Home » Our Core Capabilities at Celerity Precision

Our Core Capabilities at Celerity Precision

You only need Celerity Precision to make custom parts. They do a wide range of things, from high-volume casting to precision CNC machining and sheet metal fabrication.

Our Manufacturing Services from Prototyping to Production

Celerity Precision has all the tools and machines it needs to bring your designs to life. We are more than just a machine shop. We are a full-service manufacturing partner with the most up-to-date technology and years of experience to handle your whole project. We make it easy for you to go from the first prototype to full-scale production, all in one place.

Explore Our Core Capabilities

CNC Machining

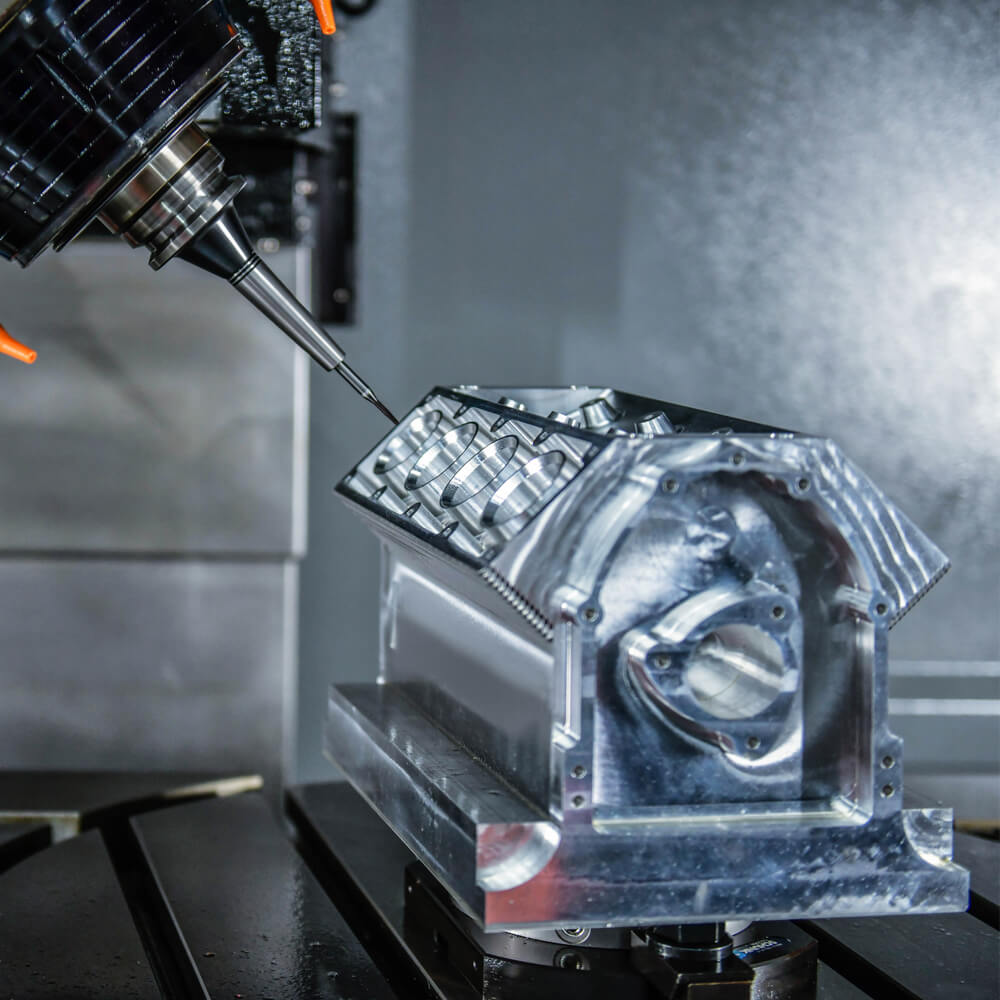

The core of our precision services, offering high-tolerance milling and turning for metal and plastic parts.

