Home » CNC Machining Materials: Metals and Plastics » Brass: Custom Brass CNC Machining Material in China

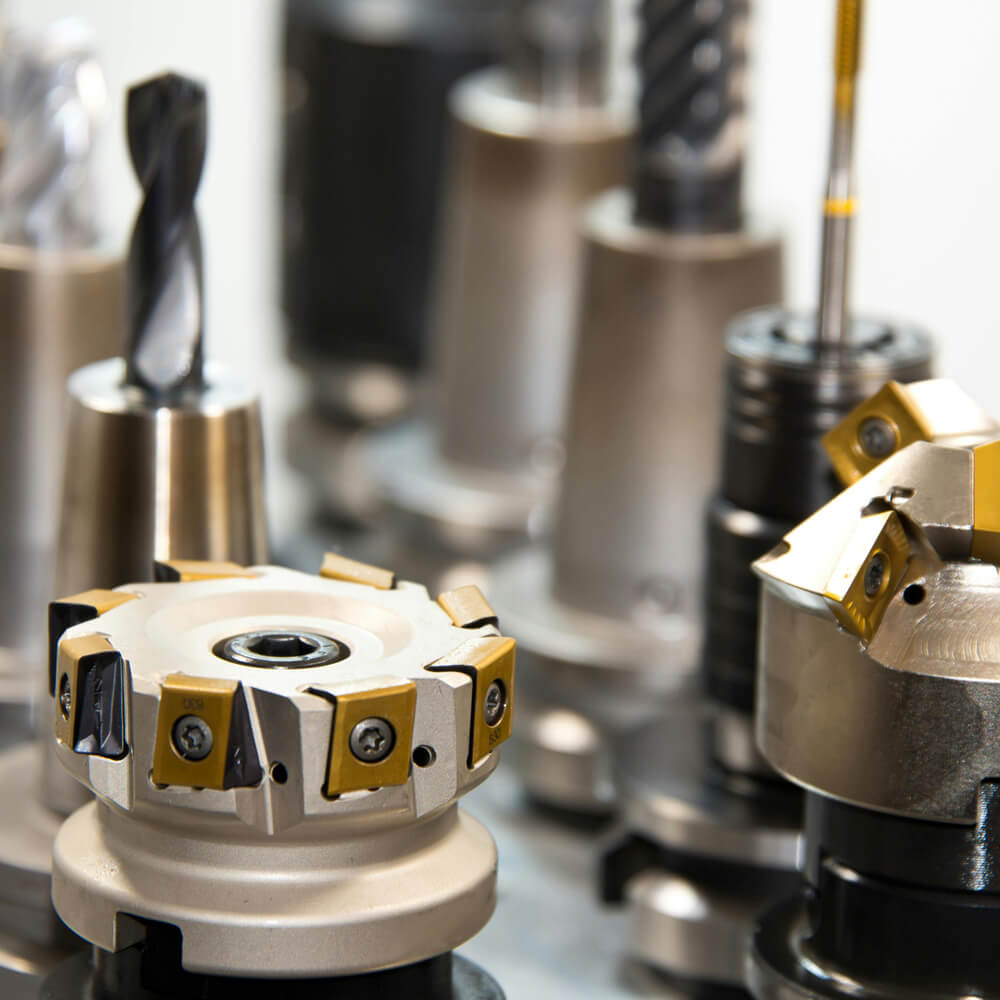

Custom Brass CNC Machining Supplier In China

Celerity Precision is a premier supplier of custom CNC machined brass parts, expertly serving clients across China and globally. We harness the exceptional machinability of brass alloys like C36000 to produce intricate components with outstanding speed and precision. Our advanced CNC turning and milling centers are perfectly suited for creating everything from high-volume plumbing fittings to decorative architectural hardware. We deliver parts with a brilliant natural luster, excellent corrosion resistance, and superior dimensional accuracy, making us the ideal partner for your brass machining needs.

For flawlessly machined brass components that combine aesthetic appeal with functional excellence, request a quote from Celerity Precision today.

