Home » CNC Machining Materials: Metals and Plastics

CNC Machining Materials: Metals and Plastics

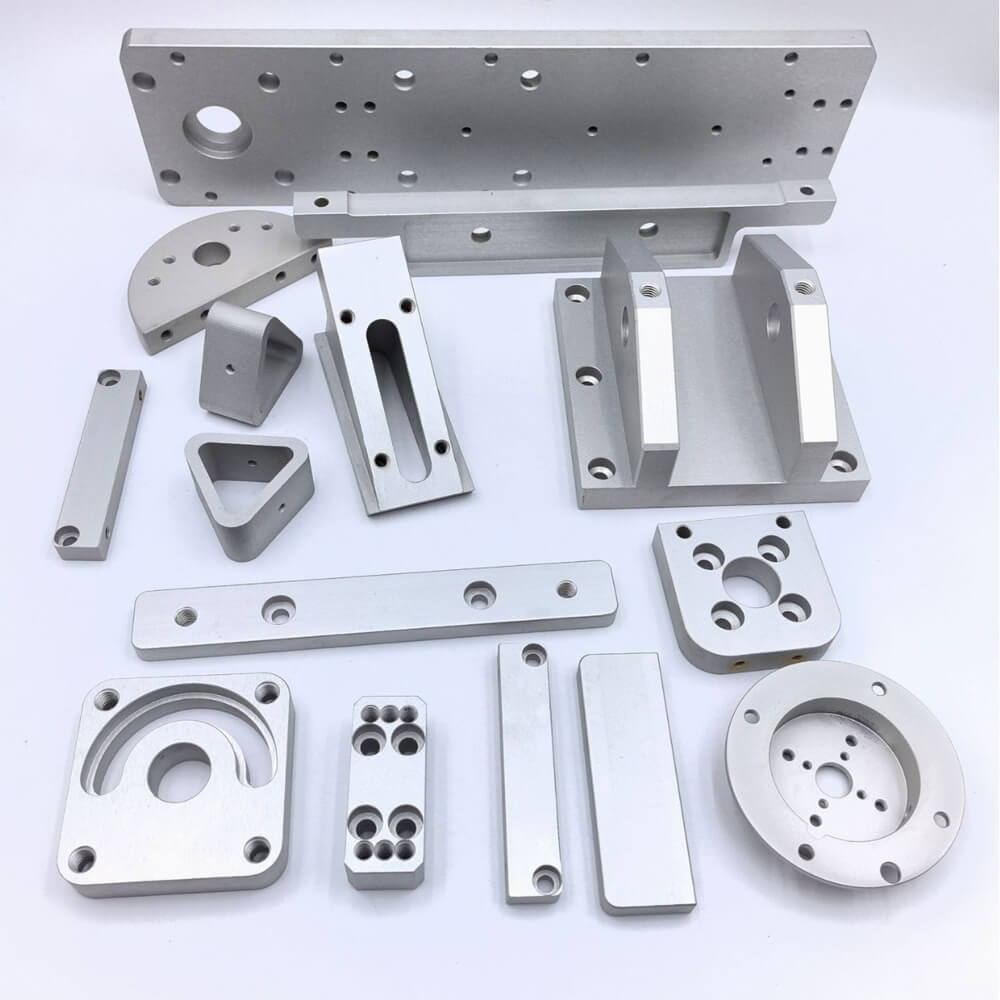

Check out the wide range of metals and engineering plastics we have in stock. We have the right materials for your project, whether you need PEEK that works well or aluminum that is light.

The Right Material for Every Application

Choosing the right material is one of the most important things to do when making something. It directly affects a part’s strength, weight, durability, chemical resistance, and cost. We have a lot of different types of metals and plastics at Celerity Precision, and we can help you choose the best one for your needs and budget.

Explore Our Material Library

Metals

A selection of our most commonly machined metals, chosen for their excellent mechanical properties and versatility.

Aluminum

A lightweight, versatile metal with an excellent strength-to-weight ratio.

Stainless Steel

Offers exceptional corrosion resistance, high strength, and a premium finish.

Steel

The workhorse of industry, offering high strength and durability at a low cost.

Titanium

The ultimate high-performance metal with unmatched strength-to-weight and biocompatibility.

Brass

An easy-to-machine alloy with a natural gold-like appearance and low friction.

Copper

The standard for electrical and thermal conductivity, ideal for heat sinks and busbars.

Bronze

A tough, wear-resistant alloy with superior bearing properties for industrial use.

Magnesium

The lightest of all structural metals, for applications where every gram counts.