CNC Milling

Utilizing 3, 4, and 5-axis technology to create parts with complex geometries and intricate features.

CNC Turning

High-speed production of cylindrical components, from simple shafts to complex multi-feature parts.

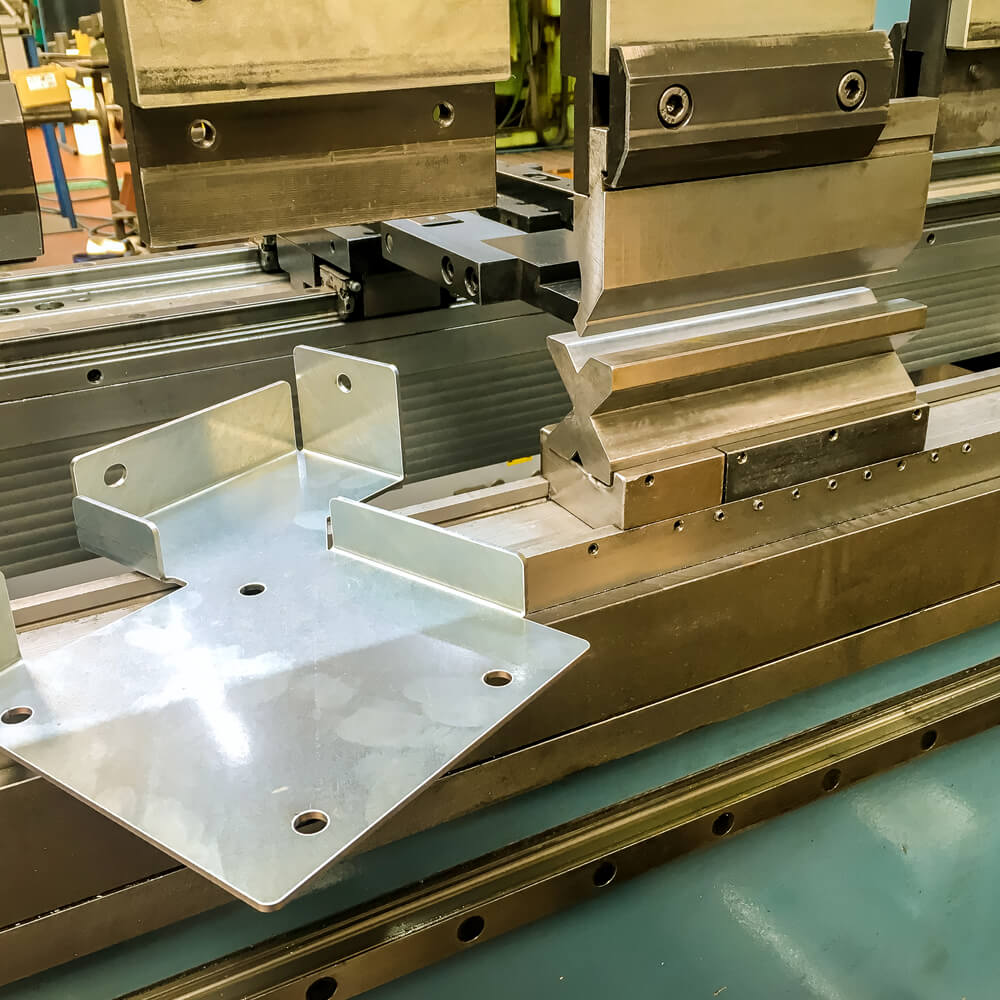

Sheet Metal Fabrication

Transforming flat sheets of metal into robust enclosures, brackets, and assemblies.

