Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Robotics & Automation

Precision Manufacturing for the Robotics & Automation Industry

Building the High-Precision, Lightweight, and Durable Components that Power the Future of Automation—from End-Effectors to Structural Frames.

- ISO 9001 Certified

- 5-Axis Complex Machining

- Rapid Prototyping for R&D

Your Agile Manufacturing Partner for Robotic Systems

The robotics and automation industry is at the forefront of modern innovation, demanding components that deliver maximum performance with minimal weight and absolute reliability. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, dedicated to producing the high-precision mechanical components that form the backbone of these advanced systems. From intricate gearbox components and custom actuator housings to lightweight robotic arm segments and durable end-effectors, we have the technology and expertise to meet the stringent demands of this dynamic field.

We understand that robotics development is a cycle of rapid iteration and rigorous testing. Our services are structured to support this cycle, offering fast, high-quality prototypes to accelerate your R&D efforts. As your designs mature, we provide a clear and reliable path to scalable production, ensuring that the precision and quality demonstrated in the prototype are perfectly replicated in every production part. We are more than a supplier; we are a precision partner committed to helping you build the next generation of automation.

The Celerity Precision Advantage for Robotics

Expertise in Complex Geometries

Our advanced 5-axis CNC machining capabilities are essential for producing the complex, organic shapes, deep pockets, and intricate features required for modern robotic components and end-of-arm tooling (EOAT).

Lightweighting & Material Specialization

We are experts in machining lightweight, high-strength materials like 6061 and 7075 aluminum, titanium, and high-performance plastics (PEEK, Delrin), which are critical for reducing inertia and improving robot speed and efficiency.

Uncompromising Precision & Tight Tolerances

Robotics demand precision. Our state-of-the-art metrology lab and rigorous in-process controls ensure we can consistently hold the tight tolerances required for perfect alignment of bearings, motors, and sensors.

Rapid Prototyping for Fast Iteration

We know speed is critical in R&D. We deliver functional, high-precision prototypes in a matter of days, allowing your engineering teams to test, validate, and innovate faster.

One-Stop Solution for Assemblies

We go beyond individual components. We can deliver complete, light-duty sub-assemblies, including the installation of bearings, fasteners, and other hardware, simplifying your supply chain.

Scalable Production for Growth

Our flexible manufacturing facility is designed to grow with you. We can seamlessly scale from producing a single prototype to a full production run of thousands of units as you bring your robotic system to market.

From CAD Model to Robotic Component: Our Process

RFQ & Engineering Collaboration

Submit your CAD assembly and part files. Our engineers provide a rapid quote and work with you to offer DFM feedback focused on weight reduction, strength, and manufacturability.

Process & Toolpath Optimization

We develop a detailed manufacturing plan, using advanced CAM software to create optimized toolpaths for complex 5-axis and multi-sided machining.

Material Sourcing & Certification

We procure certified materials from trusted suppliers and can provide full material traceability documentation for every component.

Precision Machining

Your parts are expertly machined on our advanced CNC centers. For assemblies, we machine mating components in matched sets to ensure perfect fitment.

Finishing & Assembly

Parts undergo any specified finishing, such as anodizing for durability. We then perform any required sub-assembly, such as pressing in bearings or installing threaded inserts.

CMM Inspection & Quality Assurance

All critical features and assembly datums are verified using our Coordinate Measuring Machines (CMMs). We ensure every component is within spec before shipping.

Building the Next Generation of Automation?

Let’s collaborate on the precision components that will bring your robotic system to life.

