Sheet Metal Gauge: The Importance for Sheet Metal Fabrication

Ever wondered about 18 gauge steel when you’re working with sheet metal? The term “gauge” is used a lot in metal work. But, it can be tricky if you’re new to it.

The sheet metal gauge is key for figuring out metal sheet thickness. It’s vital for tasks like building, making things, and engineering.

This article will cover the basics of sheet metal gauge. We’ll talk about its importance and how it’s used in metal projects. You’ll learn about its definition, how to measure it, and its uses in different fields.

Key Takeaways

- Understanding the concept of sheet metal gauge and its significance.

- Learning how to measure metal thickness using the gauge system.

- Discovering the importance of gauge in metal fabrication projects.

- Exploring the applications of sheet metal gauge in various industries.

- Understanding how to choose the right gauge for specific projects.

What Is Sheet Metal Gauge?

Sheet metal gauge is a measure of metal sheet thickness. It’s key to knowing how strong and durable the metal is. Gauges are used to specify the thickness of a sheet metal. It’s important to note that gauges are not standard or metric. Their values are unique and not tied to these systems.

The gauge concept is important in many fields like construction, manufacturing, and engineering. Knowing the gauge of sheet metal helps professionals pick the right material. This ensures the right balance between strength, weight, and cost for their projects.

Definition and Concept of Gauge

The gauge of sheet metal is a number that shows its thickness. A lower gauge number means a thicker sheet. On the other hand, a higher gauge number means a thinner sheet. This might seem confusing at first, but it’s a key part of working with sheet metal.

Different Gauge Systems

There are many gauge systems used, like manufacturers’ gauge systems and the American Wire Gauge (AWG) system. The AWG system is mainly for wire, but it’s also used for sheet metal sometimes. Different materials, like steel, aluminum, and copper, have their own gauge systems or charts.

It’s important to understand the differences between these gauge systems. This knowledge helps avoid mistakes in making and manufacturing. By knowing the specific gauge system used, professionals can make sure their projects meet the needed standards.

How to Read a Sheet Metal Gauge Chart

The sheet metal gauge chart is a key tool for converting gauge numbers to actual thickness. It’s vital for anyone working with sheet metal, in fabrication, construction, or manufacturing.

To use a sheet metal gauge chart well, you need to know the gauge number to thickness relationship. Generally, as the gauge number goes up, the thickness goes down. But this isn’t always true and can change with the material.

Gauge‑to‑Thickness Conversion (mm, inches)

Understanding gauge-to-thickness conversion is key. The chart shows the thickness in inches or millimeters for each gauge number. For example, 18-gauge steel is about 0.0478 inches or 1.214 mm thick.

It’s important to remember that different materials have different conversions. For example, 18-gauge aluminum is not the same as 18-gauge steel. This is why using the right chart for your material is so important.

Material‑Specific Charts (Steel, Aluminum, Copper)

Material-specific charts are a must because the gauge system changes with each material. For instance, the American Wire Gauge (AWG) system is used for non-ferrous materials like aluminum and copper. But steel has its own system.

When working with sheet metal, using the right chart for your material is critical. The wrong chart can lead to wrong thickness measurements. This could harm the structure of your final product.

By learning to read a sheet metal gauge chart and using the right chart for your material, professionals can work more accurately. This is true for fabrication, construction, or other uses.

Standard Sheet Metal Gauge Charts

To find the right metal gauge, you need to look at standard sheet metal gauge charts. These charts show the thickness of sheet metal by gauge numbers. The numbers change based on the material.

These charts are key for metalworking pros. They help pick the right material thickness for projects. They’re also handy when working with various materials, as gauge systems differ.

Steel Gauge Chart

The steel gauge chart is widely used. It lists gauge numbers and their corresponding steel sheet thicknesses in inches or millimeters. For example, a 10-gauge steel sheet is 0.1345 inches thick, while a 20-gauge sheet is much thinner at 0.0359 inches.

Here’s what a steel gauge chart might look like:

| Gauge Number | Thickness (inches) | Thickness (mm) |

|---|---|---|

| 10 | 0.1345 | 3.416 |

| 15 | 0.0673 | 1.709 |

| 20 | 0.0359 | 0.912 |

Aluminum / Non-Ferrous Gauge Chart

For aluminum and other non-ferrous metals, the gauge chart is different from steel. This is because these metals have different densities. An aluminum gauge chart gives the right thickness conversions for aluminum sheets.