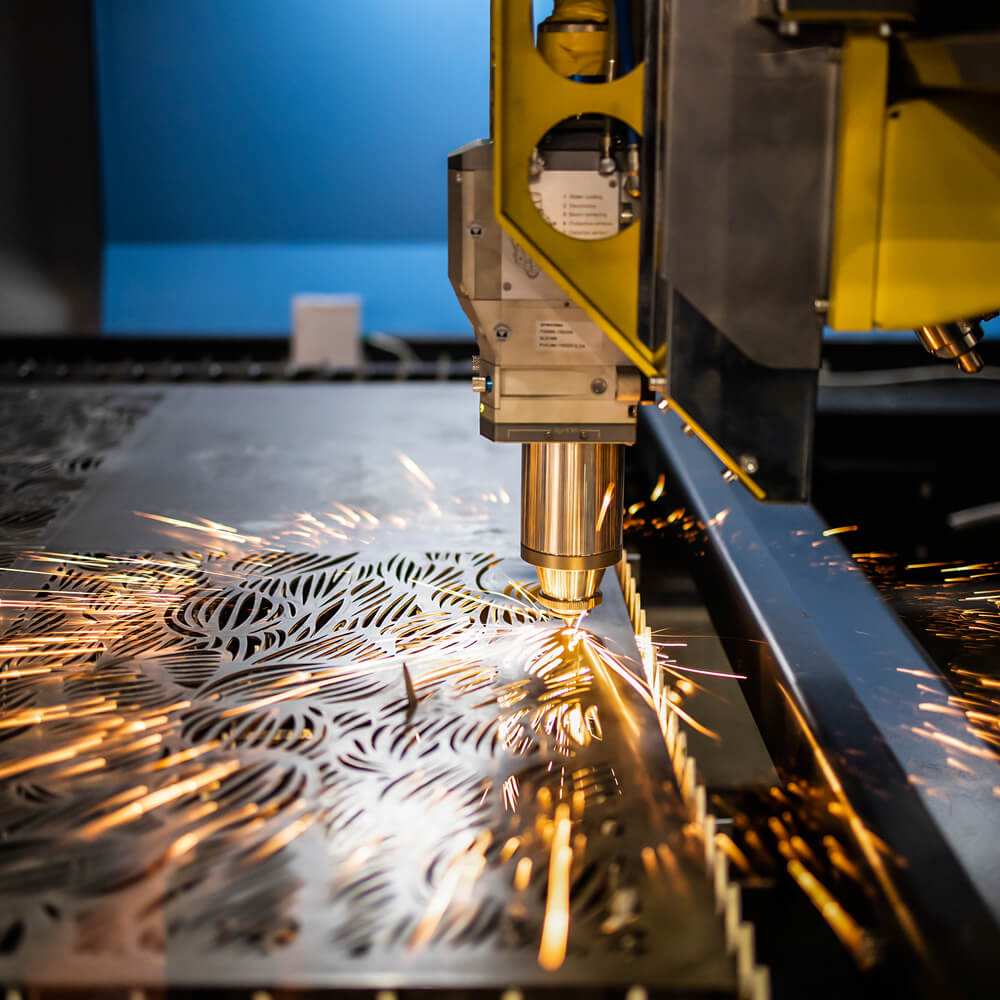

Laser Cutting

Precisely cutting intricate patterns and complex contours with clean edges and fine detail.

