Custom Laser Cutting Services in China

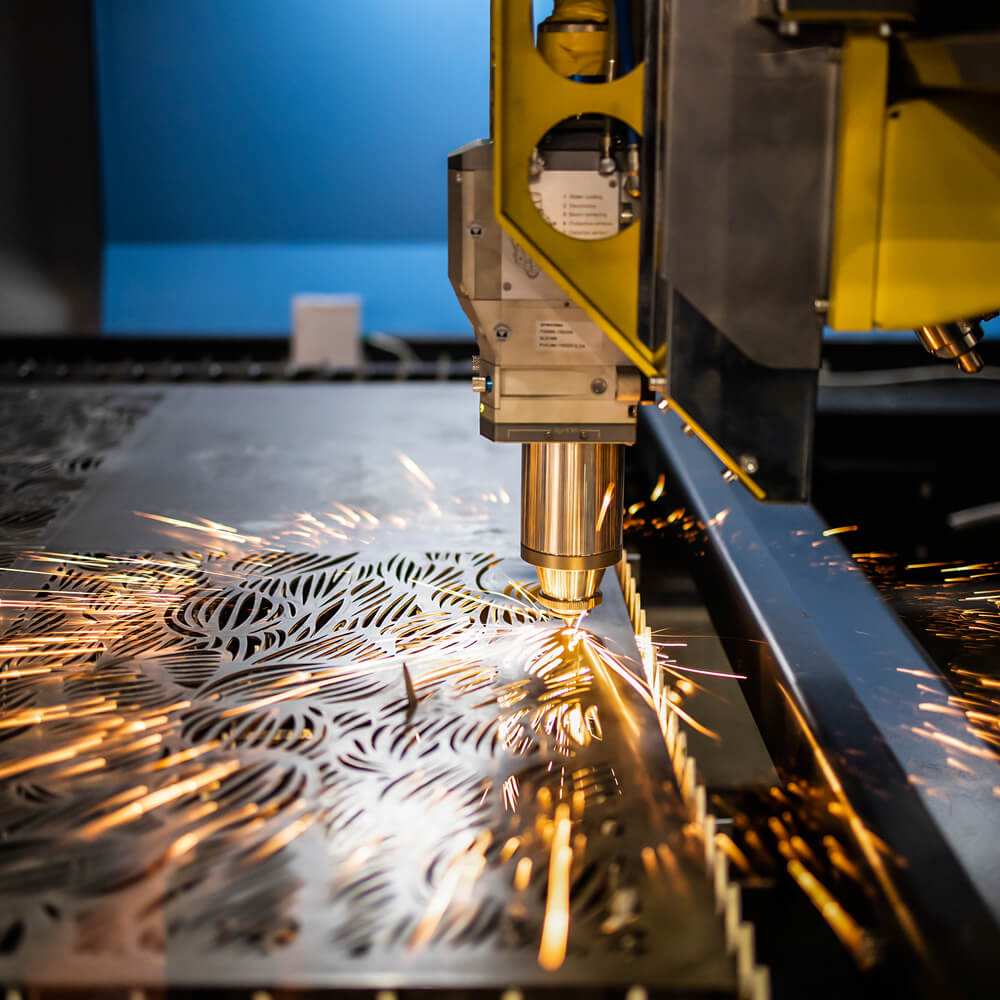

Clean Edges, Intricate Details, and Rapid Turnaround for Metal and Plastic Parts.

- ISO 9001 Certified

- Fiber & CO2 Lasers

- Prototypes to High Volume

Your Expert Partner for Precision Laser Cutting

Celerity Precision is a leading manufacturing service provider in China, specializing in high-precision laser cutting. This advanced fabrication process uses a focused, high-power laser beam to cut materials, resulting in exceptionally accurate parts with clean edges and fine details. It is the ideal method for creating complex flat-pattern components, from intricate decorative panels to robust industrial machinery parts. Our state-of-the-art facility is equipped with the latest laser cutting technology, enabling us to deliver superior quality parts from a wide range of materials with unmatched speed and repeatability.

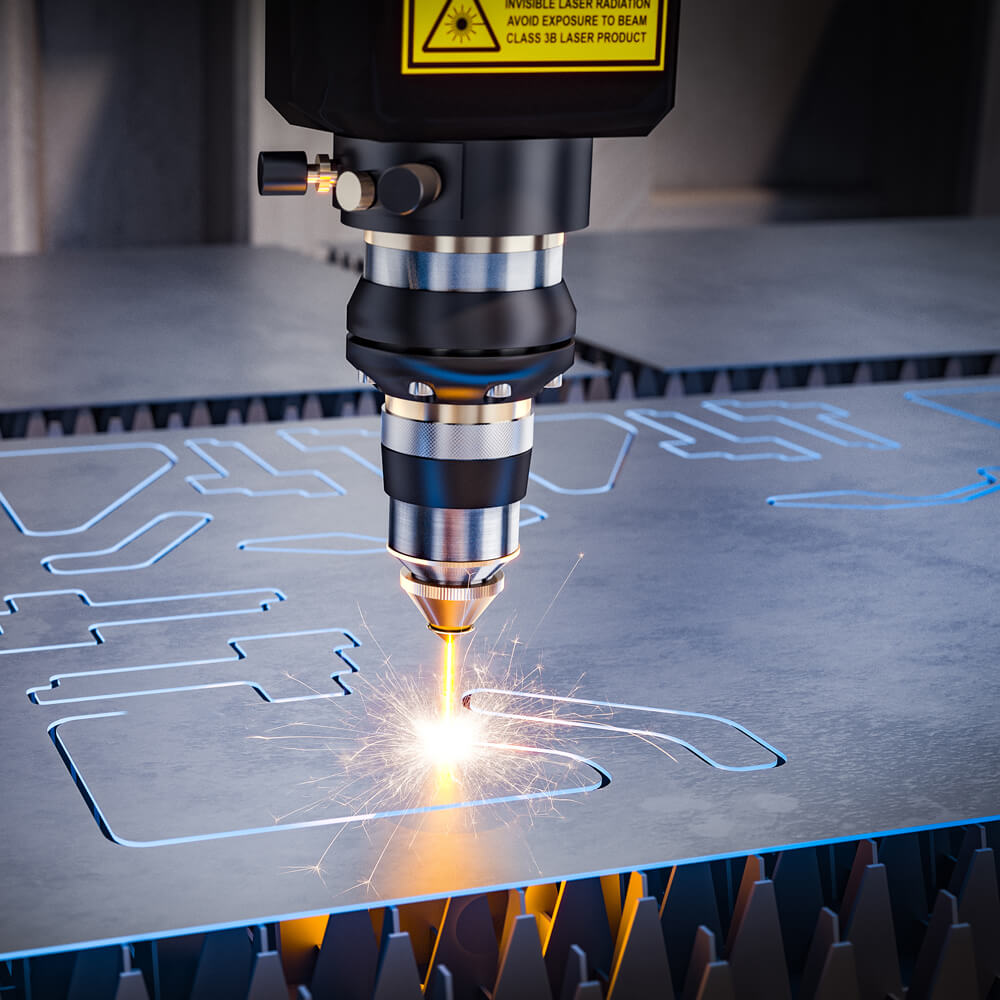

Advanced Laser Technology for Any Application

Our investment in diverse laser cutting technologies ensures we can select the optimal process for your specific material and design requirements, guaranteeing efficiency, precision, and cost-effectiveness.