Choosing the right gauge chart is critical for project success. Whether you’re working with steel, aluminum, or other metals, the correct standard sheet metal gauge chart ensures your project uses the right materials.

Why Choosing the Right Gauge Is Important

Choosing the right gauge is key because it affects the strength, durability, and cost-effectiveness of parts. The material thickness needed depends on your project’s nature and goals.

As

“The gauge of sheet metal is a critical factor that influences the overall performance and longevity of the final product.”

So, understanding gauge selection is vital for successful fabrication projects.

Strength and Durability

The gauge of sheet metal greatly impacts its strength and durability. Thicker gauges (lower numbers) offer more strength and resistance to bending. Thinner gauges (higher numbers) are more likely to bend or break under stress.

In construction, where safety is key, thicker gauges are often chosen for their durability and strength.

Weight and Cost Considerations

The gauge also affects the material’s weight and cost. Thicker gauges are heavier and pricier because they use more material. Thinner gauges are lighter and cheaper but may not be as strong.

- Thicker gauges: Heavier, more expensive, stronger

- Thinner gauges: Lighter, less expensive, potentially weaker

It’s important to find a balance between cost and performance in fabrication projects.

Application-Specific Gauge Selection

Each project needs a specific gauge based on its needs. For example, in car making, the gauge must be strong yet light to save fuel.

| Application | Typical Gauge | Reason |

|---|---|---|

| Construction | 10-14 gauge | Structural integrity and durability |

| Automotive | 16-20 gauge | Balance between strength and weight reduction |

Choosing the right gauge for your application ensures your product meets performance, safety, and cost standards.

How to Measure Sheet Metal Thickness

To get precise results in sheet metal work, knowing how to measure thickness is key. Accurate measurements are vital for making and using sheet metal in many fields.

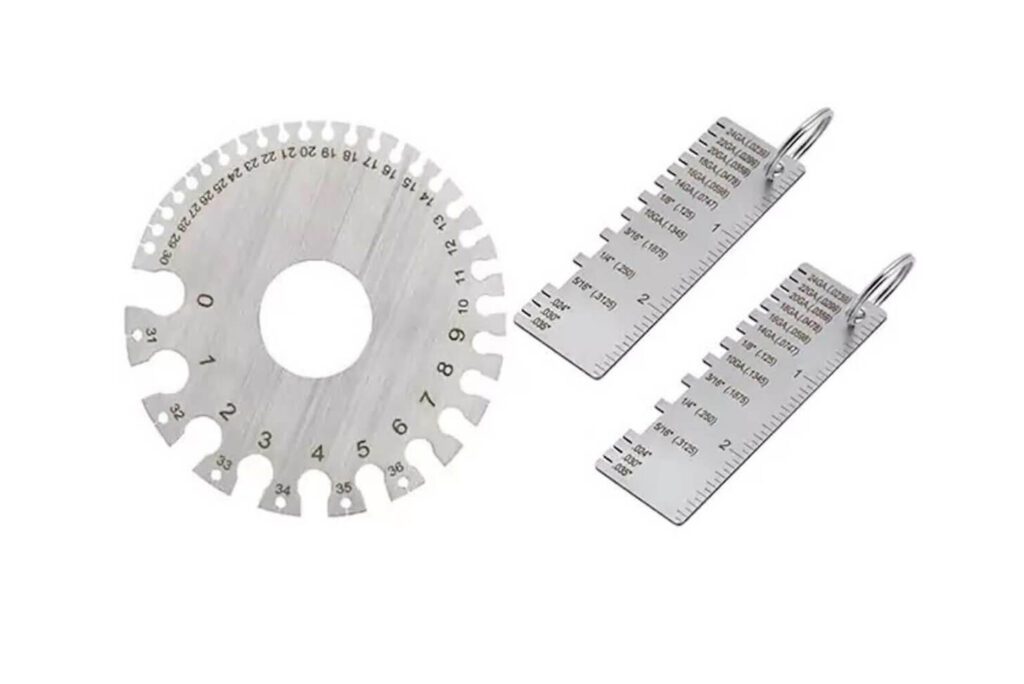

Tools for Measuring

There are several tools for measuring sheet metal thickness, each with its own benefits. The most common tools include:

- Micrometer: A precise tool for measuring sheet metal thickness. It gives accurate readings and works for many thicknesses.