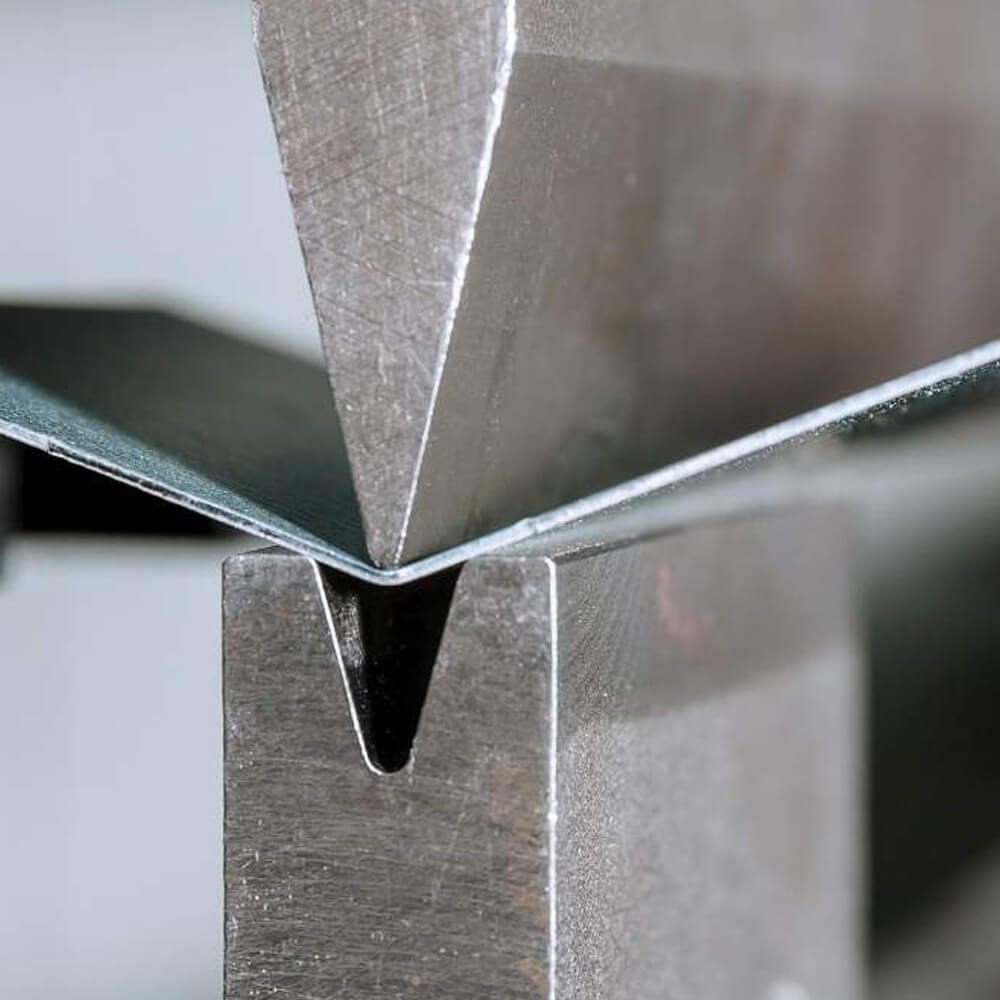

Bending

Accurately forming precise angles and multi-bend geometries with our CNC press brakes.

Welding

Creating strong, permanent joints and assemblies with our expert TIG, MIG, and spot welding services.

Die Casting

High-volume production of near-net-shape metal parts with excellent speed and consistency.

Precision Casting

Investment casting for highly complex and intricate metal parts with a superior surface finish.

Where Quality Meets Reliability in Custom Manufacturing

The Right Material for Every Process

We have a lot of different skills and things to work with. We can help you pick the right material for your process, whether it’s a high-performance PEEK for CNC machining, a formable 5052 aluminum for sheet metal fabrication, or a strong A380 aluminum for die casting. Because we have everything we need in stock, we can start your project right away.

The Final Step to Perfection

A good part isn’t done until it has the right finish. We are the only place you need to go for manufacturing. We offer a full range of finishing services that are tailored to your process and material. These are anodizing, powder coating, passivation, and plating. We do everything for you so that the part is completely finished and ready to be put together.

Industries We Serve

Because we can do all kinds of manufacturing, we can serve a lot of different industries that have high standards. For important aerospace parts, we use precision CNC machining. For the automotive industry, we use high-volume die casting. For electronics enclosures, we use expert sheet metal fabrication. We are a flexible partner who can help you with the problems that are unique to your industry.

Your Custom Parts Manufacturing Partner

One-Stop Solution

We are the only partner you need to simplify your supply chain because we offer a full range of services, from machining and casting to finishing and assembly.

Advanced Technology Across the Board

We buy the newest technology for all of our processes, such as 5-axis CNC machines, fiber lasers, and automated die casting cells.

Scalable Production

We can be your partner for the whole product lifecycle, from one-off machined prototypes to more than 100,000 cast production parts.

