CNC Milling: Custom CNC Milling Services in China

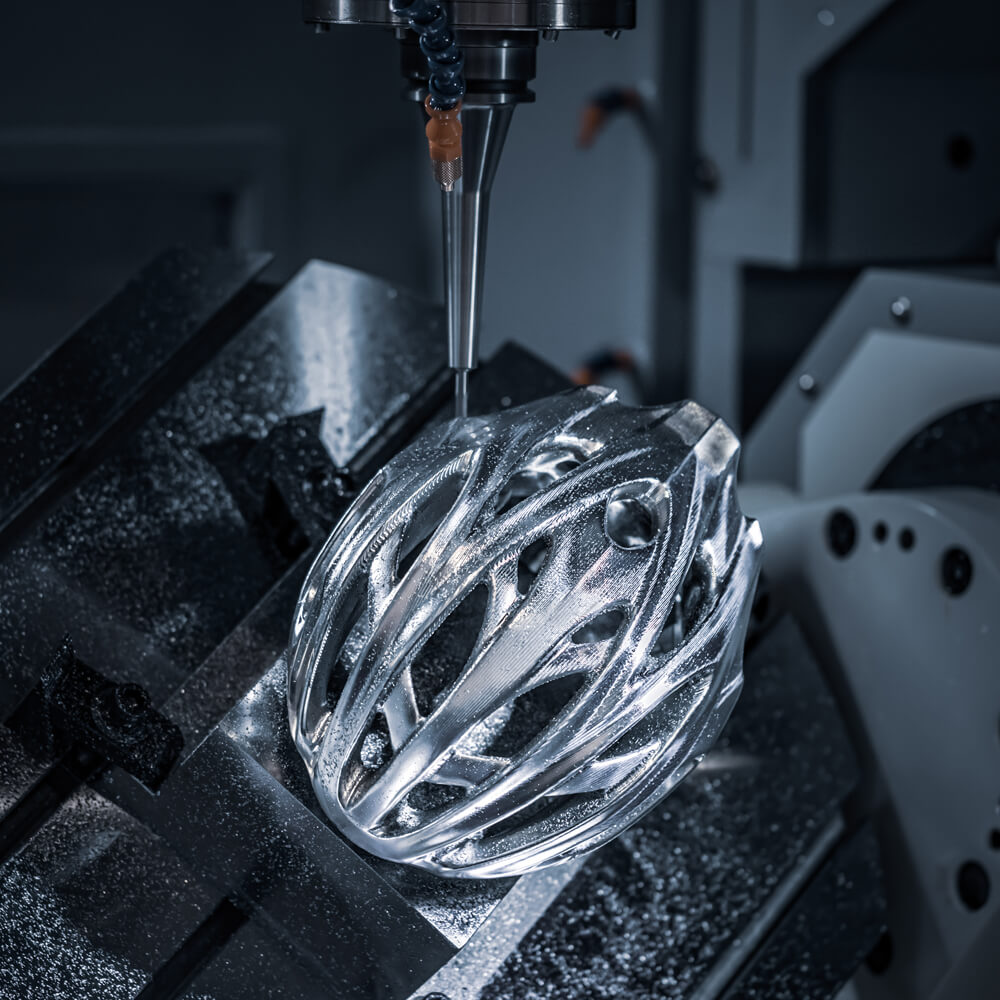

High-Precision Milling for Complex Parts, from Single Prototypes to Full-Scale Production.

- ISO 9001 Certified

- 5-Axis Capabilities

- Rapid DFM Feedback

Your Expert Partner for Precision CNC Milling

Celerity Precision is a top-notch factory in China that specializes in CNC milling with very high accuracy. This flexible subtractive manufacturing method uses spinning cutting tools to carefully remove material from a solid block. It can make things with complicated shapes, lots of details, and very tight tolerances. We use the latest CNC milling technology in our factory to make high-quality metal and plastic parts with perfect accuracy and smooth surfaces. We can make parts from your most complicated designs, like basic brackets and complicated housings and molds.