Brass in CNC Machining

Brass, an alloy of copper and zinc, is one of the easiest and most cost-effective materials to machine, earning it the benchmark status for machinability. Its unique properties make it an ideal choice for applications that require a combination of low friction, good corrosion resistance, and excellent aesthetics. At Celerity Precision, we leverage the superior machinability of brass to run our machines at high speeds and feeds, resulting in shorter cycle times, lower costs, and exceptionally smooth surface finishes for our clients.

- Outstanding Machinability: The standard for high-speed machining, enabling rapid, low-cost production.

- Excellent Corrosion Resistance: Highly resistant to corrosion from water, salts, and many chemicals.

- Low Coefficient of Friction: Ideal for creating smooth, low-friction parts like bearings and gears.

- Superior Aesthetics: Offers a bright, gold-like appearance for decorative and architectural parts.

- Good Electrical & Thermal Conductivity: A good conductor, though not as effective as pure copper.

- Lead Content Benefits: Leaded brasses (like C36000) produce small, broken chips for easy machining.

Brass C27400 (C274)

A common yellow brass known for its good combination of strength and ductility, often used for general hardware and fittings.

Tensile Strength, Yield (MPa) | 370-550 MPa |

Fatigue Strength (MPa) | ~125 MPa |

Elongation at Break (%) | 50% |

Hardness (Brinnell) | 80-160 |

Density (g/cm³) | 8.47 |

Brass C28000 (Muntz Metal)

A brass alloy known for its high strength and excellent corrosion resistance, especially in marine environments.

Tensile Strength, Yield (MPa) | 345-540 MPa |

Fatigue Strength (MPa) | ~120 MPa |

Elongation at Break (%) | 52% |

Hardness (Brinnell) | 80-150 |

Density (g/cm³) | 8.39 |

Brass C36000 (Free-Cutting Brass)

The most common brass for machining, its lead content provides unparalleled machinability, producing excellent surface finishes at very high speeds.

