Home » CNC Machining Materials: Metals and Plastics » FR-4: Custom FR-4 CNC Machining Material Supplier in China

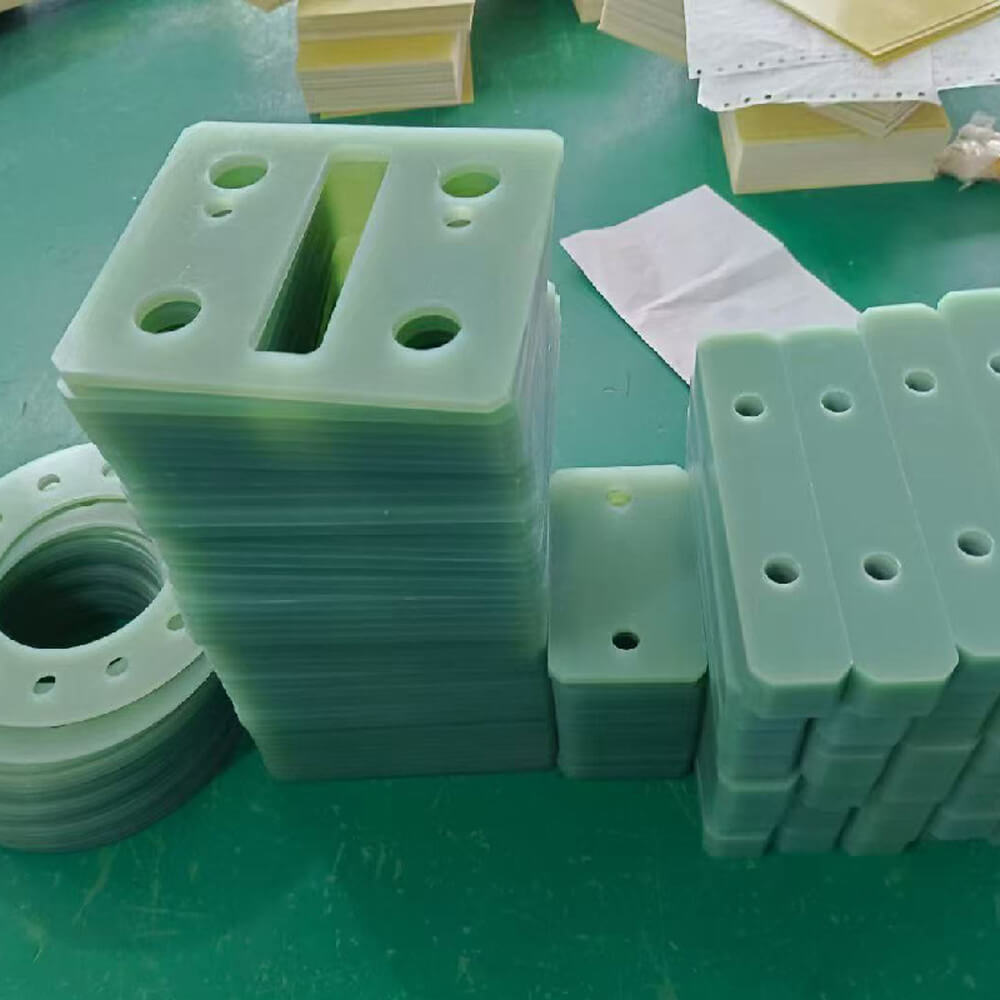

Custom FR-4 CNC Machining Services in China

High-Precision Machining of Glass-Reinforced Epoxy for Superior Structural and Electrical Applications.

