Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Medical & Healthcare

Precision Manufacturing for the Medical & Healthcare Industry

Machining Biocompatible Components, Surgical Instruments, and Medical Device Prototypes with Absolute Precision, Traceability, and Quality Assurance.

- ISO 13485 Compliant Processes

- Full Material Certification

- Ultra-Fine Surface Finishes

Your Trusted Partner in Medical Device Manufacturing

The medical and healthcare industry is defined by its mission to improve and save lives, a mission that demands the highest possible standards of quality, safety, and reliability. At Celerity Precision, we are a dedicated manufacturing partner based in Shenzhen, China, with the expertise and process controls required to serve this critical sector. We specialize in the precision CNC machining of components for surgical instruments, orthopedic implants, diagnostic equipment, and medical devices, where flawless execution is not just a goal, but a requirement.

We understand that in medical manufacturing, there is no room for error. Our entire workflow is built on a foundation of rigorous quality control, from meticulous material verification to final inspection in our metrology lab. We partner with medical innovators, from startups to established OEMs, providing the rapid prototyping services needed to accelerate development and the scalable production capabilities required to bring life-changing technologies to market.

The Celerity Precision Advantage for Medical

ISO 13485 Compliant Quality System

Our manufacturing processes are aligned with the stringent principles of ISO 13485, ensuring a robust quality management system focused on risk management, process validation, and full traceability.

Expertise in Medical-Grade Materials

We have extensive hands-on experience machining a wide range of biocompatible and sterilizable materials, including Titanium (Ti-6Al-4V ELI), Stainless Steel (316L, 17-4 PH), PEEK, and Radel®.

Full Material Traceability and Certification

We provide complete documentation for every medical project, including Mill Test Reports (MTRs) for all raw materials and Certificates of Conformance (CofC) with every shipment, guaranteeing full traceability.

Ultra-Precision Machining Capabilities

Our advanced 5-axis CNC and Swiss-style lathes are capable of producing the highly complex geometries and holding the extremely tight tolerances (down to ±0.005mm) required for intricate surgical instruments and implants.

Superior Surface Finishes

We are experts in providing the ultra-fine, smooth, and clean surface finishes critical for medical devices, including mechanical polishing, electropolishing, and passivation to ensure biocompatibility.

Secure & Confidential Prototyping

We operate under strict NDAs to protect your valuable intellectual property. Our rapid prototyping services help you quickly create functional and pre-clinical models for testing and validation.

From Design to Device: Our MedTech Manufacturing Process

RFQ & Confidential Review

Securely submit your proprietary CAD files and specifications. We review your design under a strict NDA and provide expert DFM feedback.

Process Validation & Planning

We develop a detailed manufacturing and inspection plan (MIP), identifying all critical-to-quality (CTQ) features and establishing robust process controls.

Certified Material Procurement

We source certified medical-grade materials from our approved network of suppliers and quarantine/verify all documentation before production begins.

Precision Machining

Your components are machined in a clean, controlled environment using dedicated tooling and processes to prevent cross-contamination.

Finishing & Passivation

Parts undergo critical finishing steps, such as deburring under a microscope, electropolishing, and passivation, to ensure they are free of contaminants and have a passive surface.

100% Final Inspection & Documentation

Every part undergoes a rigorous final inspection using our CMMs and vision systems. A complete documentation package, including FAI reports and CofCs, is prepared for shipment.

Accelerate Your Medical Device Innovation

Partner with a manufacturer who understands the precision and quality your project demands.

