Custom Welding Services in China

Creating Strong, Reliable, and Precise Fabrications from Custom Machined and Sheet Metal Components.

- ISO 9001 Certified

- TIG, MIG & Spot Welding

- Certified Welders

Your Expert Partner for Custom Welding & Fabrication

Celerity Precision provides expert welding services in China as a core component of our integrated manufacturing solutions. Welding is the process of joining metal parts, typically by melting the base materials and adding a filler material to form a strong, permanent bond. It is essential for creating complex assemblies, structural frames, and custom fabrications that cannot be made from a single piece of material. Our dedicated welding department is staffed by certified, highly skilled welders and equipped with modern technology to deliver assemblies that are not only strong and durable but also precise and aesthetically clean.

Advanced Welding Processes for Any Requirement

We offer a range of welding processes to suit different materials, applications, and structural requirements, ensuring we always use the best technique for your project.

TIG Welding (Gas Tungsten Arc Welding)

The premier process for high-quality, precision welding. TIG welding produces exceptionally clean, strong, and aesthetically pleasing welds with minimal spatter. It is our preferred method for stainless steel and aluminum, and is ideal for applications where appearance and weld integrity are paramount, such as in medical and food-grade equipment.

MIG Welding (Gas Metal Arc Welding)

A highly efficient and versatile process, MIG welding is perfect for rapidly joining steel, stainless steel, and aluminum components. It offers an excellent balance of speed and quality, making it the workhorse for fabricating structural frames, industrial machinery parts, and thicker plate assemblies.

Spot Welding (Resistance Spot Welding)

An extremely fast and economical process for joining overlapping sheets of metal. Spot welding is ideal for high-volume production of enclosures, brackets, and assemblies made from steel or stainless steel, creating a strong bond at localized points without adding filler material.

A Full Spectrum of Weldable Materials

Metal

A lightweight, versatile metal with an excellent strength-to-weight ratio and natural corrosion resistance.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

A strong, durable, and cost-effective material ideal for high-stress and industrial applications.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Offers excellent strength and superior corrosion resistance, making it ideal for medical, marine, and food-grade applications.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Have a Design Ready? Let's Make It Real.

The Celerity Precision Welding Advantage

Certified and Skilled Welders

Our welding team consists of certified professionals with deep expertise in TIG, MIG, and spot welding across a range of materials, ensuring every joint is strong and reliable.

Integrated "One-Stop" Fabrication

We manage the entire project lifecycle, from precision laser cutting and CNC machining the individual components to expertly welding and finishing the final assembly. This guarantees perfect fit-up and total quality control.

