Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Marine Industry

Precision Manufacturing for the Marine Industry

Engineering the Corrosion-Resistant, High-Strength, and Mission-Critical Components that Endure in the World’s Harshest Marine Environments—from Propulsion Systems to Subsea Housings.

- ISO 9001 Certified

- Expertise in Marine-Grade Alloys

- Full Material Traceability

Your Trusted Manufacturing Partner for Marine Systems

The marine industry operates at the mercy of the most corrosive natural environment on earth, demanding components that deliver absolute reliability, impeccable corrosion resistance, and unwavering strength. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, with deep expertise in producing high-precision mechanical components engineered to perform flawlessly above and below the waterline. From complex propeller shafts and robust hydraulic fittings to pressure-resistant subsea enclosures and durable deck hardware, we possess the advanced technology and materials knowledge required to meet the extreme demands of this challenging sector.

We understand that marine engineering requires a zero-compromise approach to quality. Our services are structured to support the entire lifecycle of your product, from prototyping and material validation to full-scale production runs. As your designs are proven, we provide a reliable and transparent path to manufacturing, ensuring that the material integrity and dimensional accuracy of the prototype are perfectly replicated in every part. We are not just a supplier; we are a dedicated partner committed to building the next generation of resilient marine technology.

The Celerity Precision Advantage for Marine Applications

Expertise in Marine-Grade Alloys

We are specialists in machining corrosion-resistant materials essential for marine survival, including 316L Stainless Steel, Duplex Stainless Steel, Titanium, and specific grades of Marine Bronze and Aluminum.

Uncompromising Sealing & Mating Surfaces

We excel at machining critical sealing surfaces, O-ring grooves, and flange faces to high-precision finishes, ensuring watertight integrity for housings, valves, and hydraulic systems.

5-Axis Machining for Complex Hydrodynamics

Our advanced 5-axis CNC capabilities are crucial for producing complex, hydrodynamic shapes like propellers, impellers, and custom rudder components with maximum efficiency and performance.

Full Material Traceability & Certification

We know material integrity is paramount. We provide full material traceability (MTRs) and certifications for all marine-grade alloys, ensuring your components meet stringent industry and regulatory standards.

One-Stop Solution for Assemblies

We streamline your supply chain by delivering complete, pressure-tested sub-assemblies, including the installation of certified seals, bearings, fasteners, and other hardware.

Production for Any Scale

From a one-off prototype for a research vessel to a full production run for a commercial fleet, our flexible manufacturing facility is equipped to scale with your project's demands.

From CAD Model to Seaworthy Component: Our Process

RFQ & Engineering Consultation

Submit your CAD models and technical drawings. Our engineers provide a swift quote and offer DFM feedback focused on corrosion resistance, manufacturability, and sealing integrity.