Our Core CNC Milling Services

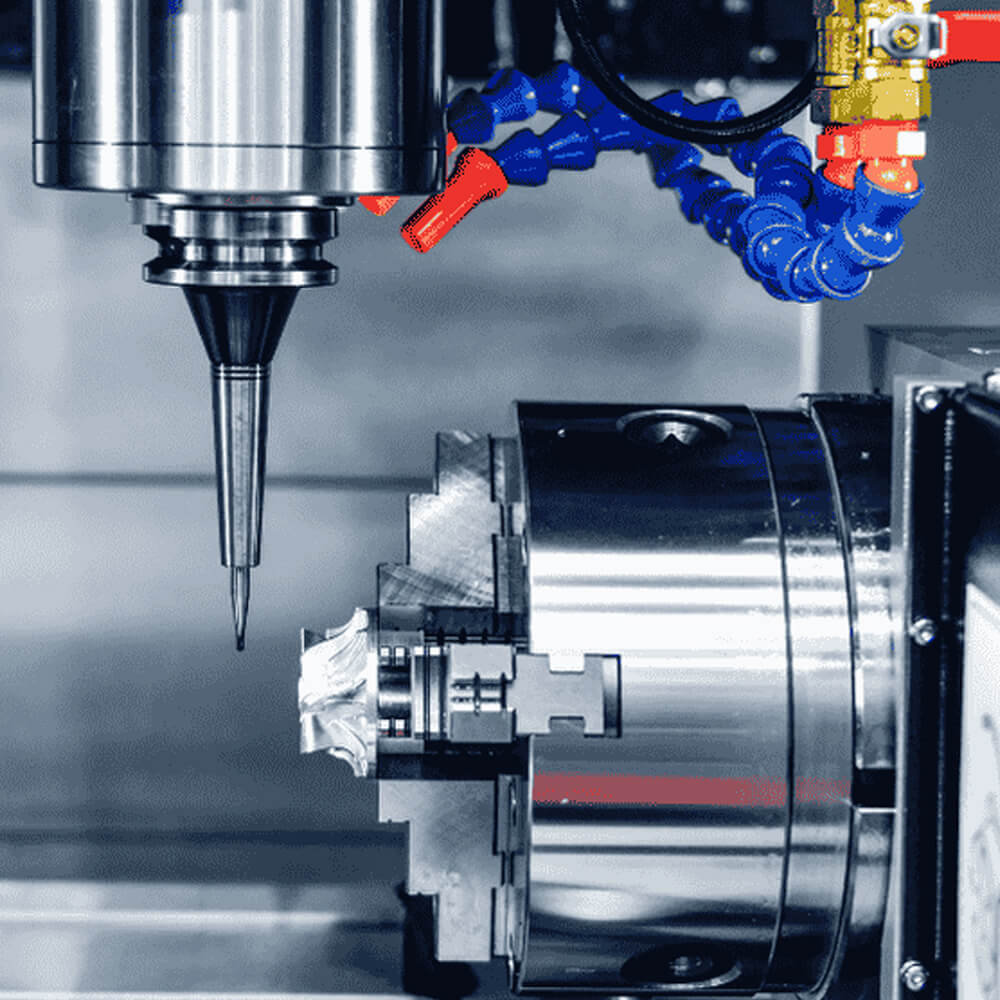

We can do a lot of different CNC milling jobs because we have bought the best tools. We pick the best and most accurate way to make your parts so that every project is of the best quality and the best value for money.

3-Axis Milling

The basic idea behind CNC milling, which is great for making things with 2.5D shapes like profiles, pockets, slots, and drilled holes. You can make a lot of different parts quickly and cheaply with our 3-axis machines.

4-Axis Milling

By adding a rotational axis (the A-axis), our 4-axis milling centers can make features on many sides of a workpiece in one setup. This makes it easier to work with, more accurate, and works well for parts with side features or cylindrical sections.

5-Axis Milling

When it comes to CNC milling, our 5-axis machines are the best. They can move the tool and/or the workpiece in five different directions at the same time. This lets you make very complex, organic shapes, compound curves, and undercuts all in one continuous toolpath. This makes the hardest projects more accurate and gives them a better surface polish.

CNC Milling Materials

Metal

Aluminum is strong, light metal that can be used for many things and doesn’t rust easily.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

Copper

Copper has great electrical and thermal conductivity, which makes it the best choice for heat sinks and electrical parts.

- Available Grades: C101 (OFHC), C110 (ETP)

- Common Finishes: As Machined, Electropolishing, Plating, Clear Coat

Brass

Brass is great for making fittings and decorative elements since it is easy to work with and looks like gold.

- Available Grades: C360

- Common Finishes: As Machined, Polishing, Plating, Brushing

Bronze

Bronze is durable and has minimal friction, it is widely used for naval hardware, bushings, and bearings.

- Available Grades: C932, C954

- Common Finishes: As Machined, Tumbling

Steel

Steel is a robust, long-lasting, and cheap material that works well in high-stress and industrial settings.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Stainless Steel

Stainless steel is very strong and doesn’t rust easily, so it’s great for use in food, medical, and maritime settings.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Magnesium

Magnesium is a very light metal that is great for uses where every gram matters.

- Available Grades: AZ31, AZ91

- Common Finishes: Chromate Conversion Coating

Titanium

Titanium is a high-performance metal that is quite strong for its weight and is also very biocompatible.

- Available Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Common Finishes: As Machined, Anodizing (for color), Sand Blasting