- Gauge Wheel: A handy tool that shows sheet metal thickness in gauge numbers. It makes it easy to find a sheet’s gauge.

- Caliper: While not as precise as a micrometer, calipers can measure sheet metal thickness. They’re good for thicker sheets.

- Ultrasonic Thickness Gauge: An advanced tool that uses sound waves to measure thickness. It’s great when touching the metal is hard.

Accounting for Tolerance and Variability

When measuring sheet metal thickness, remember to consider tolerance and variability. Sheet metal making can cause thickness variations. Knowing these variations is key for using sheet metal right.

Tolerance: Manufacturers give a tolerance range for sheet metal thickness. It’s important to know this range for accurate measurements.

Variability: Things like rolling direction, material, and making processes can change sheet metal thickness. It’s important to account for these to measure and use sheet metal accurately.

Limitations of the Gauge System

The gauge system is widely used but has some big drawbacks. One major issue is its non-linear gauge numbers. This makes it hard to understand and use correctly.

Non-Linearity of Gauge Numbers

The gauge system’s history shows that gauge numbers go down as material thickness goes up. But, this isn’t a straight line. As gauge numbers go up, the thickness goes down, but not in a simple way. This can cause mistakes and confusion, which is a big problem when exact measurements are needed.

For example, the difference in thickness between gauge 10 and 11 isn’t the same as between gauge 20 and 21. This makes calculations tricky, which is a big issue when exact thickness matters. So, just using gauge numbers can lead to big errors.

Differences Among Materials / Standards

Another big problem with the gauge system is that standards vary by material. For instance, the same gauge number can mean different thicknesses for steel, aluminum, and copper. Steel gauge follows the Manufacturer’s Standard Gauge for Sheet Steel, while aluminum and copper have their own standards. This can cause confusion when working with different materials or unclear specifications.

Experts say, “The gauge number ’18’ means nothing without knowing the material and standard.” This shows how important it is to know the gauge system being used and check the material’s thickness to avoid mistakes.

In summary, while the gauge system is traditional for measuring material thickness, its flaws, like non-linearity and material differences, need careful thought and checks. This ensures accuracy in many situations.

Practical Tips for Designers & Fabricators

For designers and fabricators, picking the right sheet metal gauge is key to success. The metal’s type and thickness greatly affect the project’s quality, durability, and cost.

Specifying Gauge in Drawings

When making drawings, it’s vital to clearly state the sheet metal gauge. You need to mention the gauge number and make sure it fits the chosen material. Using standard gauge charts helps in making precise specs.

Designers should think about the application-specific requirements. They should check if the gauge they picked meets these needs. Talking to fabricators and suppliers is a good idea to confirm the gauge’s availability and suitability.

Confirming Actual Thickness with Suppliers

After specifying the gauge in drawings, it’s important to check the actual thickness with suppliers. The actual thickness might be a bit different from the gauge number.

- Ask for certification or documentation from suppliers to confirm the sheet metal’s thickness.

- Know the tolerance limits for the gauge and make sure the material is within these limits.

By following these tips, designers and fabricators can make sure their projects use the right materials. This reduces the chance of mistakes and ensures the project’s success.

Sheet Metal Gauge Conversion Tools

Sheet metal gauge conversion tools are key for figuring out the thickness of sheet metal. They help professionals change gauge numbers to metric measurements. This ensures projects meet their specs.

For fabricators and designers, knowing sheet metal thickness is vital. It affects both function and cost. Using conversion tools makes this easier, cutting down on mistakes that could waste material or weaken structures.

Online Gauge-to-mm / Inch Calculators

Online calculators are now a top choice for fast and accurate gauge conversions. They let users enter a gauge number and get the thickness in millimeters or inches right away. Their ease of use and availability make them a must-have for professionals needing precise sheet metal specs.

Key benefits of online gauge-to-mm/inch calculators include:

- Rapid conversion of gauge numbers to metric or imperial measurements

- Accessibility from any device with an internet connection

- Reduced risk of manual calculation errors

When to Use Conversion Charts vs. Physical Measurement

Conversion charts and online calculators are great, but sometimes physical measurement is better. For example, when you need exact measurements or don’t know the gauge number, using tools like micrometers or calipers is best.

