Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Defense and Military

Precision Manufacturing for the Defense & Military Sector

Manufacturing the Mission-Critical, High-Reliability, and Ruggedized Components that Provide a Decisive Advantage on Land, at Sea, and in the Air.

- ISO 9001 & AS9100 Certified

- ITAR Registered

- Full DFARS Material Compliance

Your Secure & Reliable Partner in the Defense Supply Chain

The defense and military sector demands a level of precision, reliability, and security that is without compromise. Components must perform flawlessly under the most extreme conditions imaginable, where mission success and operator safety are paramount. Celerity Precision is a dedicated, ITAR-registered manufacturing partner in Shenzhen, China, structured to meet the rigorous requirements of the global defense industry. From lightweight aerospace-grade chassis for unmanned systems and hardened steel components for armored vehicles to intricate guidance system housings and ruggedized naval hardware, we have the technology, process controls, and security protocols to deliver components that meet the highest military standards.

We understand that defense programs are long-term commitments. Our services are designed to support the entire program lifecycle, from rapid prototyping for theater-based R&D to First Article Inspection (FAI) and full-rate, multi-year production. We function as a seamless extension of your engineering and procurement teams, providing the manufacturing excellence and rigorous documentation required for today’s advanced defense systems. We are not just a machine shop; we are a committed partner in strengthening national security.

The Celerity Precision Advantage for Defense Manufacturing

ITAR Compliance & Secure Operations

As an ITAR-registered facility, we operate under strict security protocols to protect all Controlled Unclassified Information (CUI) and technical data, ensuring the integrity and confidentiality of your program.

Expertise in Mil-Spec Materials & Processes

We are experts in machining and processing materials to strict military specifications, including DFARS-compliant aerospace aluminum, titanium, armor plate, and high-temperature superalloys.

Uncompromising Precision for Mission Systems

We consistently achieve the tight GD&T controls and micro-tolerances required for complex optical systems, targeting pods, guidance electronics, and other mission-critical electromechanical assemblies.

Robust Quality Assurance & Documentation

Our quality system is built for defense. We provide comprehensive documentation packages, including First Article Inspection Reports (AS9102), Certificates of Conformance (CoC), and full material and process traceability.

Rapid Prototyping for Warfighter Innovation

We support the rapid innovation cycle of the modern military, delivering high-fidelity, functional prototypes quickly to get critical technology into the hands of operators for testing and validation.

Full Program Lifecycle Support

We are built for long-term partnerships. Our facility can seamlessly scale from initial prototype runs to sustained, multi-year production contracts, ensuring a stable and reliable supply chain.

From Technical Data Package to Mission-Ready Component: Our Process

RFQ & Secure Data Transfer

Submit your Technical Data Package (TDP) via our secure, encrypted channels. Our defense-focused team provides a prompt, detailed quote that respects all security requirements.

Manufacturing & Quality Planning

We develop a comprehensive manufacturing plan that incorporates all military specifications, quality clauses, and process controls called out in the TDP to ensure 100% conformance.

DFARS-Compliant Material Sourcing

We procure all materials from certified, DFARS-compliant suppliers, ensuring a secure and fully traceable supply chain for every component.

Precision Machining to Print

Your parts are expertly machined to the exact specifications of your drawings and models on our advanced CNC centers, with no deviation from the engineering requirements.

Mil-Spec Finishing & Coating

Components undergo specified finishing processes from our network of certified suppliers, including MIL-A-8625 anodizing, MIL-DTL-5541 chem-film, and CARC painting.

Rigorous CMM Inspection & FAI Reporting

All critical features are verified using our CMMs. A complete First Article Inspection Report is generated for review and approval before production commences.

Developing Technology for the Modern Warfighter?

Let’s collaborate on the precision components that ensure mission success.

