Precision CNC Machining for the Aerospace & Aviation Industry

Manufacturing Flight-Critical Components with AS9100 Compliant Processes, Full Material Traceability, and Uncompromising Precision.

- ISO 9001 Certified

- 5-Axis Titanium & Aluminum Machining

- Full FAI Reporting

Your Trusted Tier Supplier for Aerospace Components

The aerospace and aviation industry operates at the pinnacle of engineering, where performance, safety, and reliability are absolute. At Celerity Precision, we understand the immense responsibility that comes with manufacturing components for this sector. We are a leading precision manufacturer based in Shenzhen, China, specializing in the production of complex, tight-tolerance parts for commercial aircraft, defense systems, satellites, and UAVs. Our facility and quality systems are built to meet the rigorous demands of the world’s most innovative aerospace companies.

Our commitment goes beyond simply machining parts. We position ourselves as a strategic partner in your supply chain, providing expert engineering feedback, rigorous process control, and comprehensive documentation. We combine our advanced manufacturing capabilities with an unwavering dedication to quality, ensuring every component we deliver is flight-ready, fully compliant, and delivered on time, helping you meet your critical project milestones.

The Celerity Precision Advantage for Aerospace

AS9100 Compliant Quality System

Our quality management system is built upon the rigorous principles of the AS9100 standard, ensuring strict process control, risk management, and a culture of continuous improvement essential for the aerospace industry.

Advanced 5-Axis & Multi-Axis Machining

We utilize state-of-the-art 5-axis CNC machining centers to produce complex monolithic components, reducing setups, increasing accuracy, and enabling the creation of intricate geometries common in modern airframe and engine design.

Expertise in Aerospace Alloys

Our team has extensive, hands-on experience machining challenging aerospace-grade materials, including Titanium (Ti-6Al-4V), high-strength Aluminum (7075, 2024), Inconel, and precipitation-hardening stainless steels (17-4 PH).

Full Traceability & Documentation

We provide complete, transparent documentation for every project, including full raw material traceability with Mill Test Reports (MTRs), Certificates of Conformance (CofC), and detailed inspection reports.

Risk Management & Process Control

We develop a robust manufacturing plan for every aerospace component, identifying and mitigating risks at every stage to guarantee consistent quality and prevent delays.

Secure & Confidential Partnership

We operate under strict Non-Disclosure Agreements (NDAs) and have secure data handling protocols in place to protect your sensitive intellectual property and proprietary designs.

From Drawing to Flight-Ready Part: Our AS9100-Aligned Process

RFQ & Technical Review

Upon receiving your Technical Data Package (TDP), our engineering team conducts a thorough review, assessing feasibility and providing expert Design for Manufacturability (DFM) feedback.

Process Planning & Risk Assessment

We develop a detailed, multi-stage manufacturing plan, including process flow, tooling selection, and the creation of custom fixtures to ensure precision and repeatability.

Material Procurement & Certification

We source certified materials from approved, reputable suppliers and verify all documentation (MTRs) to ensure full compliance and traceability.

Precision Manufacturing & Finishing

Your parts are machined under strict process controls. All subsequent processes, such as heat treatment and finishing, are managed through our certified supply chain.

First Article & In-Process Inspection

We perform and document a First Article Inspection (FAI) per AS9102 standards. In-process inspections occur at critical stages to ensure quality is maintained throughout.

Final Inspection, Documentation & Shipping

Every part undergoes a final, rigorous inspection using our CMM and other metrology tools. A complete documentation package is prepared, and parts are securely packaged for global delivery.

Have a Technical Data Package Ready?

Let our aerospace manufacturing experts review your project and provide a comprehensive, competitive quote.

Key Manufacturing Services for Aerospace

5-Axis CNC Milling

Essential for machining complex monolithic structures, airfoils, and contoured components from single blocks of aluminum or titanium.

CNC Turning with Live Tooling

Ideal for producing high-precision engine shafts, actuator components, and fittings with both cylindrical and milled features in one setup.