Tensile Strength, Yield (MPa) | 338-469 MPa |

Fatigue Strength (MPa) | 117 MPa |

Elongation at Break (%) | 50% |

Hardness (Brinnell) | 80-125 |

Density (g/cm³) | 8.50 |

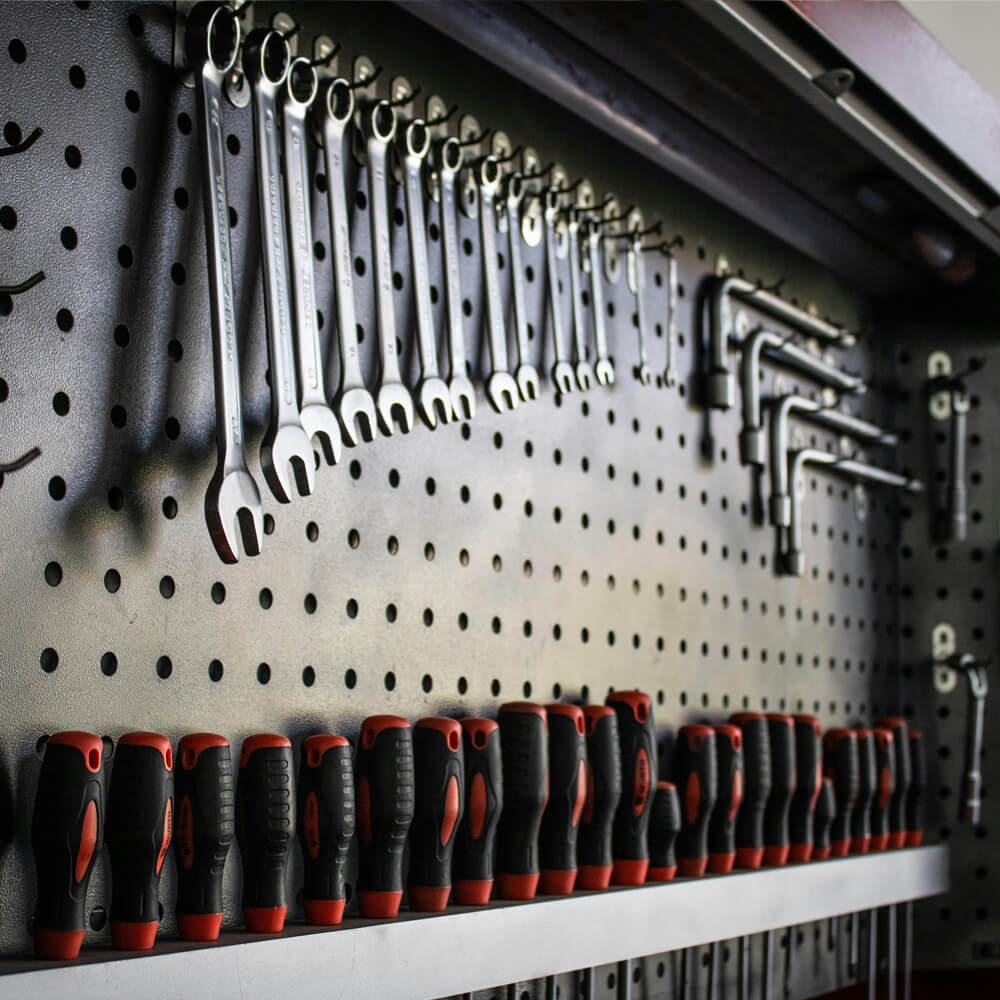

Brass CNC Machining Surface Finishes

We offer a variety of finishes to either protect the natural beauty of brass or to prepare it for specific functional requirements.

As machined

Reveals the material's bright, shiny, gold-like natural finish, which will tarnish to a darker patina over time.

Sand Blasting

Creates a uniform, low-glare matte finish for a modern, non-reflective look.

Tumbling

An efficient method for deburring and creating a smooth, semi-lustrous finish on batches of small brass parts.

Electropolish

Produces an ultra-bright, smooth, and highly polished surface, enhancing its natural luster.

Alodine

Not applicable, as this is a chemical treatment specifically for aluminum.

Electroless Plating

Electroless nickel is commonly applied to brass to increase its surface hardness and wear resistance.

Painting

A protective clear lacquer is often applied to prevent tarnishing and preserve the bright, polished appearance.

Electrophoresis

Provides a durable, uniform coating (typically black) for enhanced protection and a different aesthetic.

Brushed Finish

Creates an elegant, linear satin grain for a sophisticated, high-end decorative appearance.

Pros and Cons of Brass CNC Machining

Pros

- Exceptional Machinability: The easiest metal to machine, resulting in fast production, low cost, and excellent surface finishes.

- Corrosion Resistance: Highly resistant to water and many chemicals, making it ideal for plumbing and marine applications.

- Aesthetic Appeal: The bright, gold-like appearance makes it a top choice for decorative hardware and consumer products.

- Low Friction: Natural lubricity makes it perfect for gears, bearings, and moving parts.

Cons

- Lower Strength: Not as strong as most steels or high-grade aluminum alloys.

- Lead Content Concerns: Common alloys like C36000 contain lead, making them unsuitable for potable water or food-grade applications (lead-free alternatives are available).

- Tarnishes Over Time: Uncoated brass will oxidize and darken when exposed to air, requiring a protective coating to maintain its shine.

- Relatively Heavy: Denser than steel, and significantly heavier than aluminum.

Brass CNC Machining for Various Industries

Plumbing and Fluidics

Faucets, pipe fittings, valve bodies, and hose nozzles.

Hardware

Hinges, locks, decorative knobs, and architectural fittings.

