Types of Fits: How to Choose the Right Fits in Engineering

Ever thought about how products fit together perfectly? It’s all about the types of fits in mechanical engineering.

In engineering, how parts fit together is key for a product to work right. It’s not just about any fit. Choosing the right engineering fits is essential for a product’s reliability and performance.

When picking a fit, engineers look at many things. They consider the material, size, and what the part will be used for. The right fit helps avoid problems like too much wear or overheating, and even keeps parts from breaking.

Key Takeaways

- Understanding the different types of fits is key in mechanical engineering.

- The right fit makes sure products work well and are reliable.

- Choosing the right fit means looking at material, size, and use.

- Good fit selection stops problems like too much wear or parts breaking.

- Engineers must think about many factors when picking the right fit.

What is a Fit?

In engineering, “fit” means how parts like shafts and holes fit together. This is key for how parts work and fit together.

A fit is about the space between parts. Tolerance is how much a part can vary in size. Clearance is the space when parts are together. Knowing these helps make parts that fit right.

Definition and Significance

Fits define how parts fit together. For example, a shaft and hole can have clearance or interference. Clearance makes parts easy to put together and move. Interference needs force to fit and is for strong connections.

Importance in Mechanical Assembly

Fits are vital in making things work together. The right fit means parts work well without breaking. Here’s why fits matter in different uses.

| Application | Type of Fit | Importance |

|---|---|---|

| Rotating Shafts | Clearance Fit | Allows for smooth rotation and movement |

| Permanent Joints | Interference Fit | Provides secure and rigid connection |

| Assembly Parts | Transition Fit | Balances alignment and assembly ease |

Choosing the right fit is key for product success. It affects how well a product works and how it’s made. Engineers use fits to meet quality and performance needs.

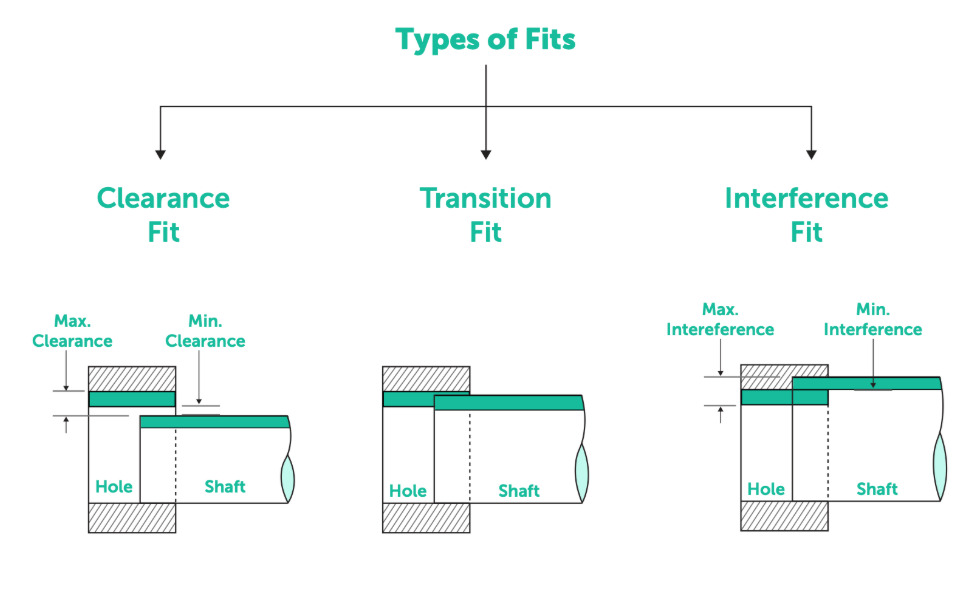

Types of Fits

Engineers need to know about different fits to make sure parts work well together. The fit type affects how well parts perform, assemble, and last. It’s key for mechanical systems to work right.

Clearance Fit

A clearance fit means the hole is bigger than the shaft. This lets parts move freely, slide, or rotate. It’s important for parts that need to move, like in bearings and shafts.

Clearance fits have a specific gap between the shaft and hole. This gap lets parts move without getting stuck. The gap size depends on the job and how precise it needs to be.

Transition Fit

Transition fits are a mix of clearance and interference fits. They have a bit of both, for parts that need to align and be easy to put together. This balance is key for parts that need to be taken apart and put back together often.

They’re good for jobs where parts need to be precise but also easy to assemble. This mix helps with both alignment and ease of use.

Interference Fit

An interference fit means the shaft is bigger than the hole. You need force or special methods like press-fitting to put it together. This fit is for parts that need to stay together tightly.

Interference fits are great for carrying loads and stresses between parts. They’re used in things like gear assemblies and heavy-duty parts. They don’t need extra fasteners.

How to Choose Suitable Fit for Your Projects

It’s key to pick the right fit for engineering projects to get the best results. The right fit depends on several factors that need to be looked at closely.

Consider Functional Requirements

Functional needs are very important when choosing a fit. For example, if parts need to move smoothly, a clearance fit is best. This allows for easy movement.

Evaluate Load, Precision, and Assembly Needs

The load and precision needed for an assembly also play a big role. For high precision, a transition fit is often better. It strikes a balance between allowing parts to fit together and not too tight.

Match the Type of Fit to Application Goals

| Fit Type | Application Goals | Characteristics |

|---|---|---|

| Clearance Fit | Free movement, rotation | Always clearance between parts |

| Transition Fit | Balance between alignment and assembly ease | May have slight clearance or interference |

| Interference Fit | Force transmission, tight assembly | Shaft larger than hole, requires force for assembly |

“The choice of fit is not just about ensuring parts fit together; it’s about ensuring they work together effectively under various operating conditions.”

Engineering Expert

In conclusion, picking the right fit for your projects is all about looking at the functional needs, load, precision, and assembly requirements. By understanding these and matching them to the right fit, engineers can make sure their projects work well and last long.

Conclusion

Finding the right fit is key to making mechanical parts work well. It’s not just a small detail in design. It affects how well a project performs, lasts, and succeeds.

There are three main types of fits: clearance, transition, and interference. Each has its own use and is best for certain jobs. Knowing these differences helps engineers make better design choices.

| Type of Fit | Characteristics | Application |

|---|---|---|

| Clearance Fit | Allows for free movement or rotation | Parts that require sliding or rotating |

| Transition Fit | Balances clearance and interference | Applications requiring both alignment and assembly ease |

| Interference Fit | Requires force or thermal methods for assembly | Parts that need to be securely joined |

In summary, picking the right fit is essential for mechanical parts to work as planned. By knowing the different fits and their uses, engineers can create better and more reliable systems.

Choosing the right fit is a big decision that affects how well mechanical parts work together. Engineers should think about the load, precision, and assembly needs. This helps make projects better and more successful.

FAQ

What is the primary purpose of using different types of fits in engineering?

What are the three main types of fits used in engineering?

How does a clearance fit differ from an interference fit?

What factors should be considered when selecting a fit for an engineering project?

Can you provide an example of an application that typically uses a transition fit?

How do engineers determine the appropriate tolerance for a fit?

When choosing the appropriate tolerance, engineers consider the part’s functional requirements, fit type, and manufacturing capabilities.

Are fits and tolerances related?

Indeed, there is a close relationship between fits and tolerances; the fit type is influenced by the tolerance of the parts, which in turn affects how well the parts function as a whole.