Precision CNC Bending Services in China

Forming Precise Angles and Complex Geometries for High-Quality Enclosures, Brackets, and Chassis.

- ISO 9001 Certified

- High Repeatability

- Advanced Tooling

Your Expert Partner for Precision Bending

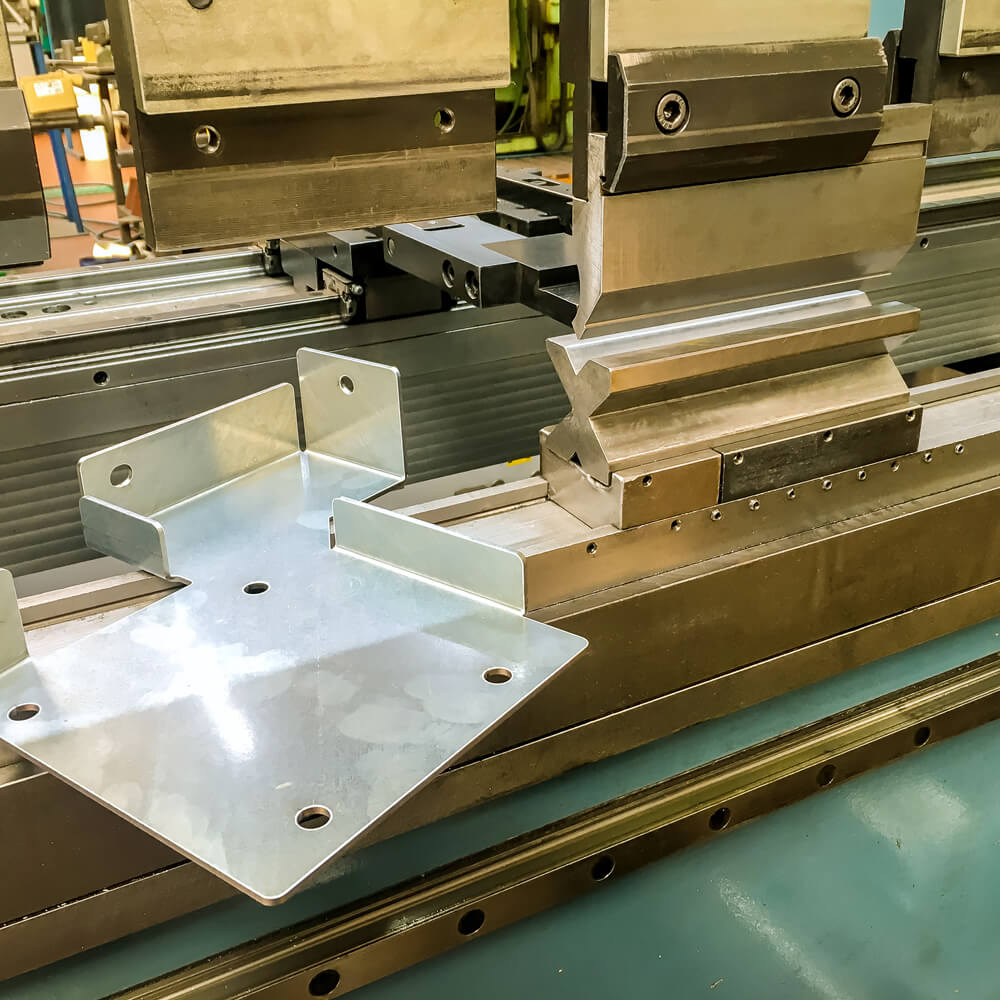

Celerity Precision is a leading manufacturing partner in China specializing in high-precision CNC bending and forming. This critical fabrication process uses a CNC press brake to accurately bend sheet metal into complex 3D shapes. Bending is fundamental to creating the structural backbone of countless products, from sturdy industrial enclosures to sleek electronic chassis. Our facility is equipped with modern, multi-axis press brakes and a vast tooling library, enabling our skilled technicians to deliver parts with exceptional angular accuracy, consistency, and adherence to your most complex designs.

Advanced Forming Technology for Any Design

Our investment in the latest bending technology ensures we can produce parts that are not only accurate but also complex, meeting the demands of modern product design with efficiency and precision.

Multi-Axis CNC Press Brakes

Our fleet of CNC press brakes are the core of our bending capability. Computer-controlled backgauges and ram positioning allow us to form multiple bends on a single part with extreme precision and repeatability, ensuring every component in a production run is identical.

