Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Industrial Machinery

Precision Manufacturing for the Industrial Machinery Industry

Building the High-Strength, Heavy-Duty, and Mission-Critical Components that Drive the Performance of Modern Industrial Equipment—from Custom Gearboxes to Large-Scale Machine Frames.

- ISO 9001 Certified

- Large & Heavy Part Machining

- Full Material Traceability

Your Strategic Manufacturing Partner for Industrial Machinery

The industrial machinery sector is the engine of modern manufacturing, demanding components that deliver unparalleled strength, wear resistance, and absolute reliability under heavy loads and continuous operation. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, equipped to produce the robust, high-precision mechanical components that are the foundation of these powerful systems. From massive-scale machine bases and intricate hydraulic manifolds to hardened gear sets and wear-resistant tooling, we have the heavy-duty technology and deep expertise to meet the rigorous demands of this foundational industry.

We understand that machine development requires both durability and precision. Our services are engineered to support the entire lifecycle of your machinery, from initial prototyping and validation to full-scale production. As your designs are finalized, we provide a seamless and dependable path to manufacturing, ensuring that the precision and material integrity of the prototype are maintained in every production part. We are more than just a supplier; we are a precision partner committed to helping you build the next generation of industrial-grade machinery.

The Celerity Precision Advantage for Industrial Machinery

Expertise in Large & Heavy Components

Our facility is equipped with large-envelope CNC mills and heavy-lifting capabilities, allowing us to expertly machine large-scale weldments, machine frames, and castings up to several tons.

Mastery of Hard & Tough Materials

We specialize in machining challenging, high-strength materials, including carbon and alloy steels, stainless steel, and cast iron, which are critical for parts requiring extreme durability and wear resistance.

Uncompromising Precision on a Large Scale

Industrial machinery demands precision. Our climate-controlled facility, large-format CMMs, and rigorous quality control ensure we can hold tight tolerances on even the largest and most complex components, guaranteeing perfect assembly and function.

Prototyping for Real-World Testing

We understand the need for physical validation. We deliver fully functional, production-quality prototypes for you to test under real-world conditions, ensuring design integrity before committing to full production.

Integrated Fabrication & Machining

We offer a one-stop solution for complex assemblies. Our capabilities include multi-station fabrication, stress-relief heat treating, and finish machining of large weldments, streamlining your supply chain.

Scalable Production for Your Needs

Our manufacturing infrastructure is designed to support your growth. We can seamlessly scale from a single, complex prototype to series production of hundreds of units as you fulfill orders for your industrial machinery.

From Engineering Drawing to Industrial Component: Our Process

RFQ & Engineering Review

Submit your CAD files and technical drawings. Our engineers provide a prompt quote and offer DFM feedback focused on improving manufacturability, reducing cost, and ensuring component strength and longevity.

Process Planning & Fixture Design

We develop a robust manufacturing plan, including the design of custom fixtures to securely hold and accurately machine large or complex workpieces.

Certified Material Procurement

We source certified steels, alloys, and castings from reputable mills and foundries and provide complete material traceability documentation (MTRs) for every project.

Heavy-Duty Machining

Your parts are expertly machined on our powerful CNC centers. For fabrications, we machine critical interfaces and datums after welding and stress relieving to ensure final accuracy.

Finishing & Post-Processing

Parts undergo any specified secondary processes, such as heat treating for hardness, precision grinding for tight surface finishes, or industrial coatings for corrosion resistance.

CMM Inspection & Quality Validation

All critical dimensions, tolerances, and geometric features are verified using our large-format Coordinate Measuring Machines (CMMs). We ensure every component meets your specifications before shipment.

Building the Future of Industrial Automation?

Let’s collaborate on the robust, high-precision components that will power your next machine.