Key Manufacturing Services for the Defense Industry

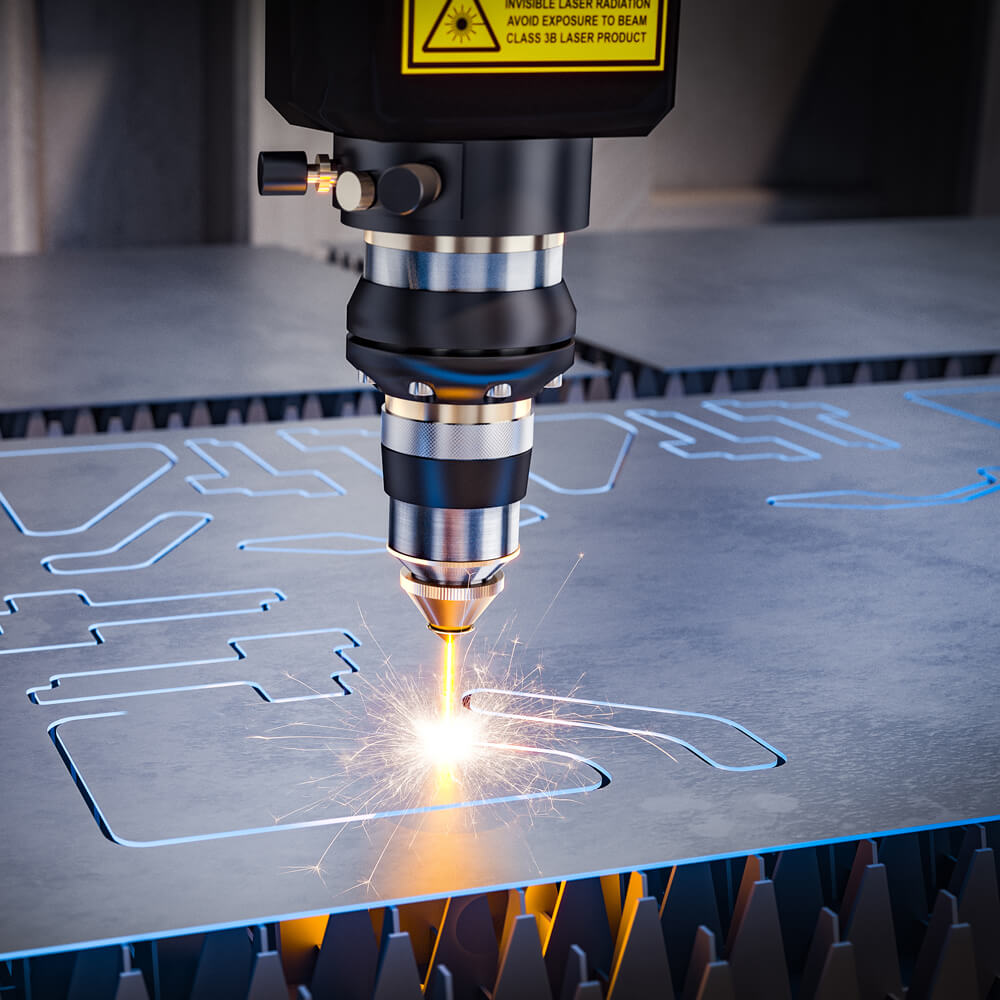

5-Axis CNC Milling

The core capability for producing complex, lightweighted chassis for avionics, fire control systems, optical benches, and unmanned vehicle structures.

CNC Turning with Live Tooling

Ideal for manufacturing munitions components, hydraulic actuators, high-pressure fittings, and complex shafts for vehicle and naval propulsion systems.