Extensive Tooling Library

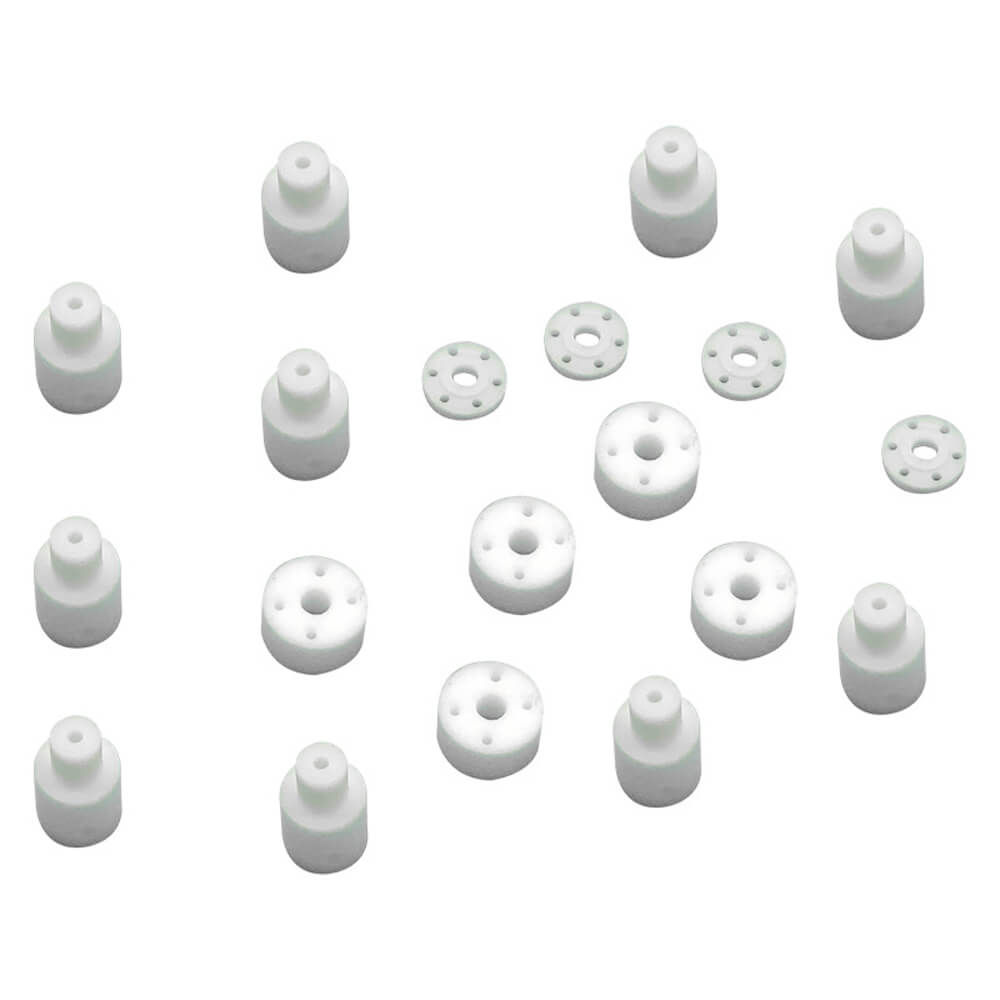

We maintain a large and diverse library of punches and dies, including various V-dies, gooseneck punches for clearing existing flanges, and hemming tools. This allows us to create a wide range of bend radii, offsets, and complex features without the need for expensive custom tooling.

Complex Multi-Bend Forming

We specialize in forming parts with intricate and challenging geometries. Our offline programming and simulation software allows us to plan the optimal bend sequence to avoid collisions and ensure manufacturability, even for the most complex enclosures and chassis.

A Full Spectrum of Formable Materials

Metal

Aluminum is strong, light metal that can be used for many things and doesn’t rust easily.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

Copper

Copper has great electrical and thermal conductivity, which makes it the best choice for heat sinks and electrical parts.

- Available Grades: C101 (OFHC), C110 (ETP)

- Common Finishes: As Machined, Electropolishing, Plating, Clear Coat

Brass

Brass is great for making fittings and decorative elements since it is easy to work with and looks like gold.

- Available Grades: C360

- Common Finishes: As Machined, Polishing, Plating, Brushing

Bronze

Bronze is durable and has minimal friction, it is widely used for naval hardware, bushings, and bearings.

- Available Grades: C932, C954

- Common Finishes: As Machined, Tumbling

Steel

Steel is a robust, long-lasting, and cheap material that works well in high-stress and industrial settings.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Stainless Steel

Stainless steel is very strong and doesn’t rust easily, so it’s great for use in food, medical, and maritime settings.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Magnesium

Magnesium is a very light metal that is great for uses where every gram matters.

- Available Grades: AZ31, AZ91

- Common Finishes: Chromate Conversion Coating

Titanium

Titanium is a high-performance metal that is quite strong for its weight and is also very biocompatible.

- Available Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Common Finishes: As Machined, Anodizing (for color), Sand Blasting

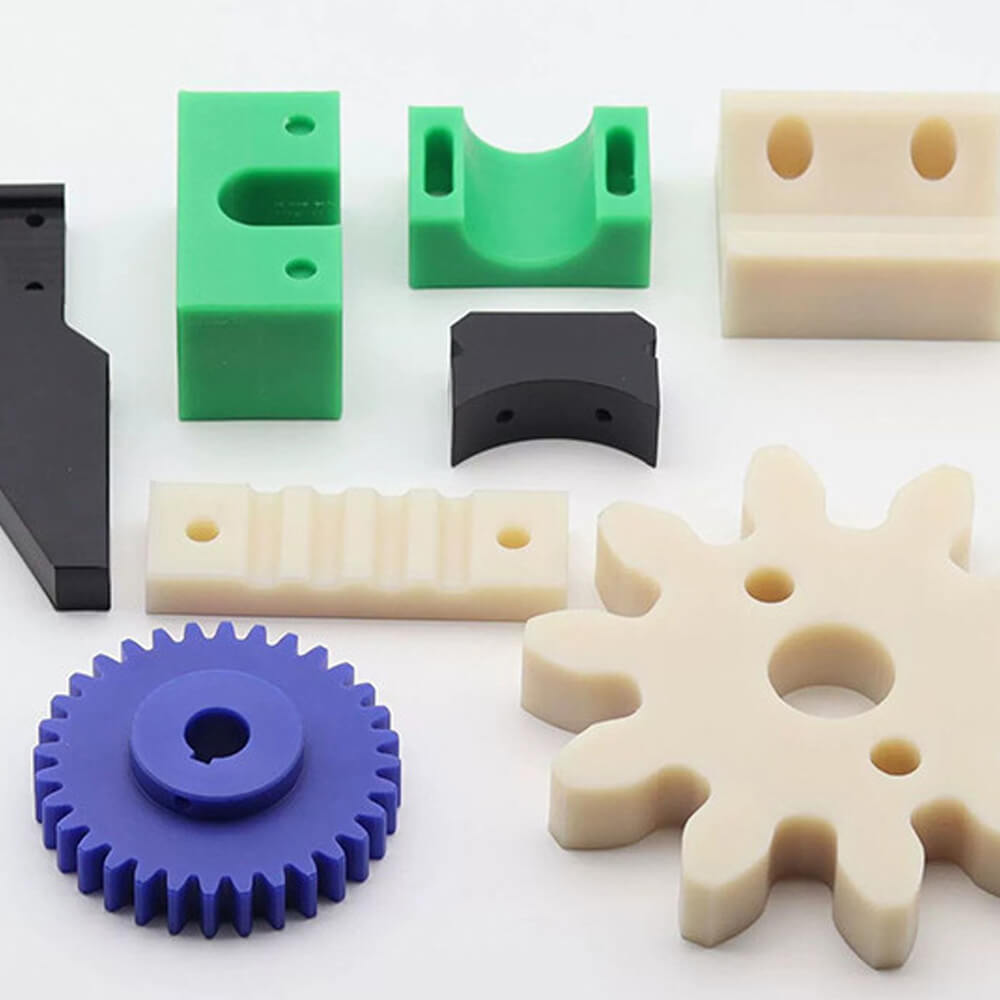

Plastic

ABS

ABS is a strong, impact-resistant, and cost-effective thermoplastic that works well for housings, enclosures, and prototypes.