Fiber Laser Cutting

The cutting edge of metal fabrication. Our high-power fiber lasers are perfect for rapidly cutting reflective materials like aluminum, copper, and brass, as well as steel and stainless steel. This technology offers incredible speed and precision, resulting in a minimal heat-affected zone (HAZ) and a smooth, clean-cut edge.

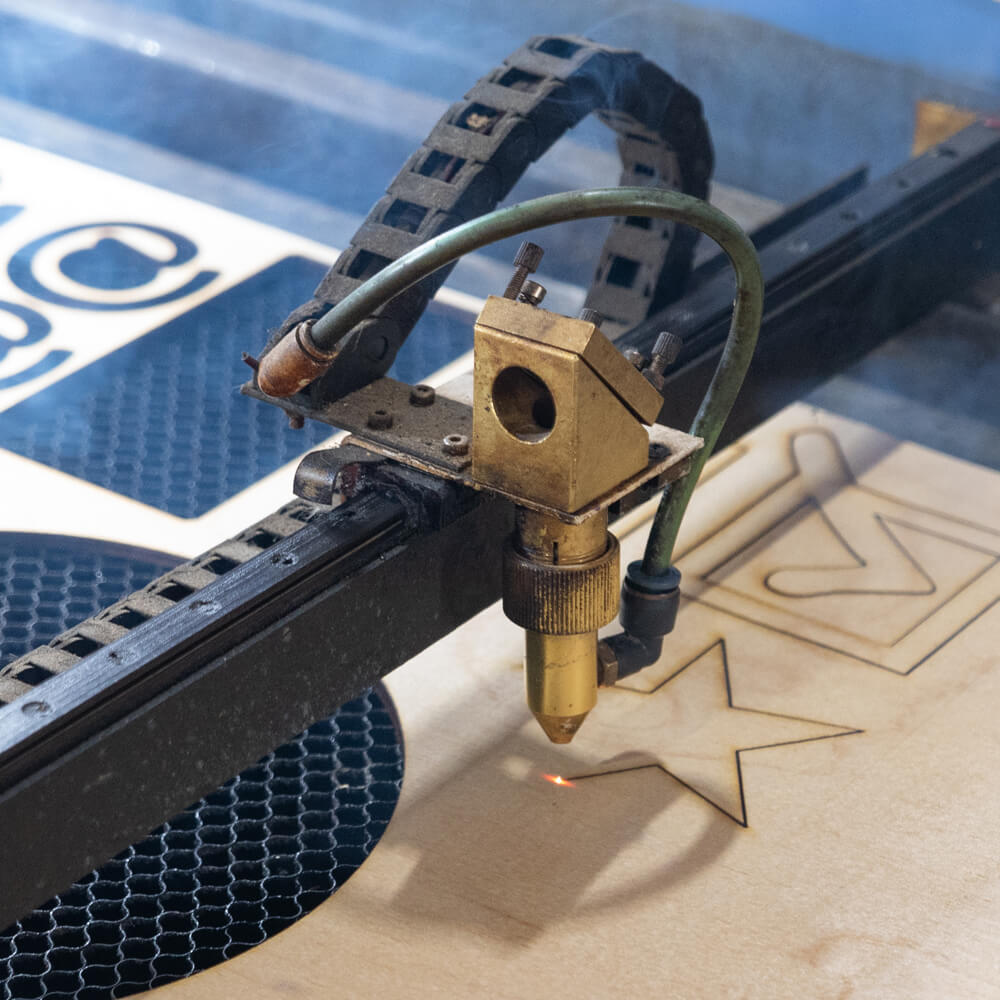

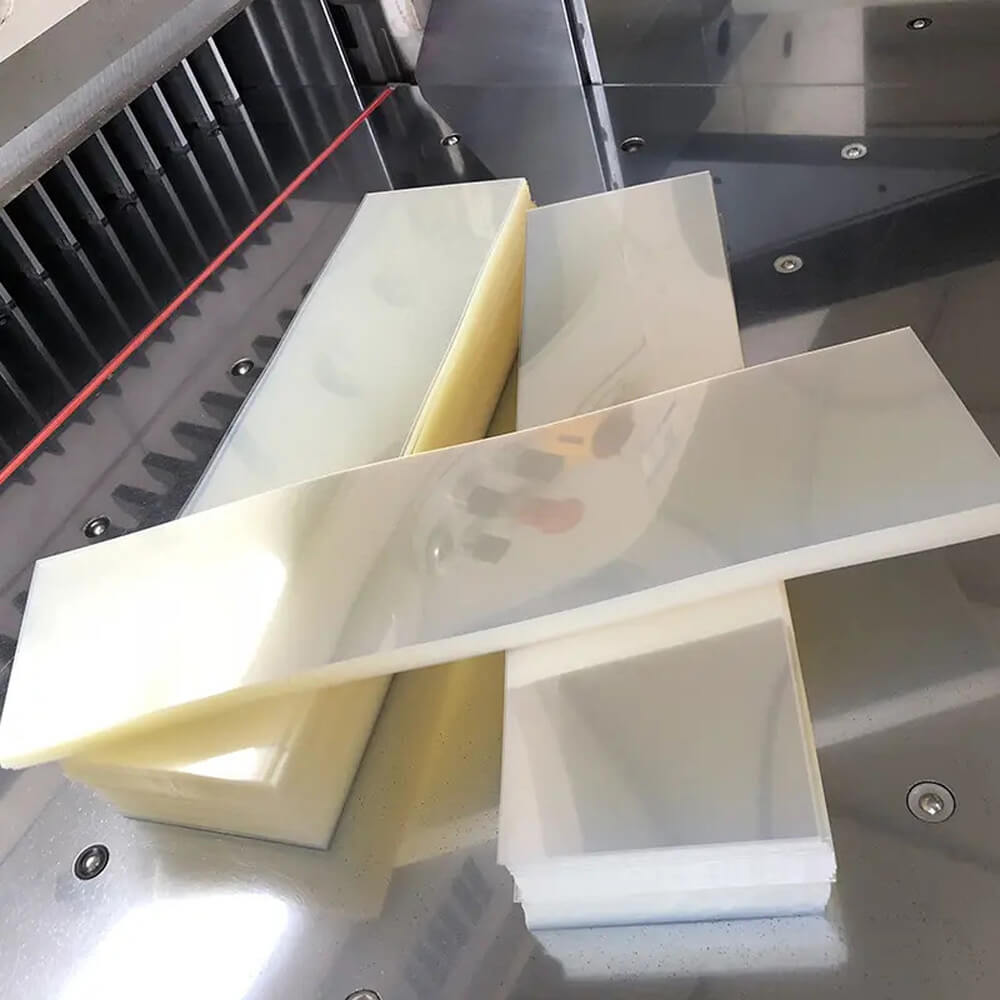

CO2 Laser Cutting

A versatile and reliable technology, our CO2 lasers excel at cutting thicker materials and a broader range of non-metallic substrates. This process is ideal for cutting plastics like Acrylic (PMMA) and Acetal (POM), as well as thicker steel plates, providing a high-quality finish across diverse applications.

