirements: durability, customization (often one-time or low-volume), cost-effectiveness, and easy maintenance.

Marine

Machining: Marine engine parts, propeller shafts, precision gears, and pump housings.

Ship structural parts, welded hull segments, support frames, and brackets are all made.

Casting: Big castings for engines, pump housings, valve bodies, and maybe even parts for the rudder.

Surface finish: coatings that protect against salt water corrosion, smooth hydrodynamic surfaces, and protective finishes.

Important requirements: resistance to corrosion, ability to last in tough conditions, large parts, and clear costs.

Energy & Power Generation

Machining: shafts for turbines, parts for generators, precision blades, and pump shafts.

Fabrication: Big structural parts for power plants (frames, supports), welded pipes, and systems that are mounted on skids.

Casting: Turbine housings, generator casings, and other large structural and load-bearing parts where casting works well.

Surface Finish: Coatings to protect against corrosion and erosion, finishing to seal surfaces, and smooth surfaces to help fluids flow better.

Key requirements include high reliability, a long lifespan, often a large size or scale, complicated materials (like high-temperature alloys), and government rules.

Defense & Military

Machining: making precise parts for military vehicles, weapons systems, platforms, avionics, missile components, and more.

Fabrication: welded armor assemblies, structural frames for cars, planes, and ships, and support structures.

Casting: cast parts for armor, vehicles, and heavy structures.

Surface Finish: Coatings for stealth or durability, treatments for wear resistance in harsh environments, and resistance to corrosion.

Key requirements: very high reliability, the ability to work in tough conditions, materials with unique properties (armor alloys, lightweight high strength), and low production volume but high specifications.

Semiconductor

Precision substrate mounts, tooling, wafer handling parts, and vacuum chamber components that need micron tolerances are all examples of machining.

Making things: structural modules for cleanrooms, welded stainless steel chambers, frames, and enclosures.

Casting: Not as common for parts that need the highest precision, but it can be used for vacuum housings, large-scale supports, or heat sinks if the cost and volume are right.

Surface Finish: Very high quality surfaces (for vacuum, optics, and semiconductor handling) that are very smooth to keep particles from forming.

Key requirements include ultra-high precision, control of contamination, a very important surface finish, materials that work with ultra-clean/ultra-high vacuum, and often custom and small batches.

Scientific Instruments

Machining: making custom parts for research labs, precision optical mounts, and parts for measuring instruments.

Fabrication: structural frames, instrument enclosures, and welded assemblies in labs or research facilities.

Casting: Maybe for big instrument bases or heavy support frames to keep things stable and add thermal mass.

Surface finish is very important for optics, measurement surfaces, and smoothness to avoid artifacts. Coatings are used to keep things clean and make them more resistant.

Key requirements: very high accuracy, often low volume or custom work, materials may be rare (Invar, ceramics, optical glass mounts), and finish and stability are important.

Drones & UAVs

Machining: frames, brackets, propeller hubs, and motor mounts; often made of lightweight materials like aluminum and carbon composite that are connected to machined parts.

Fabrication: Frames for bigger UAVs that have been welded or put together, lightweight structural assemblies, and bodies made of sheet metal.

Casting: This could be for engine parts in big UAVs or for structural parts that are cheaper when they are made in large quantities.

Surface Finish: coatings that can stand up to the weather, lightweight metal finishing, smooth surfaces for better aerodynamics, and protective resistances against weather and corrosion.

Key requirements include being lightweight but strong, having high accuracy for flight stability, being cost-sensitive (especially for consumer and inspection drones), and being able to quickly prototype and go through short cycles.

| Industry | Machining Applications | Fabrication Applications | Casting Applications | Surface Finish Applications | Key Demands / Requirements |

|---|---|---|---|---|---|

| Aerospace & Aviation | Aircraft parts (brackets, landing gear, engine components), tight tolerances, lightweight alloys (Ti, Al). | Airframe structures, fuselage panels, welded frames, support assemblies. | Engine housings, turbine blades (investment casting), large cast structural parts. | Aerodynamic & corrosion-resistant coatings; smoothness for fatigue & sealing. | Lightweight materials, fatigue & corrosion resistance, extreme precision, certification. |

| Automotive | Engine blocks, transmissions, crankshafts, prototypes; CNC for volume & complexity. | Chassis, body panels, exhausts, welded sub-assemblies. | Engine blocks, cylinder heads, suspension & drivetrain parts. | Decorative trims, corrosion coatings, interior finishes. | High volume & cost-efficiency, durability, lightweight, crash safety. |

| Medical & Healthcare | Implants, surgical tools, prosthetics; tight tolerances, biocompatible metals. | Equipment frames, instrument housings, large device weldments. | Investment casting for implants, micro or custom parts. | Polished & passivated surfaces for sterilization & biocompatibility. | Biocompatibility, sterilizability, traceability, high certification, low-volume high-precision. |

