Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Consumer Electronics

Precision Manufacturing for the Consumer Electronics Industry

From Sleek Aluminum Prototypes to High-Volume Production of Housings, Frames, and Components with a Flawless “Class A” Cosmetic Finish.

- Rapid Prototyping

- Expert Cosmetic Finishing

- Scalable Production

Your Manufacturing Partner for Next-Generation Devices

In the highly competitive consumer electronics market, product success is defined by a perfect fusion of cutting-edge technology and premium aesthetics. Celerity Precision, located in the heart of the world’s electronics manufacturing hub in Shenzhen, China, is an agile manufacturing partner built to support this demanding industry. We specialize in the rapid prototyping and mass production of custom CNC machined components—from intricate internal brackets to flawless external enclosures—that meet the high cosmetic and functional standards of modern consumer devices.

We understand that speed to market and a perfect finish are paramount. Our processes are optimized to accelerate your product development cycle, providing high-fidelity, “looks-like, feels-like” prototypes in a matter of days. As you transition to production, our scalable capabilities ensure we can deliver tens of thousands of parts with the consistent quality and cosmetic perfection that consumers expect from a premium product.

The Celerity Precision Advantage for Consumer Electronics

Flawless Cosmetic Finishes

We are experts in achieving "Class A" cosmetic finishes. From fine bead blasting and anodizing on aluminum to high-gloss polishing on plastics, we have the expertise to deliver a premium look and feel.

Rapid Prototyping & Iteration

We help you innovate faster. Our streamlined processes deliver high-quality, dimensionally accurate prototypes in as little as 3-5 days, allowing your design teams to quickly test, validate, and iterate.

Expertise in Lightweight Metals

We have extensive experience machining the materials that define modern electronics, including 6061 and 6063 aluminum for enclosures and frames, and stainless steel for durable, high-strength components.

Scalable, High-Volume Production

Our facility is designed to scale with your success. We can seamlessly transition from producing ten prototypes to a full production run of 100,000+ parts, maintaining absolute consistency and quality.

Design for Manufacturability (DFM) Feedback

Our engineers provide critical DFM feedback to optimize your designs for mass production, helping you reduce costs, improve assembly, and enhance the final product's durability.

Strategic Location & Supply Chain

Located in Shenzhen, we are at the center of the global electronics supply chain, enabling us to manage projects efficiently and integrate seamlessly with your other manufacturing partners.

From Concept to Consumer: Our CE Manufacturing Process

RFQ & Rapid DFM

Securely upload your CAD files. We provide a competitive quote and expert DFM feedback focused on cosmetic outcomes and mass production efficiency within 24 hours.

Prototype Phase

We rapidly machine your prototypes, applying the specified finishes to create high-fidelity models for design validation, marketing, and investor presentations.

Golden Sample & Process Validation

Before mass production, we produce a "golden sample" for your final approval and lock in all manufacturing and finishing parameters to ensure consistency.

Scalable Mass Production

We utilize our automated and optimized production cells to manufacture your components at scale, ensuring consistent quality across the entire run.

Cosmetic Inspection & Quality Control

Every part undergoes a rigorous cosmetic and dimensional inspection. We have established clear standards for "Class A," "Class B," and "Class C" surfaces.

Assembly & Global Logistics

We can perform sub-assembly services and manage global logistics to deliver your parts directly to your assembly line, just-in-time.

Ready to Build Your Next Great Product?

Let’s create beautiful, high-quality components that will define your brand.