Key Manufacturing Services for Robotics

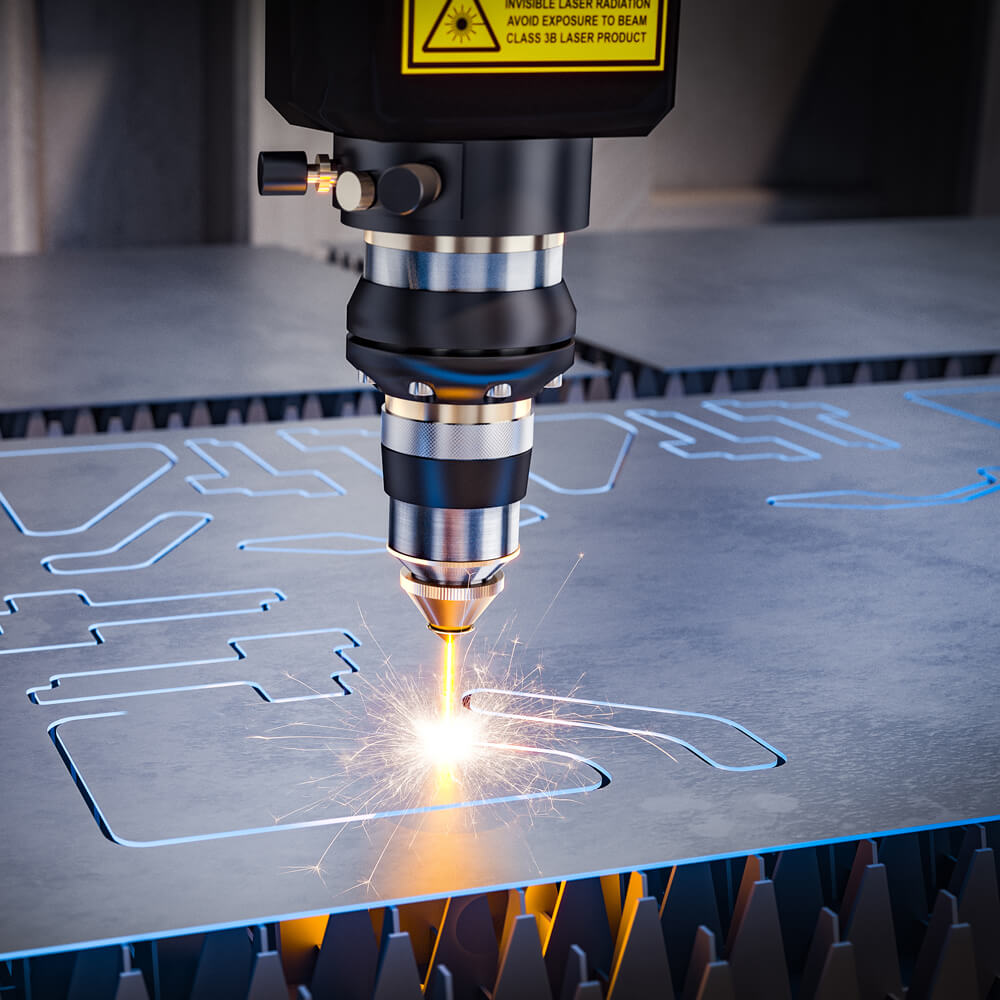

5-Axis CNC Milling

The cornerstone for creating lightweight, skeletonized structural components, complex actuator housings, and integrated end-effectors.

CNC Turning with Live Tooling

Ideal for producing high-precision motor shafts, drive components, custom standoffs, and connector bodies with milled features.

