Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Drones & UAVs Industry

Precision Manufacturing for the Drones & UAVs Industry

Engineering the High-Strength, Ultra-Lightweight, and Mission-Critical Components that Power the Next Generation of Unmanned Aerial Vehicles—from Airframes to Gimbal Systems.

- ISO 9001 Certified

- Expertise in Lightweight Alloys & Composites

- Rapid Prototyping for R&D

Your Agile Manufacturing Partner for Unmanned Systems

The drones and UAVs industry is at the cutting edge of innovation, constantly pushing the boundaries of flight endurance, payload capacity, and performance. This demands components that deliver maximum strength with minimal weight, absolute reliability, and cost-effectiveness. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, dedicated to producing the high-precision mechanical components that form the backbone of these advanced aerial systems. From intricate airframe segments and custom motor housings to lightweight gimbal components and robust landing gear assemblies, we have the technology and expertise to meet the stringent demands of this rapidly evolving field.

We understand that drone development is a cycle of rapid iteration, rigorous testing, and crucial weight optimization. Our services are structured to support this cycle, offering fast, high-quality prototypes to accelerate your R&D efforts. As your designs mature, we provide a clear and reliable path to scalable production, ensuring that the precision and lightweight characteristics demonstrated in the prototype are perfectly replicated in every production part. We are more than a supplier; we are a precision partner committed to helping you build the future of unmanned aerial capabilities.

The Celerity Precision Advantage for Drones & UAVs

Lightweighting & Material Specialization

We are experts in machining aerospace-grade aluminum alloys (7075-T6, 6061-T6), titanium, and can also machine complex features into composite materials (e.g., carbon fiber prepregs), which are critical for reducing airframe weight and improving flight efficiency.

Precision Machining for Performance

Our advanced CNC machining capabilities are essential for producing the complex, integrated features required for high-performance motors, precise gimbals, and efficient propeller hubs, ensuring optimal aerodynamics and stability.

Rapid Prototyping for Fast Iteration

We know speed is critical in R&D. We deliver functional, high-precision prototypes in a matter of days, allowing your engineering teams to test aerodynamic designs, structural integrity, and component fitment faster.

Complex Geometries for Integration

Our 5-axis machining expertise allows us to create sophisticated, integrated components that reduce part count, minimize fasteners, and improve overall structural integrity while saving critical weight.

Cost-Effective Production for Scalability

Our flexible manufacturing facility is designed to grow with you. We can seamlessly scale from producing a single prototype to a full production run of thousands of units as you bring your drone to market.

Expertise in Small & Intricate Parts

We excel at machining small, detailed components that are common in drone electronics mounts, camera stabilization systems, and actuation mechanisms, where precision is paramount.

From CAD Model to Flight-Ready Component: Our Process

RFQ & Engineering Collaboration

Submit your CAD assembly and part files. Our engineers provide a rapid quote and work with you to offer DFM feedback focused on weight reduction, material optimization, and manufacturability.

Process & Toolpath Optimization

We develop a detailed manufacturing plan, using advanced CAM software to create optimized toolpaths for complex geometries and efficient machining of lightweight materials.

Material Sourcing & Certification

We procure certified aerospace-grade aluminum, titanium, and other specified materials from trusted suppliers and can provide full material traceability documentation for every component.

Precision Machining

Your parts are expertly machined on our advanced CNC centers. For integrated components, we ensure tight tolerances for seamless assembly.

Finishing & Surface Treatment

Parts undergo any specified finishing, such as Type III hardcoat anodizing for durability on structural components or black anodizing for reduced reflectivity on camera mounts.

CMM Inspection & Quality Assurance

All critical features and assembly datums are verified using our Coordinate Measuring Machines (CMMs). We ensure every component meets spec before shipping.

Designing the Future of Unmanned Flight?

Let’s collaborate on the lightweight, high-performance components that will elevate your drone’s capabilities.

