Precision Manufacturing for the Automotive Industry

From Rapid Prototypes for EV Development to High-Volume Production Runs, We Deliver High-Performance Automotive Components with Speed and Reliability.

- IATF 16949 Compliant Processes

- Rapid Prototyping

- Scalable Production

Your Agile Partner in Automotive Manufacturing

The automotive industry is in a constant state of evolution, driven by relentless innovation in electric vehicles (EVs), autonomous driving, and high-performance engineering. Celerity Precision is an agile and modern manufacturing partner based in Shenzhen, China, built to support this fast-paced environment. We specialize in the rapid production of custom CNC machined, sheet metal, and die-cast components that meet the demanding quality, durability, and performance standards of the automotive sector.

We understand the critical importance of speed in automotive R&D and the necessity of consistency in production. Our services are designed to support your entire product lifecycle, from initial prototypes for validation and testing to bridge production and full-scale manufacturing runs. We combine advanced technology with a quality mindset based on IATF 16949 principles to deliver parts that accelerate your development cycle and strengthen your supply chain.

The Celerity Precision Advantage for Automotive

IATF 16949 Compliant Quality System

Our quality management processes are aligned with the core principles of IATF 16949, focusing on rigorous process control, defect prevention, and continuous improvement to meet the high standards of the automotive supply chain.

Rapid Prototyping & Iteration

We are built for speed. Our streamlined processes allow us to deliver high-quality, functional prototypes in a matter of days, enabling your engineering teams to test, iterate, and innovate faster.

Scalable Production Capabilities

Our facility is equipped for seamless scalability. We can take your project from a handful of prototypes to tens of thousands of production parts, ensuring consistent quality and on-time delivery as your volume needs grow.

Expertise in Automotive Materials

We have extensive experience machining a wide range of automotive-grade materials, from lightweight 6061-T6 aluminum for chassis parts and 7075 for suspension, to durable alloy steels for drivetrain components.

Advanced Manufacturing Technology

With multi-axis CNC machining, high-volume die casting, and precision sheet metal fabrication, we have the right technology to produce a wide variety of automotive components efficiently and cost-effectively.

Comprehensive Finishing & Assembly

We are your one-stop shop. We provide a full suite of finishing services, from anodizing and powder coating to heat treatment, and can deliver sub-assemblies to simplify your production line.

From Design to the Production Line: Our Automotive Process

RFQ & DFM Analysis

Submit your CAD files and specifications. Our engineers provide a rapid quote and a free Design for Manufacturability (DFM) analysis to optimize your part for cost and quality.

Process Planning (PPAP Support)

We develop a detailed manufacturing plan. For production orders, we can provide elements of the Production Part Approval Process (PPAP) as required.

Material Certification & Sourcing

We source certified automotive-grade materials from trusted suppliers and provide full traceability documentation.

Precision Manufacturing

Your parts are produced using the optimal process, whether it's high-speed CNC machining, die casting, or sheet metal fabrication.

In-Process & Final Inspection

We use SPC (Statistical Process Control) and CMM inspection to ensure consistent quality throughout the production run, verifying all GD&T callouts.

Finishing, Assembly & Logistics

Parts are finished, assembled, and securely packaged for just-in-time (JIT) delivery to your production facility anywhere in the world.

Accelerate Your Automotive Development Cycle

Get fast, reliable parts for your R&D, prototyping, and production needs.

Key Manufacturing Services for Automotive

CNC Machining

The core of our service, ideal for prototyping and producing complex, tight-tolerance components like suspension knuckles, engine blocks, and custom fittings.

CNC Turning

High-speed production of drivetrain components, shafts, bushings, and custom fasteners with exceptional precision.