A Full Spectrum of Laser-Cut Materials

Metal

Aluminum is strong, light metal that can be used for many things and doesn’t rust easily.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

Copper

Copper has great electrical and thermal conductivity, which makes it the best choice for heat sinks and electrical parts.

- Available Grades: C101 (OFHC), C110 (ETP)

- Common Finishes: As Machined, Electropolishing, Plating, Clear Coat

Brass

Brass is great for making fittings and decorative elements since it is easy to work with and looks like gold.

- Available Grades: C360

- Common Finishes: As Machined, Polishing, Plating, Brushing

Bronze

Bronze is durable and has minimal friction, it is widely used for naval hardware, bushings, and bearings.

- Available Grades: C932, C954

- Common Finishes: As Machined, Tumbling

Steel

Steel is a robust, long-lasting, and cheap material that works well in high-stress and industrial settings.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Stainless Steel

Stainless steel is very strong and doesn’t rust easily, so it’s great for use in food, medical, and maritime settings.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Magnesium

Magnesium is a very light metal that is great for uses where every gram matters.

- Available Grades: AZ31, AZ91

- Common Finishes: Chromate Conversion Coating

Titanium

Titanium is a high-performance metal that is quite strong for its weight and is also very biocompatible.

- Available Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Common Finishes: As Machined, Anodizing (for color), Sand Blasting

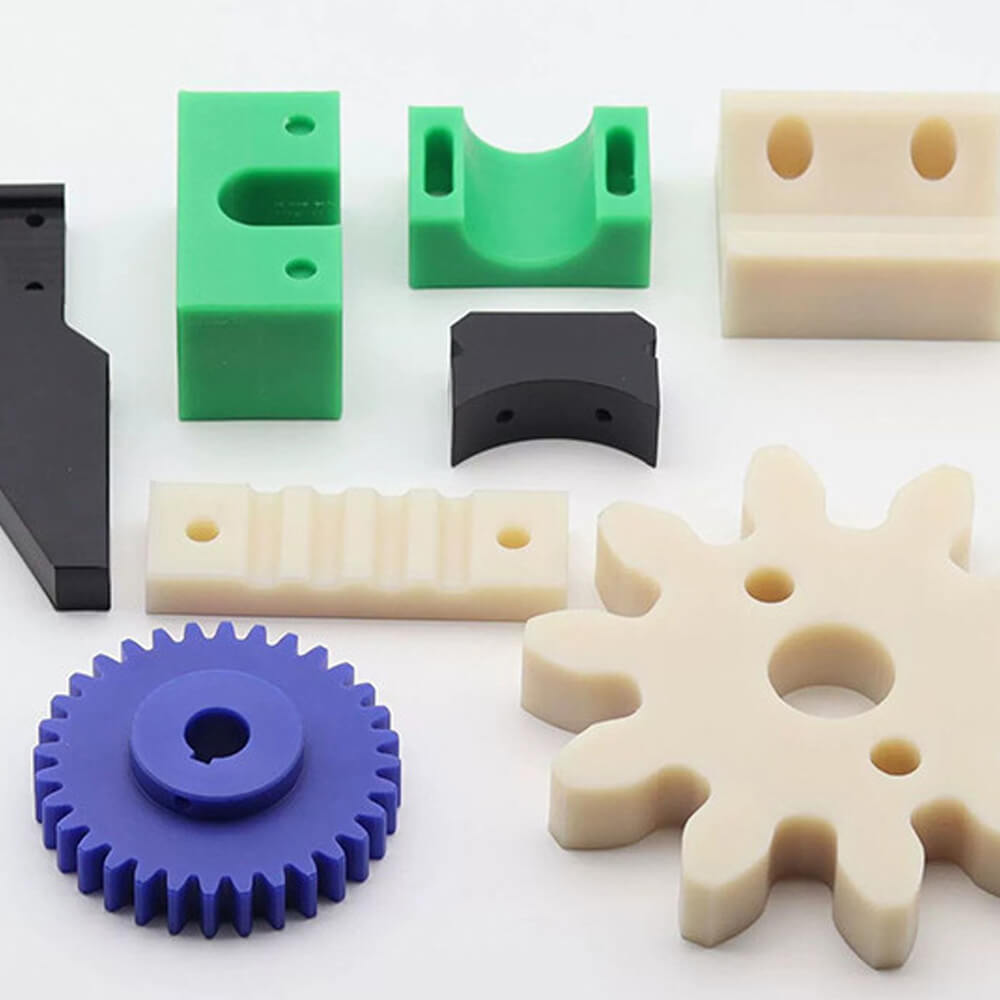

Plastic

ABS

ABS is a strong, impact-resistant, and cost-effective thermoplastic that works well for housings, enclosures, and prototypes.

Common Finishes: As Machined, Sand Blasting, Painting

PC (Polycarbonate)

PC is a sturdy, clear material that can handle heat and impact very well.

- Common Finishes: As Machined, Vapor Polishing, Painting

PLA

PLA is a thermoplastic that breaks down naturally and comes from renewable resources. It is often used for quick prototyping.

Common Finishes: As Machined, Painting

PMMA (Acrylic)

PMMA is a clear, hard plastic with great optical clarity. It is widely used as a light-weight substitute to glass.