Consider physical measurement in the following scenarios:

- When high precision is required for critical applications

- If the material’s gauge number is uncertain or unavailable

- In situations where material thickness directly impacts performance or safety

In conclusion, tools like online calculators and conversion charts are essential for planning projects well. But knowing when to use these tools versus physical measurement is also key. This ensures the highest precision and meets project needs.

FAQ – Sheet Metal Gauge

Sheet metal gauge is key in metal fabrication, with many FAQs important for success. Knowing these can greatly affect a project’s outcome, from start to finish.

Is Gauge the Same Across All Metals?

No, the gauge system varies by metal. Each material has its own gauge system due to its properties and history. For example, steel, aluminum, and copper have unique gauge charts because of their different uses and properties.

- Steel Gauge: Typically follows the Manufacturer’s Standard Gauge for Sheet Steel.

- Aluminum and Non-Ferrous Metals: Often uses a different gauge system, which can be based on the AWG (American Wire Gauge) for some applications.

It’s important to use the right gauge chart for the material. The wrong chart can cause errors in thickness, affecting the project’s quality.

Can You Substitute Gauge Between Materials?

Substituting gauge between materials is not recommended without careful thought. Different materials have different gauge systems, leading to differences in thickness. This can affect the project’s strength and performance.

For example, a 16-gauge steel sheet is thicker and stronger than a 16-gauge aluminum sheet. Always check the gauge charts for the materials you’re using to ensure the right thickness and properties.

How Accurate Is Gauge vs Metric Measurement?

The accuracy of gauge versus metric measurement varies by context. Gauge measurements are traditional, while metric measurements are more precise and universal.

Gauge can be less accurate due to its non-linear scale and material-specific variations. Metric measurements (in mm or inches) provide a direct and precise thickness, making them more reliable for critical applications.

Key Considerations:

- Use gauge charts for initial estimates and material-specific applications.

- Opt for metric measurements for precise thickness requirements.

- Always verify the actual thickness with suppliers to ensure it meets the project’s specifications.

Understanding sheet metal gauge and its measurement helps professionals make better decisions. This ensures the quality and success of their projects.

Conclusion

Knowing about sheet metal gauge is key for project success. The gauge system is complex but standardizes sheet metal thickness. This affects the product’s strength, durability, and cost.

Understanding how to read a gauge chart and the differences in systems is vital. It helps fabricators and designers make better choices. This leads to better project results.

Using the right tools, like micrometers and gauge wheels, is important. It ensures accuracy and quality in work. Knowing the system’s limits, like non-linearity and material differences, is also critical.

As the fabrication world grows, knowing about sheet metal gauge is more important. It helps professionals make high-quality products efficiently and at a good price.

FAQ

Is gauge the same across all metals?

No, gauge is not the same for all metals. Each material has its own gauge system. The same gauge number can mean different thicknesses in different materials.

Can you substitute gauge between materials?

No, you shouldn’t swap gauge between materials. The same gauge number can have different meanings in different materials. This can lead to errors.

How accurate is gauge vs metric measurement?

Gauge measurements might not be as precise as metric ones. Gauge numbers don’t always match exact thicknesses. Yet, gauge is widely used and accepted in many fields.

What is the difference between AWG and sheet metal gauge?

AWG is for measuring wire diameter, while sheet metal gauge is for sheet metal thickness. They’re related but different. The same gauge number can mean different things in each system.

How do I convert gauge to millimeters or inches?

To convert gauge to millimeters or inches, use a gauge conversion chart or calculator. These tools show the thickness for a given gauge number and material.

Why are there different gauge charts for different materials?

Different materials have different gauge charts because the same gauge number can mean different things in each material. Using the right gauge chart ensures accurate measurements.

What is the tolerance for sheet metal gauge measurements?

Gauge measurement tolerance varies by material, manufacturing process, and industry standards. Always check the specific specifications and tolerances for your application.

Can I use a gauge wheel to measure sheet metal thickness?

Yes, a gauge wheel can measure sheet metal thickness. But make sure the gauge wheel is calibrated correctly and fits the material you’re measuring.

How do I specify gauge in my drawings?

When specifying gauge in drawings, include the material type, gauge number, and any relevant tolerances or specifications. This avoids confusion or misinterpretation.