Key Manufacturing Services for Electronics

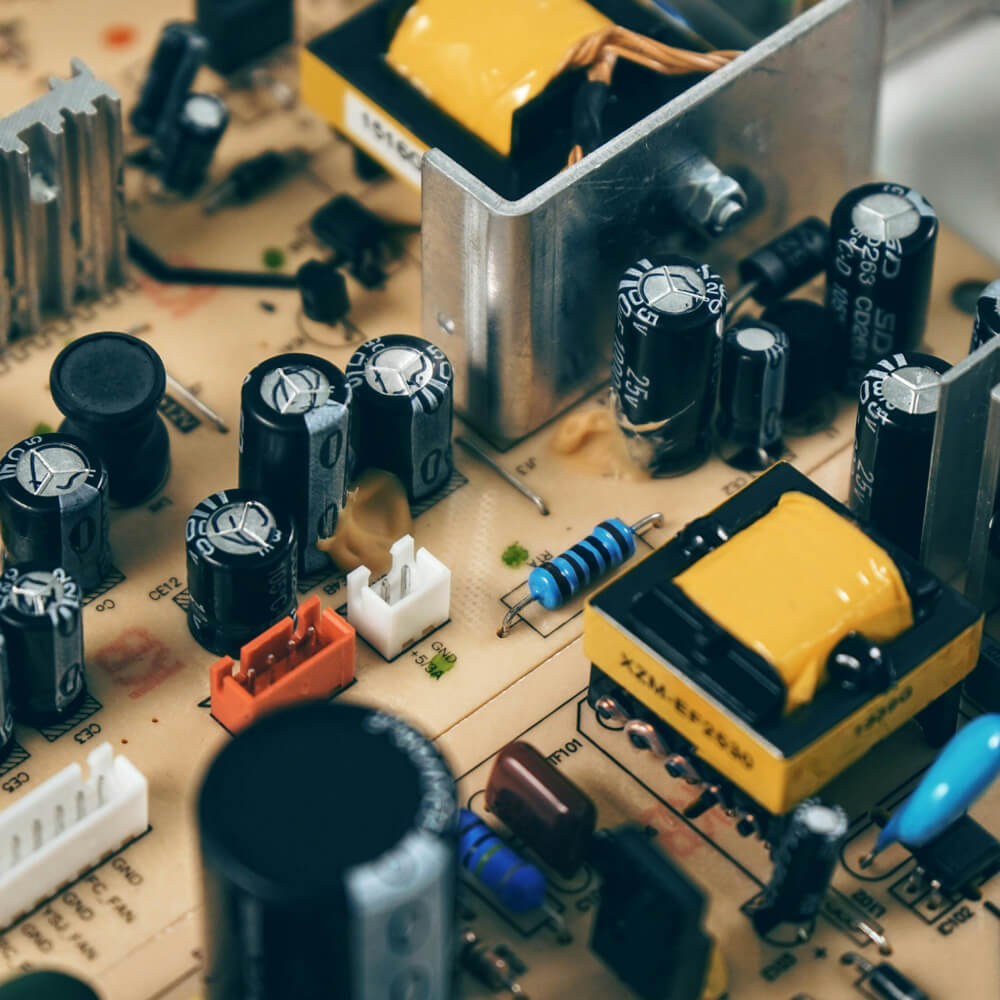

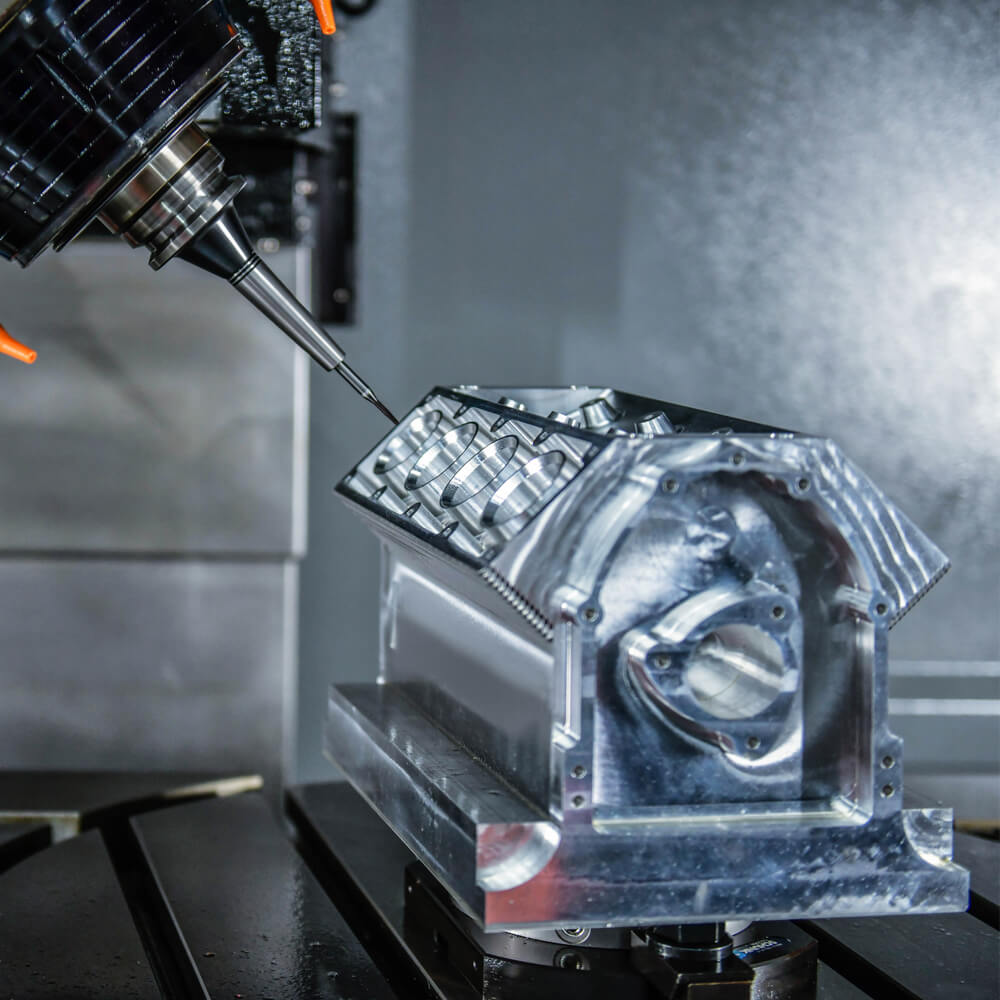

CNC Machining

The core of our service for creating high-fidelity prototypes and production parts from aluminum, stainless steel, and plastics with a premium finish.

CNC Turning

Ideal for producing round components like knobs, dials, connector housings, and standoffs with high precision.