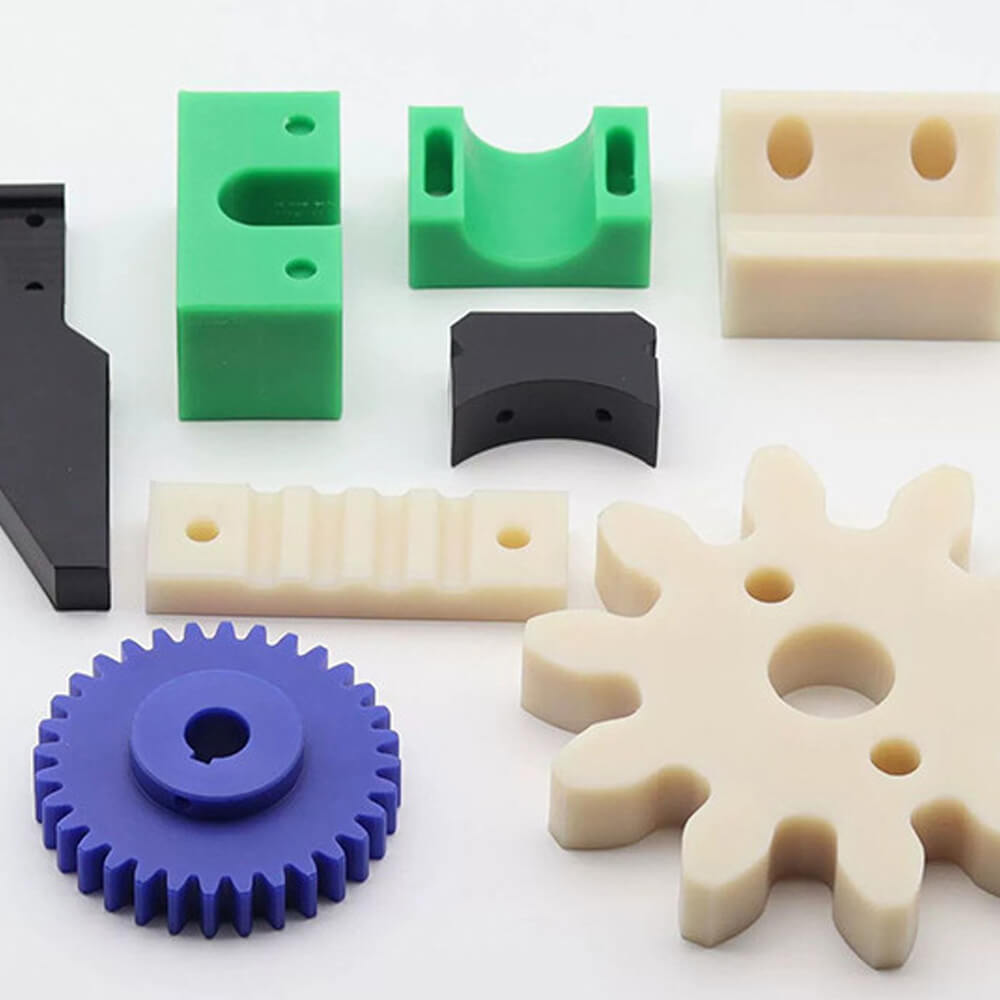

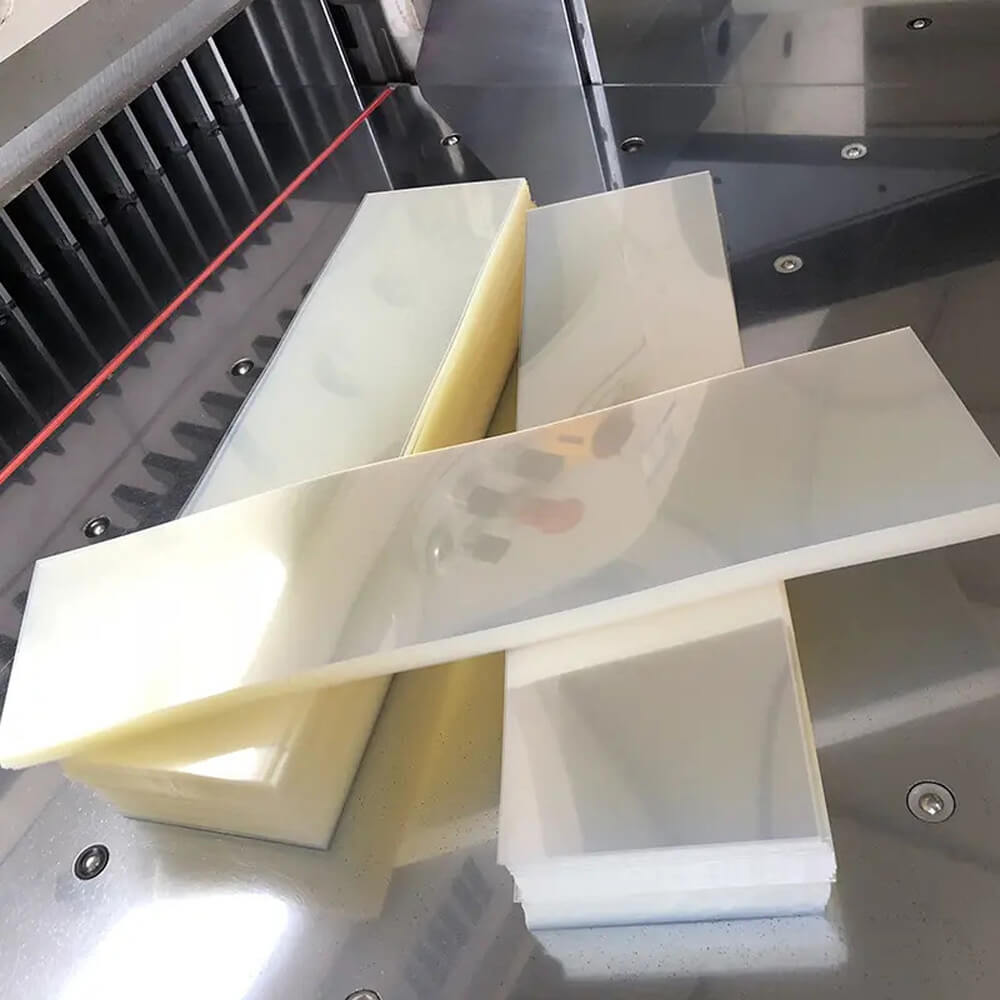

Plastic

ABS

ABS is a strong, impact-resistant, and cost-effective thermoplastic that works well for housings, enclosures, and prototypes.

Common Finishes: As Machined, Sand Blasting, Painting

PC (Polycarbonate)

PC is a sturdy, clear material that can handle heat and impact very well.

- Common Finishes: As Machined, Vapor Polishing, Painting

PLA

PLA is a thermoplastic that breaks down naturally and comes from renewable resources. It is often used for quick prototyping.

Common Finishes: As Machined, Painting

PMMA (Acrylic)

PMMA is a clear, hard plastic with great optical clarity. It is widely used as a light-weight substitute to glass.

Common Finishes: As Machined, Vapor Polishing, Flame Polishing

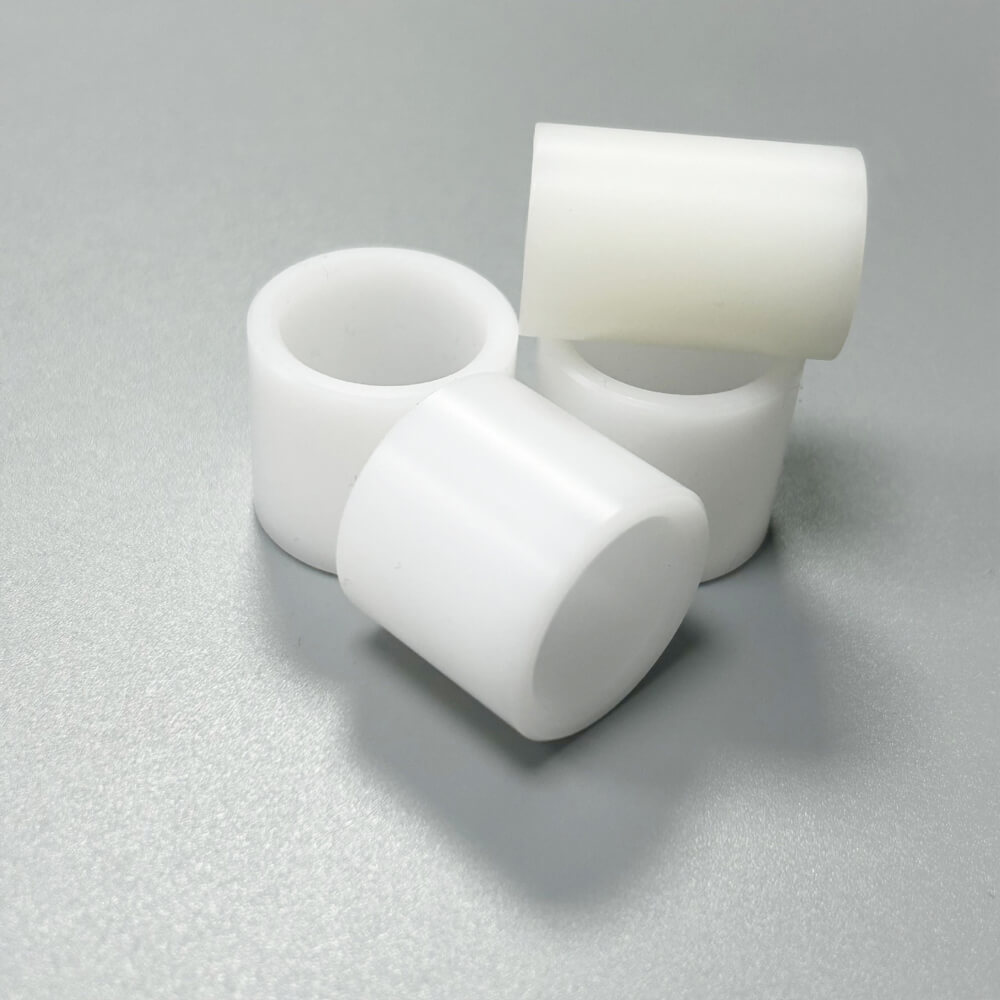

POM (Delrin/Acetal)

POM is an engineering plastic that is low-friction and high-stiffness, making it great for gears and bearings.