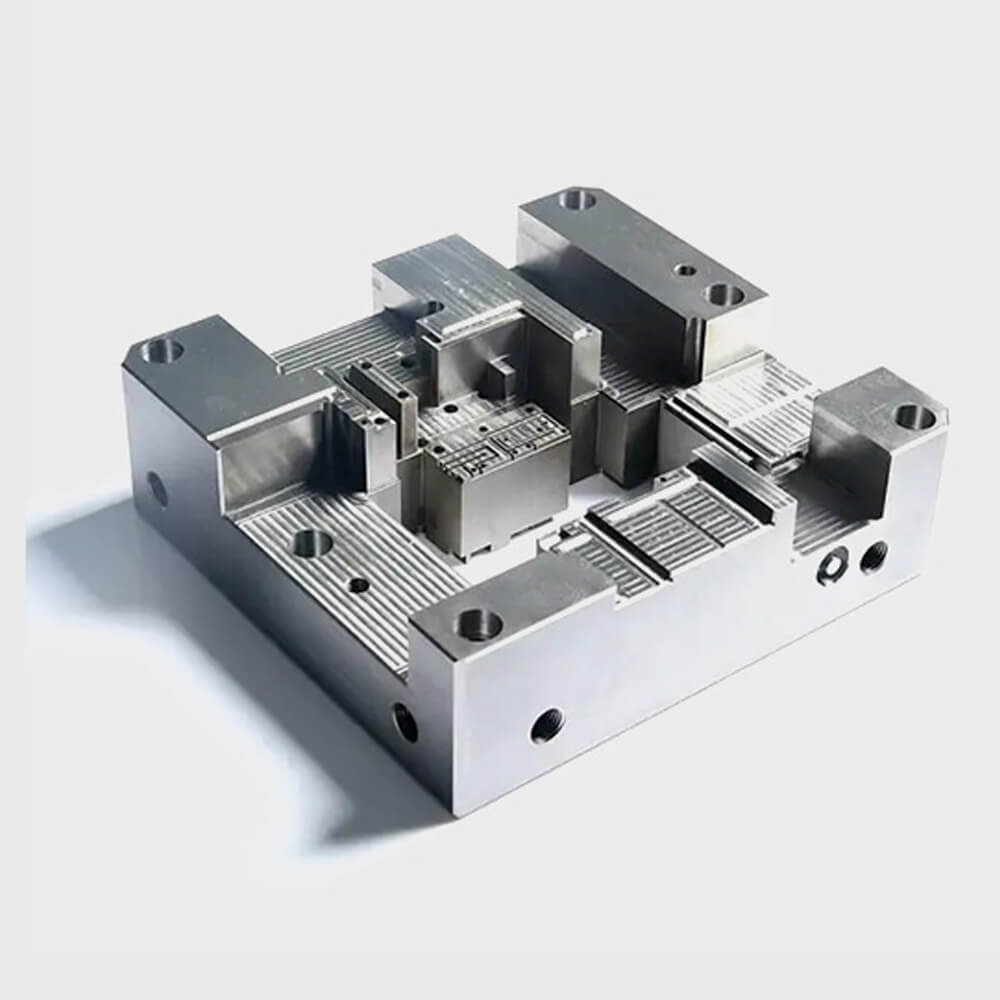

Precision Fixturing and Tooling

We design and build custom fixtures for complex weldments. This ensures that all components are held in their precise locations during welding, minimizing distortion and maintaining critical assembly tolerances.

Superior Weld Quality and Aesthetics

We pride ourselves on producing welds that are not only structurally sound but also clean and consistent. For cosmetic applications, we offer post-weld grinding and finishing to create a seamless appearance.

Adherence to Standards and Specifications

We can work to your specific welding callouts and industry standards, providing the documentation and quality assurance you need for critical applications.

Complete Finishing Services

After welding, we can seamlessly move your assembly to our in-house finishing departments for sand blasting, powder coating, painting, or passivation to deliver a fully completed product.

Advantages of the Welding Process

Creates Strong, Permanent Joints

Welding creates a permanent metallurgical bond that can be as strong as, or even stronger than, the base materials themselves.

Enables Complex Geometries

Allows for the creation of large, complex, and hollow structures that would be impossible or prohibitively expensive to machine from a single solid block.

Cost-Effective for Assemblies

It is often the most economical method for creating large or complex assemblies compared to casting or machining from billet.

Design Flexibility

Provides engineers with the flexibility to combine different material forms (e.g., sheet, tube, machined blocks) into a single, optimized fabrication.

Structural Rigidity

Welded joints create rigid, monolithic structures that are ideal for frames, chassis, and load-bearing applications.

Hermetic Sealing

TIG welding can be used to create leak-proof, hermetically sealed joints, which is essential for tanks, vessels, and vacuum chambers.

From Component to Assembly in 4 Simple Steps

Submit Design & Get Quote

Upload your CAD files for the assembly and individual components. Our team will review the design and provide a detailed quote.

DFM Review & Order Confirmation

We provide DFM feedback on joint design and fixturing. Once you approve, we begin fabricating the components.

Precision Welding & Assembly

Our certified welders use custom fixtures to precisely position and weld your components according to your specifications.

Inspection & Global Delivery

Every weldment is inspected for dimensional accuracy and weld quality before being finished (if required) and securely shipped.

Custom Welding Services - Celerity Precision

Are you looking for metal welding choices for your business that are both reliable and flexible? We have been doing this for a long time and offer a wide range of bespoke welding services. We tailor these services to meet the specific demands of each client.

Celerity Precision can do Submerged Arc Welding (SAW), MIG, TIG, Spot, Laser, and Robot Welding. We work with businesses in the construction, manufacturing, and automotive fields. We’re happy to offer services that are exactly what our clients require.

Important Points

- Metal welding options that are flexible and cheap

- Different ways to weld, such as SAW, MIG, TIG, and laser welding

- Services made just for the construction, manufacturing, and automotive industries

- The ability to weld well and make things

- Custom welding services in China that you can count on

Introduction to Welding

There are many ways to weld metals together. Every method has its own purpose. It’s an important aspect of metalworking, which includes TIG welding, MIG welding, and flux-cored welding.

What Is Welding?

Welding uses heat, pressure, or both to unite metals. You can do it with or without extra metal. The American Welding Society believes that welding is a very accurate process to unite metals.

“Welding is a precise and reliable method for joining metals.”

This definition includes a lot of different methods. Each is good for particular tasks and materials.