Cross-Disciplinary Expertise

Our engineers know how different processes work together. We give expert DFM feedback that takes into account the whole manufacturing process, which leads to a better and cheaper result.

Our Core Capabilities - Celerity Precision

Do you need manufacturing that is exact and precise? We offer the best CNC machining services at Celerity Precision. We help a lot of different businesses and needs.

We know a lot about custom manufacturing and precision engineering. This means that the products we sell are exactly what our customers need. We get reliable results on complicated projects because we have a skilled team and cutting-edge technology.

We take pride in the work we’ve done with different materials. Every project we do shows how committed we are to doing a great job.

Key Takeaways

- CNC machining services of the highest quality for many different industries

- The ability to do precision engineering and custom manufacturing

- Cutting-edge tools and a skilled team for tough jobs

- Ability to use different kinds of materials

- A promise to give results that are correct and trustworthy

Introduction to Our Capabilities

We use a lot of different ways to make things at Celerity Precision that are of the highest quality. CNC machining is a big part of what we do, and it’s our main service.

CNC machining takes away material. It cuts away material to make the part we need. This is not the same as additive manufacturing, which adds material layer by layer, like 3D printing. We can make parts with great accuracy and complicated shapes because we focus on subtractive manufacturing.

The goal of this article is to give an overview of how we make things. It shows how these methods work and what they can do for you. Our clients can see how much we help their projects by understanding these things.

In our manufacturing, we do both CNC milling and CNC turning. Both are important for making parts that are hard to make. CNC milling removes material with rotating tools, while CNC turning shapes the workpiece by rotating it.

With these methods, we can make a lot of different parts. We do everything with great care and precision, from simple parts to complicated assemblies. We can meet the needs of clients in many fields by using these methods.

CNC Machining

CNC Machining is a big part of how things are made today. It has changed the way we make things. This method is very important for making parts that are very precise and have complicated shapes.

Definition

CNC machining shapes parts with tools that are controlled by computers. It is very precise and can make parts with complicated shapes. This is great for making parts that are hard to make.

Use / How it works

The first step is to use a computer to design the parts. The design is turned into commands for the Metal CNC machine. Then, the machine cuts the part out of the raw material, which could be plastic or metal.

CNC machining can do a lot of things, such as drilling and milling. Aerospace and cars are just two of the many fields that use it.

Applications

A lot of different fields use CNC machining because it makes parts with complicated shapes and is very precise. It’s used for:

- Parts for aerospace

- Parts for cars

- Medical tools

- Machinery with precision

CNC machining is highly valued in these fields because it is accurate and dependable. It can make parts with shapes that are hard to understand.

Comparison with other Processes

CNC machining is not the same as laser cutting or making things out of sheet metal. It can make parts with complicated shapes and very high accuracy. Laser cutting is great for cutting flat sheets, but CNC machining can work with a lot of different materials and make parts that are three-dimensional.

Sheet metal fabrication only shapes metal sheets, but CNC machining can work with a lot of different materials. It’s not just in sheet form. This makes CNC machining useful for a wide range of tasks.

CNC Milling

Making things today relies heavily on CNC milling. It helps make complicated parts with a lot of accuracy.

There are many reasons why we use CNC milling. It can be used in many ways and is correct. We can make parts with exact sizes and detailed designs with this tech.

Definition

CNC milling machine cuts away material with tools that spin. This makes parts that are very complicated and very accurate.

How to Use / How It Works

CNC milling machines can make parts with very specific sizes or designs. A rotating tool cuts away material by moving along different axes. 3-, 4-, and 5-axis milling precisely make parts of different shapes. This makes parts that are very precise and have complicated shapes.

The steps for CNC milling are:

- Using CAD software to design the part

- Making a CNC program from the design

- Getting the CNC milling machine ready

- Putting the milling process into action

Applications

Many fields use CNC milling. It makes parts for cars and planes. It also makes everyday things and medical devices.