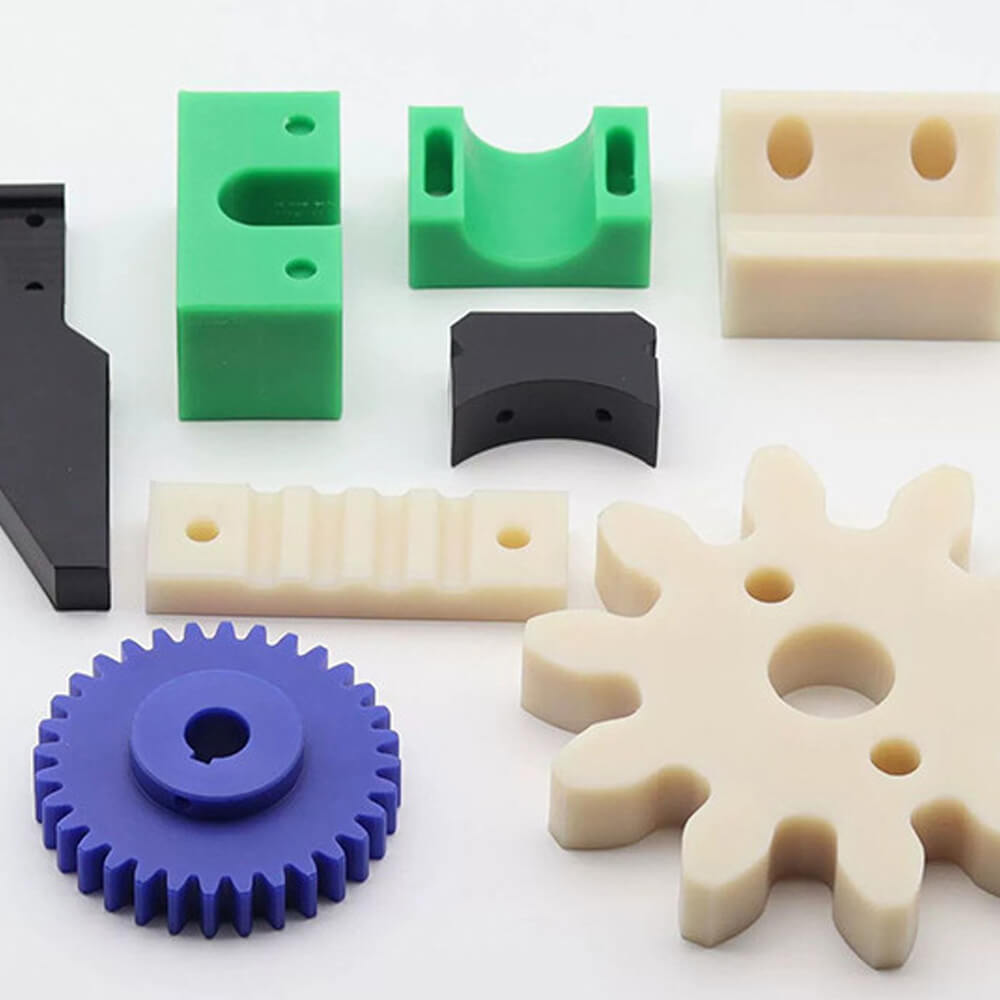

Plastic

From general-purpose prototypes to high-performance engineering components, we machine a full spectrum of polymers.

ABS

A tough, cost-effective plastic ideal for durable prototypes and housings.

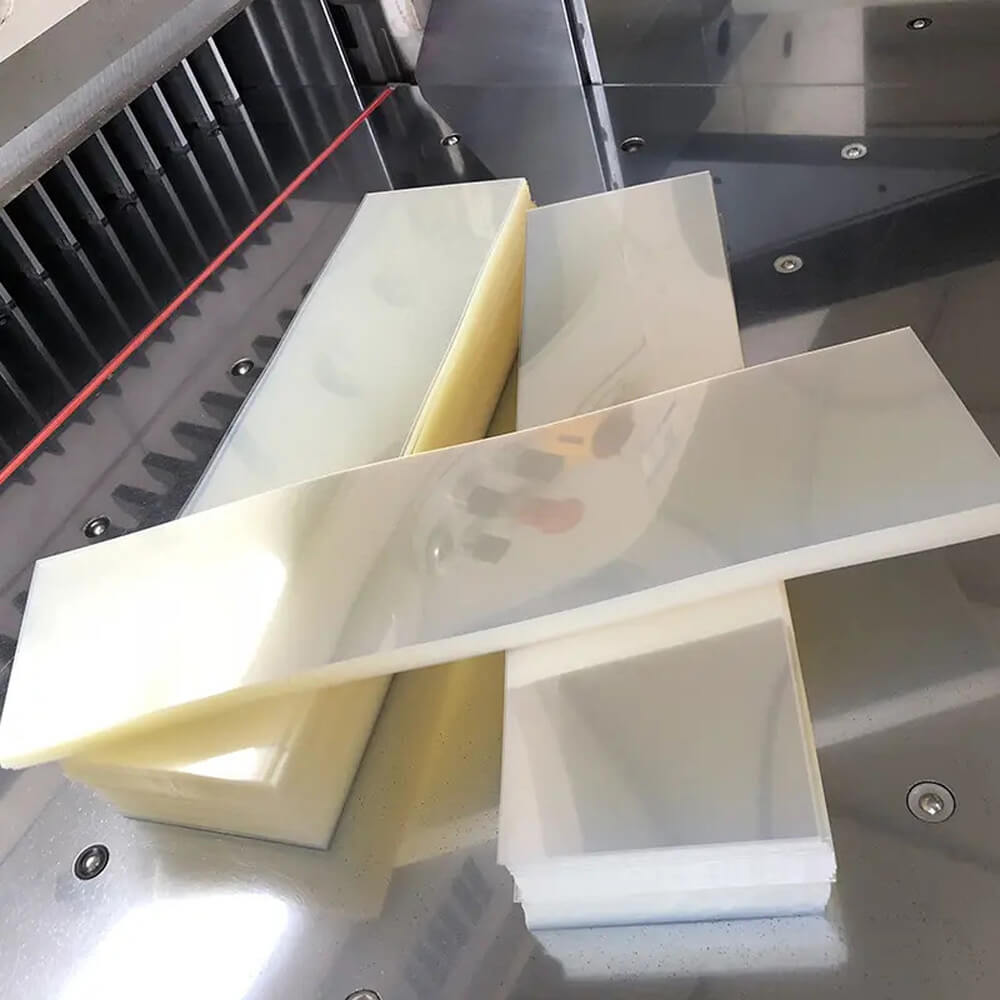

PC (Polycarbonate)

A shatter-resistant, transparent plastic ideal for strong, clear components.

PLA

A low-cost, biodegradable plastic perfect for rapid concept models.

PMMA (Acrylic)

An optically clear plastic with a glass-like finish, perfect for lenses and light pipes.

POM (Delrin/Acetal)

A stiff, low-friction engineering plastic perfect for precision mechanical parts.

PA (Nylon)

An exceptionally tough and wear-resistant plastic for gears, rollers, and wear pads.

PE (Polyethylene)

A durable and chemically resistant plastic available in LDPE, HDPE, and UHMW grades.