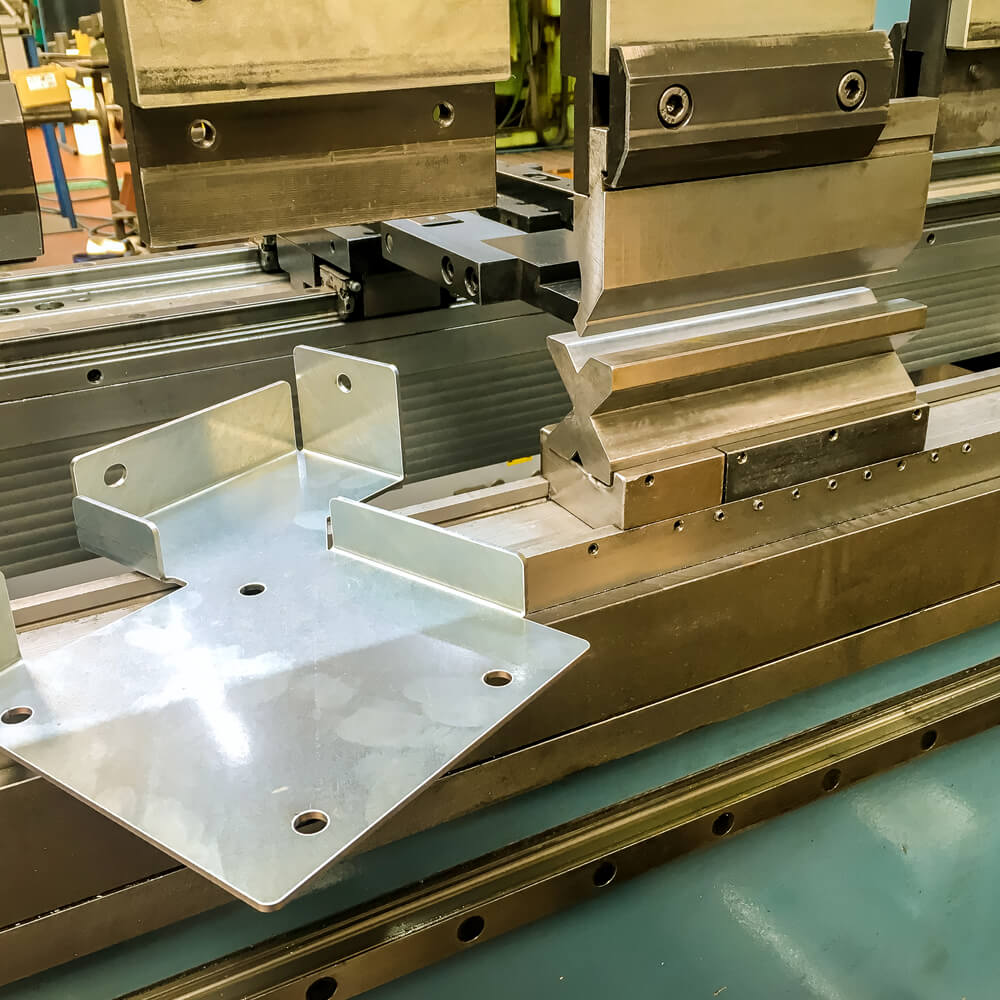

Sheet Metal Fabrication

Fabricating lightweight aluminum enclosures for avionics, as well as brackets and panels that meet strict aerospace requirements.