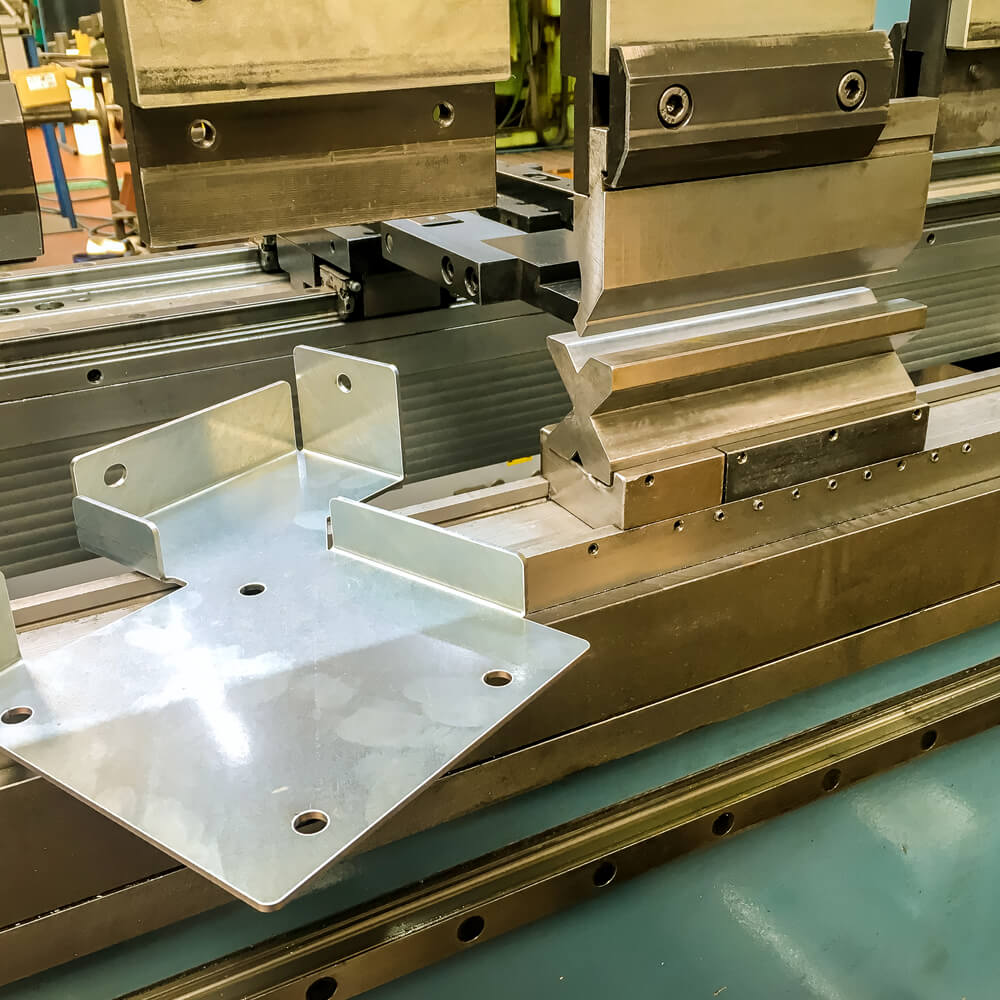

Sheet Metal Fabrication

Creating robust brackets, chassis components, and battery enclosures from steel and aluminum.

Die Casting

The perfect solution for high-volume production of complex, near-net-shape parts like housings, covers, and electronic enclosures.