Common Finishes: As Machined

PA (Nylon)

PA is a strong and flexible plastic that can stand up to chemicals and wear.

- Available Grades: PA6, PA66

- Common Finishes: As Machined

PE (Polyethylene)

PE is a typical type of plastic that can withstand chemicals and comes in varying densities for different uses.

Common Finishes: As Machined

PEEK

PEEK is a high-performance polymer that is very strong, resistant to chemicals, and stable at high temperatures.

Common Finishes: As Machined

PP (Polypropylene)

PP is a light plastic that is very elastic and resistant to chemicals. It is widely used for living hinges.

Common Finishes: As Machined

HIPS

HIPS is a cheap, stiff plastic that is easy to work with and is typically used to make prototypes before production.

Common Finishes: As Machined, Painting

PBT

PBT is a type of engineering thermoplastic that is stiff, stable in size, and can handle chemicals and heat.

Common Finishes: As Machined

PPA

PPA is a high-performance polyamide that is stronger, stiffer, and more heat-resistant than regular nylon.

Common Finishes: As Machined

PAI (Torlon)

PAI is high-performance plastic that is exceedingly strong and rigid and keeps its qualities even at very high temperatures.

Common Finishes: As Machined

PET

PET is a tough, rigid plastic used in engineering that resists chemicals well and wears well.

Common Finishes: As Machined

PPS

PPS is a high-performance thermoplastic that can withstand chemicals and high temperatures without changing shape.

Common Finishes: As Machined

PS (Polystyrene)

PS is a clear, rigid, and brittle plastic that doesn’t cost much and is typically used for prototypes.

Common Finishes: As Machined, Painting

PVC

PVC is a strong, long-lasting, and cheap plastic that doesn’t easily get damaged by chemicals or water.

Common Finishes: As Machined

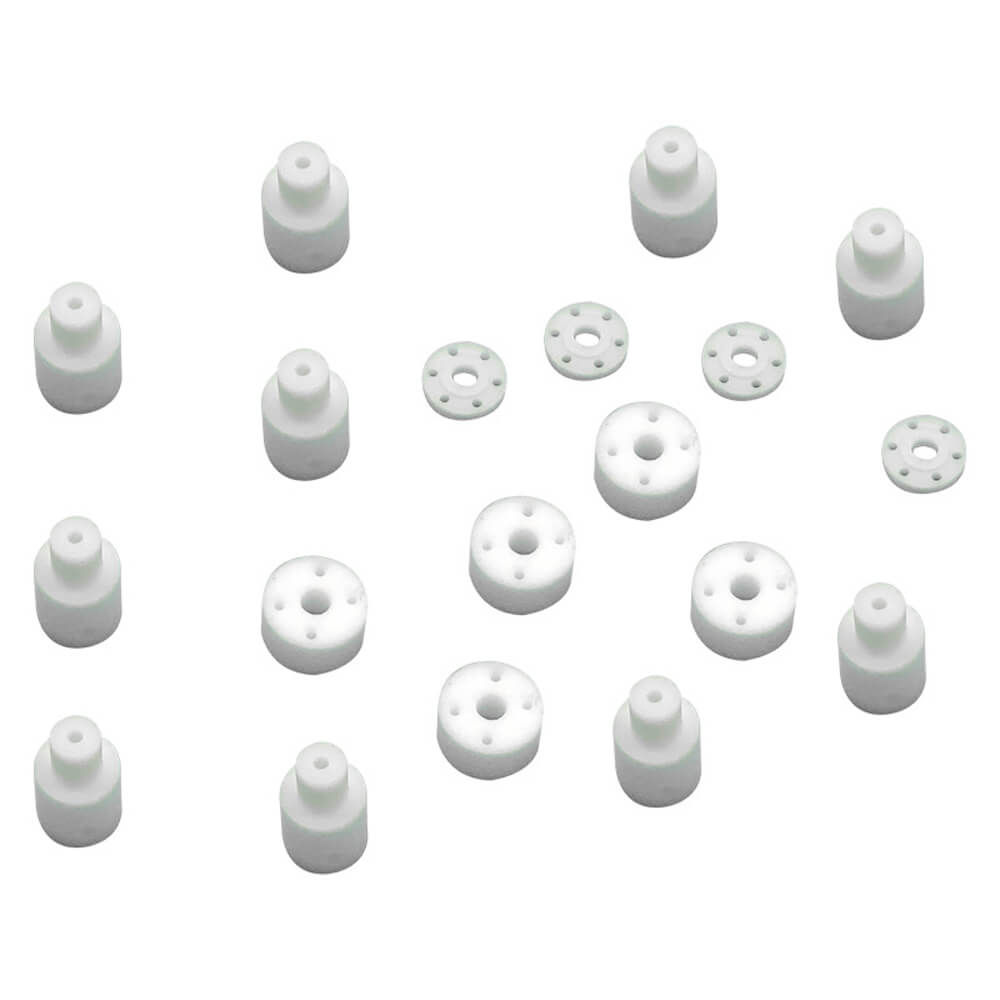

PTFE (Teflon™)

PTEE is known for having a very low coefficient of friction, being chemically inert, and being able to handle high temperatures.

Common Finishes: As Machined

Bakelite

Bakelite is a thermoset plastic that is hard, thick, and resistant to heat. It also has good electrical insulating qualities.