Common Finishes: As Machined, Sand Blasting, Painting

PC (Polycarbonate)

PC is a sturdy, clear material that can handle heat and impact very well.

- Common Finishes: As Machined, Vapor Polishing, Painting

PLA

PLA is a thermoplastic that breaks down naturally and comes from renewable resources. It is often used for quick prototyping.

Common Finishes: As Machined, Painting

PMMA (Acrylic)

PMMA is a clear, hard plastic with great optical clarity. It is widely used as a light-weight substitute to glass.

Common Finishes: As Machined, Vapor Polishing, Flame Polishing

POM (Delrin/Acetal)

POM is an engineering plastic that is low-friction and high-stiffness, making it great for gears and bearings.

Common Finishes: As Machined

PA (Nylon)

PA is a strong and flexible plastic that can stand up to chemicals and wear.

- Available Grades: PA6, PA66

- Common Finishes: As Machined

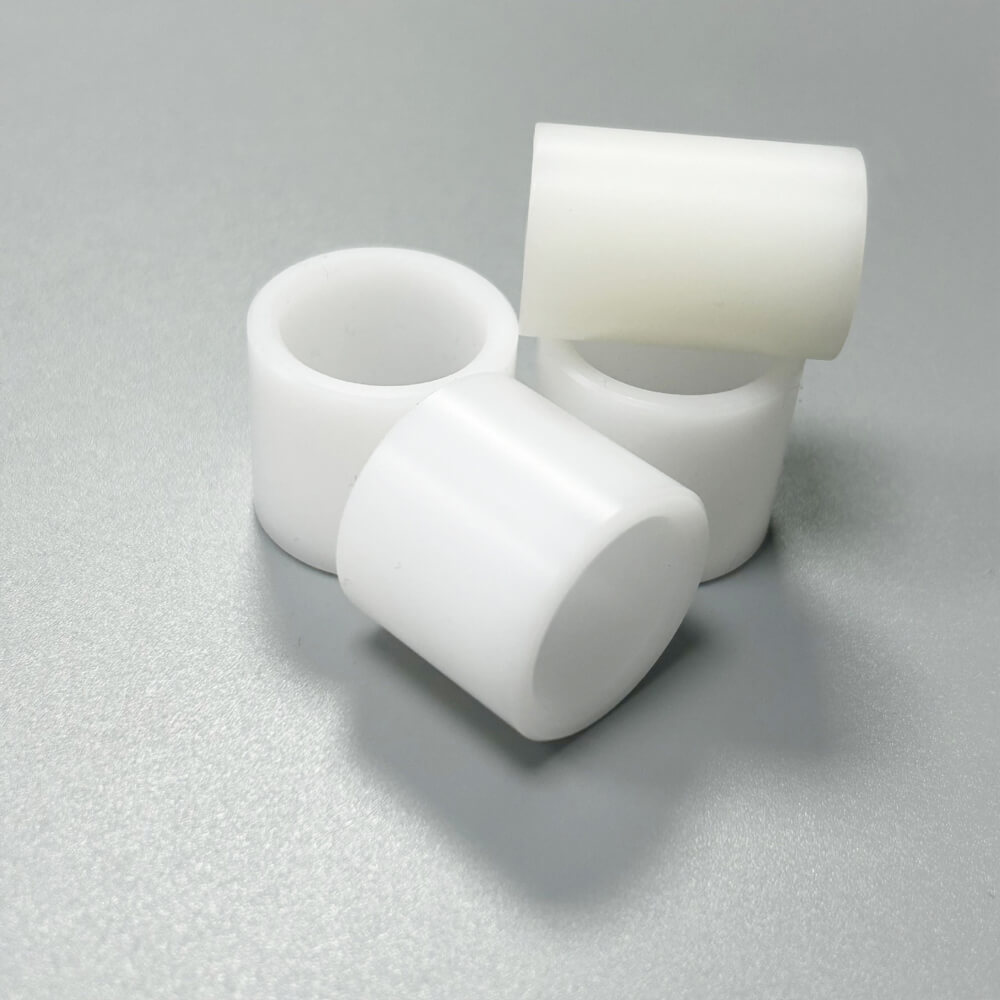

PE (Polyethylene)

PE is a typical type of plastic that can withstand chemicals and comes in varying densities for different uses.

Common Finishes: As Machined

PEEK

PEEK is a high-performance polymer that is very strong, resistant to chemicals, and stable at high temperatures.

Common Finishes: As Machined

PP (Polypropylene)

PP is a light plastic that is very elastic and resistant to chemicals. It is widely used for living hinges.

Common Finishes: As Machined

HIPS

HIPS is a cheap, stiff plastic that is easy to work with and is typically used to make prototypes before production.

Common Finishes: As Machined, Painting

PBT

PBT is a type of engineering thermoplastic that is stiff, stable in size, and can handle chemicals and heat.

Common Finishes: As Machined

PPA

PPA is a high-performance polyamide that is stronger, stiffer, and more heat-resistant than regular nylon.

Common Finishes: As Machined

PAI (Torlon)

PAI is high-performance plastic that is exceedingly strong and rigid and keeps its qualities even at very high temperatures.

Common Finishes: As Machined

PET

PET is a tough, rigid plastic used in engineering that resists chemicals well and wears well.

Common Finishes: As Machined

PPS

PPS is a high-performance thermoplastic that can withstand chemicals and high temperatures without changing shape.

Common Finishes: As Machined

PS (Polystyrene)

PS is a clear, rigid, and brittle plastic that doesn’t cost much and is typically used for prototypes.

Common Finishes: As Machined, Painting

PVC

PVC is a strong, long-lasting, and cheap plastic that doesn’t easily get damaged by chemicals or water.