Common Finishes: As Machined, Vapor Polishing, Flame Polishing

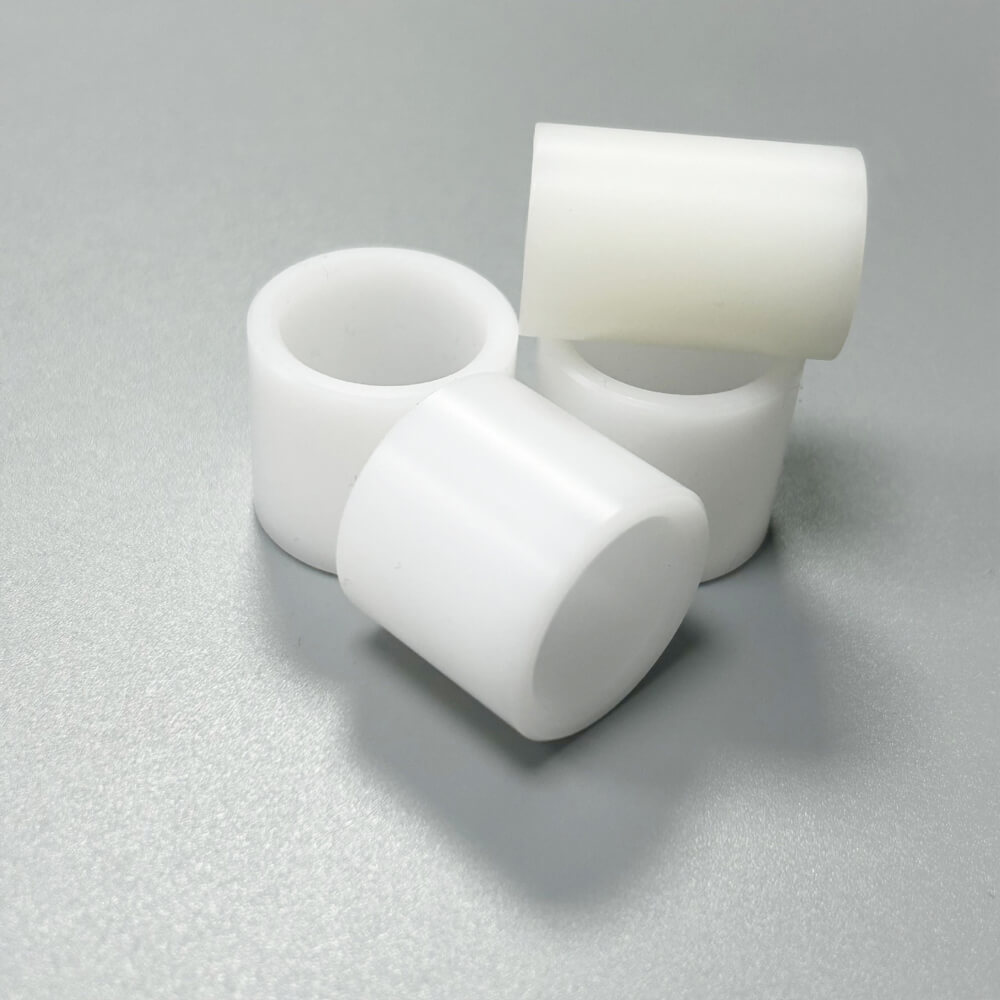

POM (Delrin/Acetal)

POM is an engineering plastic that is low-friction and high-stiffness, making it great for gears and bearings.

Common Finishes: As Machined

PA (Nylon)

PA is a strong and flexible plastic that can stand up to chemicals and wear.

- Available Grades: PA6, PA66

- Common Finishes: As Machined

PE (Polyethylene)

PE is a typical type of plastic that can withstand chemicals and comes in varying densities for different uses.

Common Finishes: As Machined

PEEK

PEEK is a high-performance polymer that is very strong, resistant to chemicals, and stable at high temperatures.

Common Finishes: As Machined

PP (Polypropylene)

PP is a light plastic that is very elastic and resistant to chemicals. It is widely used for living hinges.

Common Finishes: As Machined

HIPS

HIPS is a cheap, stiff plastic that is easy to work with and is typically used to make prototypes before production.

Common Finishes: As Machined, Painting

PBT

PBT is a type of engineering thermoplastic that is stiff, stable in size, and can handle chemicals and heat.

Common Finishes: As Machined

PPA

PPA is a high-performance polyamide that is stronger, stiffer, and more heat-resistant than regular nylon.

Common Finishes: As Machined

PAI (Torlon)

PAI is high-performance plastic that is exceedingly strong and rigid and keeps its qualities even at very high temperatures.

Common Finishes: As Machined

PET

PET is a tough, rigid plastic used in engineering that resists chemicals well and wears well.

Common Finishes: As Machined

PPS

PPS is a high-performance thermoplastic that can withstand chemicals and high temperatures without changing shape.

Common Finishes: As Machined

PS (Polystyrene)

PS is a clear, rigid, and brittle plastic that doesn’t cost much and is typically used for prototypes.

Common Finishes: As Machined, Painting

PVC

PVC is a strong, long-lasting, and cheap plastic that doesn’t easily get damaged by chemicals or water.

Common Finishes: As Machined

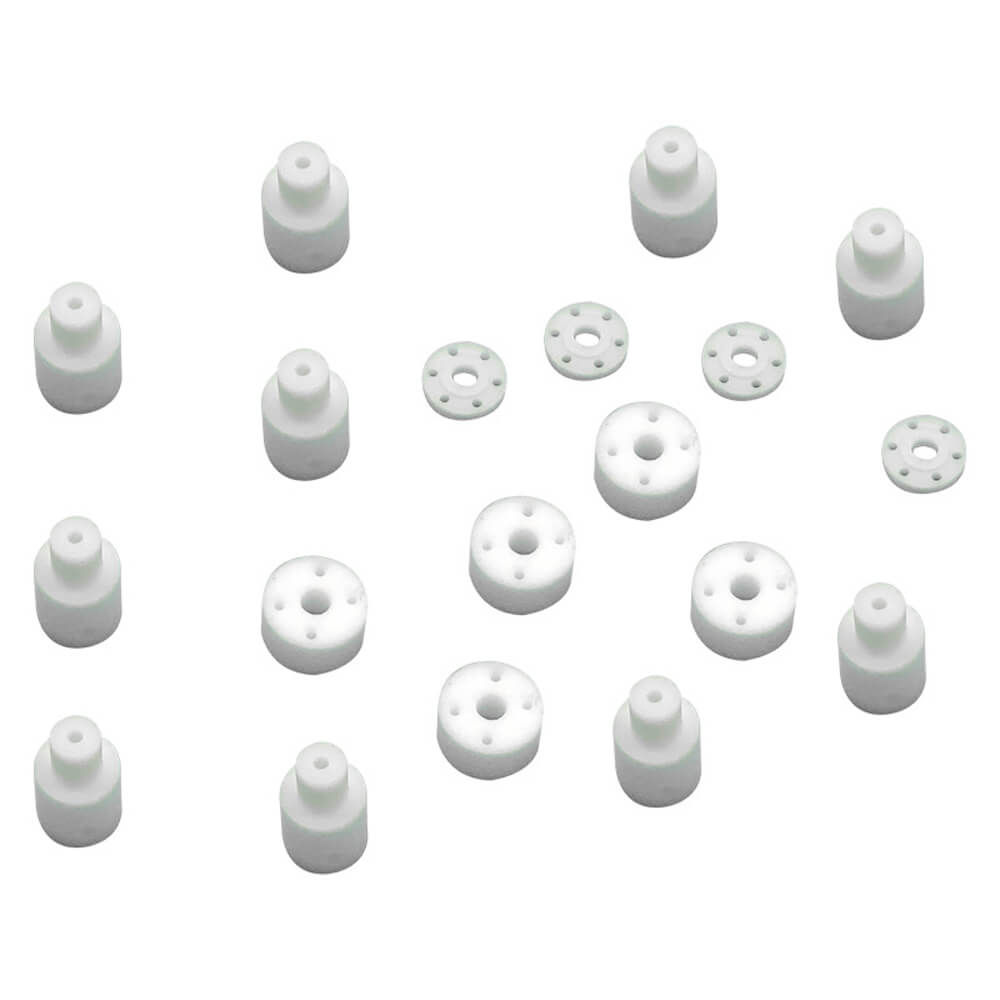

PTFE (Teflon™)

PTEE is known for having a very low coefficient of friction, being chemically inert, and being able to handle high temperatures.

Common Finishes: As Machined

Bakelite

Bakelite is a thermoset plastic that is hard, thick, and resistant to heat. It also has good electrical insulating qualities.