Common Finishes: As Machined

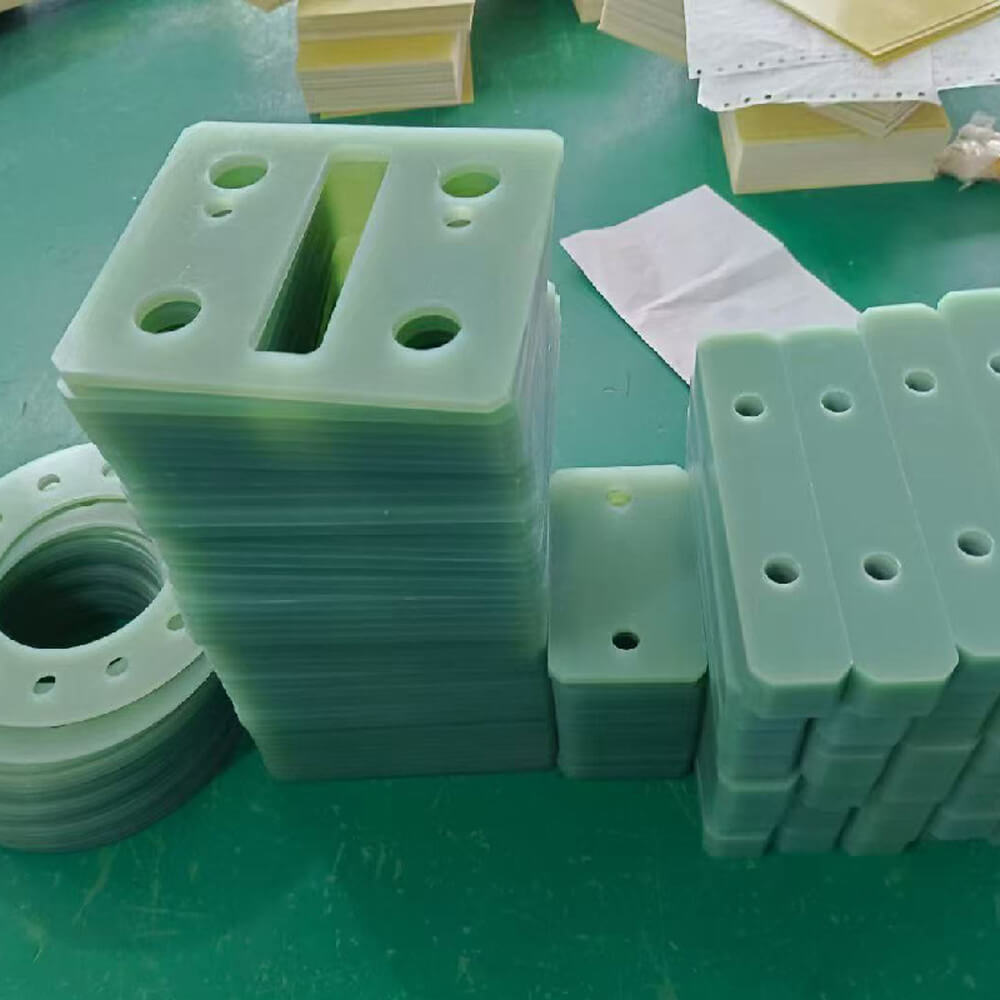

FR-4

FR-4 is a glass-reinforced epoxy laminate that is very strong and has great electrical insulation qualities.

Common Finishes: As Machined

CNC Surface Finish Enhance and Protect Your Parts

As Machined

The basic finish, which is the cheapest and most common, has obvious tool marks right from the machine.

Sand Blasting

Makes a smooth, non-reflective matte surface that looks good and helps paint stick better.

Tumbling

A mass-finishing method that quickly removes burrs and smooths off groups of parts.

Electropolishing

Makes metals like stainless steel have a finish that is super smooth, bright, and clean down to the smallest details.

Heat Treatment

A thermal procedure that changes mechanical qualities like strength and hardness (not only for looks).

Alodine

A chemical coating for aluminum that protects it from rust while yet letting electricity flow through it.

Anodizing

Makes a colored surface on metal and titanium that is sturdy, long-lasting, and attractive.

Teflon™ Coating

A fluoropolymer coating that doesn't stick and has low friction. It also resists chemicals very well.

Black Oxide

A conversion coating for steel that gives it a deep black finish without changing its size.

Electroless Plating

A uniform chemical plating procedure (like nickel) that makes all surfaces very hard and resistant to rust.

Electroplating

An electrochemical procedure that puts down a metal layer (such zinc, nickel, or chrome) for decorative or protective purposes.

Painting

A liquid coating that may be sprayed on and comes in a wide range of colors for a decorative and protective finish.

Passivation

A chemical cleaning method that makes stainless steel as resistant to corrosion as possible.

Powder Coating

An electrostatically applied powder dried to provide a finish that is stronger than regular paint.

Electrophoresis

An E-coat procedure that dips items in a coating to cover them completely and evenly.

Brushed Finish

A high-end, refined style with a unidirectional satin grain finish.

Our advanced milling centers are ready for your project.

Why Choose Celerity Precision

Multi-Axis Expertise

Because we have invested in advanced 3, 4, and 5-axis CNC milling technology, we can make very complicated parts in one setup. This means shorter lead times and more accurate results.

Uncompromising Quality Control

We are an ISO 9001-certified manufacturer, so we do strict CMM checks during the process and at the end to make sure that every machined item meets your exact specifications and tolerances.

Engineering and DFM Support

We give you expert Design for Manufacturability (DFM) advice with every quote to help you make your part's design as cheap and mistake-free as possible.

Broad Material and Finishing Capabilities

We have a huge selection of metals and plastics, and we can do all the finishing work you need to turn your part from raw material to finished product.

Rapid & Reliable Delivery

We always deliver your precision-milled parts on time because of our streamlined process, which includes 24-hour pricing and smart scheduling of manufacturing.

Prototype to Production Flexibility

No matter how many parts you need or how complicated the prototype is, we can handle it all with the same level of accuracy and care.

From Digital File to Milled Part in 4 Simple Steps

Submit Design & Get Quote

Upload your CAD file safely. Within 24 hours, our staff will give you a complete quotation and DFM feedback.

DFM Review & Order Confirmation

We assist you make your design as good as it can be. We set up production as soon as you approve the quote.

Precision Milling

Our trained specialists use the best machine (3, 4, or 5-axis) to grind your parts perfectly.

Inspection & Global Delivery

Before being safely packaged and sent to you, we carefully check each part using our CMM and other instruments.