Common Finishes: As Machined

PTFE (Teflon™)

PTEE is known for having a very low coefficient of friction, being chemically inert, and being able to handle high temperatures.

Common Finishes: As Machined

Bakelite

Bakelite is a thermoset plastic that is hard, thick, and resistant to heat. It also has good electrical insulating qualities.

Common Finishes: As Machined

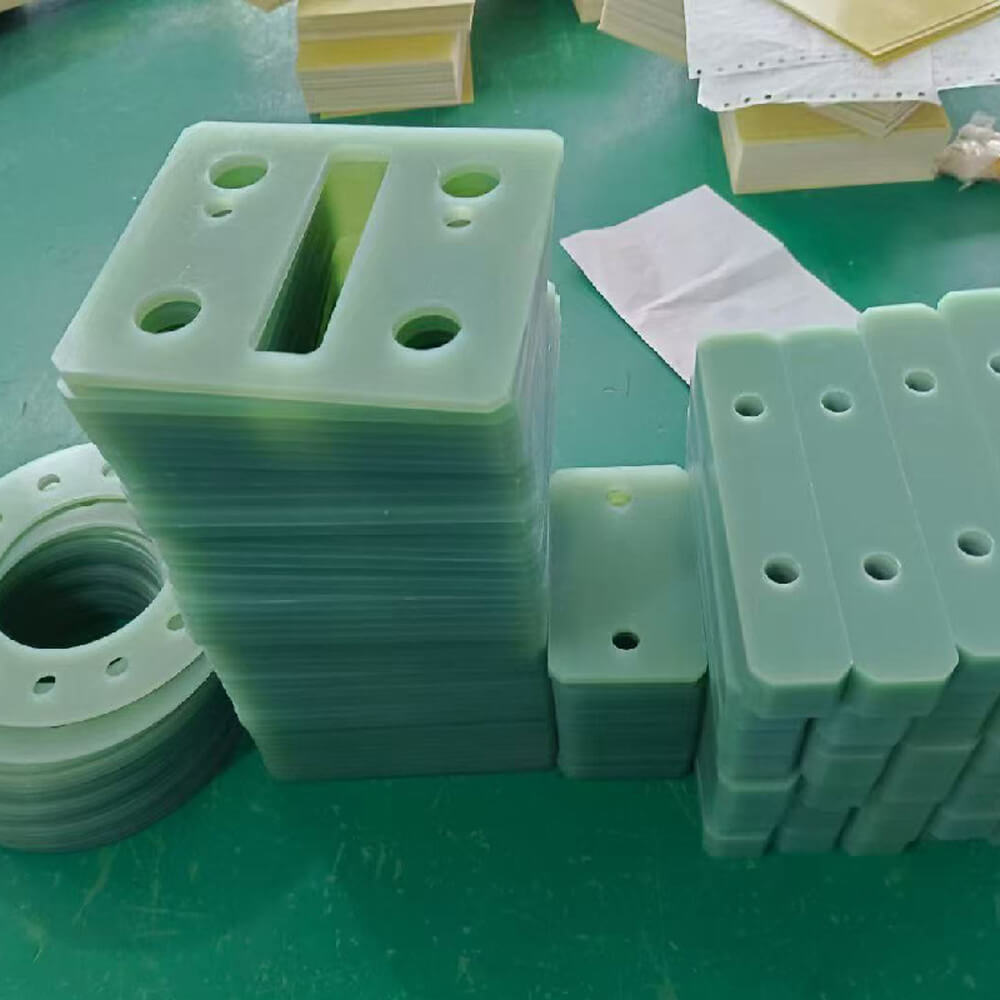

FR-4

FR-4 is a glass-reinforced epoxy laminate that is very strong and has great electrical insulation qualities.

Common Finishes: As Machined

Have a Design Ready? Let's Make It Real.

Why Choose Celerity Precision

Exceptional Angular Accuracy

Our modern CNC press brakes with precision-ground tooling allow us to hold tight angular tolerances (typically ±0.5 degrees), ensuring your parts fit together perfectly.

Unmatched Part-to-Part Repeatability

The computer-controlled process guarantees that from the first piece to the last in a high-volume run, every bend is in the exact same location with the exact same angle.

Complex Multi-Bend Capabilities

With multi-axis backgauges and advanced simulation software, we can efficiently produce parts with numerous bends in various orientations, saving you time and cost.

Expert Design for Manufacturability (DFM)

We provide critical feedback on your designs, advising on optimal bend radii, material selection, and feature placement to prevent cracking and ensure a successful outcome.

Integrated Fabrication Solution

We are your true one-stop shop. We can seamlessly take your project from laser cutting the flat pattern to CNC bending, welding, hardware insertion, and final finishing.