Different Ways of Welding

There are a lot of different ways to weld, such as gas tungsten arc welding (GTAW or TIG) and shielded metal arc welding (SMAW). There are advantages to each. The proper decision depends on the type of metal, how thick it is, and how strong the weld needs to be.

The Past and Present of Welding Methods

People have been welding for a long time. People in the past used forge welding. Arc welding began the contemporary period in the late 1800s. Thanks to new tools and methods, welding has come a long way since then.

Why it’s Important to know about different Types of Welding

It’s important to know about the many forms of welding. It helps you choose the best way to do a project. For instance, TIG welding is perfect for working with thin materials and doing accurate work. For many jobs, MIG welding is quick and effective.

Professionals that know how to weld can make sure their job is of the highest quality. They can also improve the way they do their jobs.

TIG Welding (GTAW)

TIG welding, often called GTAW, is known for generating strong welds on metals like stainless steel and aluminum. It gets high marks for being accurate and for being able to work with metals that rust readily or are not iron.

Definition and How It Works

TIG welding, which stands for Tungsten Inert Gas welding, employs a tungsten electrode that doesn’t need to be replaced. It makes an arc between the electrode and the workpiece, which melts the metal. Then it cools down and hardens into a strong connection. Using inert gases like argon and helium keeps the weld region free of air, which stops oxidation and contamination.

Tools and Setup

To TIG weld, you need a machine, a tungsten electrode that doesn’t wear out, a supply of shielding gas, and sometimes filler material. To set it up, you need to choose the suitable tungsten electrode, set up the welding equipment correctly, and make sure the shielding gas flows well. Setting things up correctly is important for good welds.

Filler Materials and Shielding Gases

Shielding gases, such as argon or helium, keep the air out of the weld. Argon is more common because it’s easy to use and performs well. To maintain the weld strong, the filler materials must be the same as the metal being welded.

Different Modes and Variations

There are numerous types of TIG welding, such as pulsed TIG welding. It manages heat and works well with thin materials. AC/DC TIG welding can be used on a number of metals. For example, AC works on aluminum while DC works on steel and stainless steel. Hot-wire TIG welding warms up the filler wire, which speeds up and improves the welding process.

MIG Welding (GMAW)

A common way to weld is via MIG, or Gas Metal Arc Welding (GMAW). People know it works well and can be used in many ways. It’s a cheap way to fuse a lot of metals together.

What it is and How it Works

MIG welding employs a wire that is always there as the filler metal and an inert gas to protect the weld. The weld pool automatically gets the wire. This generates an electric arc that melts the wire and the base metal, which makes the weld.

The technique works by keeping the welding voltage and wire feed speed in balance. This equilibrium is very important for making good welds.

Parts and Equipment

A wire feeder, a welding gun, and a power supply are all parts of MIG welding gear. The wire feeder is what controls the wire pace. The welding cannon sends the wire and gas to the weld. The arc gets its electricity from the power supply.

The welding cable, the supply of shielding gas, and the control systems are also very significant. The performance and dependability of MIG welding depend on how well these pieces are made.

Types of Shielding Gases and Wires

Choosing the right shielding gas is very important for MIG welding. It keeps the area around the weld clean. Argon, helium, and carbon dioxide are some of the most common gases. The type of metal and the quality of the weld you want will determine the gas mix.

The type of wire changes depending on the material being welded. ER70S-6 is a typical type of mild steel. ER308 is used for stainless steel, and ER5356 is used for aluminum. The quality of the weld depends on the wire’s chemical makeup and surface condition.

| Wire Type | Material | Common Applications |

|---|---|---|

| ER70S-6 | Mild Steel | General fabrication, construction |

| ER308 | Stainless Steel | Food processing, chemical plants |

| ER5356 | Aluminum | Aerospace, automotive |

Modes of Transfer

There are many ways to transfer MIG welding. Short-circuit transfer works best with thin materials. For thicker materials and smooth welds, use spray transfer. Pulsed MIG welding makes the arc more steady and fewer spatter.

There are pros and cons to each mode. The option relies on the thickness, type of material, and quality of the weld you want. MIG welding is a cheap way to do it. It’s a suitable alternative for many sectors because it’s cheaper than SAW and SMAW welding.

TIG vs MIG — Comparative Analysis

There are a few things to think about while deciding between TIG and MIG welding. These include how precise, fast, and complicated the weld should be. Each method has its own benefits and is best for certain uses.

Major Differences

TIG (Tungsten Inert Gas) welding is noted for being very accurate. It’s commonly utilized for hard welding jobs, as when you have to work with thin materials. MIG (Metal Inert Gas) welding, on the other hand, is faster and costs less. It’s ideal for welding jobs that are bigger and easier.