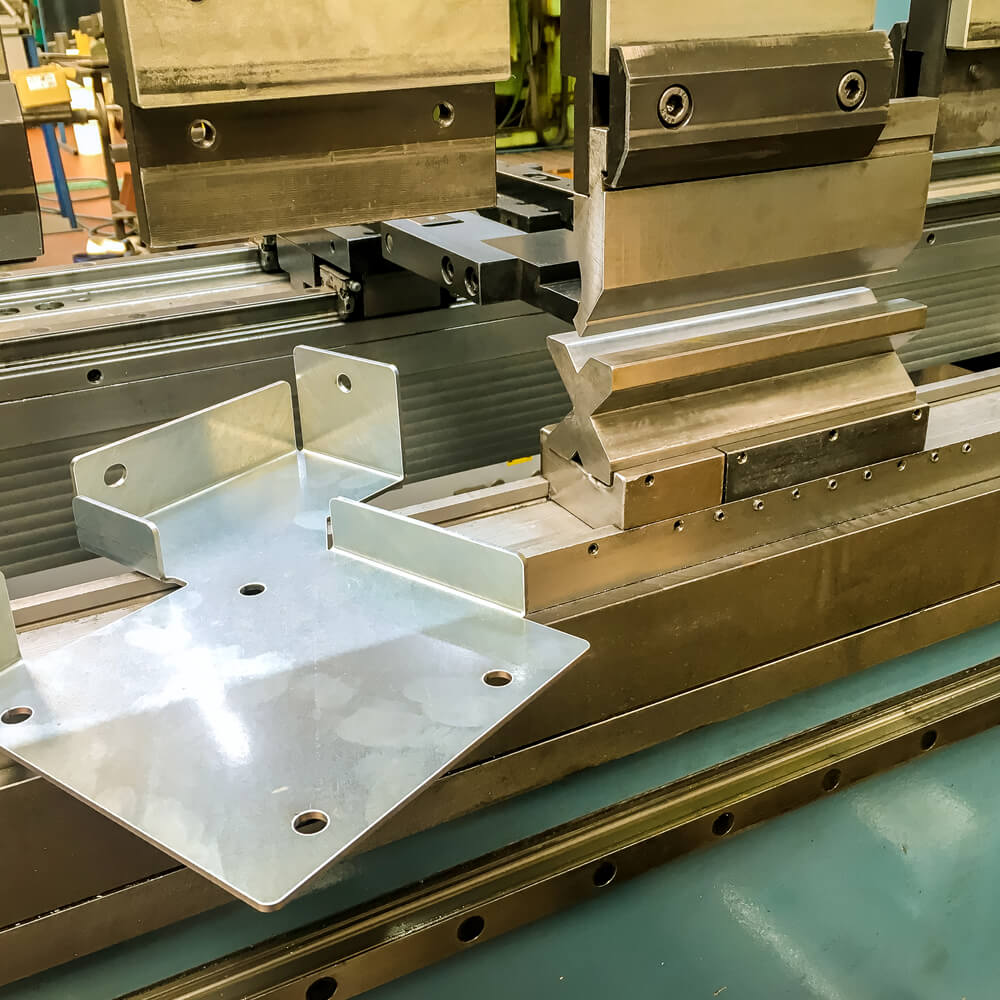

Sheet Metal Fabrication

Used for creating durable and cost-effective internal chassis, mounting brackets, and electronic enclosures for control systems.

Precision Casting

An option for higher-volume production of complex structural nodes and housings that can be post-machined for critical features.

Surface Finishing

Providing critical finishes like Type III hardcoat anodizing for wear resistance on aluminum parts and black anodizing for reduced reflectivity.

Light Assembly

Installing bearings, threaded inserts, PEM hardware, and dowel pins to deliver pre-assembled mechanical modules.

High-Performance Materials and Finishes for Robotics

Common Robotics Materials:

- Aluminum (6061-T6, 7075-T6)

- Stainless Steel (303, 304)

- Titanium (Grade 2, Grade 5)

- POM (Delrin®) for gears and bushings

- PEEK for high-performance insulators & fixtures

- FR-4 for jigs and insulating plates

Functional Surface Finishes:

- Anodizing (Type III Hardcoat for wear resistance)

- Anodizing (Type II Black for aesthetics and non-reflectivity)

- Electroless Nickel Plating (for hardness on steel parts)

- Black Oxide

- Passivation

- Bead Blasting (for a uniform, non-glare finish)

Gallery of Robotics & Automation Components

- Robotic Arm Structural Components

- End-Effectors and Gripper Jaws

- Actuator and Motor Housings

- Custom Gearbox Components

- Sensor and Camera Mounts

- Bearing Housings and Flanges

- Mobile Robot Chassis and Frames

- Custom Heat Sinks for Electronics

- Jigs, Fixtures, and End-of-Arm Tooling (EOAT)

- Drivetrain Shafts and Couplings

Frequently Asked Questions

What is the best material for a robotic arm?

6061-T6 aluminum is the most common and cost-effective choice, offering an excellent balance of strength and light weight. For applications demanding the highest possible stiffness and lowest weight, 7075-T6 aluminum or carbon fiber (which we can machine) are premium options.

Why is 5-axis machining so important for robotics?

It allows us to create highly optimized, “skeletonized” parts with complex curves and pockets that remove every possible gram of weight without sacrificing strength. This is critical for reducing motor load and increasing the speed and payload of a robot.

Can you help us reduce the weight of our components?

Absolutely. Our DFM process often includes suggestions for lightweighting strategies, such as optimizing pocket depths, using thinner walls where appropriate, and recommending higher strength-to-weight materials.

What is the best finish for a black, non-reflective robot part?

For aluminum, Type II black anodizing with a bead blast pre-finish is the best choice. It creates a durable, non-reflective, and cosmetically appealing matte black surface.

Can you hold the tight tolerances needed for bearing fits?

Yes, holding tight tolerances for press-fit bearings and motor alignments is a core competency. We machine these features to H7/g6 or your specified fit tolerances and verify them with our CMMs.

Do you make gears for robotic gearboxes?

We can CNC machine custom gear profiles from materials like Delrin (POM), Nylon, and steel. For high-precision, hardened ground gears, we work with certified partners as part of a complete solution.

What is "end-of-arm tooling" (EOAT)?

EOAT refers to any device attached to the end of a robotic arm, such as a gripper, vacuum cup, or custom fixture. We specialize in machining the custom components that make up this tooling.

How fast can you deliver prototypes for our R&D team?

Our rapid prototyping services are designed for speed. We can typically deliver moderately complex machined parts in aluminum or Delrin within 3-7 business days.

Can you assemble the parts you make for us?

Yes, we offer light mechanical assembly services. We can press-fit bearings, dowel pins, and install threaded inserts and other common hardware to deliver a more complete sub-assembly to you.

How do you ensure parts in an assembly will fit together perfectly?

We use a technique called “matched set” machining, where mating components are machined in the same setup or on the same machine to minimize tolerance stack-up. We also use our CMMs to verify the geometric dimensioning and tolerancing (GD&T) that controls alignment.

Related High-Precision Applications

Aerospace & Aviation

Machining flight-critical components to the highest standards of precision and quality.

Drones & UAVs

Applying our lightweighting expertise to components for unmanned aerial vehicles.

Medical & Healthcare

Building the precision components for surgical robots and lab automation systems.