- ISO 9001 Certified

- Excellent Electrical Insulator

- High Mechanical Strength

Your Expert Partner for FR-4 Machining

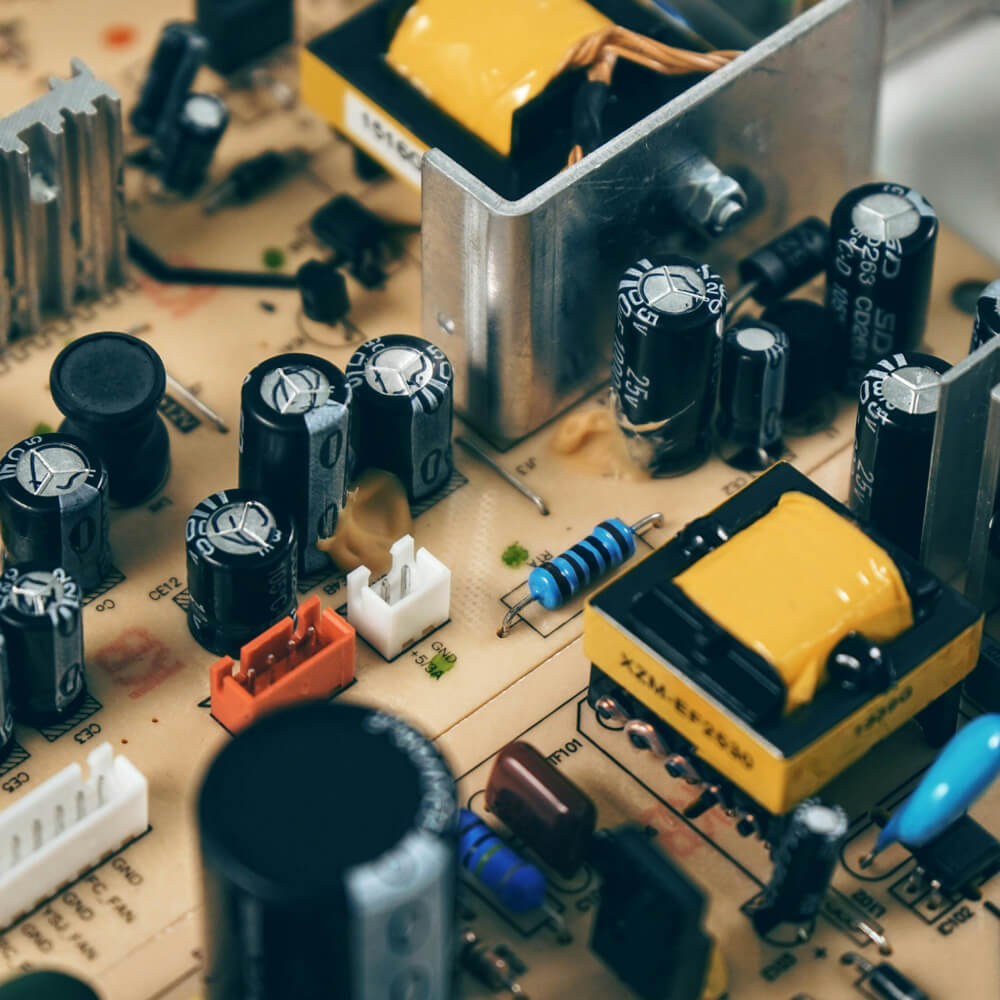

Celerity Precision is a specialized manufacturer in China offering expert CNC machining of FR-4. FR-4 is a high-performance thermoset composite material made from woven fiberglass cloth impregnated with an epoxy resin binder. It is a material of choice for applications demanding an exceptional combination of high mechanical strength, rigidity, low moisture absorption, and outstanding electrical insulating properties. From printed circuit board (PCB) substrates and test fixtures to structural insulators and terminal boards, FR-4 is a cornerstone of the electronics industry. Machining this highly abrasive material requires specialized tooling and processes, and our facility is fully equipped to machine FR-4 to your most precise specifications.

Why Choose FR-4 for Your Machined Parts?

FR-4 offers a performance level that bridges the gap between engineering plastics and metals. Its glass fiber reinforcement gives it incredible strength and stiffness, allowing it to function as a structural component, while its epoxy resin matrix provides superb performance as an electrical insulator. It is also inherently flame retardant (the “FR” stands for Flame Retardant) and maintains its properties well in both dry and humid conditions. At Celerity Precision, we utilize diamond-coated and solid carbide tooling to accurately mill, drill, and route FR-4. We employ high-speed machining techniques and powerful dust extraction systems to manage the abrasive dust and deliver parts with clean edges and precise features.

High Mechanical Strength & Stiffness

The woven glass reinforcement provides exceptional strength, rigidity, and dimensional stability.

Outstanding Electrical Insulator

Excellent dielectric strength and insulating properties, which are stable across a wide range of temperatures and frequencies.

Very Low Moisture Absorption

Resists absorbing water, ensuring that its electrical and mechanical properties remain stable in humid environments.

Inherent Flame Retardancy

Meets UL94 V-0 flame retardancy standards, making it a safe choice for electronic applications.

High Strength-to-Weight Ratio

Offers a strength level comparable to some metals but at a significantly lower weight.