The tools and how they work are the fundamental differences between TIG and MIG welding. TIG welding gives you more control by using a tungsten electrode and a separate filler material. The wire feed in MIG welding acts as both the electrode and the filler, which makes the process more efficient.

When to Use MIG and When to Use TIG

For projects that need a lot of accuracy, use TIG welding. This includes welding thin metals, rare metals, or metals that need to look good, like in aerospace or creative metalwork. MIG welding is excellent for heavy fabrication tasks like building or fixing cars since it is faster and more efficient.

Costs and Effects on Productivity

There are big differences in the cost and productivity of TIG and MIG welding. TIG welding makes strong welds, but it takes longer and requires more work, which raises labor expenses. MIG welding is faster, which means it may save time and money on big projects.

Material and Thickness Considerations

The thickness and kind of the workpiece also affect the decision between TIG and MIG. TIG welding can be used on a wide range of metals, including aluminum, stainless steel, and exotic alloys, as long as the portions are thin. MIG welding is often used on thicker materials and works well for welding steel and aluminum.

To sum up, knowing the distinctions between TIG and MIG welding is important for choosing the proper method. We can choose the best approach for getting high-quality results quickly by taking into account things like accuracy, speed, material, and thickness.

Custom Welding Services

We are experts at bespoke welding, and we get great results by combining old and new methods. Custom welding means producing one-of-a-kind welding solutions for a wide range of uses and areas.

What “Custom Welding” Means

Custom welding is the process of constructing welded things or structures that meet certain needs or specifications. It could be anything from mending and keeping equipment working to creating new parts or pieces.

The main idea behind custom welding is to fix problems with solutions that are developed particularly for our clients. It’s about using precise materials, obtaining a certain look, or fulfilling exact size needs. We want to deliver you outcomes that are better than what you expect with our custom welding services.

Different Kinds of Custom Services

We have several custom welding services for different purposes and functions. Some of these are:

- Welding Services on Site: Our crew may come to you to execute the welding, which saves you time and makes it easier for you.

- Shop Welding Services: We offer full welding services in a controlled environment for the best outcomes on projects that can be done in our workshop.

- Mobile Welding Services: Our mobile services bring our skills to you, making it easy and convenient to work on-site.

Types of Metals and Materials Served

We work with a lot of different metals and materials, such as:

| Material | Description | Common Applications |

|---|---|---|

| Stainless Steel | Resistant to corrosion, durable | Food processing, medical equipment |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, automotive |

| Mild Steel | Strong, versatile | Construction, machinery |

Synergies in Fabrication and Welding

Fabrication and welding work together to manufacture things that are welded to order. Cutting, bending, and putting things together are all parts of fabrication. Welding connects things.

All of these procedures work together to enable us build complicated structures and parts that are exactly what our clients need. We make sure that our custom welding services give complete solutions that are sturdy and of high quality by being professionals in both fabrication and welding.

Service Capabilities: MIG & TIG in Custom Services

We provide custom welding using both MIG and TIG methods. This helps us meet a lot of our clients’ needs. We make sure that complex projects are of high quality by applying these methods.

Using MIG and TIG together for Custom Work

MIG and TIG welding can be used for a variety of projects. MIG welding works well for huge, easy jobs. TIG welding is suitable for work that needs to be very accurate and exact.

- MIG welding is the best way to get things done quickly and efficiently on big jobs.

- TIG welding for accuracy and detail in complicated designs

Shop and Equipment Capabilities

We have the newest technology in our store. This helps us keep projects on track from beginning to end. We make sure that our welding is of the highest quality.

Accuracy and Tolerance What you need

It is crucial to us that we meet criteria for precision and tolerance. We teach our team to observe stringent rules. This makes sure that all projects satisfy the needs of the client.

“Precision is key in custom welding. Our team is dedicated to delivering work that meets the highest standards.”

Time to Turnaround & Workflow

We work quickly to finish projects on time. Our workflow is more efficient. We also keep our clients up to date to make sure they are happy.

- Making plans and schedules for a project

- Effective execution and tracking

- Regularly updating and talking to clients

Safety, Standards & Quality Assurance

Our welding services are all about safety and excellence. We always follow the greatest safety rules and practices. This makes sure that our welding services are the best they can be.

Best Practices and Safety Procedures

Our safety plans keep our team and gear safe. We train our staff on a regular basis to keep them up to speed on welding and safety best practices.

Some important safety steps are:

- Welding requires personal protection equipment (PPE) for everyone.