Key Manufacturing Services for Industrial Machinery

Large-Format CNC Milling

The foundation for machining large machine bases, welded frames, complex castings, and heavy-duty structural components with high precision.[

CNC Turning (Vertical & Horizontal)

Ideal for producing large-diameter flanges, heavy-duty shafts, rollers, custom hydraulic pistons, and other large cylindrical parts.

Welding & Fabrication

Certified welding services (MIG, TIG) to create robust machine frames, enclosures, and structural weldments that are then stress-relieved and precision machined.

Precision Grinding

Offering surface, cylindrical, and ID/OD grinding to achieve extremely tight tolerances and fine surface finishes on hardened shafts, guide rails, and tooling.

Heat Treating & Hardening

Providing critical services like quenching, tempering, carburizing, and nitriding to increase the hardness, strength, and wear resistance of steel components.

Heavy Assembly

Performing mechanical assembly of large components, including the installation of bearings, bushings, guide rails, and other hardware to deliver complete sub-assemblies.

High-Performance Materials and Finishes for Industrial Machinery

Common Industrial Materials:

- Carbon Steel (1018, 1045)

- Alloy Steel (4140, 4340)

- Tool Steel (A2, D2)

- Stainless Steel (304, 316, 17-4 PH)

- Cast Iron

- Aluminum (for non-structural components)

Functional Surface Finishes:

- Black Oxide (for corrosion resistance)

- Zinc Plating (for corrosion protection)

- Electroless Nickel Plating (for wear and corrosion resistance)

- Hard Chrome Plating (for extreme hardness and wear resistance)

- Powder Coating & Industrial Painting

- Passivation (for stainless steel)