Cosmetic Finish Preservation

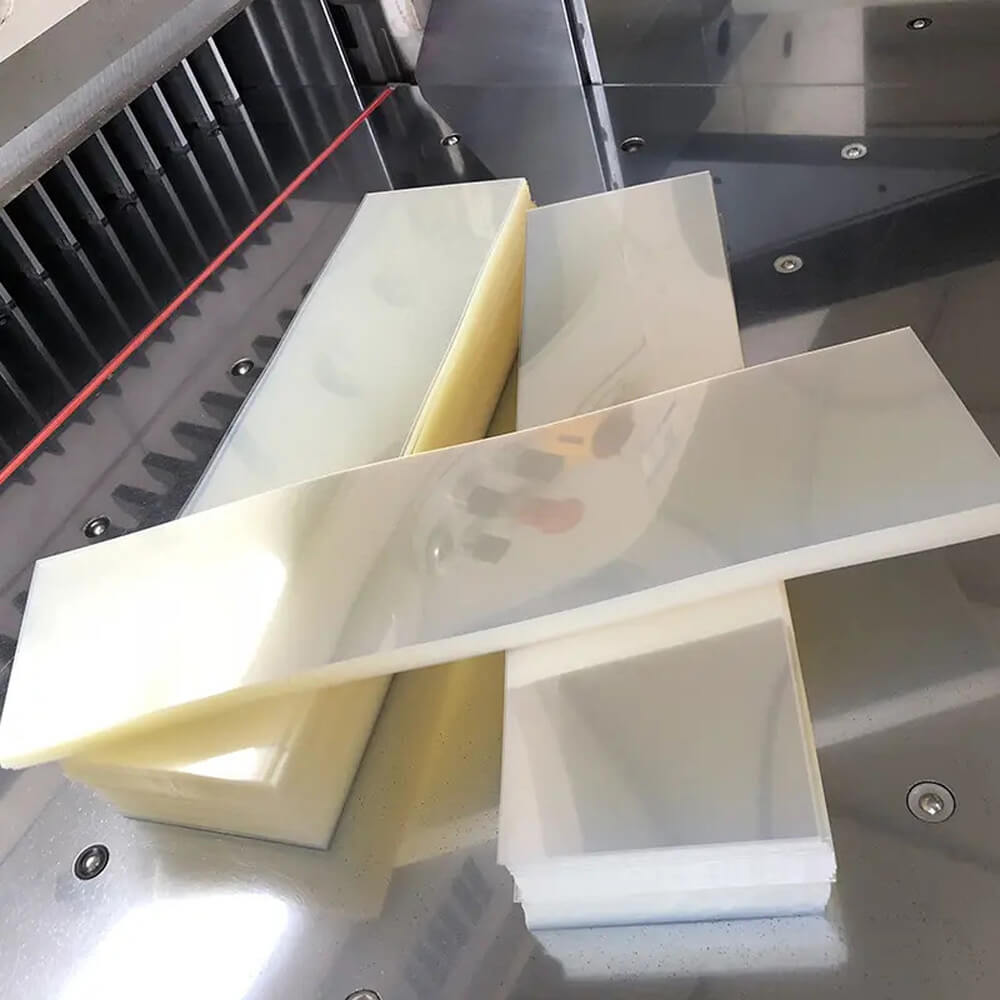

Our operators are skilled in using techniques and tooling (such as polyurethane film) to minimize die marks and protect the cosmetic appearance of your parts during the bending process.

Advantages of the Bending Process

Creates Strong, Monolithic Structures

Forming a part from a single sheet of metal creates strong corners without the need for welding, resulting in a more robust and often lighter component.

Cost-Effective for 3D Part Creation

CNC bending is a highly efficient and economical way to create three-dimensional structures compared to fabricating and welding separate pieces or machining from a solid block.

High Speed and Repeatability

The CNC process is fast, accurate, and repeatable, making it ideal for both rapid prototyping and high-volume production runs.

Enables Lightweight Designs

Complex and rigid structures can be created from thin, lightweight sheet materials, which is critical for applications in aerospace, automotive, and electronics.

Aesthetically Pleasing Corners

Formed corners are smooth and clean, providing a more professional and high-end appearance than welded joints, especially for enclosures and covers.

Versatility in Materials

The process is suitable for a wide range of common metals, allowing for great flexibility in material selection based on strength, weight, and cost requirements.

From Flat Sheet to Formed Part in 4 Simple Steps

Submit Design & Get Quote

Upload your 3D models (STEP) or 2D flat patterns (DXF). Our team provides a detailed quote and DFM feedback within 24 hours.

DFM Review & Order Confirmation

We confirm the bend sequence, tooling, and radii. Once you approve, we program the press brake.

Precision Bending

Your laser-cut flat patterns are expertly formed on our CNC press brakes by skilled operators.

Inspection & Global Delivery

Every part is rigorously inspected for dimensional and angular accuracy before being securely packaged and shipped.

Precision CNC Bending Services - Celerity Precision

“Innovation is the lifeblood of progress.” .This phrase from Steve Jobs really speaks to metal fabrication. Being precise and accurate is really important. We can now build complicated 3D things out of metal sheets in a different way thanks to CNC bending.

In China, Celerity Precision specialize in CNC bending services that are very precise. For more than 18 years, we’ve been doing this. We employ pneumatic or hydraulic press brakes to acquire the exact shape or angle you want.

We want to be the greatest at making things out of metal. We want to make sure our customers are delighted and that the work we do is of high quality. Our CNC bending skills keep growing better.

Important Points

- Knowledgeable about precision CNC bending services

- More than 18 years of expertise making things out of metal

- Using pneumatic or hydraulic press brakes for precision

- Dedication to making high-quality bent sheet metal parts

- A trustworthy partner for all your metal fabrication needs

Introduction

Manufacturers have never had such high accuracy thanks to CNC bending. Computer Numerical Control bending is the name of this technique, and it has changed the world of metal manufacture. It gives you a precise, quick, and adaptable technique to bend metal.

What is CNC bending or sheet metal bending?

Sheet metal bending is the process of bending metal sheets around a predetermined axis to make them into certain shapes. For this operation, CNC bending uses machines that are controlled by computers. It is simple to produce very accurate complex shapes and designs.

Benefits of CNC Bending Over Manual Bending or Other Methods

There are several reasons that CNC bending is better than manual bending and other methods. It works better, faster, and with more accuracy. It also saves money and materials and lets you customize things more.

This is because CNC bending can be programmed very precisely. It cuts down on mistakes made by people and speeds up manufacturing.

Applications of CNC bending

There are several uses for CNC bending, including in construction, cars, planes, and consumer items. It’s utilized to make sections for buildings, enclosures, and even decorations. Because it can do so many things, it is an important tool in modern production that lets you produce precise parts that are very complicated.

Types / Techniques of Bending

There are various ways to form metal with CNC bending. Each approach bends in a different way and is best for different situations.