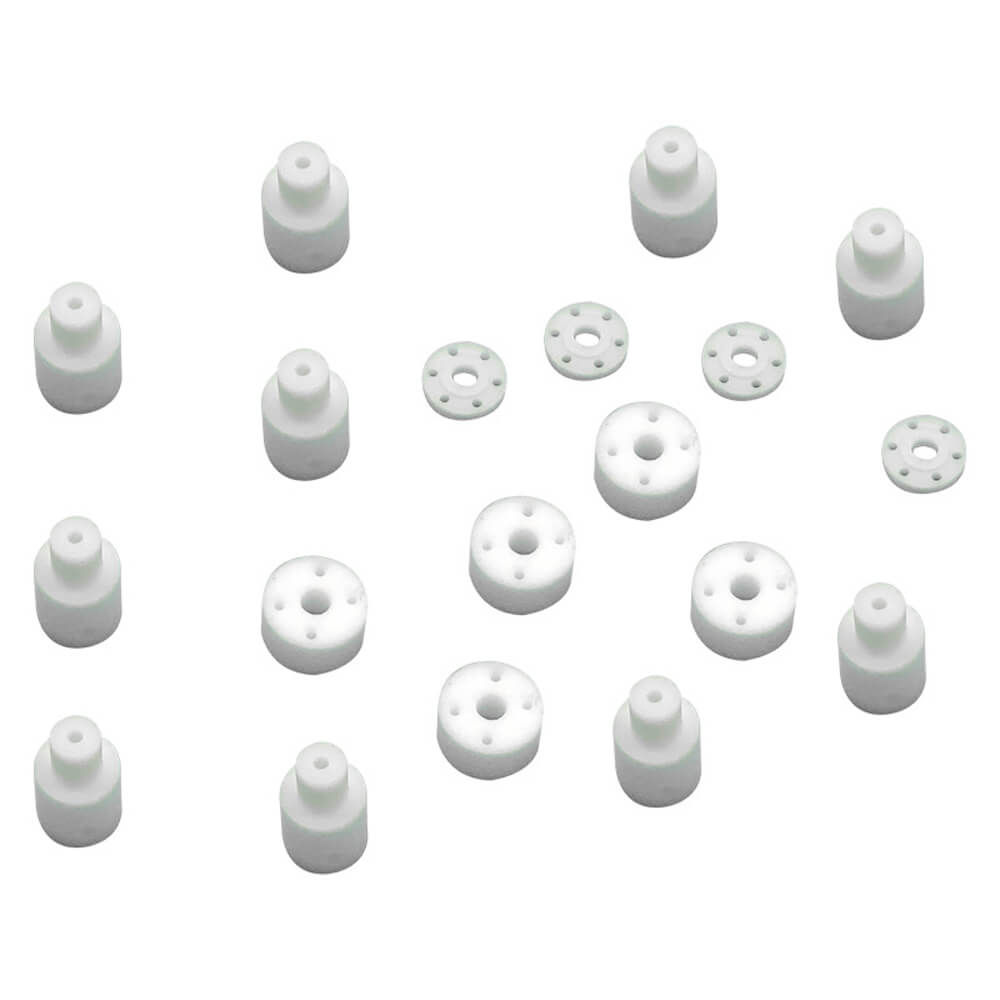

PEEK

An ultra-high-performance polymer for extreme temperature and chemical environments.

PP (Polypropylene)

PP (Polypropylene) A lightweight and tough plastic with superior chemical resistance.

HIPS

A low-cost, impact-resistant plastic ideal for pre-production prototypes.

PBT

A stiff, stable engineering plastic with excellent electrical insulating properties.

PPA

A high-performance polyamide that retains strength at high temperatures.

PAI (Torlon®)

The pinnacle of performance plastics with extreme strength and heat resistance.

PET

A strong, stable, and wear-resistant plastic ideal for food-grade applications.

PPS

A high-performance polymer with unmatched chemical and thermal resistance.

PS (Polystyrene)

A low-cost, clear plastic perfect for non-functional concept models.

PVC

A durable, cost-effective plastic with outstanding chemical and corrosion resistance.

PTFE (Teflon™)

The ultimate non-stick, chemically inert material for seals and insulators.

Bakelite

A hard, heat-resistant thermoset with excellent electrical insulating properties.

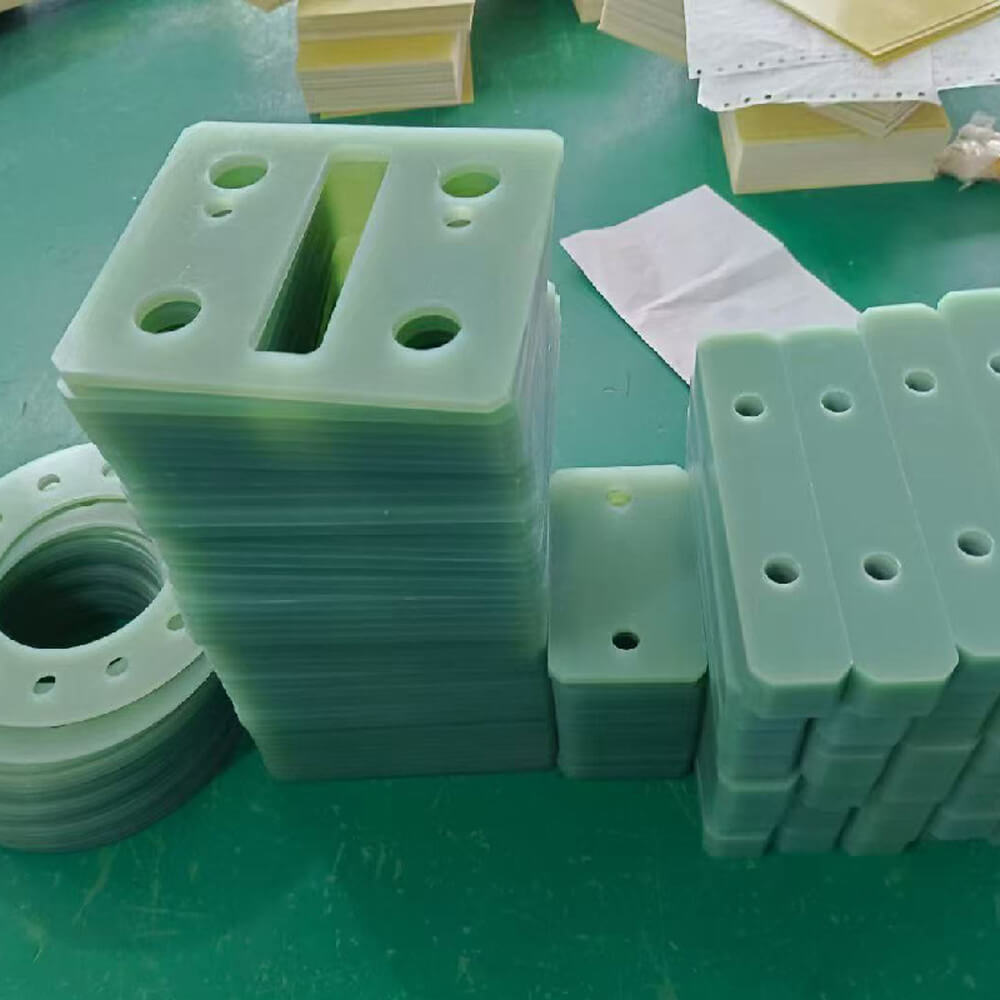

FR-4

A glass-epoxy composite with high strength and superb electrical insulation.