Key Manufacturing Services for Medical

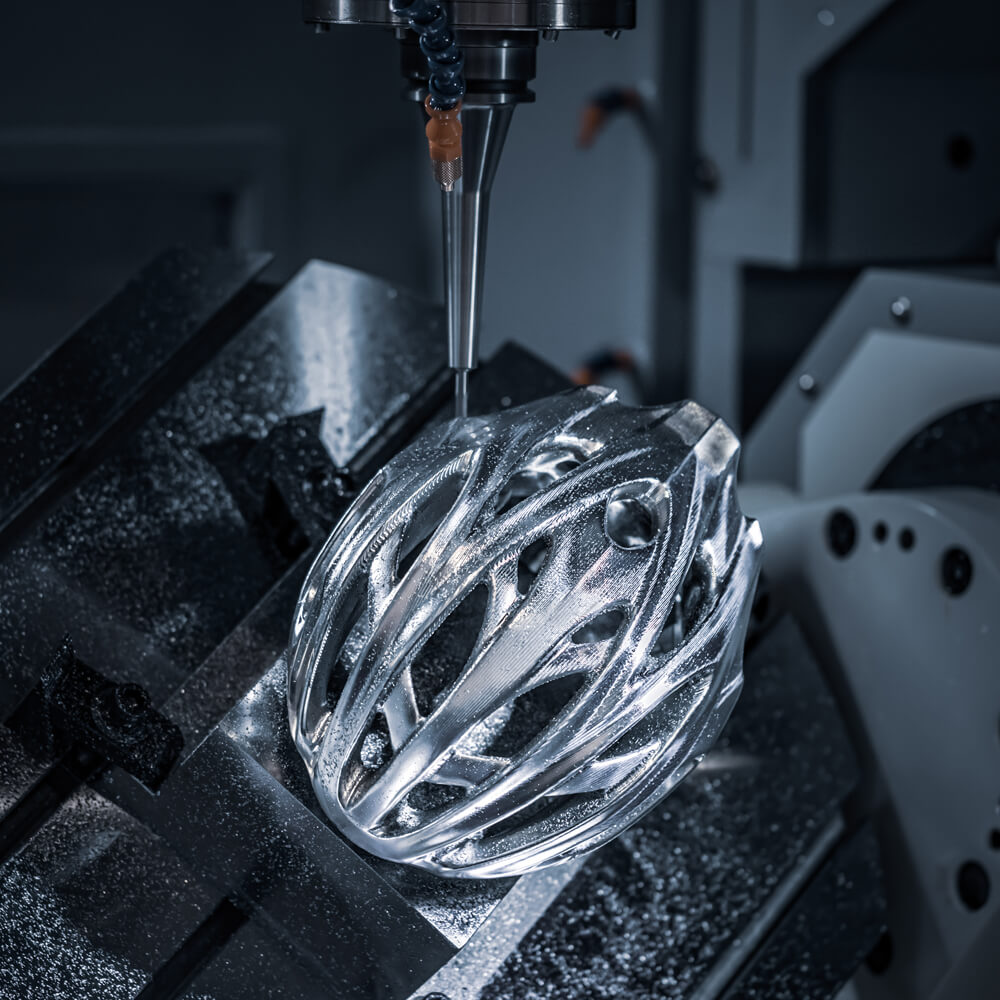

Swiss-Style CNC Machining

The gold standard for producing small, complex, and highly precise components like bone screws, dental implants, and parts for minimally invasive instruments.