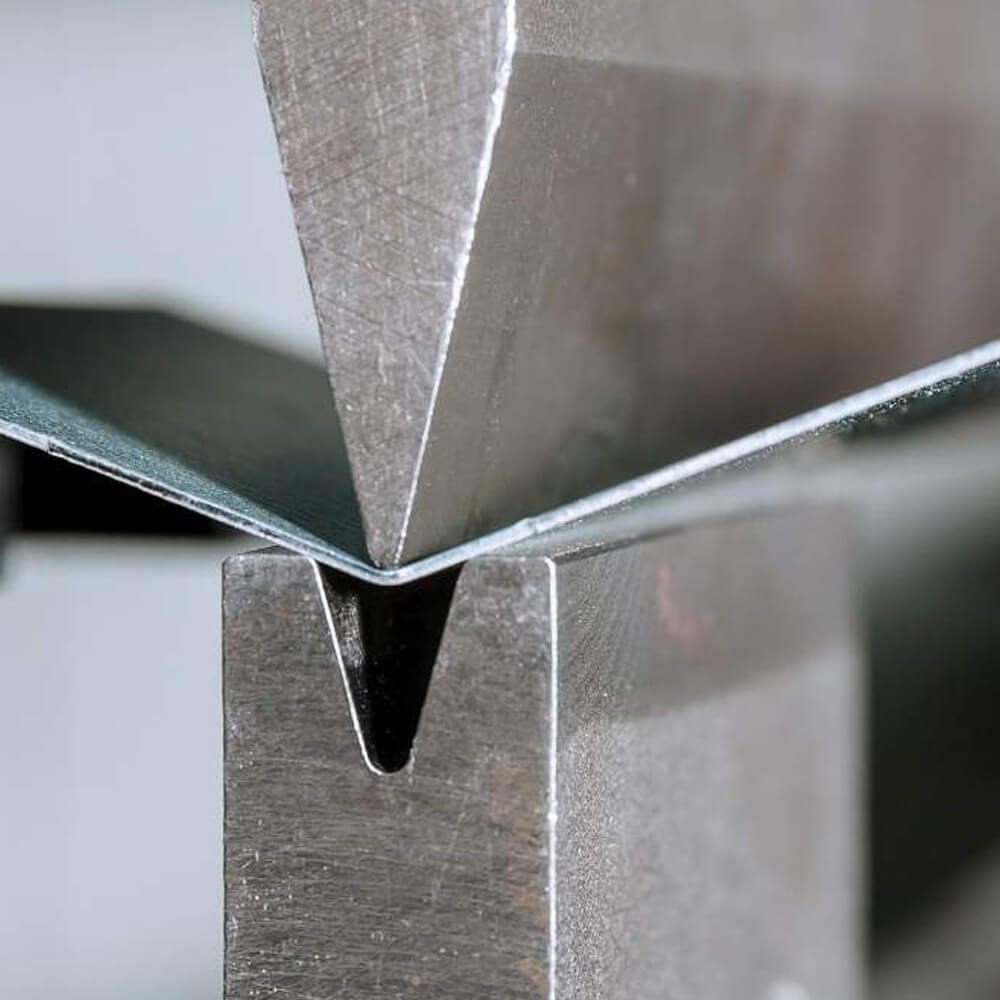

V-Bending

V-bending is a common way to bend things with a CNC machine. It bends metal at a certain angle by using a die that is formed like a V. This method works effectively with materials of different kinds and thicknesses.

Air Bending

Air bending, or partial bending, doesn’t push the material all the way into the die. The punch merely pushes it a little bit. This makes it easy to use and adaptable.

Bottoming

Bottoming bends the material until it hits the bottom of the die. It’s highly accurate and great for making exact bends.

Coining

Coining bends metal by pushing it between the punch and die with a lot of power. It’s noted for being quite accurate and is utilized for making complicated bends.

There are pros and cons to each bending method. You can pick the best way for your project if you know about V-Bending, Air Bending, Bottoming, and Coining.

| Bending Technique | Description | Advantages |

|---|---|---|

| V-Bending | Uses a V-shaped die to bend metal | Versatile, suitable for various materials and thicknesses |

| Air Bending | Punch presses material into die without fully constraining it | Flexible, simple, and adaptable |

| Bottoming | Punch presses material until it "bottoms out" in the die | High accuracy, minimal springback |

| Coining | High-force pressing between punch and die | High precision, suitable for complex bends |

How CNC Bending Machines / Press Brakes Work

Metal fabrication relies heavily on CNC bending equipment. They bend sheets of metal quickly and accurately. This makes them very important for metal work today.

Key Components

There are crucial aspects that operate together in CNC bending machines. These parts are:

- The die and punch shape the metal.

- The frame, which gives the machine strength and support.

- Back gauges help you put the metal sheet in the appropriate place.

- The press brake control, which precisely controls the bending process.

Settings and Parameters for the Machine

It is important to set the proper machine parameters for bends to be accurate. These are the settings:

- Force or tonnage is the amount of pressure needed to bend the metal.

- Bend length, which is how long the bend is along the metal sheet.

- Stroke, or how far the punch moves to bend the metal.

- Die opening: the width of the die for the metal sheet.

It’s really important to get these settings right. It makes sure the bend is right without hurting the metal or the machine.

Operation Workflow

A CNC bending machine’s operation process has a number of steps:

- Setting up: Getting the machine ready with the necessary equipment and settings.

- Programming is putting the machine’s bending sequence and settings into it.

- Sequence of bends: Following the preset bends, beginning with the most difficult ones.

Knowing about and adjusting these procedures, you may make CNC bending much more efficient and accurate.

Material Selection & Properties

It is very important to choose the correct material for CNC bending. It has an effect on how well the bending process works and how good the results are. The material you choose affects how you bend it, what tools you use, and the final qualities of the result.

Commonly Used Metals

Because they have good characteristics, many metals are widely employed in CNC bending. These are:

- Steel: Steel is a common choice for CNC bending because it is strong and can be used in many ways.

- Stainless Steel: Stainless steel is perfect for jobs that need to last because it doesn’t rust or get too hot.

- Aluminum: Aluminum is commonly utilized in the aerospace and automotive industries since it is light and doesn’t rust.

- Copper: Copper is widely used in electrical parts because it conducts electricity quite well.

How the Thickness of the Material affects the Bend Force

The thickness of the material is very important for CNC bending. It changes the amount of force needed to bend. Thicker materials need more force, which can affect the choice of tools and machines.

You need to know how the thickness of a material and the force that bends it are related. This information helps make the bending process as good as it can be and makes sure the final result is of high quality.

Grain Direction, Work Hardening, and Springback

When CNC bending, it’s crucial to know the grain direction, work hardening, and springback.

- Grain Direction: The way the material’s grains are arranged can have a big impact on how it bends. Bending the material with or against the grain can make it more likely to shatter or change shape.

- Hardening by Work: When you bend some metals, such those used in CNC bending, they became harder and less flexible. This can influence how the material behaves and how it bends.