Our Capabilities: From Materials to Custom Parts

As soon as you pick the material you want, our state-of-the-art facility is ready to make your finished part. We provide all the manufacturing services you need to turn your design into a reality.

- CNC Machining is a way to make parts by removing material with a computer.

- CNC milling is a type of machining that uses rotating cutting tools to take material off of a stationary workpiece.

- CNC Turning is a method of making cylindrical parts by using a stationary cutting tool to shape a rotating workpiece.

- Sheet metal fabrication is the process of cutting, bending, and putting together thin sheets of metal.

- Welding is a way to join metal parts by using heat, pressure, or both to make useful parts.

- Laser cutting is a very precise way to cut metal sheets into certain shapes using a focused laser beam.

- Bending is a process that uses force to shape sheet metal into angles or curves..

- Die casting is a way to make parts in large quantities and with a lot of detail by injecting molten metal into a mold.

- Precision Casting is a method of casting that uses detailed molds to make metal parts that are very accurate and complex.

A Perfect Surface Finish for Every Material

The last step in getting a part ready for production is to put on the right finish. We offer a lot of different treatments to make things work better and look better. These include long-lasting anodizing for aluminum, important passivation for stainless steel, and cosmetic powder coating and painting for almost any material. Our integrated process guarantees that your parts are perfectly prepared and finished to the highest standard.

Industries Served by Our Materials

We make parts for some of the most demanding industries in the world, where picking the right materials is very important. We know that your field has its own set of material problems. For example, Aerospace needs materials that are strong but light, Medical devices need materials that are safe for living things, and Automotive needs materials that last a long time.

Celerity Precision is More Than Just a Material Supplier

Extensive In-Stock Inventory

We keep a lot of the most common materials and grades on hand, so we can start your project right away and cut down on lead times.

Expert Engineering Guidance

Unsure which alloy or polymer is best? Our engineering team can provide expert recommendations based on your application, stress requirements, and budget.

Full Material Traceability

We get our materials from certified, trustworthy suppliers and can give you full material certifications (MTRs) for your project to make sure it meets all quality and safety standards.

Specialized Sourcing

If your project needs a rare or unique material that isn't on the list, our expert sourcing team can get it for you through our well-established supply chain.

CNC Machining Materials: Metals and Plastics - Celerity Precision

What if the right material could make or break the success of your project? When making parts and pieces, picking the right material is just as important as the process of making them.

We use precise methods to make parts for many different uses, and CNC machining is known for being both flexible and accurate. We can make parts out of different metals and plastics quickly and cheaply with this method.

The metals and plastics you choose for CNC machining are very important for the quality, durability, and function of the finished product. We can make the best choices for our projects if we know what different materials are good for and what they can do.

Key Takeaways

- Choosing the right materials is very important in CNC machining.

- Different kinds of metals and plastics have different properties.

- Choosing the right materials will affect how well the final product works and how good it looks.

- CNC machining makes it possible to make things quickly and cheaply.

- To get the results you want, you need to know how materials work.

Introduction to CNC Machining Materials

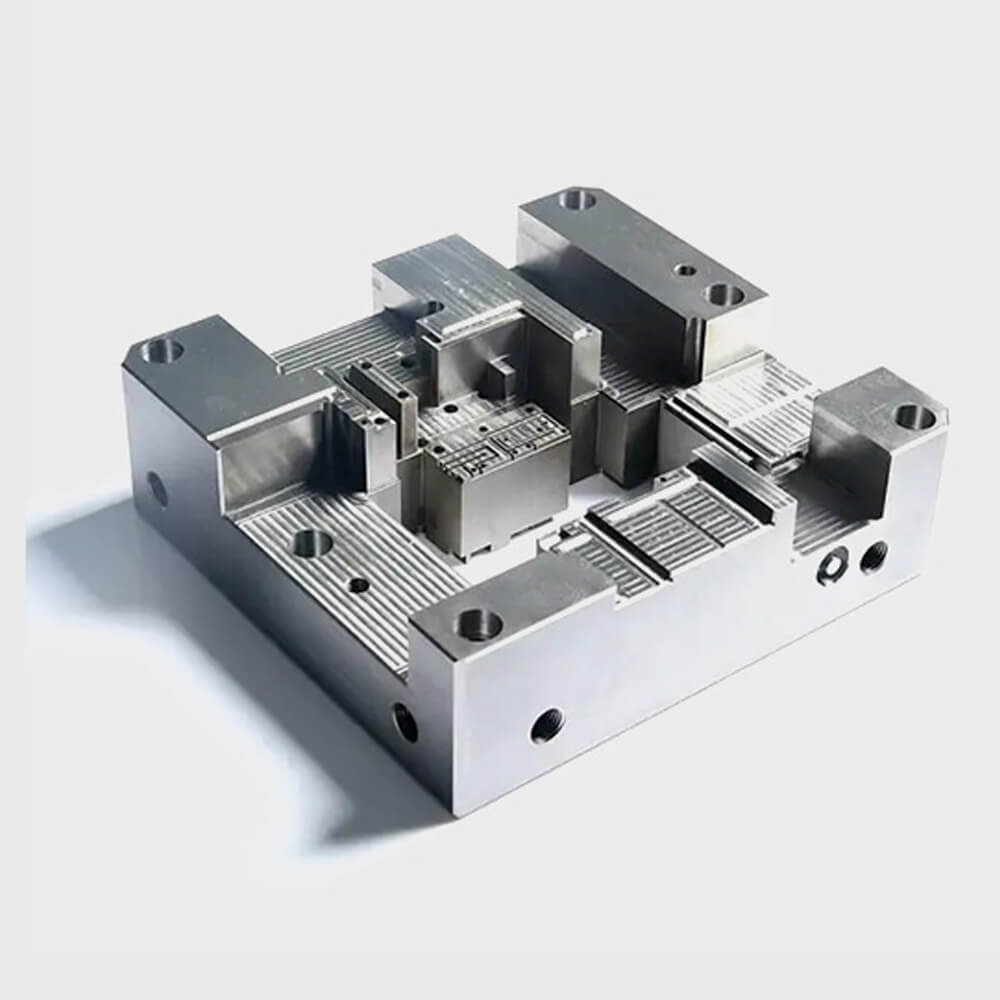

CNC machining has changed the way things are made. It helps us make very precise parts that are very complicated. This tech boost has made us more productive and cut down on mistakes, which is very important in today’s factories.