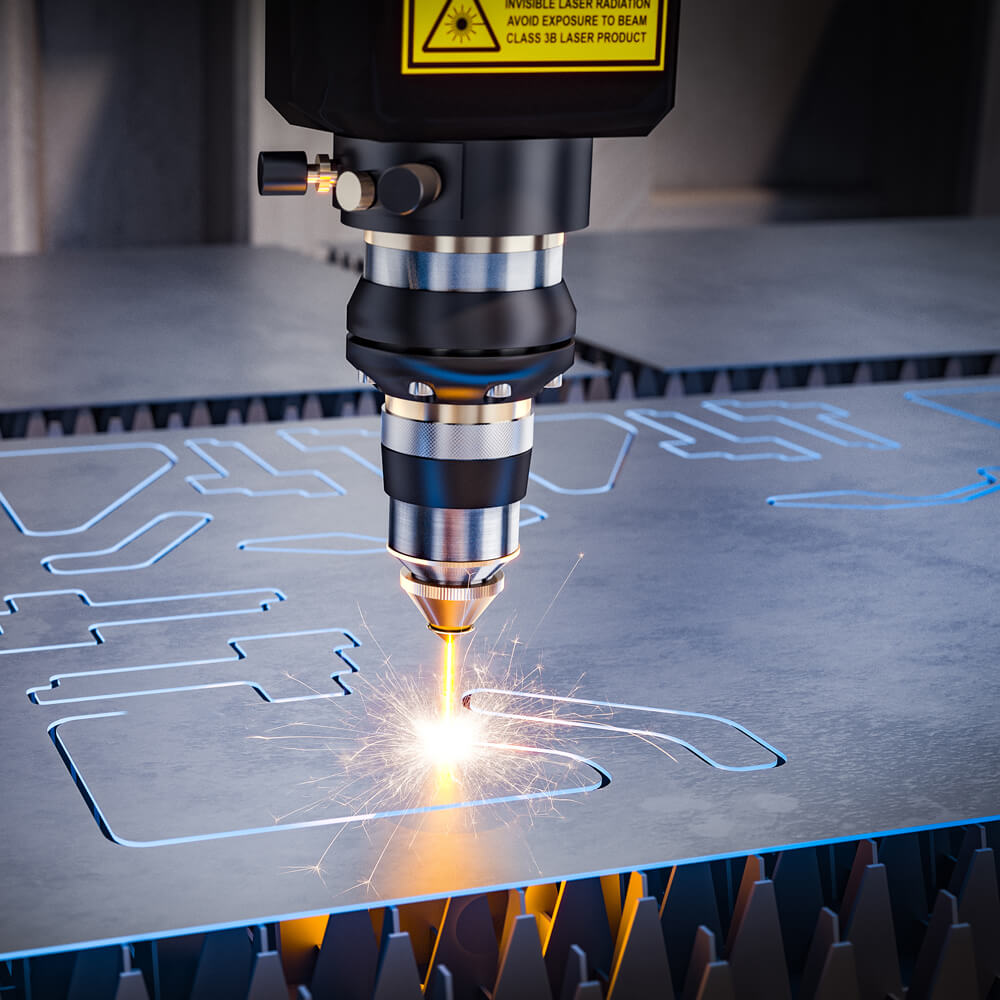

Process & Toolpath Strategy

We develop a detailed manufacturing plan, leveraging advanced CAM software to create optimized toolpaths for complex geometries and ensure superior surface finishes to inhibit corrosion.

Certified Marine-Grade Material Sourcing

We procure certified materials from globally trusted suppliers and provide complete documentation, guaranteeing your components are made from the specified alloy.

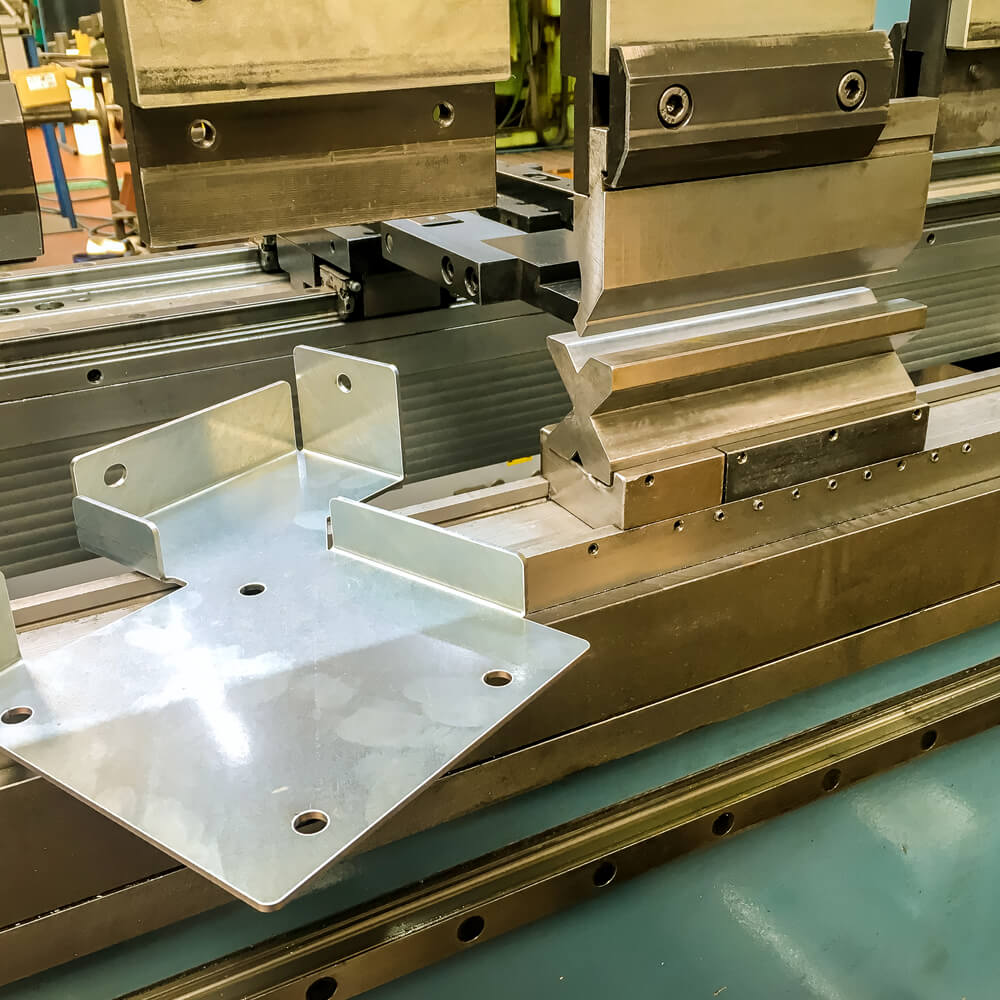

Precision Machining

Your parts are expertly machined on our advanced CNC centers. Mating components and sealing surfaces are machined in matched sets to guarantee perfect fitment and watertight seals.

Finishing & Passivation

Parts undergo any specified finishing processes, such as electropolishing for maximum corrosion resistance or hard anodizing for aluminum components used above the waterline.

CMM Inspection & Pressure Testing

All critical features are verified using our Coordinate Measuring Machines (CMMs). For enclosures, we can facilitate pressure testing to validate sealing integrity before shipping.