- Springback: Springback is the way the material wants to go back to its original shape after being bent. To get the right bends, you need to know and take into consideration springback.

Design Considerations for CNC Bending

When making parts for CNC bending, there are a few important things to keep in mind. This makes sure that the bends are right and exact. To get the best outcomes from CNC bending services, you need to know about these design factors.

Rules for the Bend Radius and the Minimum Bend Radius

The bend radius is very important when bending with a CNC machine. It has a direct impact on the quality of the finished product and the bending process. The shortest bend radius that won’t hurt the material is the minimum bend radius. The minimum bend radius is usually the same as the thickness of the material, however this might change based on the type of material and the way it is bent.

For example, materials that are more ductile can bend more tightly. To keep from cracking, harder materials may need bigger radii. To make parts that can be bent easily, you need to know how the material works and how it reacts to the bending process.

Distances from Bend to Bend and from Bend to Edge/Hole

The distance between bends and the distance from a bend to the edge or a hole are very important design factors. These distances can change how accurate the part is and whether or not the bending procedure is possible. To keep the material from changing shape, it’s best to have a certain space between bends and between bends and edges or holes.

| Material Thickness | Min. Bend-to-Bend Distance | Min. Bend-to-Edge Distance |

|---|---|---|

| 1–2 mm | 3–4 mm | 2–3 mm |

| 2–4 mm | 5–6 mm | 3–4 mm |

| 4–6 mm | 7–8 mm | 4–5 mm |

Allowances, Precision, and Tolerances

Tolerances are very important for CNC bending. They set the limits on how much the bending process can change. To make parts that satisfy the required standards, accuracy is very important. When developing pieces, designers need to think about the material’s characteristics and the tolerances of the bending process.

You also need to think about springback, material variation, and other things. This makes sure that the finished product is the right size and quality.

Springback Compensation and Overbend Strategies

Springback is a common problem with CNC bending. After bending, the material tends to go back to its previous shape. Designers can utilize overbend solutions to make up for springback. To get the final shape you want, you need to bend the material more than the angle you want.

It’s really important to know how the material will spring back. For correct bending, it’s important to use the right compensating methods.

Tooling & Dies

For precise bends in CNC bending, the correct tools and dies are very important. The quality and precision of the bend depend a lot on how these parts are designed and chosen.

Different Kinds of Punches and Dies

There are a lot of different punches and dies that can be used for CNC bending. Each one is made for a distinct type of bending. A few of them are:

- Straight Punch: Works well for small bends.

- Bending Punch: For bends that are complicated and have different radii.

- Arc Punch: Makes bends that are curved.

The material, the bend radius, and the needs of the project will all affect the punch and die you choose.

Limitations on Die and Punch Design

There are some rules to follow when making punches and dies:

- Die Opening: The width of the die opening affects the bend radius. It needs to be planned out well.

- Clearance: There needs to be enough space between the punch and die to keep the material from getting damaged.

- Die Shape: The form of the die changes the shape of the bend. That needs to be taken into account when designing it.

Manufacturers may enhance their CNC bending by learning these design criteria and picking the proper tools. This makes things more accurate and efficient.

Experts say, “The right tooling is essential for high-quality bends.” Good tooling and die design are vital for successful CNC bending.

Process Layout & Best Practices

Getting the process configuration just right is critical for accurate and cost-effective CNC bending. A well-thought-out plan helps you prevent mistakes and makes sure your bends are right.

Order or Sequence of Bending

The bends’ order has a great impact on the quality of the output. Start with little bends or bends that are inside the part and work your way out. This method protects the previous bends from harm.

Bend the general shape first for the hard parts. After that, bend the details. This procedure helps form the complete thing before making small tweaks.

Using Positioning, Fixturing, and Back-gauges

To use CNC bending, the positioning and fixturing must be right. Back-gauges are vital because they help the metal find its way. This makes sure that it is in the right spot for each curve.

You can bend items very accurately with back-gauges. They let the operator alter everything as needed to reach the correct angle and location for the bend.

Minimizing Errors and Common Mistakes

Cracking, bending too much, and changing shape are all difficulties that happen a lot with CNC bending. Learning about the materials’ properties and making the process as quick as feasible might help you avoid these complications.

| Error Type | Cause | Prevention Strategy |

|---|---|---|

| Cracking | Excessive bending force or incorrect die selection | Adjust bending force, select appropriate die |

| Over-bending | Insufficient springback compensation | Adjust bend angle to compensate for springback |

| Deformation | Improper support or incorrect bending sequence | Ensure proper support, optimize bending sequence |

CNC bending operators may make their work better and more consistent by knowing what causes common mistakes and how to avoid them.

Quality Control and Inspection

For high-quality CNC-bent parts, thorough quality control and inspection are very important. It’s very important to make sure the pieces are accurate and precise. This makes sure they fulfill exact specifications and operate as needed in various areas.

Quality control in CNC bending entails making sure that products meet strict criteria. This includes checking their size, bend angle, radius, and other things.

Measuring Bend Angle, Radius, and Dimensional Accuracy

It’s really important to get the bend angle and radius just correct. This makes sure that the parts fit the design. To do this, a number of tools and procedures are employed, such as:

- Angle gauges and protractors for measuring how much something bends

- Radius gauges for checking the bend radius

- Coordinate measurement machines (CMMs) for precise size

Check visually: Cracks, Surface Finish, and Deformations

Visual inspection is also very important for quality control in CNC bending. It’s about checking parts for visible problems like cracks, a lousy surface polish, or problems with their shape. This is how experts find parts that don’t fulfill quality criteria.

Some common mistakes that are looked for are:

- Cracks or cracks in the bent part

- Problems with the surface, like scratches or markings

- Shape issues that might change how the part works

Cost, Efficiency & Sustainability Considerations

Cost-effectiveness, efficiency, and long-term viability are all important in CNC bending. These things affect every part of the production process. Manufacturers want to make their processes better in a lot of ways.

Waste of Materials and Optimization

To make CNC bending more cost-effective, it’s important to cut down on material waste. Waste may be cut down by putting pieces on sheet metal in a wise way. Advanced software helps you plan and optimize bending, which saves material without lowering quality.