What is CNC machining?

Computers control machine tools in CNC machining. We can make parts out of metals and plastics with great accuracy. This lets us make parts with precise designs and tight fits that meet the needs of many industries.

Why Choosing the Right Material is Important in CNC Machining

In CNC machining, picking the right material is very important. It has an effect on how well a part works, how long it lasts, and how much it costs. Aluminum and stainless steel are two examples of metals that are strong and don’t rust. Plastics like ABS and polycarbonate are light and bendable.

CNC Machining: Metals vs. Plastics

When it comes to CNC machining, metals and plastics each have their own pros and cons. Metals are strong and durable, perfect for high-stress jobs. Plastics are flexible and cheaper, great for many uses, from everyday items to aerospace parts. Knowing the differences helps pick the best material for a project.

Material Selection Criteria

Choosing the right material for CNC machining is very important. The quality, durability, and cost of the product depend on the material. When we choose materials, we think about a lot of important things.

Mechanical Properties (Strength, Hardness, Wear)

The material’s mechanical properties are very important. It’s very important that things are strong, hard, and resistant to wear. Steel and titanium are strong and long-lasting, making them great for cars and planes.

Titanium is also a great choice for planes because it is strong, light, and doesn’t rust easily.

An expert in the field says, “The right material can make all the difference in how well a product works and how long it lasts.” This is true for parts that get a lot of use. Bronze or brass is a good choice because it lasts a long time and doesn’t rust.

Machinability and Cost Consequences

Machinability is how simple it is to work with a material. We think about how fast the tool cuts, how much wear it gets, and how good the finish is. Brass and aluminum are easy to work with, which saves time and money.

People like aluminum because it is easy to work with and light. It’s great for places where you need to lose weight.

Thermal, Chemical, and Environmental Factors

Materials react differently to heat and chemicals. Stainless steel or titanium are the best choices for places with high temperatures or corrosive conditions. Copper is a good material for moving heat around because it does so well.

| Material | Thermal Conductivity | Corrosion Resistance |

|---|---|---|

| Copper | High (~385–400 W/m·K) | Fair |

| Stainless Steel | Low (~15–25 W/m·K) | Excellent |

| Titanium | Low (~15–22 W/m·K) | Excellent |

Availability, Stock Sizes, and Grades

It’s also important that the materials are easy to get. We check grades and lead times to make sure things get there on time. Some grades of aluminum are easier to find than others, which can change schedules.

In the end, it is hard to choose the right material for CNC machining. We think about the availability, mechanical properties, machinability, and thermal and chemical factors. This makes sure that we make parts that are high quality and meet all the requirements.

Metals for CNC Machining

Choosing the right metal for CNC machining is important for getting the right performance, cost-effectiveness, and ease of manufacturing. Different metals have different properties, such as strength, weight, machinability, resistance to corrosion, cost, and others.

We will look at some of the most common metals used in CNC operations below: aluminum, stainless steel, steel (carbon and alloy), titanium, brass, copper, bronze, and magnesium.

Aluminum

Aluminum is a very popular metal for CNC machining because it is strong for its weight, easy to work with, and resistant to corrosion.

Advantages

Lightweight (density ~2.70 g/cm³), perfect for applications where weight matters

High machinability, especially for alloys like 6061 and 5052

Good resistance to corrosion, especially when anodized

Good weldability

Considerations

Some strong alloys, like 7075, are harder to weld or anodize.

Aggressive environments may require extra surface treatment.

Applications

Parts for airplanes, electronics cases, car parts, and fixtures

Stainless Steel

When strength, durability, and resistance to rust are important, stainless steel is used.

Advantages

Very good at resisting corrosion, especially grades 304 and 316

Good strength and resistance to wear in a range of situations

Considerations

Less machinable than softer metals, and tools wear out faster.

Costs of materials and machining are higher.

Applications

Equipment for processing food, hardware for boats, medical devices, and structural parts that get a lot of use

Steel

People often choose carbon steel and alloy steels because they are strong, cheap, and easy to find.

Advantages

Strong and long-lasting tensile strength

Good for parts that hold up structures and carry loads

Many grades can be heat-treated to make them better.

Considerations

Less resistant to corrosion (needs coating or alloying)

Different grades and heat treatments affect how easy it is to machine.

Applications

Shafts, gears, machine frames, and structural parts

Titanium

Titanium and its alloys, like Ti-6Al-4V, are high-quality materials that are used in important and high-performance applications.

Advantages

Very good strength-to-weight ratio

Very good at resisting corrosion

Compatible with living things (great for medical implants)

Considerations

Hard to machine (low machinability, high tool wear)

High cost of materials and machining

Applications

Parts for planes, medical implants, and high-performance car parts

Brass

Brass (an alloy of copper and zinc) is chosen because it is easy to work with, doesn’t rust, and looks nice.

Advantages

Great machinability and a smooth surface finish

Looks nice in gold and yellow

Good resistance to corrosion

Considerations

Not as strong as steel

Costs a little more and needs careful tooling to keep from sticking.

Applications

Electrical connectors, valves, fittings, decorative hardware, and musical instruments

Copper

Copper is very valuable because it conducts electricity and heat very well, which makes it perfect for making precise electrical parts.

Advantages

Very good at conducting electricity and heat

Very good ductility and malleability

Considerations

Soft and ductile, which makes it hard to machine cleanly (burrs and sticking).

More expensive and wears out tools faster than steels

Applications

Electrical bus bars, connectors, heat exchangers, and decorative items

Bronze

Bronze, which is copper mixed with tin or other metals, is used for things that need to be resistant to wear and corrosion.

Advantages

Good resistance to wear and rust

Many bronze alloys can be worked with moderate ease.

Best for parts that rub against or slide against each other

Considerations

Moderate mechanical strength in comparison to steels

Some grades of bronze are harder to work with.