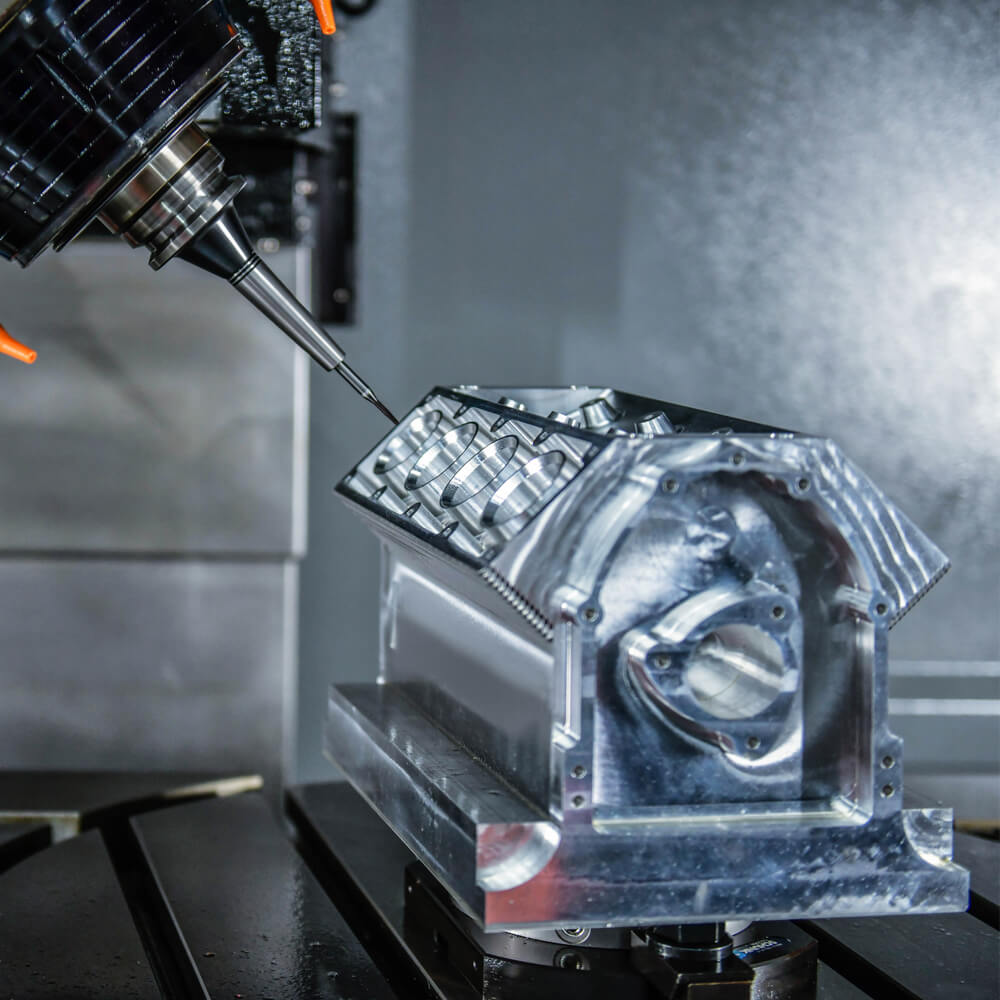

5-Axis CNC Milling

Ideal for machining complex, organic shapes for orthopedic implants (e.g., knee, hip components) and ergonomic surgical instrument bodies.

CNC Turning

High-precision turning of cannulated instruments, fittings, and components for diagnostic equipment with exceptional concentricity.

