Home » CNC Machining Materials: Metals and Plastics » ABS: Custom ABS CNC Machining Services in China

Custom ABS CNC Machining Services in China

Rapid Prototyping and Production of Tough, Impact-Resistant Plastic Components.

- ISO 9001 Certified

- Excellent for Prototypes

- In-House Finishing & Painting

Your Expert Partner for ABS Machining

Celerity Precision is a leading manufacturer in China providing expert CNC machining services for ABS (Acrylonitrile Butadiene Styrene). ABS is one of the most popular and versatile engineering thermoplastics in the world, prized for its excellent toughness, high impact strength, and ease of machining. It is the go-to material for a vast range of applications, from functional prototypes and electronic enclosures to automotive interior parts and consumer product housings. Our facility is fully optimized for machining ABS, allowing us to quickly and cost-effectively transform your designs into durable, high-quality plastic parts with an excellent surface finish.

Why Choose ABS for Your Machined Parts

ABS offers an outstanding balance of mechanical properties, manufacturability, and cost, making it an ideal choice for a wide variety of projects. Its amorphous structure allows it to be machined very cleanly, producing parts with fine details and a smooth surface finish. Furthermore, it is easily finished, painted, or bonded, providing exceptional design flexibility. At Celerity Precision, we leverage the excellent machinability of ABS to produce your parts rapidly, whether you need a single “looks-like, feels-like” prototype or a full production run of end-use components.

High Impact Strength & Toughness

Excellent resistance to impact and physical shock, making it very durable.

Great Machinability

Can be machined quickly and easily, resulting in a smooth surface finish and low cost.

Cost-Effective

One of the most affordable engineering plastics, ideal for both prototyping and production.

Excellent Aesthetics

Produces a smooth, matte finish that can be easily painted, textured, or plated.

Good Dimensional Stability

Holds its shape well after machining with low moisture absorption.

Easy to Post-Process

Can be easily solvent-welded, bonded, painted, and finished.

Standard Machining Grade ABS

This is the most common grade, offering a well-balanced profile of toughness, stiffness, and impact resistance. It is available in natural (beige) and black as standard colors, with other colors available upon request.

| Tensile Strength, Yield (MPa) | 45 MPa |

| Elongation at Break (%) | 20% |

| Hardness (Brinnell) | 105 |

| Density (g/cm³) | 1.05 |

Surface Finishing Options for ABS

ABS is one of the most versatile plastics for finishing, allowing for a wide range of aesthetic and functional enhancements.

As Machined

The standard finish, which is typically a smooth, clean, matte surface. Machining marks are usually very fine.

Painting

Excellent for painting. It provides a perfect base for achieving any desired color, gloss level, or texture.

Sand Blasting

Creates a uniform, textured matte finish, which is great for hiding fingerprints and providing a non-slip feel.

Vapor Polishing

A secondary process where a solvent vapor is used to melt the outer surface, creating a smooth, glossy, and near-transparent finish on the part.

Electroplating

ABS can be electroplated (chrome-plated) through a specialized process to give it a metallic appearance and increased durability.

Pros and Cons of ABS CNC Machining

Pros

- Excellent Toughness: Resists cracking and chipping, making for durable end-use parts.

- Low Cost: Both the material and the machining process are very affordable.

- Great for Prototyping: The ideal material for creating realistic "looks-like, feels-like" functional prototypes.

- Finishing Versatility: No other common plastic offers as many high-quality finishing options.

- Fast Machining: Can be machined very quickly, leading to short lead times.

Cons

- Poor Chemical Resistance: Can be damaged by common solvents, oils, and acetones.

- Low UV Resistance: Not suitable for long-term outdoor use, as it can become brittle and fade when exposed to sunlight.

- Lower Strength than Engineering Plastics: Not as strong or stiff as materials like POM, PEEK, or Nylon.

- Lower Temperature Resistance: Has a relatively low continuous service temperature compared to high-performance plastics.

Applications of CNC Machined ABS Parts

Rapid Prototyping

Creating realistic form, fit, and function prototypes before investing in injection mold tooling.