| Consumer Electronics | Device housings, precision metal frames, prototypes. | Sheet metal brackets, enclosures, small assemblies. | Casings, frames with complex geometry. | Anodizing, polishing, plating for aesthetics & protection. | High volume, cost-sensitive, lightweight, attractive appearance, fast cycle times. |

| Robotics & Automation | Precision gears, joints, arms, actuator housings. | Structural frames, robotic bases, gantry weldments. | Base housings or arm components with complex geometry. | Smooth joints, corrosion protection, wear coatings. | Precision, durability, modularity, sensor compatibility, reliability. |

| Industrial Machinery | Shafts, housings, bearings, mechanical components. | Frames, supports, platforms, weldments for heavy machines. | Bases, housings, gear cases, pump bodies. | Wear & corrosion coatings, fitting surfaces. | Robustness, custom designs, maintainability, cost efficiency. |

| Marine | Propeller shafts, gears, pump housings, marine engines. | Hull structures, brackets, welded supports. | Engine & valve housings, rudders, large structural parts. | Marine coatings, anti-corrosion layers, hydrodynamic surfaces. | Corrosion resistance, harsh environment durability, large-scale, cost control. |

| Energy & Power Generation | Turbine shafts, precision blades, generator parts. | Power plant frames, supports, welded piping systems. | Turbine & generator housings, structural cast parts. | Corrosion/erosion coatings, sealing finishes, smooth flow surfaces. | Reliability, long lifespan, heat-resistant materials, regulatory compliance. |

| Defense & Military | Weapon components, vehicle & aircraft parts, avionics. | Vehicle/ship frames, welded armour, structural supports. | Armour castings, vehicle & platform components. | Coatings for stealth, wear & corrosion resistance. | Extreme reliability, harsh-environment tolerance, special alloys, low-volume precision. |

| Semiconductor | Wafer handling parts, vacuum chamber components, tooling with micron tolerances. | Cleanroom frames, stainless enclosures, chamber weldments. | Vacuum housings, heat sinks (limited use). | Ultra-smooth, particle-free, high-purity finishes. | Ultra-high precision, contamination control, clean materials, small batch custom work. |

| Scientific Instruments | Optical mounts, precision measurement components. | Instrument frames, lab enclosures, welded assemblies. | Stable cast bases or support frames. | Smooth & clean optical/mechanical surfaces. | High precision, stability, exotic materials, low volume, fine finishes. |

| Drones & UAVs | Prop hubs, frames, motor mounts, lightweight metal parts. | Structural frames, lightweight assemblies, sheet metal parts. | Engine parts, structural housings (for large UAVs). | Protective coatings, aerodynamic & corrosion finishes. | Lightweight strength, flight stability, rapid prototyping, cost-effective production. |

Final Thoughts

To make smart choices, you need to know how different manufacturing processes work. We have looked at services for machining, fabrication, casting, and finishing surfaces. Each one has its own uses in business.

We at Celerity Precision are proud to be a dependable partner in the manufacturing industry. We provide our clients with the best manufacturing solutions that meet their needs. Our expertise in precision engineering lets us make parts that meet high standards in a lot of different areas.

The different ways of making things show how advanced and adaptable modern manufacturing is. It is very important for fields like aerospace, automotive, medical, and consumer electronics. Understanding these steps can help you reach your goals and make more.

In short, your business can benefit a lot from working with a partner like Celerity Precision. We are a top choice because we focus on precision engineering and offer a wide range of manufacturing solutions. We’d love to help you with your next project.

FAQs

What kinds of manufacturing services does Celerity Precision offer?

We do CNC machining, sheet metal fabrication, die casting, and surface finishing. These services support various industries.

What is CNC machining and how do you use it?

CNC machining is a very exact process. It uses machines that are controlled by computers to make complicated parts. We use it in the aerospace, automotive, and medical fields.

What kinds of things can be used for die casting?

Die casting can be done with metals like aluminum, zinc, and magnesium. This lets us make parts with certain qualities for different purposes.

How does the finish on the surface affect how well manufactured parts work?

The finish on the surface has a big effect on how well parts work, how long they last, and how they look. We have different finishes that can make things work better and look better.

What kinds of businesses does Celerity Precision work with?

We work with the aerospace, automotive, medical, and consumer electronics industries. We offer customized solutions for the needs of each industry.

Can Celerity Precision handle production runs of all sizes?

Yes, we can do both small runs of prototypes and large-scale production. This gives our customers the ability to be flexible and grow.

What are the advantages of using precision casting in production?

Precision casting lets you make shapes and details that are very complicated. It allows us to create accurate components with minimal waste.