Applications

Bushings, bearings, valves, and parts for boats

Magnesium

Magnesium is the lightest structural metal that is often used in CNC machining. It has a lot of potential for reducing weight.

Advantages

Very low density (about 1.74 g/cm³) and a high strength-to-weight ratio

Good machinability (works with a lot of aluminum machining setups)

Considerations

Chips that catch fire—need to be handled carefully while being machined

Less resistant to corrosion, usually needs a surface coating

Applications

Lightweight housings, parts for cars and planes, and structural parts for the aerospace and automotive industries

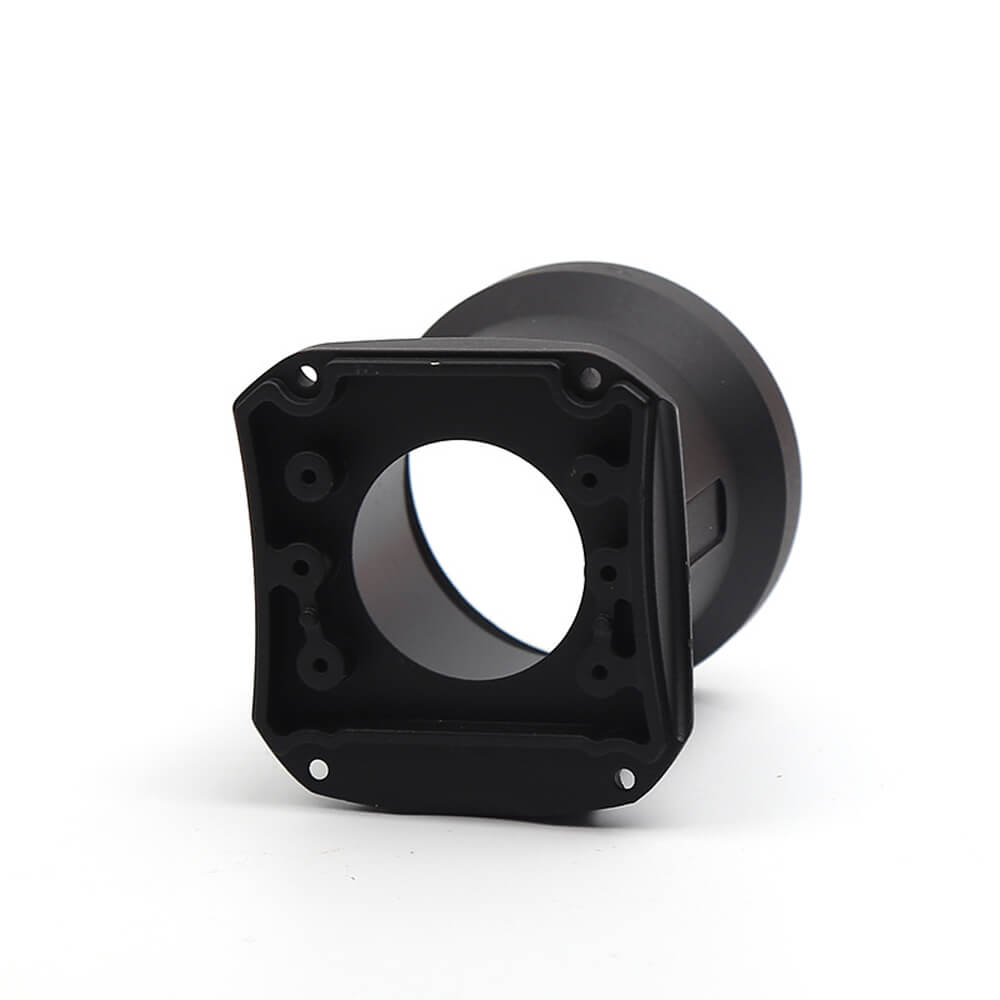

Plastics for CNC Machining

Choosing the right plastic material is just as important as choosing the right metal when CNC machining plastics. Plastics have different levels of strength, how they react to heat, how easy they are to work with, how much moisture they absorb, how resistant they are to chemicals, and how much they cost. We will look at a wide range of plastics below, from common commodity plastics to high-performance engineering plastics, and see how they work in CNC machining.

ABS (Acrylonitrile Butadiene Styrene)

CNC machining often uses ABS as a thermoplastic. It has a good mix of cost, machinability, and mechanical performance.

Advantages

Good toughness and resistance to impact.

Easy to work with and has a nice finish.

Cheap for making prototypes and production parts.

Considerations

Lower heat deflection temperature than plastics that work better.

May need careful tooling and cooling to keep from melting or warping while being machined.

Applications

Common uses include parts for consumer electronics, appliances, and the inside of cars..

PC (Polycarbonate)

Polycarbonate is a clear (or colored) plastic that is known for being strong and clear.

Advantages

Very tough and has good optical properties.

Considerations

Machining needs to pay attention to tool marks, heat generation, and chip removal.

Applications

Some common uses are lenses, guard covers, and clear parts for machines.

PLA (Polylactic Acid)

PLA is a biodegradable plastic that is more common in 3D printing, but it can also be CNC machined in some situations.

Advantages

PLA comes from plants, so it’s sustainable, and it’s easy to process.

Considerations

It doesn’t hold up as well to heat and isn’t as good for tough mechanical or thermal uses; it may shrink or change shape.

Applications

Common uses include prototypes, parts that don’t need a lot of stress, and parts for learning.

PMMA (Acrylic)

Acrylic, which is often called “Plexiglas,” is a clear thermoplastic that has a good finish and good optical clarity. It machines well for parts that need a smooth, shiny finish.

Advantages

Very clear, good finish, and easy to polish.

Considerations

It’s more brittle than many engineering plastics, so it needs to be carefully fixed to avoid cracking.

Applications

Common uses include light covers, displays, and clear housings.