Inherent Flame Retardancy

Low flammability and very low smoke and toxic gas emissions when burned.

FR-4 (Standard Grade)

This is the most widely used grade. It offers an excellent combination of mechanical, thermal, and electrical properties, making it suitable for the vast majority of structural and insulating applications. It is typically a translucent light green, yellow, or black.

| Tensile Strength, Yield (MPa) | 310 MPa |

| Dielectric Strength (V/mil) | 500 V/mil |

| Max. Temp. (Continuous) | 140°C (284°F) |

| Density (g/cm³) | 1.85 |

G-10 (Non-Flame Retardant)

A related material with similar mechanical properties to FR-4 but without the flame-retardant additives. It is sometimes specified for applications where flame retardancy is not a requirement.

Surface Finishing Options for FR-4

FR-4 is a functional material that is not suitable for cosmetic finishing.

As Machined

This is the only finish available. FR-4 machines to a clean, hard, and slightly textured surface. The cut edges will clearly show the layered, woven glass fiber structure. The standard color is a translucent light green, but it can also be yellow or black.

Pros and Cons of FR-4 CNC Machining

Pros

- Superior Electrical Insulation: The primary advantage, making it the default choice for PCBs and electrical mounting plates.

- Extremely Strong and Rigid: Can be used for structural components, jigs, and fixtures where stiffness is critical.

- Dimensionally Stable: Low thermal expansion and near-zero water absorption ensure it holds tolerances perfectly.

- Flame Retardant: A crucial safety feature for any electronic or electrical enclosure.

Cons

- Extremely Abrasive to Machine: The glass fiber content is highly abrasive and will destroy standard high-speed steel (HSS) tooling almost instantly. It requires expensive diamond-coated or solid carbide tools.

- Produces Hazardous Dust: The fine glass dust generated during machining is a serious respiratory hazard and requires powerful vacuum and filtration systems for safe handling.

- Brittle in Thin Sections: While strong, it is a rigid composite and can be prone to chipping or delaminating during machining, especially on thin walls or fine features.

- Cannot be Formed or Welded: As a cured thermoset composite, it cannot be bent, formed, or welded. All features must be machined.

Applications of CNC Machined FR-4 Parts

Electronics & PCBs

Structural components for printed circuit boards, test fixtures, and solder pallets.

Electrical Engineering

Terminal boards, busbar supports, high-voltage insulators, and switchgear components.

Industrial Machinery

Jigs, fixtures, and machine guards that require electrical insulation.

Aerospace & Defense

Insulating plates and structural components for avionics and electronic systems.

Prototyping

Creating robust, functional prototypes for electronic enclosures and mechanical insulators.

Medical Devices

Insulating components and structural plates for diagnostic and imaging equipment.

FR-4 Machining FAQ

What is the main difference between FR-4 and G-10?

They are very similar glass-epoxy laminates. The key difference is that FR-4 contains bromine, which makes it flame retardant (it will self-extinguish when a flame is removed). G-10 does not have this property. For most electronic applications, FR-4 is the required standard.

Why is FR-4 so difficult to machine?

The woven glass fibers that give FR-4 its strength are extremely hard and abrasive. They act like sandpaper on cutting tools, causing them to wear down very quickly. This requires specialized, expensive tooling and can increase machining costs.

Is the dust from machining FR-4 dangerous?

Yes. The fine, airborne glass dust is a respiratory hazard. Celerity Precision uses high-powered vacuum extraction systems directly at the cutting tool to capture the dust at its source, ensuring a safe process.

Can FR-4 be used in a wet environment?

Yes, it has extremely low moisture absorption and excellent resistance to water, making it very stable in humid or wet conditions.

What color is FR-4?

The most common color is a translucent, light yellowish-green. Black is also a standard option.

Can you tap threads directly into FR-4?

Yes, threads can be tapped directly into FR-4, and they are surprisingly strong due to the glass reinforcement. For applications with very high loads or frequent assembly, installing threaded inserts is recommended.

Is FR-4 a good thermal insulator?

Yes, it is both a good electrical and thermal insulator. It does not conduct heat well.

How do you prevent delamination when machining FR-4?

We use very sharp tools, high spindle speeds, and specific cutting strategies (like “climb milling”) to ensure the tool is shearing the glass fibers cleanly rather than pulling them apart, which prevents delamination and fraying at the edges.