- Regularly taking care of equipment to keep it from breaking down

- Properly storing and handling chemicals and materials

Standards and Codes That Matter

We follow standards set by groups like the American Welding Society (AWS) and the International Organization for Standardization (ISO). These guidelines assist make sure that our welding is safe and of excellent quality.

We follow AWS and ISO standards in the following areas:

- Qualification of welding procedures

- Welder qualification for performance

- Ways to check and test

Welding Procedure Specifications (WPS)

Our Welding Procedure Specifications (WPS) explain how we weld, what we use, and how we do it. These papers are very important for keeping our work high quality and consistent.

Testing, Inspections, and Certifications

We check and test our welds very carefully to make sure they are good. Our facilities have the latest testing equipment. Our crew is certified to check and test things according to the rules.

Here are some of the steps we take to inspect and test:

- Check with your eyes

- Testing with X-rays (RT)

- Testing using sound waves (UT)

- Testing of machinery

Final Thoughts

Businesses in many different fields can get reliable, affordable, and precise solutions from custom welding services in China. These services include anything from MIG and TIG welding to more modern methods like laser and robotic welding. They are made to satisfy the specific needs of each project while making sure that the work is strong, long-lasting, and efficient.

Construction, manufacturing, and automotive firms can get customized solutions, quick turnaround times, and strict quality standards that meet AWS and ISO certifications by partnering with an experienced welding partner. Custom welding in China can handle any job, big or small, with the correct tools and knowledge.

If your business requires reliable custom welding services in China, don’t wait—call us now to talk about your project needs and get a free estimate. Our team is ready to give you more than you expect in terms of accuracy, quality, and speed.

FAQs

What makes MIG and TIG welding different?

There are two types of welding: MIG (GMAW) and TIG (GTAW). A continuous wire and an inert gas protect the arc in MIG. For the weld, TIG uses a tungsten electrode that doesn’t wear out and an inert gas. We use MIG for thick materials and quick production. TIG is suited for thin materials and precise work.

What kinds of things can you weld with MIG and TIG?

We work with a lot of different materials, such as steel, aluminum, and stainless steel. We can work with different kinds and thicknesses of metal. This makes us useful in the building, industrial, and automobile industries.

Why are shielding gases important in welding?

Weld areas are protected by shielding gases like argon and helium. They stop problems that atmospheric gasses can create. For each type of welding and material, we pick the proper shielding gas.

How do you make sure that your welding services are safe and of high quality?

We stick to strict safety rules and best practices. We meet standards like ISO and AWS. We check and test our welds for quality on a regular basis, and our welders are certified.

Can you do custom welding work for hard projects?

Yes, we do bespoke welding work. For certain jobs, we use MIG and TIG welding. Our team makes sure that difficult projects are done with accuracy and quality, and that they are delivered on time.

What are the advantages of laser welding?

Laser welding is accurate, doesn’t use much heat, and doesn’t change the shape of the metal. It’s perfect for making precise and intricate welds. To better serve our customers, we stay up to date on innovative technology like laser welding.

What do you do with different sorts and thicknesses of metal?

Our crew knows how to work with different types and thicknesses of metal. For each material and thickness, we change the way we do things and the tools we use. This makes sure that the welds are of good quality.

How long does it usually take to finish bespoke welding jobs?

The time it takes to finish a project depends on how big, complicated, and what it’s made of. We help our clients make a plan for when things will happen. This makes sure that we meet their needs and get things done on time.

Welding FAQ

What is the difference between TIG and MIG welding?

TIG welding uses a non-consumable tungsten electrode and is a slower, more precise process that creates cleaner, higher-quality welds. MIG welding uses a continuously fed wire electrode and is much faster, making it more efficient for production and thicker materials.

Will welding distort my parts?

The heat from welding can cause some distortion. We minimize this by using proper fixturing, optimized welding sequences, and post-weld stress relieving when necessary.

What materials are the easiest to weld?

Mild steel and 300-series stainless steel are generally the easiest and most common materials to weld with excellent results.

Do you offer DFM analysis?

Aluminum has high thermal conductivity (which pulls heat away) and a surface oxide layer that must be thoroughly cleaned and removed for a quality weld. It requires specialized equipment (AC TIG) and a high level of operator skill.

Do you grind the welds smooth after welding?

We can! A standard weld is left “as-welded.” If you require a smooth, seamless finish for cosmetic reasons, please specify “grind welds smooth” on your drawing.

What is a "weld callout" on a drawing?

It is a standardized symbol that provides specific instructions to the welder, such as the type of weld (e.g., fillet, butt), the size of the weld, and its location.