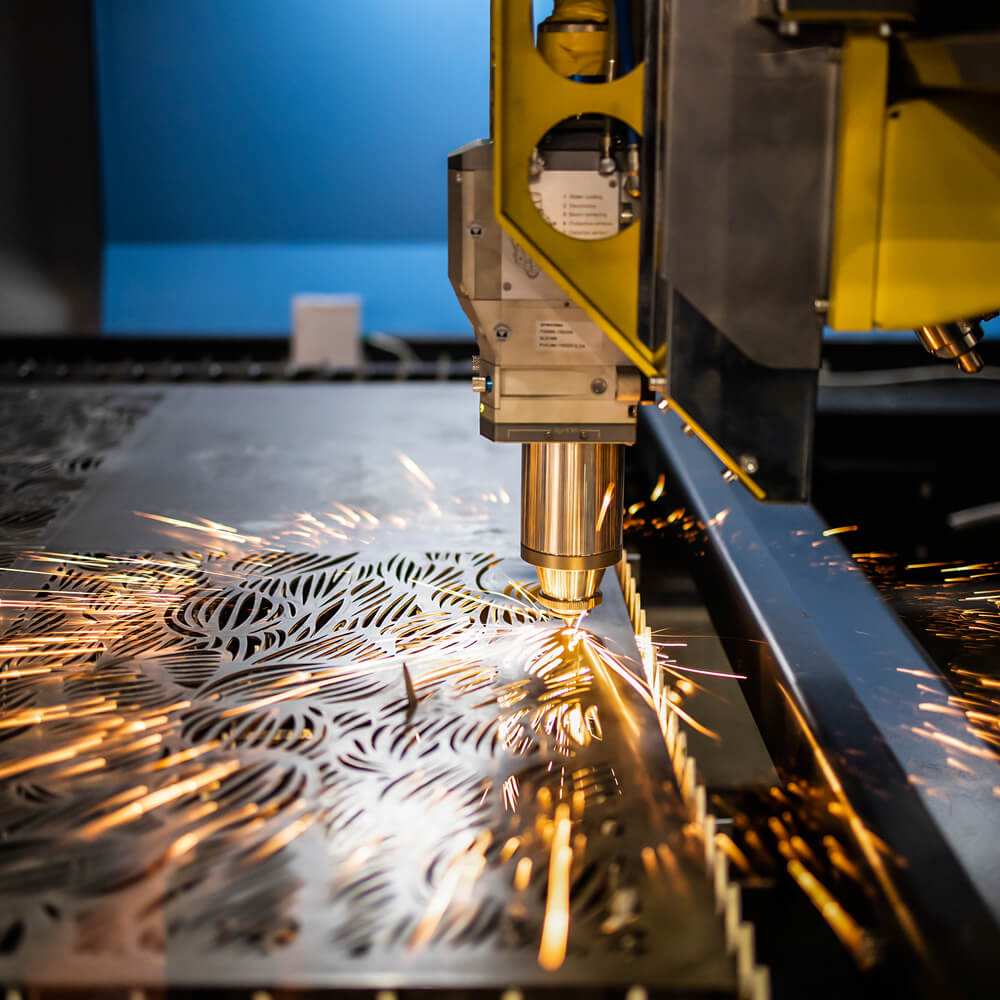

Laser Cutting & Marking

Used for cutting internal brackets and chassis from sheet metal, and for permanently etching logos, serial numbers, and regulatory marks.