A solid nesting plan can help you waste up to 20% less. This saves money and is better for the environment.

Cycle Time and Machine Use

For CNC bending to be efficient, it is important to use machines correctly and shorten cycle times. This entails making plans for production, keeping machines in good order, and employing innovative ways to bend things.

| Factor | Impact on Efficiency | Potential Improvement |

|---|---|---|

| Machine Maintenance | Reduces downtime | Regular scheduled maintenance |

| Production Scheduling | Optimizes machine utilization | Advanced planning and scheduling tools |

| Bending Sequence | Minimizes cycle time | Optimized bending sequences |

CNC Benders: Safety, Operator Training, and Maintenance

For CNC bending to be sustainable, it is important to keep people safe and machines working well. Operators can have a lot fewer accidents and be more productive if they get thorough training.

Taking care of machines on a regular basis makes them last longer and run better. This keeps you from having to pay for repairs or replacements later.

- Do frequent safety checks

- Give operators training on a regular basis

- Set up routine maintenance for CNC bending machines.

CNC bending companies can make their production more cost-effective, efficient, and long-lasting by concentrating on these areas.

Comparison: CNC Bending vs Other Fabrication Processes

CNC bending is a popular method for making metal because it is fast and accurate. You should compare it to other techniques to see how it works.

There are a lot of ways to create metal pieces, such as stamping, laser cutting, and welding. CNC bending is unusual because it can bend things into very precise forms. A professional states, “CNC bending combines precision with flexibility in a unique way.”

Bending vs. Laser Cutting and Bending, etc

There are pros and cons to both CNC bending and laser cutting, as well as bending after cutting. Laser cutting is useful for making shapes and designs that are very intricate. CNC bending is superior at turning these into three-dimensional shapes. Using both together can manufacture pieces with accurate bends that are hard to make.

- CNC bending is the best way to make bends that are exact and always the same.

- Laser cutting is the greatest way to cut geometries that are hard to cut.

- Combining the two can improve the process of making things go more smoothly.

Where Bending is Preferred and Where it Isn’t

CNC bending is suitable for projects that need accuracy and consistency, like in the automotive and aerospace industries. But it’s not good for sections that need very small bends or materials that are hard to bend without breaking.

A manufacturing expert explains, “Knowing when CNC bending is not the best is as important as knowing when it is.” This highlights how important it is to pick the correct method for each section.

| Process | Advantages | Limitations |

|---|---|---|

| CNC Bending | High precision, flexibility | Limited by material properties |

| Laser Cutting | High accuracy, complex shapes | Limited to 2D cutting |

| CNC Bending + Laser Cutting | Combines precision bending with complex cutting | Requires multiple machines, increased cost |

In short, CNC bending is an important step in making metal parts since it is accurate and quick. Manufacturers can choose the best solution for their purposes by knowing the pros and cons of laser cutting.

Final Thoughts

CNC bending is a flexible and accurate way to make things. It has a lot of uses and advantages. In this post, we’ve spoken about what it is, its benefits, the many types, and how it can be used.

This procedure is very important in modern manufacturing since it is accurate and quick. We also talked about picking materials, design, and quality control.

We offer high-quality CNC bending services in China. We use high-tech tools to give you accurate and quick bending solutions. We’re here to help with V-bending, air bending, or any other method you require.

In short, CNC bending is a useful way to make your manufacturing better. We would like you to look at our CNC bending services. Find out how we can benefit your business.

FAQs

What is CNC bending, and how does it work?

CNC bending is a method of shaping metal into exact shapes. It has machinery that are controlled by computers. These machines bend metal parts to fit a certain shape.

What are the advantages of employing CNC bending services?

CNC bending is accurate and works quickly. It can make shapes that are really complicated effortlessly. This is why it’s perfect for a lot of metal tasks.

What kinds of metals can you bend with CNC bending?

We can bend a lot of metals, such as aluminum and steel. The type of metal you choose depends on what the project needs.

How do you find out the smallest bend radius for a metal part?

We look at how thick and what kind of metal it is. We use what we know to figure out the appropriate bend radius for each job.

What are the differences between coining, air bending, bottoming, and V-bending?

These are different ways to bend things. A V-shaped die is used for V-bending. Air bending bends without hitting the ground. Bottoming bends to a certain angle. Coining employs a lot of pressure to make exact bends.

How can you make sure that CNC-bent parts are good?

We pay close attention to choosing the right materials and programs. We use tools and our eyes to check parts to make sure they satisfy standards.

Can CNC bending be used to make shapes and geometries that are hard to make?

CNC bending is helpful for making shapes that are hard to make. Our machines can make precise bends, so they may be used for a lot of different things.

What are the best ways to reduce material waste and improve CNC bending processes?

We make plans meticulously to cut down on waste. We make the process faster by using nesting and the correct tools.

What are the benefits of CNC bending over other ways to make things?

CNC bending is accurate and quick. It’s also cheaper for making complicated pieces than laser cutting and bending.

Can CNC bending be utilized for both small and big production runs?

Yes, CNC bending works for any size of run. Our machines are adaptable and can meet a variety of applications.

Bending FAQ

What is a CNC press brake?

It is a machine that uses a punch (upper tool) and a die (lower tool) to bend sheet metal. The “CNC” aspect means that the position of the material (via the backgauge) and the depth of the bend are computer-controlled for precision.

What is a "bend radius" and why is it important?

The bend radius is the inside radius of the corner. It’s critical because if the radius is too small for the material and thickness, the metal can crack on the outside of the bend. Our standard is typically 1x the material thickness.

Will the bending process leave marks on my parts?

Bending can sometimes leave faint lines or marks from contact with the die. For cosmetic parts, we can use special tooling or protective films to minimize these marks.

What are your standard tolerances for bends?

We typically hold angular tolerances of ±0.5 degrees and dimensional tolerances on flange length of ±0.2mm. Tighter tolerances are often possible.

What is "springback"?

Springback is the tendency of a metal to spring back slightly after being bent. Our modern CNC press brakes automatically calculate and compensate for springback to achieve the correct final angle.

Can you bend very thick or very thin material?

We can bend a wide range of thicknesses. Our capability depends on the material’s strength and the length of the bend. Please send us your specific requirements for a capability review.