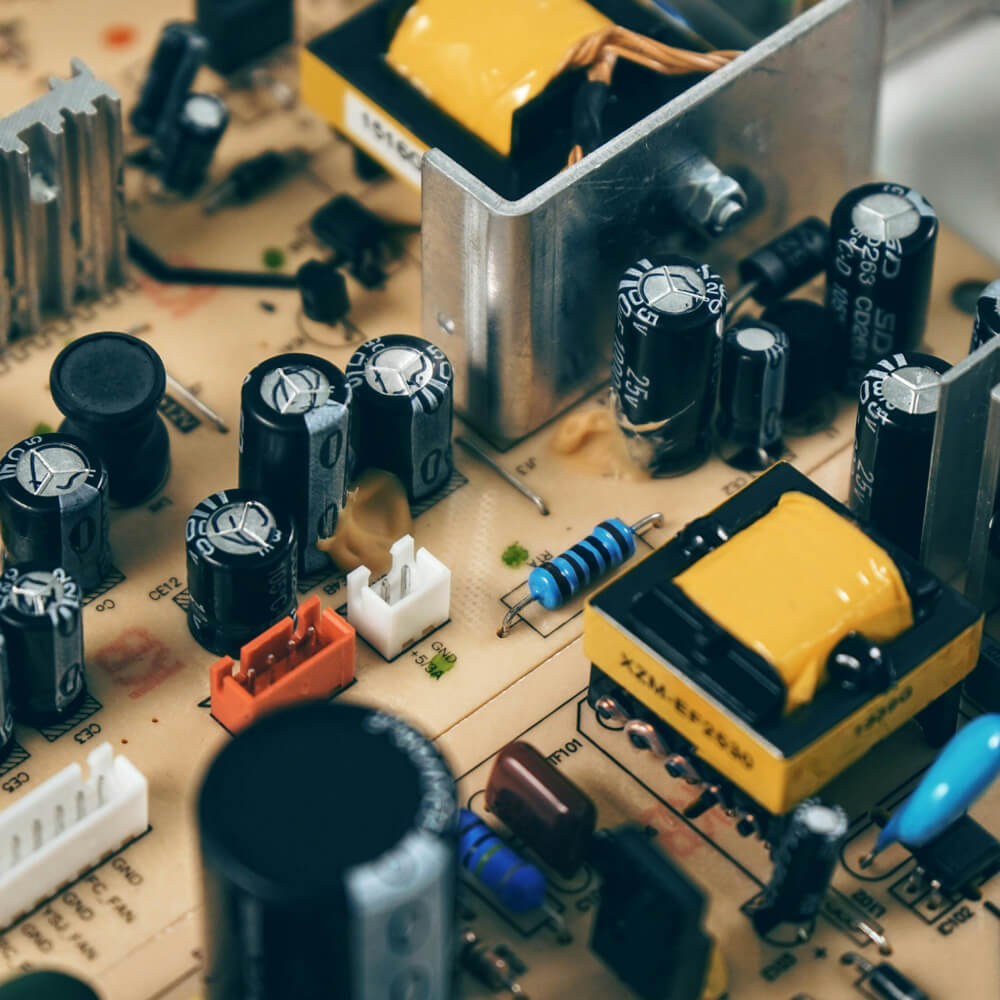

Consumer Electronics

Housings for remote controls, printers, keyboards, and other electronic devices.

Automotive

Interior trim components, dashboards, and housings for non-critical parts.