How We've Helped Our Clients Succeed

Challenge

A client in the aerospace business needed a complicated monolithic housing made of 7075 aluminum with deep pockets and thin walls.

Solution & Result

We were able to process the whole part in one setup using our 5-axis milling method. This got rid of the tolerance stack-up and gave us a part that was lighter and stronger ahead of schedule.

Challenge

A robotics company needed a set of custom actuator mounts made of 6061 aluminum with holes and side features that were just right for them.

Solution & Result

Our 4-axis milling centers let us process all of the features without having to fix them again. This made sure that everything was perfectly lined up and that we could make 500 identical parts over and over again.

Challenge

A medical device designer asked for a model of a handheld surgical tool made of PEEK that had a curved, comfortable surface.

Solution & Result

We used 5-axis milling at the same time to make the smooth, organic shape. The end result was a prototype that was completely biocompatible and worked, and it fit the designer's ergonomic vision perfectly.

Custom CNC Milling Services - Celerity Precision

“The way to get started is to quit talking and begin doing.”. Walt Disney’s statement is quite true when it comes to building things. CNC milling is the most important part of modern making. It affects the way we produce parts with shapes that are hard to work with.

In China, Celerity Precision offer CNC milling services that are made to order. We use cutting-edge tools to create pieces out of aluminum, copper, and plastic. We can do milling, rotating, and more on 3, 4, and 5 axes. This helps us meet the high standards of a lot of fields, including aerospace, automotive, and consumer electronics.

We can create items with tolerances of 0.05 mm or less. We can start working on your order in three business days. Our main goals are to keep pricing reasonable, make customers happy, and deliver on schedule.

Important Points

- Custom CNC milling services that can do 3-, 4-, and full 5-axis milling.

- Precision machining of a wide range of materials, such as aluminum, copper, and plastic.

- Lead times start at three business days, and tolerances can be as low as 0.05 mm.

- Working with industries like aerospace, automotive, and consumer electronics.

- Make sure your customers are happy, deliver on schedule, and charge a fair price.

Introduction to CNC Milling

Many ways of making things use CNC milling as their main technology. It shapes materials with machines that are controlled by computers. This method is accurate and flexible, which changes how we produce parts and pieces.

What is CNC Milling?

CNC milling uses spinning tools to cut away material from a workpiece. It makes shapes and patterns that are hard to understand. This procedure is very important for producing custom pieces that fit perfectly.

“CNC milling” is the process of using computers to control milling machines. These robots can execute a lot of different things, from simple cuts to complicated chores, all by following the instructions that have been programmed into them.

The Past and Present of Milling Machines

In the early 1800s, milling machines were first made. Over time, they’ve gotten a lot better. First, they were manual, which meant that only skilled persons could use them. CNC technology revolutionized everything; it made milling automatic and more accurate.

There are now many types of milling machines, such as horizontal and vertical ones. They are made to do certain things. The newest multi-axis machines can create parts that are even more complicated.

What makes milling different from other CNC processes?

CNC milling is special because it can make shapes that are hard to make. When you turn anything, you rotate the workpiece to make portions that are symmetrical and circular. Milling, on the other hand, employs tools to take away material, which gives you additional shape options.

- Milling is great for making unique parts and complicated shapes.

- Turning is best for making items that are symmetrical and spherical.

- Routing is a common way to cut and shape materials, especially in woodworking and sign making.

If you know these differences, you can choose the proper CNC technique for a job. It makes sure that items are created to the proper standards and quality.

How CNC Milling Works — Process Workflow

There are several steps to CNC milling, and it is a complicated procedure. It starts with designing and concludes with the finished product on the CNC milling machine. Every stage is important for creating parts that are of good quality.

Design Phase: CAD and Design for Manufacturability (DFM)

During the design phase, CAD software is used to make a digital model. This makes sure that the part can be created quickly. DFM, or Design for Manufacturability, makes ensuring that the design works with the manufacturing process.

CAM and Generating Toolpaths / G-Code

After the design is done, CAM software makes the G-code and toolpaths. This stage transforms the design into directions for the CNC milling machine. It directs the machine exactly how to grind the part.

Machine Setup: Workholding, Fixtures, Tool Selection, Axis Orientation

Setting up the machine is very important for CNC milling to work. It means picking the suitable tools, workholding, and fixtures. You also need to make sure that the axis is set up appropriately. Each part makes sure that the part is created correctly and with care.

Execution: Roughing vs Finishing, Feed / Speed / Spindle Operation

During the execution step, the CNC milling machine does the milling. There are two steps: roughing and finishing. Roughing takes away most of the material, while finishing makes the portion exact and smooth. For the best results, the feed rate, speed, and spindle operation are all controlled.

Knowing how each step of CNC milling works and how to make it better helps create parts quickly and precisely. CNC milling machines are necessary for producing parts, no matter how basic or complicated they are. No other current manufacturing tool can equal their accuracy and flexibility.

Learn more about how CNC milling works.

Types of CNC Milling Machines & Variants

There are many different types of CNC milling machines, and each one has its unique strengths. They help us produce parts that are very precise and accurate. This works for a lot of different projects and industries.

Milling Machines: Vertical vs. Horizontal

Depending on where the spindle is, CNC milling machines are mostly vertical or horizontal. Face milling and drilling are two things that vertical milling machines are fantastic for. Their spindle goes straight up and is parallel to the worktable.

For getting rid of a lot of material, horizontal milling machines work well. Their spindle is straight down and parallel to the worktable.

It depends on the project’s needs whether to use vertical or horizontal equipment. This includes the kind of material and the finish that is desired.

Fixed, universal, or multi-axis milling machines

There are different numbers of axes on CNC milling machines. In the X, Y, and Z directions, 3-axis milling machines move. Milling machines with four or five axes have additional axes that can turn. This allows them deal with complicated shapes and cuts down on the number of setups they need.

Multi-axis machines are very important for creating pieces with a lot of intricacy. They are often utilized in cars and planes.

Milling Machines for Specific Tasks

There are additional milling machines that are made for certain jobs. Plunge milling machines are quick at taking away material. Universal mills can do a lot of different milling activities.

These machines are useful in a variety of fields. They make specialized solutions for hard jobs.

Review all our manufacturing capabilities like CNC machining, CNC milling, CNC turning, laser cutting, bending, welding, sheet metal fabrication, die casting and precision casting.