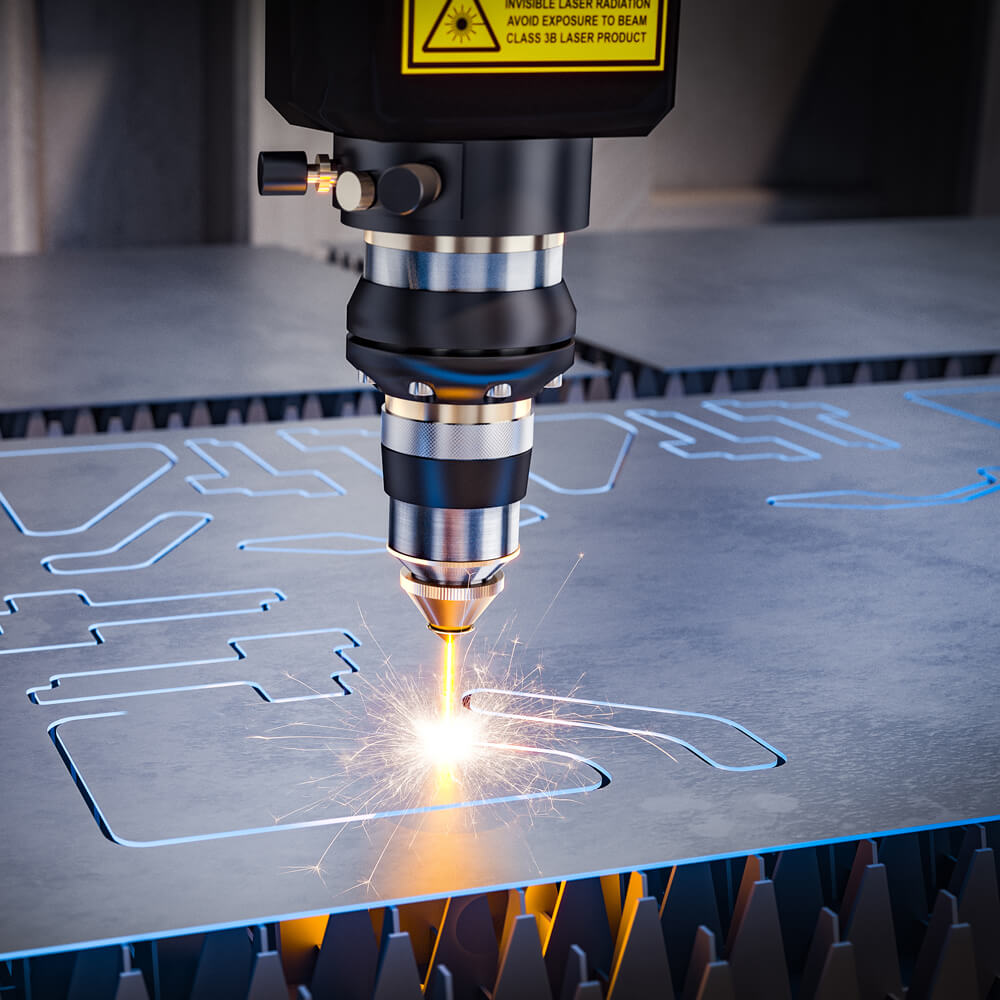

Laser Cutting

Rapidly cutting custom flanges, gaskets, and brackets from sheet materials with high accuracy.

Welding

Expert TIG and MIG welding for creating strong, rigid assemblies for frames, exhaust components, and chassis parts.

Automotive-Grade Materials and Durable Finishes

Common Automotive Materials:

- Aluminum (6061-T6, 7075-T6, A380)

- Stainless Steel (304, 416)

- Alloy Steels (4140, 4340)

- Carbon Steels (1018, 1045)

- High-Performance Plastics (PEEK, PPA, Delrin)

- Zinc Alloys (Zamak 3, Zamak 5)

Durable Surface Finishes:

- Anodizing (Type II & Type III Hardcoat)

- Powder Coating

- Electrophoresis (E-Coating)

- Zinc Plating

- Electroless Nickel Plating

- Heat Treatment (Hardening & Annealing)

Gallery of Automotive Components

- Suspension Components (Knuckles, Control Arms)

- EV Motor Housings & Covers

- Battery Enclosures & Busbars

- Engine Components (Blocks, Heads, Pistons)

- Transmission & Drivetrain Parts

- Custom Brackets & Mounts

- Turbocharger Components

- Brake Calipers & Components

- Fluid System Manifolds & Fittings

- Interior Decorative Trim

Frequently Asked Questions

Can you support our PPAP requirements?

Yes, for production orders, we can work with you to provide the required elements of a PPAP submission, including dimensional layouts, material certifications, and process control plans.

What is your lead time for automotive prototypes?

We specialize in rapid prototyping. Depending on complexity, we can often deliver CNC machined prototypes in as little as 3-7 business days, helping you accelerate your R&D cycles.

Do you work with electric vehicle (EV) startups?

Absolutely. We are an ideal partner for EV companies, offering the speed and agility needed for prototyping and the scalability required to move into production for components like battery enclosures, motor housings, and busbars.

What is the most common aluminum for automotive parts?

6061-T6 is the most versatile and widely used for a variety of brackets, chassis, and general components. For high-stress applications like suspension parts, 7075-T6 is often preferred. For high-volume die-cast parts, A380 is the industry standard.

Can you handle high-volume production runs?

Yes. Our facility is equipped with automated systems like bar feeders for CNC turning and robotic cells for die casting, making us highly efficient for production runs of thousands to hundreds of thousands of parts.

How do you ensure quality and consistency in a large production run?

We use Statistical Process Control (SPC) to monitor critical dimensions throughout the production process. Regular in-process inspections ensure that any deviation is caught and corrected immediately, guaranteeing consistency from the first part to the last.

What is the best finish for a chassis or suspension part?

For maximum durability and corrosion resistance, a multi-layer finish is often best. This typically involves a protective coating like E-coating or Zinc Plating, followed by a durable topcoat like Powder Coating.

Do you offer any services for motorsport/racing teams?

Yes, our rapid prototyping and expertise with high-performance materials like titanium, 7075 aluminum, and PEEK make us an excellent partner for motorsport teams that require lightweight, high-strength, custom components on a tight deadline.

Can you machine castings from another supplier?

Yes, we frequently provide secondary CNC machining services on castings or forgings provided by our clients to add high-precision features.

How do you ensure your material is genuine and meets specifications?

We source all materials from certified, reputable suppliers and can provide Mill Test Reports (MTRs) to verify the chemical composition and mechanical properties of every material lot we use.

Related High-Performance Applications

Aerospace & Aviation

Applying our tight-tolerance machining expertise to flight-critical components.

Industrial Machinery

Manufacturing the robust gears, shafts, and housings that power industry.

Energy & Power Generation

Producing durable components for traditional and renewable energy systems.