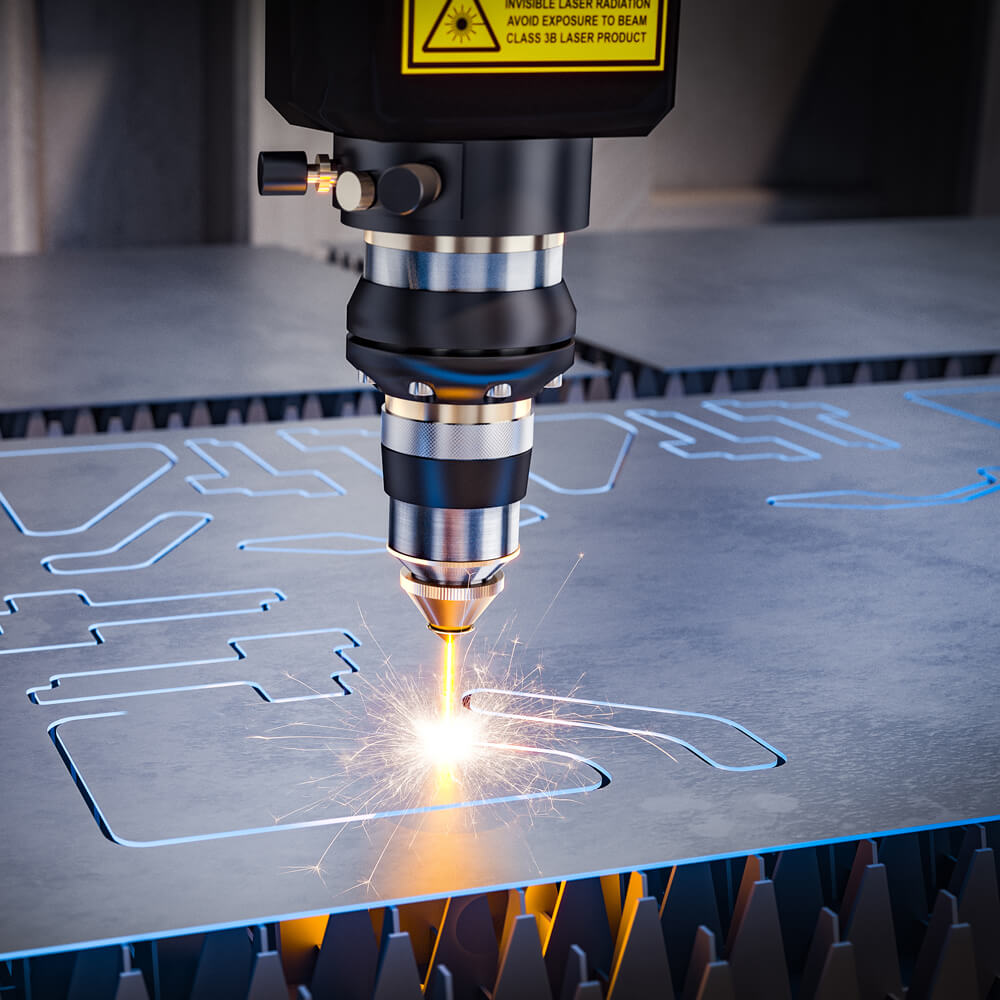

Laser Cutting

Precisely cutting thin profiles and features in stainless steel and titanium sheet for instrument components and implants.

TIG Welding

Expert, high-purity laser and TIG welding for creating hermetically sealed enclosures and assemblies for medical devices.

Precision Finishing

A critical service including passivation, electropolishing, and bead blasting to achieve the specific, clean surface required for medical applications.

Biocompatible Materials and Certified Finishes

Common Medical-Grade Materials:

- Titanium (Grade 5 ELI / Ti-6Al-4V, Grade 2)

- Stainless Steel (316L, 17-4 PH, 440C)

- PEEK (Unfilled, Medical Grade)

- Radel® (PPSU) & Ultem™ (PEI)

- Cobalt-Chrome (CoCr)

- Acetal Copolymer (POM-C)

Critical Surface Finishes:

- Passivation per ASTM A967

- Electropolishing

- Anodizing (Type II for color coding, Type III for wear resistance)

- Bead Blasting for a fine, matte, non-glare finish

- Laser Marking for UDI and traceability

- Mechanical Polishing to a mirror finish

Gallery of Medical & Healthcare Components

- Orthopedic Implants (Spinal, Knee, Hip)

- Bone Screws and Fixation Plates

- Surgical Instruments (Handles, Jaws, End-Effectors)

- Dental Implants and Abutments

- Components for Robotic Surgery Systems

- Housings for Diagnostic Equipment

- Fluidic Manifolds for Analysis Devices

- Custom Laboratory Equipment

- Components for Prosthetics

- Endoscopic and Laparoscopic Instrument Parts

Frequently Asked Questions

Are your processes compliant with ISO 13485?

While we are not formally certified to ISO 13485, our quality management system is rigorously aligned with its principles, including risk management, process validation, and full traceability, allowing us to confidently serve the medical device industry.

How do you ensure material traceability?

Traceability is paramount. We source all medical-grade materials from certified suppliers and provide Mill Test Reports (MTRs) for every lot. We maintain lot control throughout the entire manufacturing process, from raw material to finished part.

What does "biocompatible" mean?

A material is biocompatible if it does not cause a toxic or immunological response when exposed to the body. We work with well-established biocompatible materials like Titanium, 316L Stainless Steel, and PEEK.

What is passivation and why is it critical for medical parts?

Passivation is a chemical cleaning process that removes any free iron and other contaminants from the surface of stainless steel. This is critical for medical parts to prevent any potential for corrosion and to ensure a pure, passive surface.

Can you machine PEEK for long-term implantable devices?

Yes, we have extensive experience machining implant-grade PEEK (e.g., PEEK-OPTIMA™). We use dedicated tooling and handling procedures to prevent contamination and maintain the material’s integrity.

How do you handle deburring on very small, intricate parts?

For medical components, we perform deburring manually under high magnification (microscopes). This meticulous process ensures that every edge is perfectly clean and free of any microscopic burrs.

Do you operate a cleanroom?