CNC Milling Operations & Techniques

To make CNC Machining better, you need to know how milling works and what tools to use. Milling processes can do a lot of various things to match varied shapes and needs of workpieces.

Different Kinds of Milling Work

There are different types of milling procedures, such as face milling, plain milling, angular milling, and form milling. An end mill or face mill is typically used to make flat surfaces while face milling. Using a slab mill or plain milling cutter, plain milling makes flat surfaces that are parallel to the mill’s axis.

Form milling and angular milling can help you make shapes and profiles that are hard to make. When you do angular milling, you cut at an angle to the surface of the workpiece. To make certain forms or profiles, form milling requires a particular milling cutter.

Roughing and Finishing Passes

In milling, roughing and finishing passes are quite important. Roughing passes swiftly get rid of a lot of material by employing large end mill bits or milling bits at high feed rates. Finishing passes use smaller tools and slower feed rates to get the best surface polish and precision.

Climb vs. Regular Milling

The type of milling you choose depends on the material of the workpiece and the finish you want. Climb milling, where the cutter moves with the feed, makes the tool last longer and makes the finish better. When the cutter is against the feed, it’s called conventional milling. This is utilized for hard surfaces or specialized finishes.

Deep Cavities, Undercuts, and Complicated Shapes

To mill complicated structures like deep cavities and undercuts, you need particular tools and methods. Extended-reach end mills or specific milling cutters can get into deep holes. You could need multi-axis milling or specific tools to make undercuts and intricate profiles.

Learn about the analysis of CNC milling process.

Materials & Tooling of CNC Milling

CNC milling can work with a lot of different materials, but you need to know a lot about both the materials and the tools. We work with metals like aluminum and steel, as well as polymers and composites. Each one has its own unique features and applications.

CNC Milling Materials

People typically mill metals because they are robust and may be used in many ways. Aluminum is light and doesn’t rust. Steel is strong and hard. We mill plastics and composites because they are light and have special qualities.

Types of Tools

Picking the appropriate tool is just as crucial as picking the right material. End mills are useful for a multitude of things, such as facing and slotting. Face mills work best on level surfaces. Ball nose mills and thread mills can work with complicated forms and threading.

Materials and Coatings for Tools

The material and coating of the tool have a big impact on how long it lasts and how well it works. Some tools are made of high-speed steel (HSS), carbide, or diamond-coated steel. Coatings like TiN and TiAlN help by lowering friction and guarding against wear and corrosion.

Tool Life, Wear, and Maintenance

To keep your tools in good repair and know how to avoid wear on them is important for quality and fewer downtime. The life of a tool relies on the material, coating, cutting parameters, and the material being milled. It’s important to examine and maintain things on a regular basis, like replacing or sharpening tools. We also make tools last longer by changing the cutting parameters and adding coolants.

Design Considerations & Limitations of CNC Milling

To design for CNC milling, you need to know what it can and can’t do. We need to consider about a lot of factors when we use CNC milling to make parts. This makes sure that we can make our parts well and for a fair price.

Surface Finish and Tolerances

In CNC milling, tolerances and surface smoothness are very important. You might need to take extra steps or use special equipment if the tolerances are really tight. This could make things take longer and cost more. We need to strike a balance between accuracy and affordability.

| Tolerance Type | Description | Typical Application |

|---|---|---|

| Dimensional Tolerance | Specifies the acceptable deviation in size | Parts requiring precise fit |

| Geometric Tolerance | Defines the allowable variation in shape | Aerospace and automotive components |

| Surface Finishes | Describes the surface texture or roughness | Parts requiring smooth finish, e.g., consumer products |

Geometric Limitations

It can be harder to do CNC milling on parts with undercuts, thin walls, and deep voids. For example, undercuts could demand unique equipment or ways to do them. We need to design these elements very carefully to determine the best technique to produce them.

Factors that Affect Cost

Good design means knowing how much CNC milling will cost. Costs like setup, cycle time, and wastage of materials mount up. We can save money without compromising quality by reducing back on these things.

- Setup costs: The expense of getting the machine ready to make something.

- Cycle time: The amount of time it takes to finish one machining cycle.

- Material waste is the amount of material that is thrown away during machining.

Limitations and Alternatives

CNC milling is fantastic for a lot of things, but it’s not ideal. For shapes or materials that are hard to work with, 3D printing or laser cutting might be better. When we design parts that are hard to CNC mill, we should consider about these choices.

To sum up, you need to know a lot about CNC milling’s pros and cons before you can design for it. We can build designs that are both efficient and cheap by looking at tolerances, forms, costs, and other possibilities.

Learn more about design

People utilize CNC milling for a lot of things, like art and aerospace. It shows how accurate and dependable this method is. It can work with a lot of different things.

Uses in Industry

CNC milling is very important in the sectors of aerospace, automotive, and medicine. In the aerospace industry, it creates complicated parts with great accuracy. The automobile industry utilizes it to make engine parts and parts for custom cars.

It helps make personalized surgical equipment and implants in medicine. This indicates that it can be used in many ways.

| Industry | Common Applications | Benefits |

|---|---|---|

| Aerospace | Engine components, aircraft parts | High precision, complex geometries |

| Automotive | Engine parts, custom car components | Precision, material versatility |

| Medical | Custom implants, surgical instruments | High accuracy, biocompatibility |

Making Prototypes, Custom Parts, and Batch Production

CNC milling is an excellent way to make prototypes and custom products. It’s quick and precise, making it great for early concepts. It makes sure that every part is the same when you make a lot of them.

Non-business, Hobby, or Artistic Uses

You can also use CNC milling for tasks that aren’t industrial or creative. People who like to do things like make detailed designs and sculptures utilize it. It’s perfect for creative work because it’s precise and flexible.

In short, CNC milling is used for a lot of things, from creating parts to making art. It’s a must-have for making complicated and personalized things because it’s accurate, flexible, and dependable.

Advantages & Challenges of CNC Milling

Modern manufacturing relies heavily on CNC milling. It is quite accurate, flexible, and may be used again and over again. These characteristics make it necessary for a lot of production needs.

Main Advantages

CNC milling is very precise, which means it can make parts with elaborate designs and shapes that are hard to make by hand. High accuracy is very important in industries like medical and aerospace. Even little mistakes can be very important.