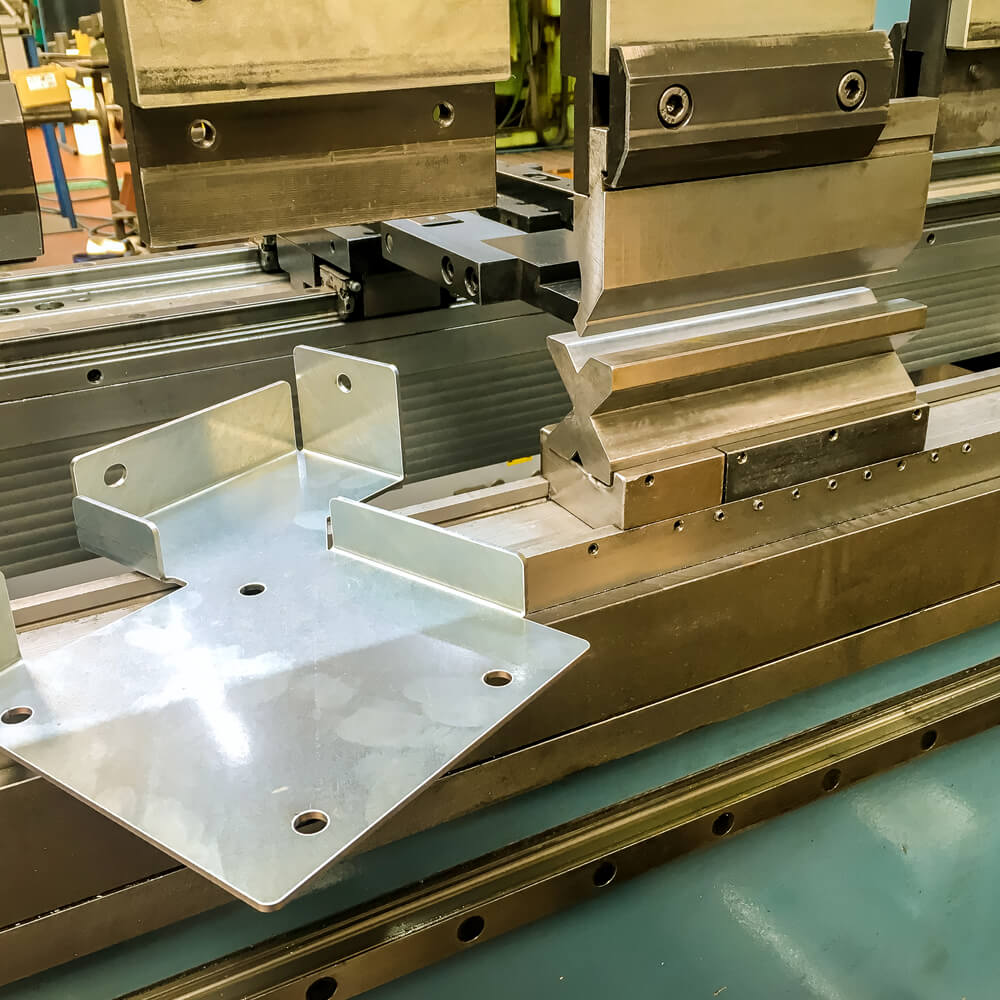

Sheet Metal Fabrication

Creating custom internal chassis, mounting brackets, and EMI shields with high precision.