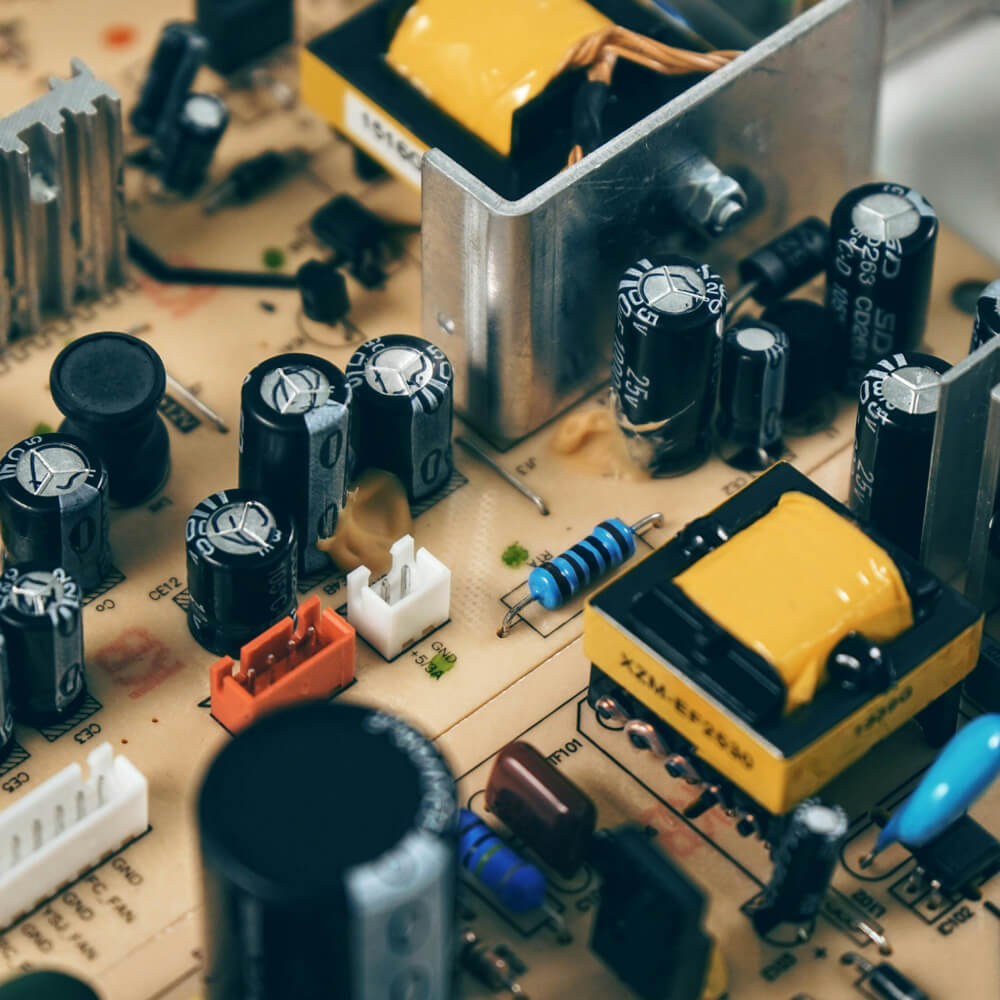

Electronics

Electrical connectors, terminals, and threaded standoffs.

Mechanical

Low-friction gears, bearings, bushings, and ammunition casings.

Musical Instruments

Components for brass instruments like trumpets and trombones.

Consumer Goods

High-end cosmetic casings, watch components, and decorative items.

Frequently Asked Questions (FAQ)

Why is C36000 brass called "free-cutting"?

The small amount of lead in the alloy acts as a microscopic lubricant and chip breaker, allowing the material to be cut at extremely high speeds with minimal tool wear, producing a superior finish.

Will my brass parts tarnish or turn green?

Yes, if left uncoated, brass will naturally oxidize in the air, developing a darker brown patina. In wet environments, it can develop a green patina (verdigris). A clear lacquer or coating is required to prevent this.

Is brass magnetic?

No, brass is a non-magnetic material.

Is brass a good electrical conductor?

Yes, it is a good conductor, though not as conductive as pure copper. It is often used for electrical terminals and connectors where its hardness and machinability are also important.

What is the main difference between brass and bronze?

The main difference is the primary alloying element. Brass is primarily an alloy of copper and zinc. Bronze is primarily an alloy of copper and tin (though other elements like aluminum are also used).

Can brass be welded or soldered?

Brass is excellent for soldering and brazing. Welding is possible but can be difficult due to the zinc content, which can vaporize at high temperatures.

Is brass safe for drinking water applications?

Standard C36000 brass is not, due to its lead content. However, specific lead-free or low-lead brass alloys are available and required for potable water fittings.

How do I clean and polish brass parts?

Uncoated brass parts can be cleaned and restored to a bright shine using a commercial brass polish and a soft cloth.