CNC milling has the following benefits:

- Very precise and accurate

- Ability to create intricate shapes

- Being able to choose different materials

Comparison

CNC milling and CNC turning are different because they make different things. CNC milling is the best way to make shapes that are hard to make. CNC turning is used to make parts that are round or spherical.

Bending is also important, especially for sheet metal. Bending shapes the material into the shape you want, while CNC milling cuts it.

CNC Turning

CNC turning machine is a key part of a lot of manufacturing processes. It has changed the way round parts are made. This is a great way to make parts that are round and fit perfectly.

Definition

When you do CNC turning, you turn a workpiece around a fixed axis. This is the axis along which a cutting tool moves to cut away material. This makes parts that are symmetrical and round with great accuracy.

Use / How It Works

In CNC turning, the workpiece is put on a spindle and turned. A cutting tool that is controlled by a computer moves along the workpiece. This method works well for making things like pins and shafts.

Applications

A lot of businesses use CNC turning. These are things like cars, planes, and medical equipment. People use it to make everything from simple things like bolts to complicated engine parts.

Comparison (CNC Turning Vs CNC Milling)

Both CNC turning and CNC milling are used for precise machining. But they are used for different things. CNC milling is better for parts with complicated shapes, while CNC turning is better for round parts.

This table shows how CNC turning and CNC milling are alike and different:

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Primary Use | Producing cylindrical parts | Creating complex geometries |

| Workpiece Movement | Rotates around a fixed axis | Remains stationary, tool moves |

| Typical Applications | Shafts, pins, bushings | Molds, dies, complex parts |

Welding is also very important in making things. You can make high-quality parts with CNC turning, but you need to weld them together. CNC turning makes welding easier by being more precise.

Sheet Metal Fabrication

Cutting, bending, and putting together metal sheets is what sheet metal fabrication is all about. It’s important for making parts and products in a lot of different areas.

Definition

It’s the skill of making things out of sheets of metal. This means cutting, bending, and putting them together. It shapes raw metal into what we need.

Use / How It Works

First, we choose the right metal for the job. Then we used tools like laser cutting to make it the right size. Then, we use bending methods to shape it. Finally, we use welding or rivets to put the pieces together.

Here are the most important steps:

Using CAD software to design the product

Getting the metal the right size

Bending it into the shape it needs to be

Putting the pieces together to make the final product

Putting coatings or treatments on it to finish it

Applications

You can find sheet metal fabrication in a lot of places, such as:

Aerospace: for parts and pieces of airplanes

Automotive: for parts of the body and engine of a car

Construction: for roofs, walls, and other parts of buildings

Consumer goods: electronics, appliances, and more

Comparison with Machining and Other Processes

There are some advantages to sheet metal fabrication over machining. It’s great for making shapes that are hard to make with heavy materials. It’s also cheaper for parts that need to be bent a lot or have big surfaces.

But it’s not perfect. It’s not good for parts that need to be very precise or have complicated structures inside. For those, 3D printing or machining might be a better choice.

The main benefits are:

It can build shapes and structures that are hard to understand.

For some parts, it’s cost-effective.

It works with a lot of metals and alloys.

To sum up, sheet metal fabrication is a useful and adaptable process. It’s essential in many industries. Knowing its strengths and weaknesses helps us use it well to make a variety of metal products.

Laser Cutting

We make complicated parts differently now that we can cut them with lasers. We use this technology at Celerity Precision to make parts that are very precise and high-quality.

Definition

Laser cutting is a very precise way to cut through materials with a strong laser. It’s great for making complicated parts and pieces. This method is great for making detailed designs that are hard or impossible to make with older cutting methods.

Laser cutting has a lot of advantages, such as the ability to cut complicated shapes, very high accuracy, and very little waste of materials. It’s also quicker than other ways to make precise cuts.

Applications

Many industries, such as aerospace, automotive, and medical device manufacturing, use laser cutting. It’s very accurate, which is great for making parts that need to fit tightly and have smooth edges.

Aerospace: Parts that need to be very precise and have complicated shapes.

Automotive: Parts like custom brackets, gears, and other small parts that are very detailed.