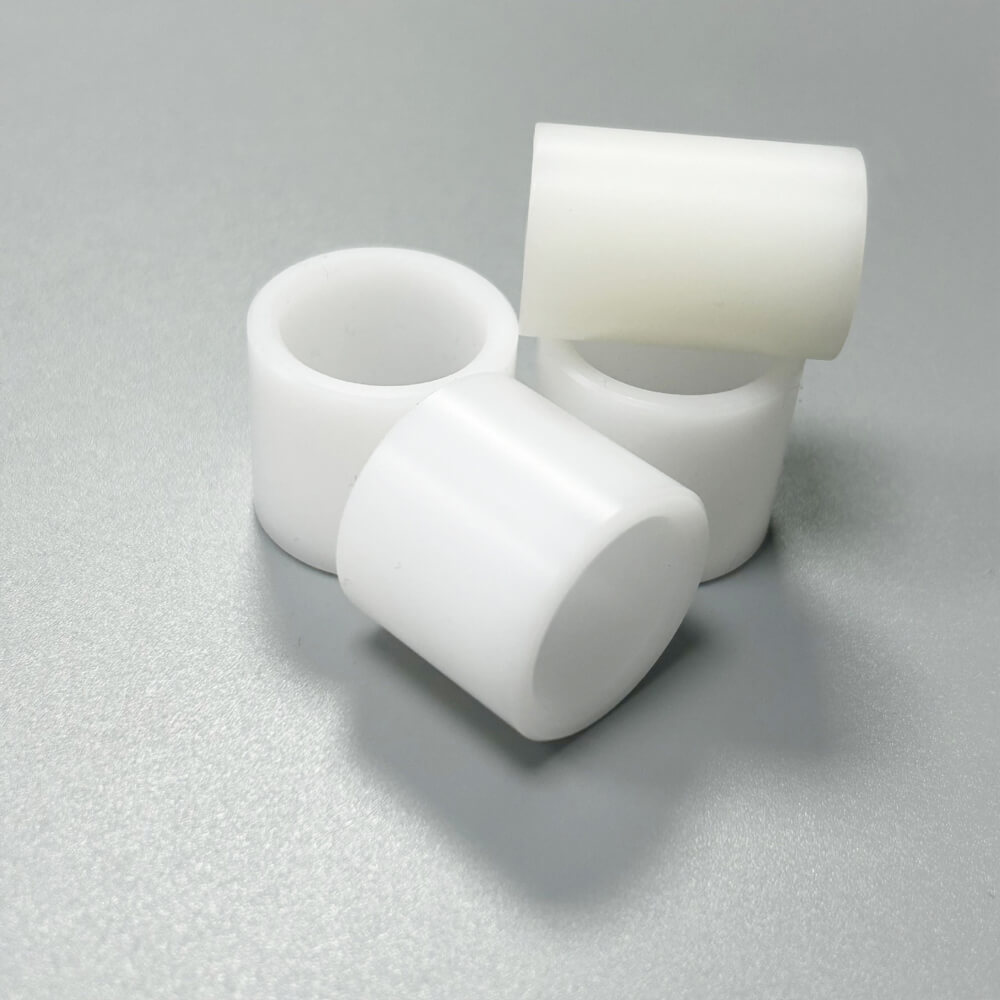

POM (Delrin / Acetal)

Polyoxymethylene (POM) is a hard engineering plastic that doesn’t wear down easily and has low friction.

Advantages

Easy to machine, low friction, and good dimensional stability.

Considerations

You might need to choose the right tools, and for some grades, moisture uptake and creep might be important.

Applications

Common uses include gears, bearings, sliding parts, and structural machined parts.

PA (Nylon)

Nylon (polyamide) is a type of engineering plastic that is strong, resistant to wear, and easy to work with.

Advantages

Strong, resistant to wear and tear, and works well mechanically.

Considerations

It can soak up moisture, which can change its size; machining and finishing must be done carefully.

Applications

Common uses include bushings, sliding parts, and other functional parts in industry.

PE (Polyethylene)

Polyethylene (PE) is a common type of plastic that is often used to machine large, simple parts or in low-stress situations.

Advantages

It is cheap, easy to work with for simple shapes, and has great chemical resistance.

Considerations

Low stiffness, may bend or break under load or heat, and may need special fixtures or design precautions.

Applications

Tanks, chemical containers, liners, and simple structural parts in CNC plastic machining.

PEEK (Polyether Ether Ketone)

PEEK is an engineering plastic that works very well. It’s one of the best options for CNC-machined plastic parts that need to be very strong.

Advantages

Great at resisting heat (can be used at high temps all the time).

Great dimensional stability and strong resistance to chemicals.

With the right setup, it is easy to machine precision parts.

Considerations

A lot more expensive than regular plastics.

Machining needs skill, tools, and careful management of the process.

Applications

Parts for aerospace, medical implants, chemical processes, and bearings that work at high temperatures..

PP (Polypropylene)

PP is another type of commodity plastic that can be easily worked with and is resistant to chemicals.

Advantages

Cheap, resistant to chemicals, and light.

Considerations

Not as stiff or strong as engineering plastics; can handle moderate heat.

Applications

Common uses include housings, containers, and non-critical mechanical parts.

HIPS (High Impact Polystyrene)

HIPS is a type of polystyrene that has been changed to make it stronger against impacts. It is often used in prototypes and consumer goods.

Advantages

Good for machining at a low cost, good surface finish, and easy to paint or coat.

Considerations

It doesn’t resist heat or mechanical stress as well as many engineering plastics.

Applications

Common uses include parts for prototypes, display components, and low-load housings.

PBT (Polybutylene Terephthalate)

PBT is a type of plastic used in engineering that is often used to make parts by injection molding, but it can also be machined for moderate strength and stability.

Advantages

It has good electrical insulation, decent mechanical performance, and in many cases, it can be machined easily.

Considerations

Freeform CNC may need to be dried out if it absorbs moisture, which is less common than with metals or simpler plastics.

Applications

Common uses include housings with moderate mechanical loads, electrical connectors, and insulators.

PPA (Polyphthalamide)

PPA is a polyamide (nylon family) that works better and can handle heat and stress better.

Advantages

It can handle higher temperatures and is stronger than regular nylon.

Consideration

higher cost, fewer machining references, and the need to carefully choose the tools and settings needed.

Applications

Parts for cars that go under the hood, electronics parts, and structural parts in places with high heat.

PAI (Torlon®)

Polyamide-imide (PAI), like Torlon®, is one of the best plastics for machinability.

Advantages

Very strong mechanically, stable in heat, and resistant to chemicals.

Considerations

Very high cost, difficult machining requirements, and fewer suppliers of machined stock.

Applications

Typical uses include aerospace, parts that need to work at high temperatures, and bearings and bushings that need to work in very harsh conditions.

PET (Polyethylene Terephthalate)

PET is a common material for machining parts that need moderate strength, good machinability, and a low cost.