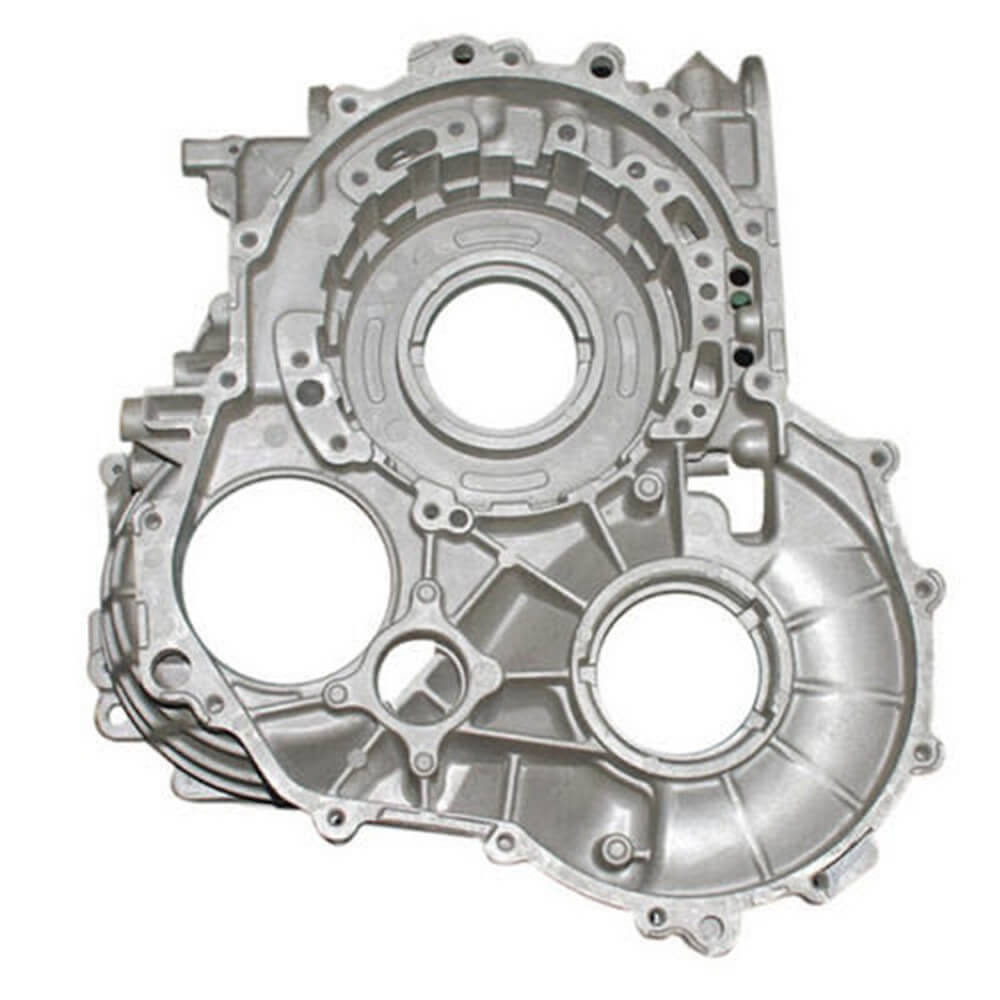

Die Casting

A cost-effective solution for high-volume production of complex metal parts like frames and internal structural components.

Cosmetic Finishing

A critical service including bead blasting, brushing, anodizing, and painting to achieve the perfect aesthetic for your product.

Premium Materials and Flawless Finishes

Common CE Materials:

- Aluminum (6063, 6061)

- Stainless Steel (304, 316L)

- Brass

- Plastics (ABS, PC, PMMA)

- Magnesium

Signature Surface Finishes:

- Bead Blasting (Fine, uniform matte texture)

- Anodizing (Type II, in custom colors like Space Gray, Silver, Gold)

- Brushed Finish

- High-Gloss Painting

- Polishing (for stainless steel and acrylic)

- Powder Coating (for durable internal components)

Gallery of Consumer Electronics Components

- Laptop and Notebook Enclosures

- Smartphone and Tablet Frames

- High-End Audio (Headphone, Speaker) Components

- Smartwatch and Wearable Housings

- Camera Bodies and Lens Mounts

- Drone Components

- Knobs, Dials, and Buttons

- Internal Chassis and Brackets

- Custom Heat Sinks

- Connector Housings

Frequently Asked Questions

What is a "Class A" surface?

In product design, a “Class A” surface is any primary cosmetic surface that the user sees and touches. We have rigorous inspection standards to ensure these surfaces are free of any scratches, dents, or finish inconsistencies.

Can you match the anodized colors of major brands?

Yes, we have extensive experience in color matching for Type II anodizing to achieve popular electronic finishes like “Space Gray,” “Silver,” and “Gold.” This requires careful process control and we often use colorimeters to ensure consistency.

What is the best material for a laptop enclosure?

Aluminum, typically 6061 or 6063, is the most common choice. It is lightweight, strong, feels premium, and can be beautifully finished with anodizing and bead blasting.

How fast can you deliver prototypes?

Our rapid prototyping service is designed for speed. For most machined aluminum or plastic parts, we can deliver finished prototypes to you in as little as 3-7 days.

Can you handle production volumes of 100,000+ pieces?

Yes. We can design dedicated production cells and use automation to efficiently scale our manufacturing to meet high-volume production demands while maintaining quality.

What is bead blasting and why is it so popular for electronics?

Bead blasting is a process that uses fine glass beads to create a very fine, smooth, non-reflective matte texture. It is popular because it creates a premium, fingerprint-resistant finish that feels great to the touch.

Do you offer assembly services?

Yes, we can perform sub-assembly services, such as installing heat-set inserts into plastic parts, bonding components, or installing simple hardware, to simplify your final assembly process.

How do you ensure cosmetic quality across a large production run?

We establish approved “limit samples” or a “golden sample” at the start of the project. Every part produced is then compared against this approved standard under controlled lighting conditions by our trained cosmetic inspectors.

Can you machine logos or lettering?

Yes, we can use fine-end mills to engrave logos directly into the part. For a different look, we also offer precision laser marking services.

How do you protect our new product designs?

We operate with the utmost discretion and are committed to protecting your intellectual property. We sign NDAs for every project and have strict internal controls on data access.

Related High-Precision Applications

Robotics & Automation

Building the precise and lightweight components for modern automation systems.

Drones & UAVs

Specializing in the ultra-lightweight and strong components essential for unmanned aerial vehicles.

Medical & Healthcare

Applying our cosmetic finishing expertise to the housings of medical devices.