Key Manufacturing Services for Drones & UAVs

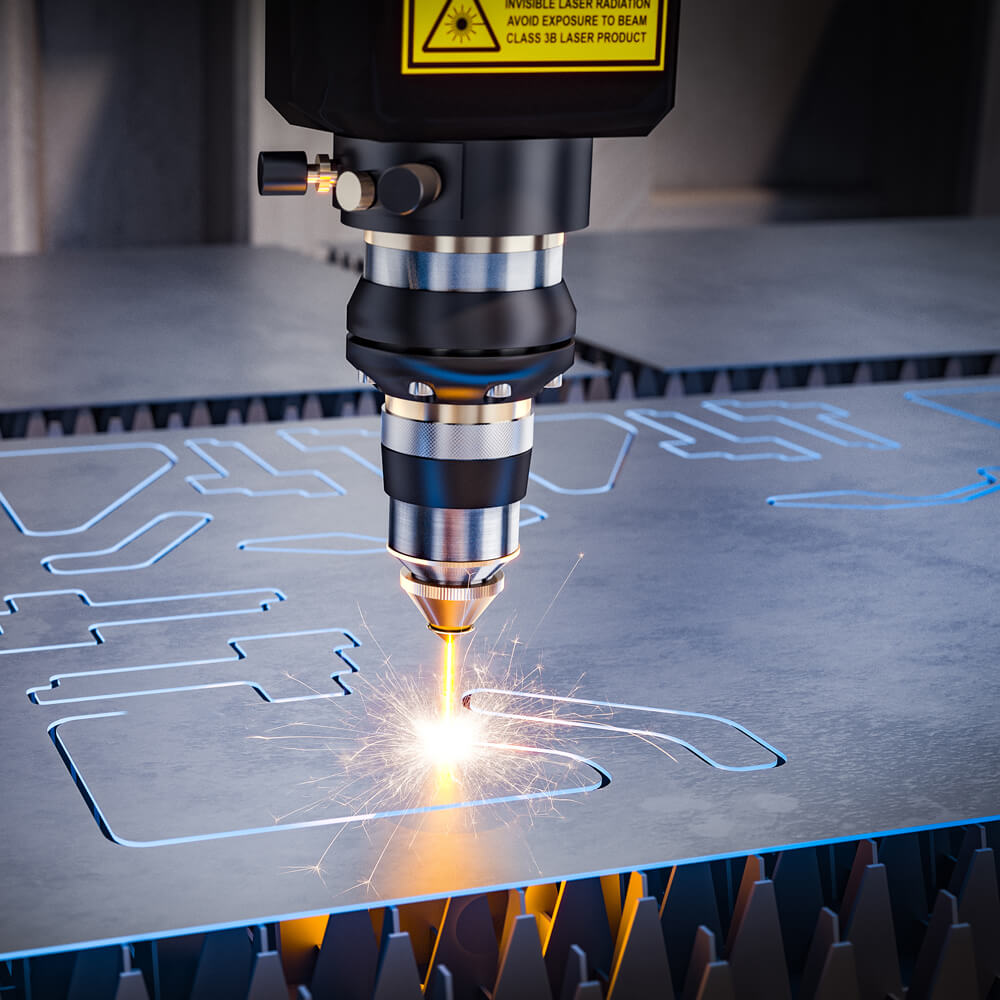

5-Axis CNC Milling

The cornerstone for creating complex, lightweighted airframe structures, motor mounts, gimbal frames, and integrated payload housings.

CNC Turning with Live Tooling

Ideal for producing precision motor shafts, custom propeller hubs, landing gear components, and drive shafts with milled features.