Medical Devices: Precise cutting for devices and instruments that need high accuracy.

Comparison with Other Methods

Laser cutting is better than other methods because it is more accurate and can make more complicated designs. CNC machining takes away material, but laser cutting doesn’t touch the material and is better for some jobs.

Laser cutting cuts or separates things, while welding joins them together. Both are important for making things, but they do different things.

Laser cutting, CNC machining, and welding can all be used together to fix tough manufacturing problems. This lets us offer complete solutions for tough projects.

Bending

Bending is an important step in making metal parts. It shapes metal into curves or angles. This is very important in fields like construction, aerospace, and automotive.

Definition

Bending a material, usually metal, into a different shape. It bends the material without breaking it by using force.

Use / How it works

We bend flat metal to make shapes that are hard to make. The metal is bent and held in place by a die. Modern machines, such as press brakes, make bends exact and consistent.

Applications

There are many ways to bend sheet metal. It helps make frames, enclosures, and other things. Used in:

Aerospace: for complicated parts of airplanes

For car body parts, automotive

Building: for structural parts and enclosures

Comparison (with other forming processes)

Bending is better than CNC machining or laser cutting in some ways. It’s great for making shapes that are hard to make with a lot of tools. But the best choice depends on what the project needs, like how thick the material is and how accurate it needs to be.

Experts say that bending is an important part of making things today. It lets you make a lot of parts with accuracy and speed.

“The skill of bending isn’t just about changing the shape of metal; it’s also about building the backbone of many businesses.”

— Expert in the field

Welding

Welding machine is an important part of making things. Using heat and pressure, it connects two metal pieces. This is very important in many areas, such as planes, cars, and construction.

Basic Principles of Welding

There are many ways to weld, and each one works best for a different job. Some of them are Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). They use different methods to heat up the metal and keep it safe while welding.

Stick welding, or SMAW, is simple to use and works well for a lot of jobs. GMAW, which stands for “MIG” welding, is quick and makes strong welds. People often use it to make cars and other things.

Uses of Welding

Welding is used in a lot of places because it works well to join metals. Welding puts parts together in the process of making a car. Welding is very important for making parts for planes that need to be strong and exact.

Welding is also important for making things like bridges and houses. It’s also used to make machines and tools that need strong connections.

Comparing to Other Ways to Join

Welding is not the same as die casting or precision casting. Casting shapes metal when it’s melted. Welding joins metal parts that are already made. This makes it easier to design and make things.

| Joining Method | Primary Use | Advantages |

|---|---|---|

| Welding | Joining metal parts | Flexibility, strong joints |

| Die Casting | Producing complex metal parts | High precision, complex geometries |

| Precision Casting | Creating intricately detailed metal components | Detailed features, minimal waste |

Experts say that the project’s needs will determine whether you should use welding, die casting, or precision casting. This includes how many will be made and what the final product should look like.

“Welding is an indispensable process in modern manufacturing, providing a reliable way to join metals with great strength and durability.”

To sum up, welding is very important for making things. It helps metal parts stick together better. People use it to build houses, machines, cars, and planes, among other things.

Die Casting

Die casting is a process in which hot metal is pushed into a mold. This makes parts that fit together perfectly. It’s great for making metal shapes and details that are hard to make.

Overview of the Process

Die casting uses a lot of pressure to pour hot metal, like aluminum or zinc, into a mold. The metal hardens when it is under pressure, making parts with smooth surfaces and exact sizes.

First, a die is made out of metal. During casting, it breaks into two parts that hold each other together. The mold opens and the part comes out after the metal has hardened.

There are different types of die casting like hot chamber, cold chamber, and vacuum die casting.

Applications

Many things, like cars, planes, and gadgets, use die casting. It makes parts for engines, gearboxes, and other complicated structures.

It’s great for thin-walled parts with complicated shapes. Other methods may not be as effective or may be more expensive.

Comparing with Other Methods

Die casting is much better than other methods. It works quickly and makes parts that are the right size. But making the mold first can cost a lot. It’s best for making a lot of pieces.