While we do not operate a certified cleanroom for assembly and packaging, we maintain a highly clean, organized, and climate-controlled manufacturing environment suitable for producing high-precision medical components.

Can you add part numbers or UDI marks?

Yes, we offer precision laser marking services to add permanent part numbers, lot codes, logos, or Unique Device Identification (UDI) marks to your components.

What is the difference between 316 and 316L stainless steel?

316L has a lower carbon content (“L” for Low Carbon). This makes it more resistant to sensitization and corrosion after welding and is the preferred grade for most medical applications.

How do you protect our intellectual property?

We treat all client data with the utmost confidentiality. We readily sign NDAs before any technical data is exchanged, and our internal systems and access controls are secure to protect your proprietary designs.

Related High-Precision Applications

Scientific Instruments

Creating the high-precision components that power laboratory and research equipment.

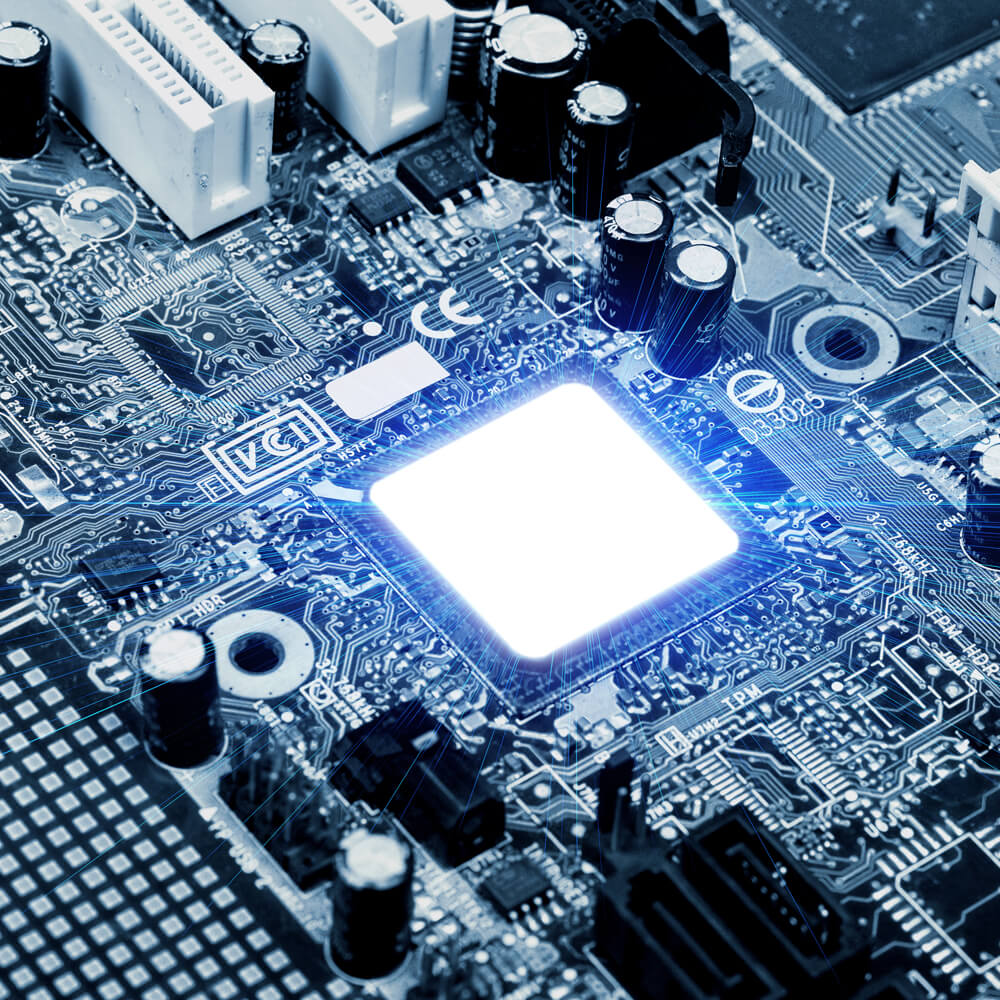

Semiconductor

Machining ultra-high-performance materials for sensitive processing equipment.

Robotics & Automation

Building the precise and reliable components for modern automation systems.