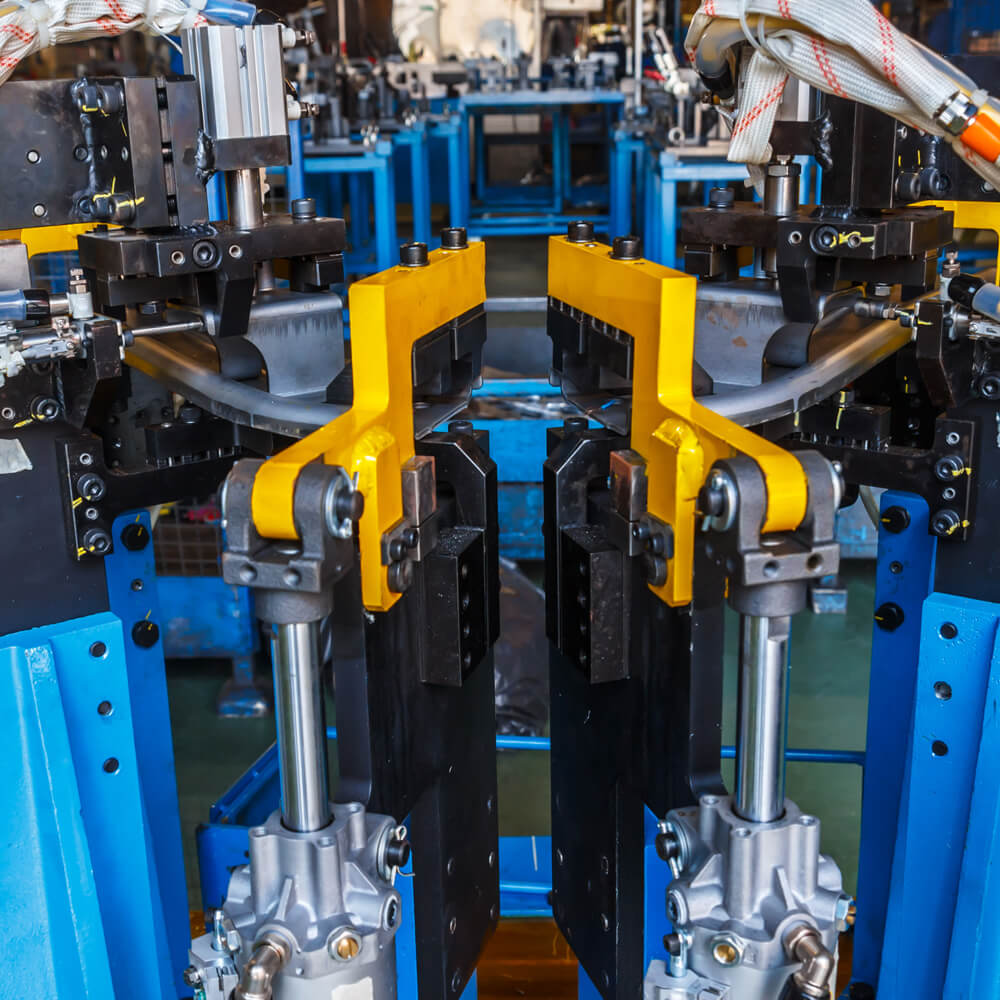

Jigs & Fixtures

Creating custom, low-cost jigs and fixtures for assembly lines.

Consumer Products

Housings and components for a wide range of household goods and toys.

Medical

Housings for non-critical diagnostic equipment and laboratory devices.

ABS Machining FAQ

What is the main difference between ABS and PLA?

ABS is much tougher, more durable, and has a higher temperature resistance than PLA, making it better for functional parts. PLA is easier to 3D print and is biodegradable, making it popular for simple, non-functional prototypes.

What colors is ABS available in?

The standard stock colors for machining are natural (a creamy beige) and black. We can source other colors, but for custom colors, painting is the most common and effective solution.

Can machined ABS be as strong as an injection molded ABS part?

Yes, a part machined from a solid block of extruded ABS is typically stronger and more isotropic (has uniform strength in all directions) than an injection molded part, which can have weld lines and internal stresses.

How do you achieve a glossy finish on ABS?

A high-gloss finish can be achieved through two main methods: applying a gloss paint, or through a process called vapor polishing, where a solvent vapor melts the surface to a smooth sheen.

Is ABS safe for food contact?

Standard ABS is generally not considered food-safe. Specific FDA-compliant grades are available but must be requested.

How do you prevent ABS from warping during machining?

ABS has good dimensional stability, but like all plastics, it can be subject to internal stresses. We use sharp tools, proper feed rates, and effective cooling to minimize heat buildup and prevent warping.

Can you tap threads directly into ABS?

Yes, threads can be tapped directly into ABS for light-duty applications. For stronger, more durable threads, we recommend installing threaded inserts.

Is ABS a good electrical insulator?

Yes, ABS has good electrical insulating properties, which is one reason it is widely used for electronic enclosures.