Common Finishes: As Machined

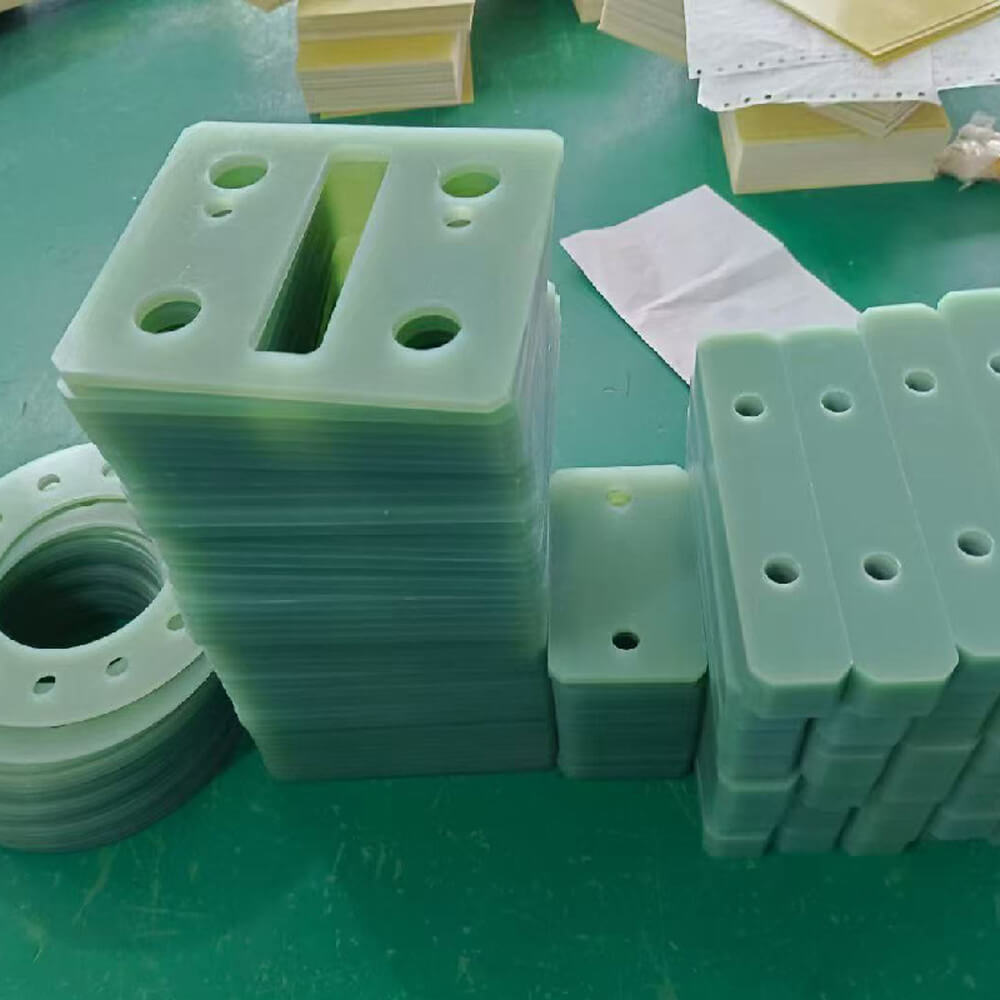

FR-4

FR-4 is a glass-reinforced epoxy laminate that is very strong and has great electrical insulation qualities.

Common Finishes: As Machined

Have a Design Ready? Let's Make It Real.

The Celerity Precision Laser Cutting Advantage

State-of-the-Art Equipment

Our investment in both high-power Fiber and versatile CO2 lasers ensures we use the best technology for your specific material and design, guaranteeing optimal results.

Exceptional Precision and Detail

We can cut highly intricate patterns, sharp corners, and small features with tolerances as tight as ±0.1mm (±0.004"), producing parts that are impossible to create with traditional methods.

Superior Edge Quality

Our finely tuned laser processes produce a smooth, clean-cut edge with a minimal heat-affected zone (HAZ), reducing the need for secondary deburring or finishing operations.

Material and Nesting Optimization

Our advanced software automatically nests your parts on the sheet material to maximize yield and minimize waste, directly reducing your per-part cost.

Rapid & Scalable Production

Laser cutting is an extremely fast process. We can produce a single prototype or scale up to thousands of identical parts with perfect repeatability and quick turnaround times.

Integrated Fabrication Partner

We are more than just a cutting service. We can seamlessly transition your laser-cut parts to our in-house CNC bending, welding, and finishing departments to deliver a complete, assembled product.

Advantages of the Laser Cutting Process

Design Freedom

Allows for the creation of nearly any 2D shape, including extremely complex geometries, intricate cutouts, and fine details that are not possible with mechanical cutting.

High Speed and Efficiency

Laser cutting is a very fast process, especially on thin materials, making it ideal for both rapid prototyping and high-volume production.

Non-Contact Process

There is no physical contact between the machine and the material, which eliminates tool wear and reduces the risk of material deformation or contamination.

Minimal Heat-Affected Zone (HAZ)

The focused energy of the laser creates a very narrow kerf and a small HAZ, preserving the material's properties and structural integrity close to the cut line.

Excellent Repeatability

As a digitally controlled CNC process, laser cutting offers exceptional part-to-part consistency, ensuring every piece in a production run is identical.

Low Tooling Costs

Unlike stamping or punching, laser cutting requires no custom tooling, making it extremely cost-effective for prototypes and low-to-medium volume production.

From Digital File to Laser-Cut Part in 4 Simple Steps

Submit Design & Get Quote

Securely upload your 2D files (DXF, DWG) or 3D models. Our team provides a detailed quote and DFM feedback within 24 hours.

DFM Review & Order Confirmation

We review your design for manufacturability and help optimize material usage. Once approved, we prepare the cutting program.

Precision Laser Cutting

Your parts are expertly cut on the optimal laser machine (Fiber or CO2) by our skilled operators.

Inspection & Global Delivery

Every part is inspected for dimensional accuracy and edge quality before being securely packaged and shipped to your door.

Custom Laser Cutting Services - Celerity Precision

“The advance of technology is based on making it fit in so that you don’t really even notice it, so it’s part of everyday life.” – Bill Gates

For precise custom laser cutting on a variety of materials, we use cutting-edge technology. We offer laser cutting services in China for a wide range of sectors, from creating goods to crafting.

A CAD file guides a strong, concentrated laser beam that cuts through materials. It melts, burns, or turns parts into gas to make perfect cuts and detailed drawings. This makes it very important in today’s world of manufacturing.

Important Points

- Cutting solutions with high accuracy for a range of materials

- High-tech tools for personalized laser cutting services

- Different uses in many fields

- Detailed patterns and exact cuts

- An important tool in modern production

Introduction to Laser Cutting

Laser cutting is a way to cut through things without touching them. It uses a laser beam. It makes very little waste and is very accurate. This technology is very important in many fields since it can carve complicated forms with great accuracy.

What is Laser Cutting? Definition and Principle

When you use a laser to cut through anything, you use a laser beam. It operates by directing a strong laser beam at a limited area. This melts or turns the substance into gas, and then a jet of gas blows it away.

This approach makes it possible to make precise cuts with negligible heat distortion. For different materials, it’s important to control the laser’s power and frequency, as well as the gas that helps it work.

The Past and Present of Laser Cutting Technologies (CO₂, Fiber, etc.)

In the 1960s, the first CO2 laser was made. There are now new types of lasers, such as Nd:YAG lasers and fiber lasers. People use CO₂ lasers a lot these days, mostly to cut things that aren’t metal.