Advantages

It is stiff and easy to work with, and it is widely available.

Considerations

Moisture absorption can change properties, and the finish and stability may need to be treated again.

Applications

Common uses include housings, structural supports, and parts that aren’t too heavy.

PPS (Polyphenylene Sulfide)

PPS is a thermoplastic that works well, resists chemicals, and stays stable at high temperatures.

Advantages

Works well in chemical environments that are hard on machines and in situations where mechanical loads are moderate.

Considerations

It may cost more and require a complicated machining setup.

Applications

Common uses include parts for chemical processing, parts for cars that go under the hood, and parts for electrical and insulation work.

PS (Polystyrene)

PS (polystyrene) is a cheaper type of plastic that is used to make parts that don’t need a lot of mechanical work.

Advantages

Low cost, easy to machine for simple shapes, and a nice surface finish.

Considerations

Comparatively brittle, low heat resistance, and limited ability to handle mechanical loads.

Applications

Common uses include prototypes, display parts, and housings or covers that don’t need a lot of weight.

PVC (Polyvinyl Chloride)

People use PVC a lot in sheets, tubing, and machined parts because it is resistant to chemicals.

Advantages

It is cheap, widely available, and has great resistance to chemicals.

Considerations

Machining can make harmful fumes, so good ventilation is needed. It also has moderate mechanical strength.

Applications

Common uses include parts for chemical processing, conduit, and housings in situations with low mechanical load.

PTFE (Teflon™)

PTFE (polytetrafluoroethylene) is known for being very resistant to chemicals, having very little friction, and being able to lubricate itself.

Advantages

It can handle high temperatures, has very little friction, and is very resistant to chemicals.

Consideration

It’s hard to machine to tight tolerances because it’s soft, creeps, and has bonding problems. Special tools and processes are needed.

Applications

Common uses include seals, bushings, chemical valves, and high-performance bearings.

Bakelite (Phenolic)

Bakelite is a thermoset material (phenolic resin) that was used in the past for electrical and mechanical parts.

Advantages

Good electrical insulation, heat resistance (for a thermoset), and stability under load.

Considerations

It is brittle and has limited ductility, and when machining it, you need to be careful about chipping and dust control.

Applications

Common uses include electrical insulators, old mechanical parts, and fixtures.

FR-4 (Glass-Epoxy Composite)

FR-4 is a common laminate composite for printed circuit boards, but it can also be machined into parts for electronics that need to be strong or move.

Advantages

Good dimensional stability, electrical insulation, and moderate machinability.

Considerations

It has reinforcing glass fiber, which makes fibers and dust when it is machined, so they need to be controlled. Also, tools wear out more quickly.

Advantages

Common uses include PCB cores, housing parts for electronics, and structural panels in electronics.

Comparison: Metals vs Plastics

Different CNC machining jobs need metals and plastics with different properties. The right choice depends on what the app needs. These include cost, strength, weight, thermal and electrical behavior, and tool wear.

Strength and Weight

When you choose between metals and plastics, you have to think about how strong and heavy they are. Metals are stronger and last longer, making them great for things that need a lot of strength. But they are heavier than plastic.

Plastics are lighter, which is important in the aerospace and automotive fields where weight is important.

Thermal and Electrical Conductivity

When it comes to heat and electricity, metals and plastics act differently. Metals are good at conducting heat and electricity, which makes them useful for things that need these properties. Plastics are better for electrical insulation or places where heat doesn’t move around very well because they don’t conduct electricity.

Cost and Tool Wear

When choosing between metals and plastics, cost is a big factor. Like titanium, metals can be more expensive to machine because of the forces and tool wear. Plastics are cheaper, but they can be hard to work with, which can cause tools to wear out and cost problems.

Common Uses

It’s important to know when to use metals and when to use plastics. In the aerospace, automotive, and industrial fields, metals are best for needs that require high strength and durability. Plastics are useful in many areas, such as electronics, consumer goods, and medical devices. They are light, resistant to corrosion, and good at insulating electricity.

Machining Considerations for Specific Materials

When you use CNC machining to work with different materials, there are a few important things to keep in mind. The way you machine something depends on the material you choose. This includes things like how fast you need to go, how much you need to feed, what tools you need, and what you need to do after machining.

Optimizing Speed, Feed, and Tooling

Different materials need different settings to be machined. For instance, aluminum needs fast speeds and feeds. But to keep titanium from wearing down and getting hot, you need to go slower and use special tools.

Surface Finish and Post-Processing

The finish of a machined part is determined by the material and the machining process. You may need to do extra things like deburring or anodizing at times. This helps you get the look and feel you want.

We can make our machining better by knowing what problems certain materials have. We can make sure that our CNC machining is very good for a lot of different materials. This includes metals like stainless steel and plastics like polycarbonate.

CNC Machining Materials FAQs

What are the most common metals that CNC machines work with?

Aluminum, stainless steel, and steel are some metals that are used a lot. Titanium is another material we use. These are picked because they are strong and can be used in many ways.

What are the advantages of using aluminum in CNC machining?

Aluminum is a good material for CNC machining. It doesn’t rust easily, is strong, and is light. This makes it great for the automotive and aerospace fields.

Which types of plastic can be CNC machined?

We use plastics like PMMA, PLA, PC, and ABS. Each one is picked because of its special qualities, like being tough or clear.

How do I decide whether to use plastic or metal for my CNC machining project?

The choice depends on what your project needs. Think about the cost, weight, and strength. We help you choose the best material for you.

What things make a material easier or harder to machine?

Hardness and toughness are important for machinability. The chemical makeup of the material does too. We use this information to pick the right tools and settings.

How does the speed and feed rate of CNC machining change depending on the material?

The speed and feed rates change depending on the material. You need special tools and slower speeds to work with harder materials like titanium.

Can CNC machining make parts with complicated shapes?

Yes, CNC machining can make parts with shapes that are hard to work with. It can do a lot of things very accurately, like drilling and milling.

What can you do to CNC machined parts after they are made?

We do things like deburring and finishing surfaces. These make CNC parts look and work better.

How can I make sure that CNC machined parts are of high quality?

We carefully check parts by inspecting and testing them. This makes sure they meet all the quality standards.

What kinds of materials work well at high temperatures?

We use titanium, stainless steel, and plastics like PEEK and PPS for high heat. They stay stable and don’t break down easily.