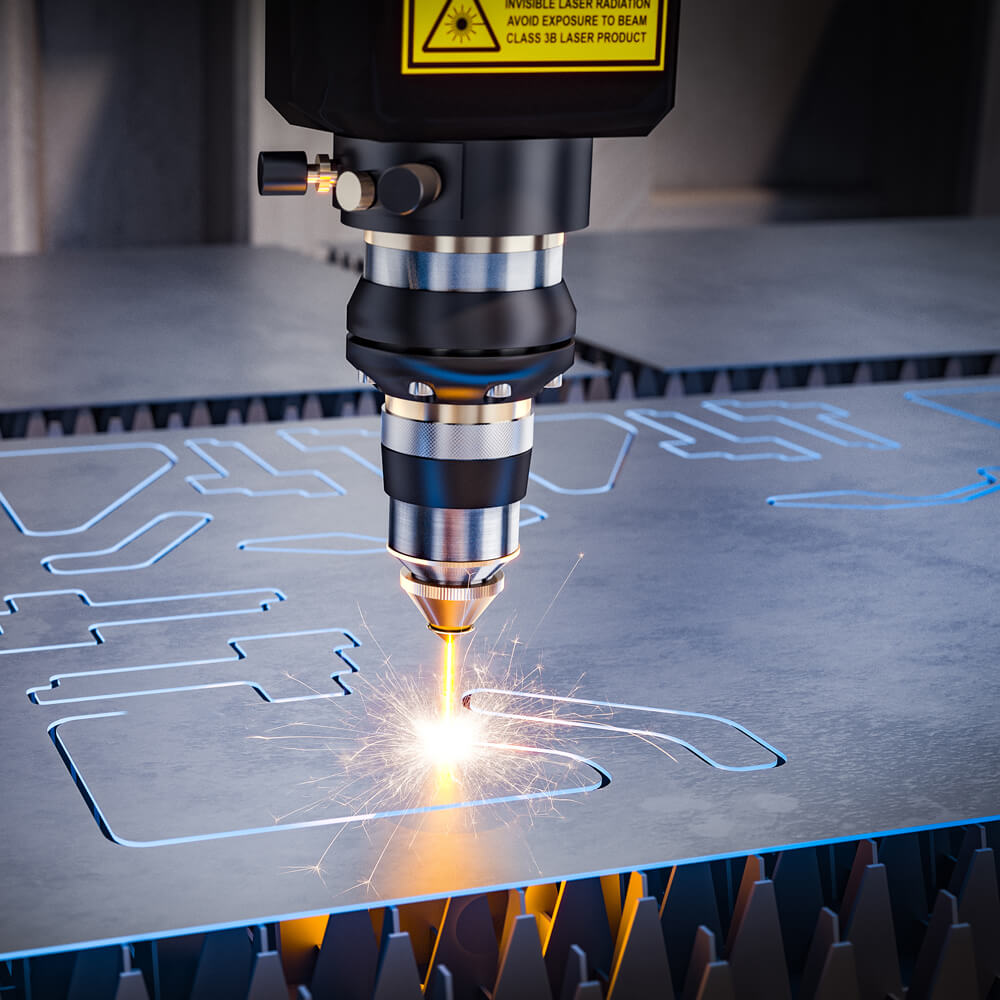

Laser Cutting

Precisely cutting complex profiles and patterns in sheet materials like titanium and stainless steel for brackets and shims.

TIG Welding

Expert, high-purity TIG welding of stainless steel and aluminum assemblies for fluid lines, tanks, and structural supports.

Precision Casting

Providing near-net-shape investment castings for complex components like turbine blades and structural nodes, reducing machining time and material waste.

Aerospace-Grade Materials and Compliant Finishes

Common Aerospace Materials:

- Aluminum (7075-T6, 6061-T6, 2024-T3)

- Titanium (Grade 5 / Ti-6Al-4V)

- Stainless Steel (17-4 PH, 316L, 304L)

- Alloy Steels (4130, 4340)

- Superalloys (Inconel, Hastelloy)

- High-Performance Plastics (PEEK, PAI/Torlon®)

Compliant Surface Finishes:

- Anodizing (Type II & Type III Hardcoat) per MIL-A-8625

- Chemical Conversion Coating (Alodine) per MIL-DTL-5541

- Passivation per AMS 2700

- Electroless Nickel Plating

- Powder Coating & Painting

- Heat Treatment

Gallery of Aerospace Components

- Structural Brackets & Ribs

- Avionics Housings & Enclosures

- Engine Mounts & Fittings

- Landing Gear Components

- Turbine Blades & Vanes

- Hydraulic Manifolds

- Actuator & Sensor Housings

- Fuel System Components

- UAV Structural Frames

- Satellite & Spacecraft Components

Aerospace Manufacturing FAQ

Are you AS9100 certified?

Our quality management system is built to be fully compliant with the principles and rigorous requirements of the AS9100 standard, ensuring the highest level of process control and documentation for our aerospace clients.

How do you handle material traceability?

We have a strict material control process. We source all aerospace materials from certified suppliers and provide full Mill Test Reports (MTRs) that trace the material lot back to its origin. This documentation is included with every shipment.

Can you provide First Article Inspection (FAI) Reports?

Yes, we provide comprehensive FAI reports compliant with the AS9102 standard. Our quality team documents every dimension, feature, and note on your drawing to provide formal verification that the first production part is 100% compliant.

What is your experience with machining titanium and Inconel?

We have extensive experience with these challenging materials. We utilize specialized tooling, rigid machines, and optimized cutting strategies (e.g., high-pressure coolant, trochoidal milling) to successfully machine titanium and other superalloys while maintaining tool life and part integrity.

How do you ensure the confidentiality of my proprietary designs?

We take intellectual property protection very seriously. We are always prepared to sign a Non-Disclosure Agreement (NDA) before reviewing any technical data, and our internal data systems are secure to protect your sensitive information.

What is your typical lead time for aerospace prototypes?

Lead times depend on complexity and material, but for moderately complex aluminum or stainless steel prototypes, we can often deliver parts in as little as 2-3 weeks.

Do you manage outside processes like heat treatment and NDT?

Yes, we manage a network of certified and trusted partners for specialized processes like heat treatment, non-destructive testing (NDT), and specific plating requirements, providing you with a single, accountable point of contact.

What tolerances can you hold on complex 5-axis parts?

We can consistently hold positional tolerances of ±0.025mm (±0.001″) on complex, multi-sided parts. Tighter tolerances are often achievable depending on the specific geometry and material.

How do you control quality during a production run?

After the FAI is approved, we use statistical process control (SPC) methods, with regular in-process inspections at set intervals to monitor critical dimensions and ensure the entire production run remains within specification.

What information do you need for an accurate quote?

For the most accurate quote, please provide a complete technical data package, including 3D CAD models (STEP), 2D drawings with all dimensions and tolerances, material specifications, finishing requirements, and the desired quantity.

Related High-Performance Applications

Defense & Military

Manufacturing rugged, mission-ready components that meet stringent military specifications.

Drones & UAVs

Specializing in the ultra-lightweight and strong components essential for unmanned aerial vehicles.

Scientific Instruments

Creating custom, high-precision components for laboratory and research equipment.