“The development of fiber lasers has marked a significant shift in the industry, with higher efficiency and lower maintenance than traditional CO₂ lasers.” – Expert in the field

Types / Classifications of Laser Cutting Methods (Fusion, Vaporization, Oxygen-assist, etc.)

There are a few different ways to cut using lasers. When you use fusion cutting, the material melts and is blown away by gas. With vaporization cutting, the material is turned into vapor right away. Oxygen-assisted cutting employs oxygen to make cutting easier, mostly for metals.

Each process has its pros and cons, and some materials and uses are better suited to some than others. To pick the proper laser cutting technology, you need to know these differences.

Laser Types & Key Technology Components

You should learn about the many types of lasers and their parts. This helps you choose the best laser cutting machine. When it comes to laser cutting, CO₂ and fiber lasers are the best.

Nd:YAG, CO₂, and Fiber Lasers

There are different types of lasers used in laser cutting, and each has its unique strengths. The most common varieties are Nd:YAG lasers, fiber lasers, and CO₂ lasers.

- CO₂ lasers employ gas to make the beam. They work well for cutting wood, acrylic, and plastic.

- Fiber lasers use a fiber that has been doped. They work best for cutting metals like copper, aluminum, and stainless steel.

- Lasers Nd:YAG: These lasers can cut through both metals and non-metals. They are recognized for being strong and accurate.

| Laser Type | Primary Use | Characteristics |

|---|---|---|

| CO₂ Lasers | Non-metallic materials | Ideal for wood, acrylic, plastics |

| Fiber Lasers | Metals | Effective for stainless steel, aluminum, copper |

| Nd:YAG Lasers | Metals and non-metals | High power, precision cutting |

Source or Generator for Lasers

The laser generator is the most important part of the machine. It makes the laser beam. The quality of the generator has an effect on how well it cuts and how good it looks.

System for Delivering Beams: Mirrors, Optics, and Fibers

The cutting head gets the laser beam from the beam delivery system. There are optics, mirrors, and fibers in it. These make sure the beam is concentrated and under control.

Nozzle, Cutting Head, and Focusing Lens

The nozzle and focusing lens are on the cutting head. They are very important for making exact cuts. The lens concentrates the beam, and the nozzle sends the help gas in the right direction.

Knowing these parts helps make laser cutting work better and more accurately.

Process Parameters & Machine Specifications

It’s crucial to know how laser cutting machines function if you want to achieve good cuts. The machine’s specs and how it cuts impact how fast, how accurately, and how well it works.

Wavelength, Beam Quality, and Laser Power

The power of the laser is very important for the speed and quality of the cut. You can cut thicker things faster with more power. But it also makes it more likely that something may get damaged or overheated.

The quality of the beam depends on how accurate the incision is. Finer details and smoother edges come from better beams. Different materials need different wavelengths of laser light to work with them. The wavelength of the laser impacts how it interacts with the material.

Speed of Cutting, Position of Focus, and Pulse vs. Continuous Operation

Cutting speed is really important for getting things done. It is important to find the optimum speed without sacrificing quality. The cut quality also depends on the focus point. You can change it to manage the kerf width and lower the risk of heat damage.

Whether to use pulse or continuous operation depends on the quality of the material and the edge. For some materials, pulsed lasers provide you more control over the heat.

Material Thickness Limits and Multi-Pass Cutting Strategies

Different machines can only handle certain thicknesses of materials. Knowing these constraints helps you plan and make cuts that are good. You can utilize multi-pass cutting procedures on thicker materials. This procedure helps keep the heat under control and make cleaner cuts.

Kerf Width, Edge Quality, and Heat-Affected Zone (HAZ)

The kerf width is the width of the cut, which is affected by the laser and the cutting settings. A narrower kerf is better because it doesn’t waste as much material. The Heat-Affected Zone (HAZ) is the area around the cut that was changed by heat. To keep the qualities of materials, it’s important to keep HAZ as low as possible. Edge quality is vital; smoother edges mean better cuts.

| Parameter | Description | Impact on Cutting |

|---|---|---|

| Laser Power | Energy output of the laser | Affects cutting speed and quality |

| Beam Quality | Focus and precision of the laser beam | Influences edge quality and detail |

| Cutting Speed | Rate at which the laser moves through the material | Impacts productivity and cut quality |

| Kerf Width | Width of the cut made by the laser | Affects material waste and cut precision |

Materials for Laser Cutting

We cut a lot of different materials with lasers, including metals and non-metals. Because of this, laser cutting is a top choice in many areas.

Metals

Laser cutting is a good way to cut metals like brass, copper, aluminum, stainless steel, and titanium. varied metals have varied properties that make them good for different things.

- Stainless steel is ideal for many things because it’s strong and doesn’t rust.

- Aluminum is great for vehicles and planes since it’s light and doesn’t rust.

- Copper and brass are good for carrying electricity, thus they are utilized in electronics and ornamentation.

- Titanium is strong and doesn’t rust. It’s utilized in planes and medical gadgets.

Not Metals

Laser cutting can also be used on things that aren’t metal, like wood, plastic, acrylic, leather, and textiles. You can find these in garments, signs, and furniture.

- Plastics and acrylics are great for making signs and decorations since they are high quality and can be used in many ways.

- Wood: It’s great for making crafts and furniture with intricate designs and exact cutting.

- Leather and Fabrics: Laser cutting can make intricate designs in leather and fabrics that are utilized in fashion and upholstery.

Materials to Avoid

But not all materials can be safely sliced with a laser. These are PVC, certain polymers, and materials that are coated or made up of more than one material.

- PVC: When you cut it, the chlorine in it can generate poisonous vapors.

- Some Plastics: When heated, some plastics can let off compounds that are bad for you.

- Coated or Composite Materials: They could let off dangerous chemicals or hurt the laser cutter.

It’s important to know what laser cutting can and can’t do with different materials. Choosing the proper materials and settings helps you achieve the best cuts and work faster.

Machine Operation & Workflow

There are a number of important processes in the laser cutting process, from planning to completing. To achieve the greatest outcomes, you need to know these steps.

Design & CAD/CAM Preparation, Path Planning

The first thing to do is design and get ready for CAD/CAM. CAD/CAM software helps you make plans and develop the code that the laser machine needs. Planning a good path reduces waste and increases efficiency.

Importing CAD drawings makes parts rapidly. The CAD/CAM’s accuracy makes sure that the finished product fulfills the design standards.

Focal Adjustment and Parameter Calibration

Calibration of the parameters is necessary before cutting. This changes the parameters of the laser machine to fit the material. Focal adjustment is also important for getting the laser beam to hit the surface of the material.

Actual Cutting Process: Rough & Finish Passes, Gas Use, Cutting Order

There are a number of steps involved in the cutting process. It has rough and finish passes. A rough pass cuts initially, and then a finish pass smooths out the edge. The material and the quality you want will determine the type of assist gas you use. The cutting order is meant to be as efficient as possible and to need minimum handling of materials.

Actual Cutting Process: Rough & Finish Passes, Gas Use, Cutting Order

After cutting, you need to do some post-processing. This includes cleaning, completing the edges, and getting rid of burrs or rust.

By taking care of these measures, producers can get good outcomes from laser cutting.