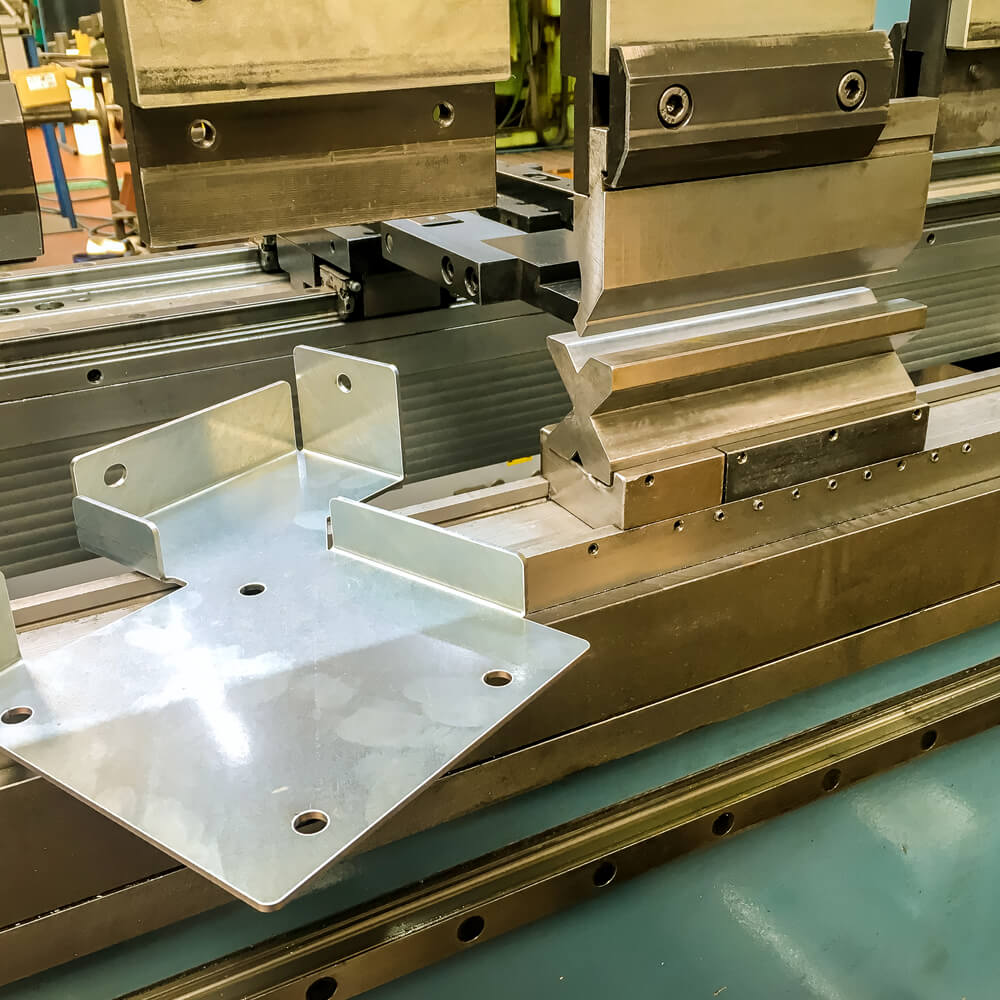

Sheet Metal Fabrication

Used for creating durable and cost-effective internal chassis, mounting brackets, and protective enclosures for electronic components.

Precision Grinding

Offering surface and cylindrical grinding for critical dimensions on shafts, bearing seats, and other components requiring ultra-fine tolerances.

Surface Finishing

Providing critical finishes like Type III hardcoat anodizing for wear resistance and durability on aluminum parts, and black anodizing for reduced optical reflectivity.

Light Assembly

Installing bearings, fasteners, and other hardware to deliver pre-assembled mechanical modules for gimbals, landing gear, and payload interfaces.

High-Performance Materials and Finishes for Drones & UAVs

Common Drone Materials:

- Aluminum (7075-T6, 6061-T6)

- Titanium (Grade 5)

- Stainless Steel (for specific high-strength applications)

- Carbon Fiber Composites (for machining of features)

- High-Performance Polymers (PEEK, Delrin®)

Functional Surface Finishes:

- Anodizing (Type III Hardcoat for wear and corrosion resistance)

- Anodizing (Type II Black for aesthetics and non-reflectivity)

- Electroless Nickel Plating (for hardness and corrosion resistance)

- Bead Blasting (for a uniform, non-glare finish)

- Passivation (for stainless steel components)

Gallery of Drone & UAV Components

- Lightweight Airframe Structures & Segments

- Motor Mounts & Housings

- Gimbal Stabilizer Components

- Camera Mounts & Payload Interfaces

- Landing Gear Assemblies & Components

- Propeller Hubs & Adapters

- Battery Trays & Enclosures

- Control Surface Actuator Mounts

- Custom Fasteners & Brackets

- Electronic Component Housings

Frequently Asked Questions

What is the best material for a drone airframe?

7075-T6 aluminum alloy offers an excellent balance of high strength and low weight, making it a popular choice for structural airframe components. For even higher strength-to-weight ratios, titanium can be used for critical stress points.

Why is precise machining important for drone motors?

The motor housing and shaft components must be machined to very tight tolerances to ensure smooth rotation, proper bearing fit, minimal vibration, and efficient power transfer, all of which directly impact flight performance and endurance.

Can you help us reduce the weight of our drone components?

Absolutely. Our DFM process often includes suggestions for lightweighting strategies, such as optimizing wall thicknesses, designing with internal ribbing or pockets, and recommending higher strength-to-weight ratio materials.

What is the best finish for a matte black, non-reflective drone part?

For aluminum components, Type II black anodizing is an excellent choice. Combined with a pre-blast surface finish, it provides a durable, matte black, and non-reflective surface ideal for aerial photography or surveillance drones.

Can you hold the tight tolerances needed for gimbal bearing fits?

Yes, holding tight tolerances for bearing fits and precise alignment of optical components within a gimbal is a core competency. We machine these features to specified tolerances and verify them with our CMMs.

Do you make components for electric drone motors?

Yes, we frequently machine motor shafts, housings, stator mounts, and other precision components for electric motors used in drones and UAVs, ensuring high precision for optimal performance.

What is a "gimbal system" on a drone?

A gimbal is a mechanism that allows a camera or sensor to remain stable and level, regardless of the drone’s movement (pitch, roll, yaw). It requires highly precise machining for its bearings, motor mounts, and structural components.

How fast can you deliver prototypes for our drone R&D team?

Our rapid prototyping services are designed for speed. We can typically deliver moderately complex machined parts in aluminum within 3-7 business days, allowing your engineering teams to test and iterate quickly.

Can you machine components from carbon fiber composites?

While we primarily machine metals, we can machine features into pre-cured carbon fiber composite parts, such as drilling holes or creating precise interfaces for metal components.

How do you ensure parts in a complex drone assembly will fit together perfectly?

We use techniques like “matched set” machining where mating components are processed together to minimize tolerance stack-up. Our CMM inspection verifies all critical datums and fits before parts are shipped.

Related Lightweight & High-Performance Applications

Robotics & Automation

Creating precise, lightweight components for collaborative robots and automation systems that require agility and speed.

Consumer Electronics

Manufacturing intricate, lightweight chassis and internal mechanisms for next-generation mobile devices and portable electronics.

Scientific Instruments

Building lightweight, precision mounts and components for portable diagnostic equipment and field-deployable sensors.