CNC milling may also work with metals, polymers, and composites. Different endmills are used for different jobs and materials.

| Benefit | Description | Industry Impact |

|---|---|---|

| Precision | Ability to create detailed and complex parts | Aerospace, Medical |

| Versatility | Works with many materials | Automotive, Consumer Products |

| Repeatability | Consistent production of parts | Industrial Manufacturing, Prototyping |

Common Problems

There are a number of problems with CNC milling. Setting it up is one big problem. Setting it up and picking the correct tools requires professional workers.

Waste of materials is another problem. It happens when the wrong tools are used or the machining settings are not right. To save money and work more efficiently, you need to cut down on waste.

Making complicated pieces is also very expensive. Costs can go up if you need special tools and have to do a lot of tasks.

Being aware of these problems can help you get better at CNC milling. Manufacturers can save money and work more efficiently by dealing with the problems of complicated setups, wasted materials, and the high cost of complicated parts.

Future Trends & Developments of CNC Milling

A huge change is about to happen in CNC milling. This transformation is due to modern multi-axis and high-speed milling, greater automation, and AI and simulation technology. These improvements will make CNC milling more accurate, faster, and useful in more ways.

Advanced High-Speed and Multi-Axis Milling

In CNC milling, advanced multi-axis and high-speed milling are very popular. They allow us construct complicated forms with more accuracy and speed. For instance, 5-axis milling can manufacture detailed pieces all at once, which means you don’t require as many fixtures.

High-speed milling speeds up the milling process without sacrificing accuracy. Advanced CAM software and new spindle technology make this possible.

| Technology | Benefits | Applications |

|---|---|---|

| Multi-Axis Milling | Complex geometries, reduced setup times | Aerospace, automotive, medical devices |

| High-Speed Milling | Increased productivity, improved surface finish | Mold and die making, aerospace components |

Automation, AI, Simulation, Digital Twin in Milling

CNC milling is changing because of automation, AI, simulation, and digital twin tech. They let you keep an eye on things in real time, guess when maintenance will be needed, and plan operations more effectively.

“The integration of digital twin technology allows for the virtual replication of CNC milling processes, enabling the prediction of possible issues and the optimization of machining parameters before actual production begins.”

AI can look at data from CNC machines to guess how much wear and tear tools will get and recommend ways to make them better. Simulation software evaluates to see if parts can be manufactured and finds the best toolpaths, which cuts down on mistakes and waste.

New Materials, Tool Coatings, and Sustainable Milling Practices

CNC milling is all about sustainability these days. We’re trying to use less energy, make less trash, and use products that are good for the environment. New materials and tool coatings are being produced that last longer, make finishes better, and work with challenging materials.

- To protect the environment, people are using green cutting fluids and MQL systems.

- Nanocomposite coatings and other advanced tool coatings make tools live longer and operate better.

- Advanced CNC milling is being used to machine new materials such strong metals and composites.

These trends and improvements are very important as we push the limits of CNC milling. They will change how things are made in the future. We can make our production more efficient, accurate, and creative by using new technology and environmentally responsible methods.

Final Thoughts

CNC milling is important for creating complicated parts for a lot of different areas, including medicine, autos, and aerospace. People recognize it for being accurate, flexible, and able to do the same thing over and over. This makes it very important in today’s production world.

CNC milling is very important for making high-quality, exact parts. CNC milling will grow even better when technology improves, especially with automation and multi-axis milling. This will help it satisfy the rising demand for parts that are exact.

We think that CNC milling is a big part of making things more efficient and new. CNC milling will become more important as the necessity for precision parts grows. It will change the way sectors that need precise engineering work in the future.

CNC Milling FAQs

What does CNC milling mean?

CNC milling is a very exact approach to create things. It has machinery that are controlled by computers. These machines use spinning tools to take away material.

What kinds of CNC milling machines are there?

There are a lot of CNC milling machines. They come in three types: vertical, horizontal, and 3-axis. There are other machines with four or five axes. Plus, there are machines that are made just for certain jobs.

What kinds of materials can you use CNC milling on?

CNC milling can work with a lot of different materials. This covers metals, polymers, and things made of both.

What is the difference between roughing and finishing passes in CNC milling?

Roughing takes away a lot of stuff. Finishing makes the surface smooth and straight.

What are the benefits of using CNC milling?

CNC milling is accurate and can do many things. It can create shapes that are hard to construct. It also makes sure that the parts are always the same.

What are the problems that come with CNC milling?

CNC milling can be hard. It could waste material and cost more for items that are hard to make.

How can I make parts for CNC milling?

Keep CNC milling in mind when you design parts. Think about how much they will cost and how they will be created. Think about tolerances and how the surface looks.

What can you do with CNC milling?

Many fields employ CNC milling. This encompasses the medical, automotive, and aerospace fields. It is also used to make prototypes and custom parts.

What does tooling do in CNC milling?

When CNC milling, it’s very important to choose the correct tools. There are a lot of different kinds of mills and cutters. To make sure quality, it’s necessary to keep instruments in good shape.

What will CNC milling look like in the future?

CNC milling is getting better and better. There will be more machines with more than one axis and faster speeds. There are also plans for automation, AI, and simulation. Sustainable milling is also.

CNC Milling Resources

FAQs

What is the difference between CNC milling and CNC turning?

In milling, a rotating tool removes material from a stationary workpiece, ideal for creating flat surfaces, pockets, and complex shapes. In turning, the workpiece rotates while a stationary tool removes material, ideal for creating cylindrical parts.

What is 5-axis CNC milling, and why is it better?

5-axis milling allows the cutting tool to approach the workpiece from five different directions simultaneously. It is better for creating highly complex, curved surfaces and undercuts in a single setup, which improves accuracy and efficiency.

What is the maximum part size you can mill?

Our milling capabilities can accommodate parts up to [Insert Max X Dimension, e.g., 1200mm] x [Y Dimension] x [Z Dimension]. Please contact us for specific inquiries about large parts.

Can you mill hardened steel?

Yes, we offer hard milling services. This process uses specialized cutters and techniques to machine materials that have already been heat-treated, allowing for very high-precision finished parts.

What tolerances can you achieve with CNC milling?

We can consistently achieve tolerances of ±0.025mm (±0.001″). For critical features, tighter tolerances down to ±0.005mm (±0.0002″) are possible depending on the geometry and material.

How do you ensure a good surface finish on milled parts?

We achieve superior surface finishes by using high-quality cutting tools, optimized feed rates and spindle speeds, and advanced toolpath strategies (like scallop or high-speed finishing passes).