Safety, Environmental & Health Considerations

When using a laser cutter, you need to think carefully about safety, the environment, and your health. It uses powerful lasers, diverse materials, and maybe even toxic gasses. This means that safety rules are particularly crucial. We will talk about how to keep the area safe and healthy when using laser cutting technology.

Ventilation, Exhausting Fumes & Toxic Materials

To get rid of fumes and particulates, laser cutting needs good ventilation. A good exhaust system lowers the chances of breathing in and coming into contact with harmful substances. We recommend that you install a separate ventilation system for laser cutting.

Risk of Fire and Material Hazards

Laser cutting can start fires because it uses high temperatures and materials that catch fire easily. It’s crucial to find out whether things can catch fire and do things to stop fires from starting. Also, knowing how materials reflect light can help keep people safe.

Material Safety – What to Avoid, Proper Handling of Harmful Fumes

When laser cut, some materials, like PVC and some polymers, give off poisonous vapors. You should know which materials are safe to cut and which ones you shouldn’t. To eliminate health dangers, it is important to handle and throw away materials correctly and to have good fume extraction.

Following these safety procedures will considerably decrease the risks of laser cutting. This makes the workplace safer for everyone.

Advantages & Disadvantages

Laser cutting is a flexible method that is quick and very accurate. Many businesses like it. It can cut without touching and form complicated shapes, which are both great features. But it does have certain problems.

Benefits: Precision, Speed, Non-contact Cutting, Complex Shapes

There are a lot of good things about laser cutting. It can make incredibly precise cuts and designs with a lot of detail. It’s also quick, so you can manufacture more in a shorter amount of time. It also cuts without touching the cloth, which helps save it from getting damaged.

It’s great for making shapes that are too hard for other methods to make. This gives designers and producers more options. It helps them make new and useful things.

Limitations: Cost, Power Requirements, Material Limitations, Reflectivity Issues

But laser cutting isn’t always ideal. The equipment and their upkeep are quite expensive, which is a huge problem. The electricity needs might also be significant, which adds to the costs.

Lasers can’t cut through all kinds of materials. Some need extra attention or preparation. For example, it’s hard to cut metals like copper and aluminum because they reflect light. This could hurt the laser or screw up the cut.

| Advantages | Disadvantages |

|---|---|

| High precision and accuracy | High initial investment cost |

| Fast cutting speed | Significant power requirements |

| Non-contact cutting reduces material damage | Material limitations and reflectivity issues |

| Ability to cut complex shapes | Potential for high operational costs |

Applications & Use Cases

People utilize laser cutting for a lot of activities, like building items and making art. It shows how accurate, useful, and adaptable this technology is.

Uses in Industry

Laser cutting is very important in fields like electronics, vehicles, and planes. It cuts metal into complicated forms for vehicle parts.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Cutting metal parts for vehicles | Precision, speed |

| Aerospace | Cutting complex shapes in metal and composites | Accuracy, reduced material waste |

| Electronics | Cutting PCBs and other electronic components | Precision, minimal thermal distortion |

Experts say that laser cutting has revolutionized how items are made. It manufactures complicated parts with high accuracy and less waste. “The use of laser cutting in industrial manufacturing has significantly improved production efficiency and reduced costs.”

Creative / Decorative Applications

People also utilize laser cutting to make art and decorations. It cuts out designs and patterns in a variety of materials. This is why artists and designers love it.

It has given artists and designers new opportunities. They can effortlessly bring complicated drawings to life.

Emerging Applications

Micro-cutting and working with sophisticated materials are two new uses for laser cutting. Laser cutting is getting even better because of these new uses.

- Micro-cutting for precise engineering

- Working with innovative materials like composites and smart materials

- Working with other technologies, such as 3D printing

As laser cutting technology grows better, we’ll see even more creative usage in a variety of fields.

It’s important to get the correct laser cutting machine. You should think about a few key things. This includes the machine’s specifications, price, and how to maintain it functioning well.

Checklist for Machine Specifications

Look at a few important specs to find the best laser cutting machine. These are:

- Power and wavelength of the laser

- Bed size and thickness of material that can be cut, as well as options for assist gas and cutting head capabilities

- Specifications for accuracy and precision

When you know these parameters, you can be sure the machine will work for you. For instance, thicker materials demand higher laser power. Some materials need the appropriate wavelength.

Cost Considerations

When you acquire a laser cutting equipment, the price is very important. You should ponder about:

| Cost Factor | Description | Impact |

|---|---|---|

| Runtime Costs | Energy consumption and operational hours | Directly affects production expenses |

| Consumables | Nozzles, lenses, and assist gases | Influences ongoing operational costs |

| Maintenance | Regular servicing and part replacement | Impacts machine longevity and performance |

As noted by industry expert, “The total cost of ownership for a laser cutting machine goes beyond the initial purchase price. It’s essential to consider ongoing expenses to ensure the machine remains a valuable asset over its lifespan.” John Doe, Laser Cutting Specialist.

Maintenance and Longevity of Components

It’s very important to keep your laser cutting machine in good shape. This means:

- Cleaning lenses and cutting heads on a regular basis

- Replacing old or broken parts and updating software for the best performance

Your machine will perform properly for a long time if you pay attention to these things.

Quality Control & Performance Metrics

In laser cutting, where accuracy is very important, high-quality outputs are quite important. Quality control is vital for how the finished product looks, such as the quality of the edges and the polish on the surface.

Kerf Variation, Tolerance, Edge Quality, Surface Finish

There are a few things that affect the edge quality of laser cutting. The laser’s power, cutting speed, and the material are all things that affect this. A nice edge is smooth and doesn’t get too hot.

The finish of the surface is also quite essential. It’s important for cuts that will be viewed or worked on later. The surface polish depends on the laser’s wavelength, the type of gas used, and the qualities of the material.

| Factor | Influence on Edge Quality | Influence on Surface Finish |

|---|---|---|

| Laser Power | Higher power can improve edge quality by reducing thermal damage. | Higher power may result in a rougher surface finish if not controlled. |

| Cutting Speed | Optimal speed enhances edge quality by minimizing dross and burr. | Excessive speed can lead to a poorer surface finish. |

| Assist Gas | Proper gas selection and pressure improve edge quality. | Assist gas can significantly affect the surface finish, with some gases producing cleaner cuts. |

Kerf variation and tolerance are also very important. The breadth of the cut is called the kerf, and changes in kerf can change how accurate the cut is. Parts fit well when there are tight tolerances.

Control of Distortion, Accuracy, and Repeatability

For laser cutting to work consistently, it needs to be accurate and repeatable. Accuracy means that the cut part is the right size for what it was meant to be. Repeatability means creating pieces that are always within the prescribed tolerances.

“The key to achieving high accuracy and repeatability lies in the precise control of the laser cutting process, including the laser source, the cutting head, and the motion system.”

Controlling distortion is also very important. When cutting, thermal distortion can change the contour of the part. Cutting settings can be carefully controlled before and after cutting to reduce distortion.

By paying attention to these quality control and performance indicators, manufacturers may develop products that are always high quality and quickly.

Future Trends and Innovations

New technologies make the future of laser cutting look good. These improvements will make cutting more accurate, faster, and better for the environment. There are a few trends that are starting to change the business.