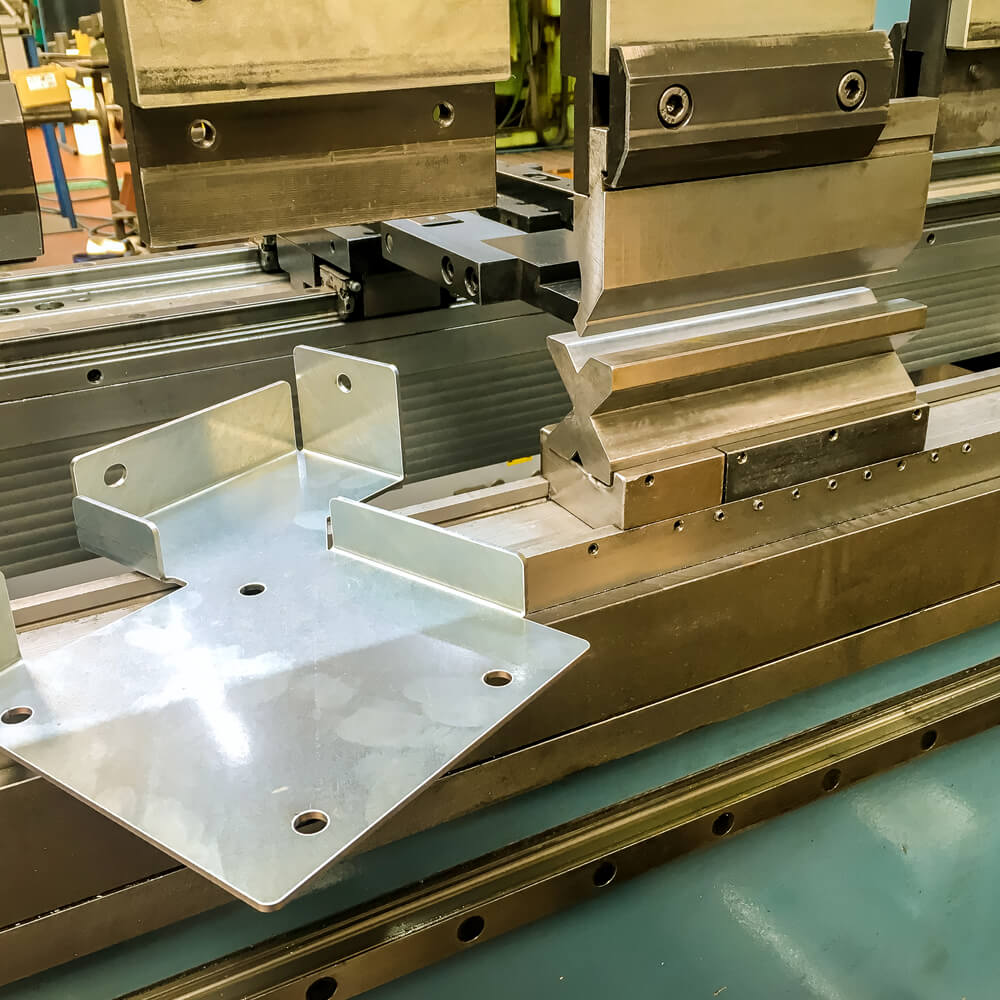

Sheet Metal Fabrication

Used for creating ruggedized electronic enclosures, consoles, brackets, and internal armor plating to military specifications.

Mil-Spec Finishing

A complete solution for sourcing certified finishes, including Chemical Conversion Coatings (Chem-Film), MIL-SPEC anodizing, CARC painting, and black oxide.

Certified Welding & Fabrication

Providing AWS-certified welding for armored vehicle components, structural frames, ground support equipment, and naval mounts.

Electromechanical Assembly

Providing light-duty assembly of machined components with specified hardware, connectors, and wiring to deliver integrated, pre-tested sub-assemblies.

High-Performance Materials and Finishes for Defense Applications

Common Defense-Grade Materials:

- Aluminum (7075-T6, 6061-T6)

- Titanium (6Al-4V Grade 5)

- Stainless Steel (17-4 PH, 15-5 PH)

- Alloy Steels & Armor Plate

- Nickel Alloys (Inconel®, Monel®)

- High-Performance Polymers (Vespel®, PEEK)

Common Mil-Spec Finishes:

- Anodizing (MIL-A-8625 Type II & III)

- Chemical Conversion Coating (MIL-DTL-5541)

- CARC (Chemical Agent Resistant Coating) Painting

- Black Oxide (MIL-DTL-13924)

- Passivation (AMS 2700)

- Dry Film Lubricant Coatings

Gallery of Defense & Military Components

- Fire Control & Targeting System Housings

- Optical Benches and Sensor Mounts

- UAV & Drone Structural Components

- Munitions, Fuse, and Missile Bodies

- Armored Vehicle Suspension and Hull Components

- Naval Weapon System Mounts and Housings

- Electronic Warfare (EW) Chassis and Enclosures

- Custom Rifle Components (Receivers, Handguards)

- Guidance and Navigation System Housings

- Ground Support and Test Equipment Fixtures

Frequently Asked Questions

Are you ITAR registered?

Yes, Celerity Precision is registered with the U.S. Department of State Directorate of Defense Trade Controls (DDTC) and maintains a comprehensive compliance program for handling ITAR-controlled technical data.

How do you handle Controlled Unclassified Information (CUI)?

We operate on a secure, segregated network with strict access controls. All CUI is handled in accordance with NIST 800-171 guidelines to ensure confidentiality and integrity.

Can you source DFARS-compliant materials?

Absolutely. We have an established supply chain of DFARS-compliant material suppliers and provide full mill certifications and traceability for all defense-related projects.

What is the process for First Article Inspection (FAI)?

We perform a complete FAI according to AS9102 standards on the first production piece. This includes a 100% dimensional inspection, material and process certifications, and a full report submitted to you for approval.

Can you machine armor steel and other hard materials?

Yes, we have the heavy-duty machinery and specialized tooling required to effectively machine armor plate, hardened alloy steels, and other difficult-to-machine materials used in defense applications.

Do you manage outside processing for mil-spec coatings like CARC?

Yes, we manage the entire supply chain. We work with our network of NADCAP and mil-spec certified finishing partners to deliver a complete component, including complex paint and coating systems like CARC.

Can you hold the tight tolerances needed for optical and sensor systems?

Yes, holding tight geometric dimensioning and tolerancing (GD&T) for optical alignment is one of our core competencies. We use high-precision CMMs to verify features like perpendicularity, parallelism, and true position.

Can you support multi-year production contracts?

Yes, we are structured to support long-term production. We can enter into long-term agreements (LTAs) to ensure price stability and continuity of supply for the life of your program.

Do you sign Non-Disclosure Agreements (NDAs)?

Yes, we execute NDAs with all our defense customers as a standard part of the engagement process to provide the highest level of legal protection for your intellectual property.

What is your experience with unmanned systems?

We have extensive experience manufacturing lightweight, high-strength structural components, chassis, and sensor mounts for a variety of unmanned aerial vehicle (UAV) and unmanned ground vehicle (UGV) platforms.

Related Mission-Critical Applications

Aerospace & Aviation

Machining flight-critical components for commercial and military aircraft, where reliability is non-negotiable.

Drones & UAVs

Specializing in the ultra-lightweight and strong components essential for unmanned aerial vehicles.

Scientific Instruments

Building ultra-precise components for advanced sensing, imaging, and measurement systems that demand the highest levels of accuracy.