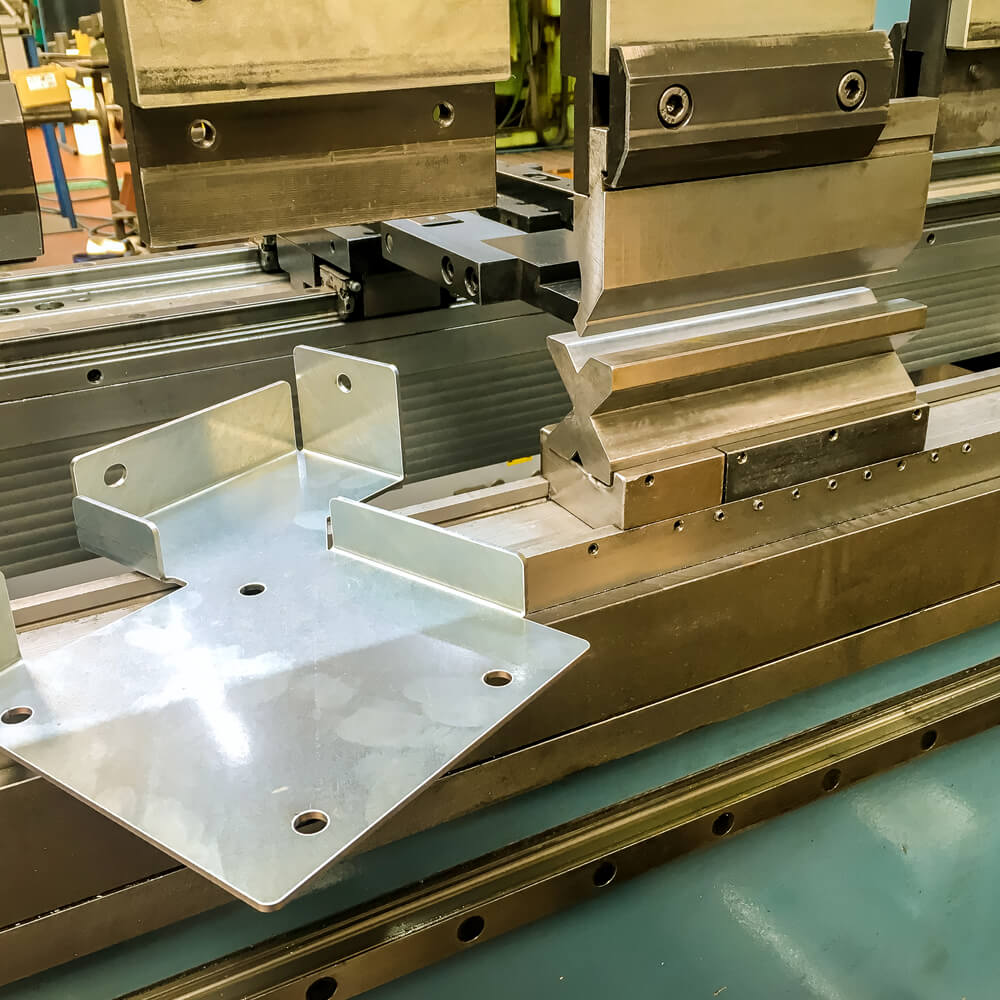

Gallery of Industrial Machinery Components

- Machine Bases and Structural Frames

- Gearbox Housings

- Large-Scale Shafts and Rollers

- Hydraulic Manifolds and Blocks

- Custom Gears and Splines

- Bearing Housings and Mounts

- Press and Die Components

- Machine Tooling, Jigs, and Fixtures

- Conveyor System Components

- Cams and Levers

Frequently Asked Questions

What is the best material for a heavy-duty machine frame?

Fabricated and stress-relieved A36 or 1018 carbon steel is the most common and cost-effective choice, offering excellent strength and stability. For applications requiring higher strength or specific properties, alloy steels may be used.

Why is post-weld machining important for fabrications?

Welding introduces stress and can cause material to warp. Stress-relieving the weldment and then machining all critical surfaces and holes in a single setup ensures that all features are flat, parallel, and perpendicular for accurate final assembly.

Can you help us with material selection for wear resistance?

Absolutely. Our engineers can recommend the best combination of base material and post-processing, such as using 4140 pre-hardened steel or applying heat treatment and hard chrome plating to achieve the desired surface hardness and durability.

What is the best finish for corrosion resistance in an industrial environment?

For steel parts, zinc plating or electroless nickel plating offer excellent corrosion protection. For a durable and aesthetic finish on external components, industrial powder coating is a superior choice.

Can you hold the tight tolerances needed for bearing and shaft fits on large parts?

Yes, this is a core competency. We use precision grinding and climate-controlled CMM inspection to hold tight diametrical and positional tolerances required for bearing fits (e.g., H7/g6) on large and heavy components.

Do you manufacture custom gear sets?

We can CNC mill and turn custom gear profiles from a variety of steels and alloys. For high-precision, AGMA-rated ground gears, we work with certified partners to manage the entire process for you.

What is a hydraulic manifold, and why is it complex to machine?

A hydraulic manifold is a block that directs the flow of fluid in a hydraulic system. It requires machining intricate, intersecting internal channels and ports. Precision is critical to prevent leaks and ensure the proper function of hydraulic valves.

How do you handle and machine very large and heavy parts?

Our facility is equipped with overhead cranes for safe lifting, large-capacity CNC machines with extended travels, and robust custom fixturing designed to handle the weight and forces involved in machining large components accurately.

Can you assemble the large components you manufacture?

Yes, we offer heavy assembly services. We can install large bearings, bushings, guide rails, and other hardware to deliver a more complete and tested mechanical sub-assembly.

How do you ensure the quality and accuracy of a part that is several meters long?

We use large-format Coordinate Measuring Machines (CMMs) and laser trackers to accurately measure parts that are too large for standard inspection equipment. Our process controls ensure that dimensional accuracy is maintained throughout the manufacturing cycle.

Related Heavy-Duty Applications

Automotive Manufacturing

Creating precision tooling, dies, and fixtures for automotive production lines.

Energy & Power Generation

Machining large-scale components for turbines, generators, and power transmission systems.

Aerospace & Defense

Manufacturing large tooling, jigs, and ground support equipment for the aerospace industry.