Building for the Marine Environment?

Let’s collaborate on the precision-engineered components that will withstand the toughest conditions.

Key Manufacturing Services for the Marine Industry

5-Axis CNC Milling

The cornerstone for creating complex, single-piece components like subsea housings, propeller blades, and custom valve bodies, minimizing the need for corrosion-prone welds.

CNC Turning with Live Tooling

Ideal for producing high-precision propeller shafts, hydraulic pistons, custom fittings, and connector bodies with exceptional concentricity and surface finishes.

Precision Grinding

Used for creating ultra-precise bearing journals and sealing surfaces on shafts and pistons, ensuring smooth operation and long service life.

Wire EDM & Sinker EDM

An effective method for creating intricate internal features, keyways, and splines in hardened or difficult-to-machine marine alloys.

Surface Finishing

Providing critical finishes like passivation for stainless steels to maximize corrosion resistance, electropolishing, and Type III hardcoat anodizing for aluminum.

Mechanical Assembly & Testing

Assembling and pressure-testing sealed enclosures and hydraulic components to ensure they are ready for deployment upon arrival.

High-Performance Materials and Finishes for Marine Applications

Common Marine-Grade Materials:

- Stainless Steel (316/316L)

- Duplex Stainless Steel (2205)

- Titanium (Grade 2, Grade 5)

- Marine Aluminum (5083, 6061-T6)

- Nickel Alloys (Inconel®, Monel®)

- Marine Bronze

Functional Surface Finishes:

- Passivation (essential for stainless steel)

- Electropolishing (for a smooth, ultra-clean, corrosion-resistant surface)

- Anodizing (Type III Hardcoat for wear and corrosion resistance on aluminum)

- Chromate Conversion Coating

- Bead Blasting (for a uniform, non-glare finish)

Gallery of Marine & Subsea Components

- Subsea Camera and Sensor Housings

- Propellers and Impellers

- Propulsion System Shafts and Couplings

- Custom Deck Hardware (Cleats, Fairleads)

- Hydraulic Manifolds and Valve Bodies

- Winch and Hoist Components

- Rudder and Steering System Components

- Sonar and Transducer Housings

- ROV (Remotely Operated Vehicle) Components

- Custom Flanges and Fittings

Frequently Asked Questions

What is the best material for components in direct contact with saltwater?

For most applications, 316L stainless steel offers an excellent balance of corrosion resistance and cost. For more demanding or mission-critical applications, Duplex stainless steel, Titanium, or Nickel Alloys like Monel® provide superior resistance to pitting and crevice corrosion.

Why is passivation so important for stainless steel marine parts?

The machining process can embed free iron into the surface of stainless steel, which can become a site for rust to begin. Passivation is a chemical process that removes this free iron and restores the material’s natural, passive chromium-oxide layer, maximizing its corrosion resistance.

Can you manufacture completely watertight enclosures?

Absolutely. We specialize in machining housings with high-precision O-ring grooves and sealing faces. We control surface roughness and dimensional tolerances to ensure a reliable, high-pressure seal, which we can then have pressure tested for verification.

What is the best finish for aluminum parts used on a boat?

For aluminum, Type III hardcoat anodizing provides a very hard, thick, and durable layer that offers excellent protection against both corrosion and wear-and-tear.

Can you hold the tight tolerances needed for propeller shafts?

Yes, holding tight tolerances for shaft straightness, bearing journal diameters, and keyway locations is a core competency. We often use precision grinding after turning to achieve the required accuracy and surface finish.

What is Duplex stainless steel, and when should it be used?

Duplex is a grade of stainless steel with a mixed microstructure that gives it nearly double the strength of 316L and superior resistance to stress corrosion cracking. It is ideal for high-stress applications like propeller shafts or critical structural components in chloride-rich environments.

How do you ensure a perfect fit for flanges and mating parts?

We use a “matched set” machining approach, where mating components are machined in the same setup to minimize tolerance stack-up. We also use our CMMs to verify bolt patterns and sealing surface flatness to ensure a perfect, leak-free assembly.

Can you make custom, high-performance propellers?

Yes, our 5-axis CNC machines are perfectly suited for manufacturing custom propellers and impellers with complex blade geometries for optimized hydrodynamic performance.

How fast can you deliver prototypes for testing?

Our rapid prototyping services can deliver moderately complex machined parts in marine-grade aluminum or stainless steel, often within 1-2 weeks, allowing your engineering teams to test and validate designs quickly.

Do you offer material certification for your marine components?

Yes, we provide full material certifications (MTRs) for every project, tracing the material back to the mill. This is standard practice for us and ensures you are getting the exact marine-grade alloy you specified.

Related High-Stakes Applications

Semiconductor Industry

Applying our expertise in machining complex parts with extreme precision to components for semiconductor manufacturing equipment.

Scientific Instruments Industry

Building ultra-precise components for oceanographic sensors, deep-sea research equipment, and environmental monitoring systems.

Defense & Military

Manufacturing mission-critical components for naval vessels, submarines, and advanced maritime security systems.