Advances in Laser Technology

New laser technologies, such as ultrafast lasers and green lasers, are making cutting easier. Ultrafast lasers can cut through things without hurting them too much. This is because their pulses are relatively brief.

These new lasers can cut through a wide range of materials, such as sophisticated composites and metals that reflect a lot of light. They may also cut through thicker materials and make edges sharper.

Smart Controls, Integrated CAD/CAM, and Automation

Laser cutting is a significant deal with automation now. People are using CAD/CAM software with machines to speed up and improve the quality of work. This speeds up and improves productivity.

Machines function better when they have smart controls and sensors. They change the settings as needed to get the precise cut. This makes it easy to build bespoke pieces and forms that are hard to make.

| Feature | Traditional Laser Cutting | Automated Laser Cutting |

|---|---|---|

| Design Integration | Manual CAD/CAM integration | Automated CAD/CAM integration |

| Process Control | Manual parameter adjustment | Real-time monitoring and adjustment |

| Production Speed | Variable, dependent on operator | Consistent, high-speed production |

Sustainable Practices, Material Development, Energy Efficiency

Now, laser cutting is all about sustainability. Makers are trying to make lasers that use less energy and methods that are better for the environment. This is good for the world.

New materials are also making a difference. More and more people are using recycled materials and bio-based composites. Also, there is a movement to recycle more and throw away less.

- Making laser technologies that use less energy

- More usage of materials that are made from plants and recycled materials

- Using recycling methods in manufacturing

These new ideas and trends will keep changing the world of laser cutting. They will help things flourish and make new uses possible in numerous areas.

Glossary of Key Terms

Anyone who works with laser cutting has to know the words that are used. To utilize this technology well, you need to understand some words that are important.

This dictionary has crucial words and definitions for laser cutting. It makes it easier for you to understand this complicated technology.

Key Terms and Definitions

Assist Gas: Laser cutting works better with gases like oxygen, nitrogen, or air. They take away molten material, stop oxidation, or cool the edge of the cut.

Beam Quality: This tells you how sharp a laser beam may be. This has an effect on how precise and good the cut is.

CO₂ laser: A kind of laser that employs a mix of gases. People often use it to cut things that aren’t metal.

Fiber laser: A laser that employs a doped fiber. Because it has a high power density and metals absorb it well, it is typically used to cut metals.

Kerf: The width of the cut that the laser makes. It depends on the material, the type of laser, and the power settings.

Laser Power: The amount of energy the laser gives off, which is measured in watts. It changes how fast and well you can cut.

Nd: YAG Laser: A solid-state laser that uses yttrium aluminum garnet that has been doped with neodymium. It can be used for a lot of different material processing jobs.

| Term | Definition |

|---|---|

| Pulse Mode | A mode of laser operation where the beam is emitted in pulses. It's useful for precision cutting and reducing heat input. |

| Continuous Wave (CW) | A mode of laser operation where the beam is emitted continuously. It's often used for cutting thicker materials or where high cutting speeds are required. |

| Focal Length | The distance between the focusing lens and the point at which the laser beam is focused. It affects the spot size and intensity. |

| Heat-Affected Zone (HAZ) | The area around the cut that is affected by the heat generated during the laser cutting process. It can potentially alter material properties. |

To use laser cutting technology well, you need to know what these important terms mean. Knowing this terminology will help you use laser cutting systems better, whether you’re making things in an industrial setting, making prototypes, or doing artistic work.

Final Thoughts

Laser cutting has gone from being a specialist technique to becoming a key part of modern design, industry, and innovation. Its unequaled accuracy, adaptability, and ability to deal with a wide range of materials make it essential in many fields, including automotive, aerospace, electronics, signage, and creative design. Laser cutting lets businesses make complicated shapes, finer tolerances, and faster production schedules than ever before by turning digital drawings into real things with amazing accuracy.

There are certain problems, such the expense of the initial investment, the need for power, and the fact that some materials can’t be used, but the benefits are much more than the problems. Laser technology is always getting better, with new features like ultrafast and green lasers, automation, and smart controls that work together. This makes it more useful and efficient. Also, the move toward more environmentally friendly procedures and new materials means that laser cutting will be cheaper and better for the environment in the future.

In today’s competitive market, working with a trustworthy source of custom laser cutting services in China gives you access to the latest technology, qualified professionals, and solutions that can grow with your business. Laser cutting is still the best way to make things with high precision, whether you require complex parts, a lot of them, or custom designs. It will keep pushing the boundaries of quality and innovation in manufacturing for decades to come.

FAQs

What is laser cutting?

A powerful laser beam cuts through metals, polymers, and wood when it cuts. It performs this with a lot of care and accuracy.

What kinds of lasers are used for laser cutting?

The three major types of lasers employed are CO₂, fiber, and Nd:YAG lasers. Each one has its own pros and cons.

What kinds of things can laser cutting cut?

Laser cutting can cut through a lot of different things. This comprises metals, plastics, wood, acrylic, leather, and cloth.

What are the good things of laser cutting?

Laser cutting is very fast and precise. It doesn’t touch anything and can cut out complicated forms. This makes it useful and quick.

What are the drawbacks of laser cutting?

Laser cutting has some problems, such as being expensive and using a lot of power. It also has problems with the material and reflectivity that might affect the quality of the cut.

How can I pick the best laser cutting machine for what I need?

Check out the machine’s characteristics, price, and upkeep needs. Also, think about what kinds of materials you’ll be cutting.

When using a laser cutting machine, what safety measures should I take?

Always use safety gear and make sure there is enough air flow. To avoid mishaps, keep fire risks in check and handle materials safely.

How can I make sure that the cut is good?

Look at the edge quality, surface finish, and kerf variation of the cut. Also, pay attention to how accurate and repeatable it is.

What new uses are there for laser cutting?

Micro-cutting, sophisticated materials, and industrial uses are some of the new uses. This encompasses the electronics, aerospace, and automobile industries.

How can I make my laser cutting process better?

Set the parameters, change the focus point, and think about post-processing. For improved results, use smart controls and automation.

What will laser cutting look like in the future?

Look for improvements in laser technology, such as ultrafast and green lasers. You should also seek for innovative materials, more environmentally friendly techniques, and better energy efficiency.

Laser Cutting FAQ

What is the difference between Fiber and CO2 lasers?

Fiber lasers are more efficient and faster for cutting thin, reflective metals like aluminum and copper. CO2 lasers are better for cutting thicker metals and a wider range of organic materials like plastics and wood.

What is the maximum thickness you can cut?

This depends on the material. We can typically cut steel up to 20mm, stainless steel up to 15mm, and aluminum up to 12mm. Please send your specific requirements for a precise capability assessment.

What file format is best for laser cutting?

A 2D vector file in DXF or DWG format is ideal as it provides the direct toolpath for the laser.

What is "kerf"?

Kerf is the width of the material that is removed by the laser beam during cutting. We automatically compensate for the kerf to ensure your final parts have the exact dimensions you specified.

Will the edge of my part be rough?

No, laser cutting produces a very smooth, high-quality edge. On acrylic, it can even produce a flame-polished edge. On metals, the edge is clean with minimal burr (dross).

Can you laser etch or engrave parts?

Yes, in addition to cutting, our lasers can be used to etch part numbers, logos, and other markings directly onto the surface of your components.