Die casting is cheaper for big orders than CNC machining. CNC is better for making small batches and changing designs.

Precision casting is similar, but it can make parts that are even more complicated. The choice between die casting and precision casting depends on the part’s needs, like material and size.

Precision Casting

We make detailed parts with a smooth finish at Celerity Precision by using precision casting. This method is great for making parts that are hard to make and need to be very precise and detailed.

Definition and Process

A wax model of the part is the first step in precision casting, also known as investment casting. A material that doesn’t melt in the heat covers this wax. Then, the wax is melted away, leaving an empty space.

To make the last part, molten metal is poured into this hole. The precision casting process is great for making parts with thin walls and complicated shapes.

Uses and Applications

In the aerospace, automotive, and medical fields, precision casting is very important. It’s great for making things like turbine blades, engine parts, and surgical tools. It is a top choice because it can make parts with great accuracy and finish.

A comparison of die casting and other casting methods

Die casting and precision casting are not the same. Die casting forces molten metal into a mold under pressure. To make the cavity, precision casting uses a wax pattern. This lets precision casting make parts that are more detailed and have more complicated shapes.

Precision casting is more accurate and has a better surface finish than other methods. It’s perfect for where these are important. Die casting might be faster and cheaper than precision casting. Still, it’s worth it because it can make complicated parts with great accuracy. You can also use it with welding to make complicated parts.

Final Thoughts

Businesses can make better choices when they know how different manufacturing processes work. We’ve talked about welding, CNC machining, die casting, and precision casting. Each one has its own uses and strengths.

When choosing a process, think about what you need. CNC machining is great for making parts that are complicated and need to be very accurate. Die casting is a good way to make a lot of metal parts quickly. Precision casting is great for making parts with a lot of detail. Welding is a great way to put things together in many ways.

We help you make these choices so you can find the one that works best for you. This makes sure that your products are of the highest quality and made quickly. To make a smart choice, think about the costs, how long it will take, and the materials needed.

Capabilities FAQs

What is CNC machining, and how does it work?

We can make complicated parts very accurately with CNC machining. It cuts away material with machines that are controlled by computers. We get exact and dependable results this way.

What are the advantages of CNC milling compared to CNC turning?

CNC milling is a great way to make parts with lots of angles. CNC turning works better for parts that are the same on both sides. CNC milling is more flexible, but for some jobs, CNC turning is faster.

What is sheet metal fabrication, and how does it work?

Sheet metal fabrication makes things out of sheets of metal. It has steps like cutting, bending, and welding. Because it doesn’t cost much, it’s used in a lot of fields, from construction to making everyday things.

What is the difference between CNC machining and laser cutting?

Laser cutting is used to make very precise cuts in materials. CNC machining is a way to make complicated parts by taking away material. Laser cutting works best on thin materials, while CNC machining works best on shapes that are hard to cut.

What does bending mean, and how is it used in making things?

Changing the shape of metal by bending it into angles or curves. People often use it with CNC machining and sheet metal. Bending lets us make complicated parts with perfect control.

What are the benefits of welding compared to other ways to join things?

Welding connects metal pieces, making them strong and long-lasting. It’s great for putting together complicated things. CNC machining and sheet metal go well with welding.

What is die casting and how does it work?

Die casting makes a lot of complicated parts with great accuracy. It pours hot metal into a mold. This method makes parts with smooth surfaces and detailed designs.

What is precision casting, and how is it different from die casting?

Precision casting uses investment casting to make complicated parts with a lot of accuracy. It might cost more and take longer, but it’s more flexible than die casting.

How do I pick the best way to make things for my project?

We think about how many you need, the material, and how complicated the part is. This helps us choose the best way to do your project. We want to be efficient and save money.

What does CNC machining do to make complicated parts?

CNC machining is very important for making parts that are very complicated with great accuracy. It uses advanced tech and skilled people. CNC machining is vital for creating detailed and accurate parts in modern manufacturing.