Home » CNC Machining Materials: Metals and Plastics » Magnesium: Custom Magnesium CNC Machining Material Supplier in China

Custom Magnesium CNC Machining Services in China

Ultra-Lightweight, High-Performance Components Machined with Expert Precision and Safety.

- ISO 9001 Certified

- Lightest Structural Metal

- Aerospace & Automotive Expertise

Your Expert Partner for Magnesium Machining

Celerity Precision is a specialized manufacturer in China offering expert CNC machining services for magnesium alloys. As the lightest of all structural metals, magnesium boasts an extraordinary strength-to-weight ratio, making it the ultimate material choice for applications where weight reduction is the most critical design driver. From demanding aerospace components and high-performance automotive parts to lightweight robotics and portable electronics, we possess the specialized knowledge, equipment, and stringent safety protocols required to machine this advanced material to your exact specifications.

Why Choose Magnesium for Your Machined Parts?

Magnesium offers a significant performance advantage over both aluminum and plastics. It is 33% lighter than aluminum and 75% lighter than steel, yet offers comparable or even superior strength-to-weight performance. While machining magnesium requires special handling due to its flammable nature, the benefits are unparalleled for high-performance applications. At Celerity Precision, we have implemented rigorous safety procedures and utilize specific tooling and high-speed machining techniques to safely and efficiently machine magnesium alloys, unlocking their full lightweight potential for our clients.

Extremely Lightweight

The lowest density of all structural metals, offering dramatic weight savings.

Excellent Strength-to-Weight Ratio

Provides high stiffness and strength in a very lightweight package.

Outstanding Machinability

Can be machined faster than aluminum, allowing for very rapid production cycles.

Superior Damping Capacity

Excellent at absorbing shock and vibration, which is ideal for high-performance and electronic applications.

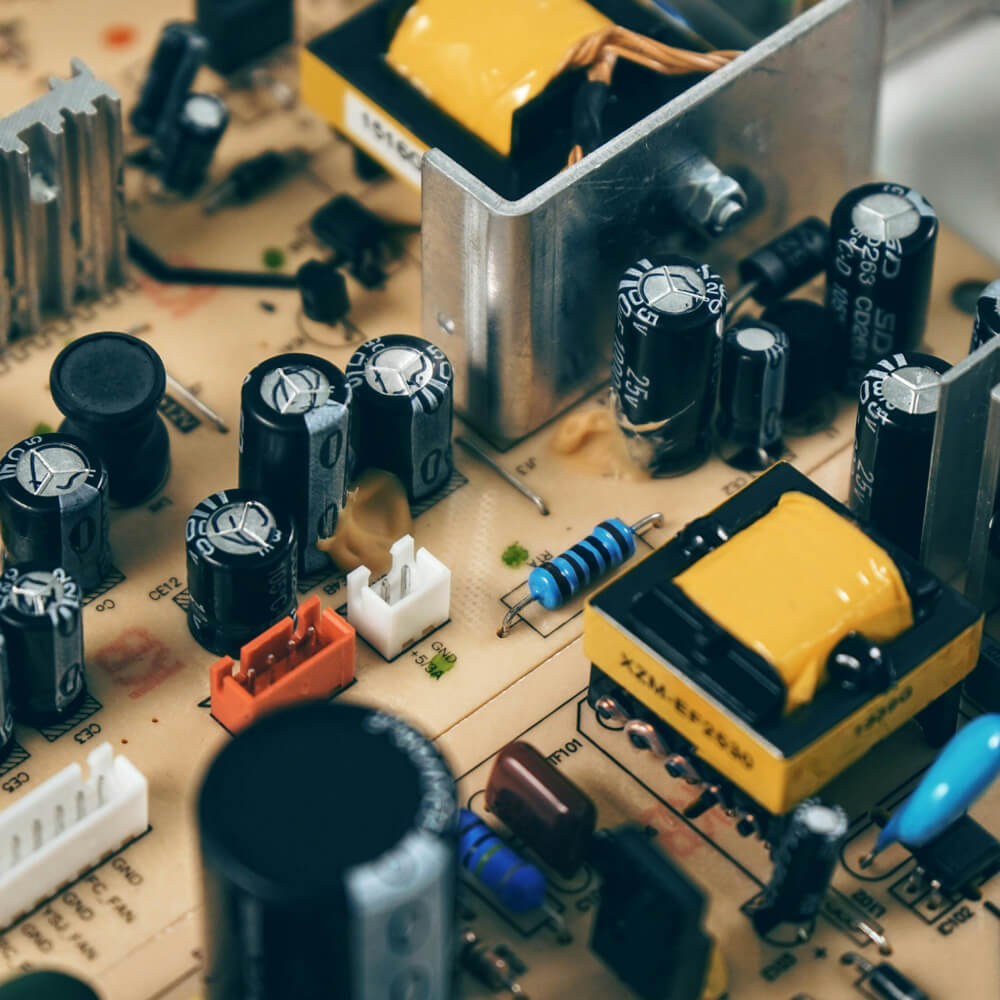

EMI/RFI Shielding

Offers excellent electromagnetic and radio frequency interference shielding.

High Thermal Conductivity

Effectively dissipates heat, though not as well as aluminum.

AZ31B

The most common wrought magnesium alloy, offering a good combination of strength, ductility, and corrosion resistance at room temperature. It is a versatile choice for a wide range of structural applications.

| Tensile Strength, Yield (MPa) | 250-290 MPa |

| Elongation at Break (%) | 15-20% |

| Hardness (Brinnell) | 55-70 |

| Density (g/cm³) | 1.77 |

AZ91D

The most common die-cast magnesium alloy, known for its excellent castability and a good balance of strength and corrosion resistance. Often used as a starting blank for secondary machining.

| Tensile Strength, Yield (MPa) | 240 MPa |

| Elongation at Break (%) | 3-7% |

| Hardness (Brinnell) | 63 |

| Density (g/cm³) | 1.81 |

Surface Finishing Options for Magnesium

Magnesium is highly susceptible to corrosion and always requires a protective finish. We offer a range of specialized coatings to ensure the durability and longevity of your magnesium parts.

As Machined

This is a temporary condition only. Parts must be coated immediately after machining to prevent corrosion.

Alodine

The most common and effective pre-treatment. It creates a thin chemical film that provides good corrosion resistance and is an excellent primer for painting.

Sand Blasting

A common pre-treatment step to create a clean, uniform surface that improves the adhesion of subsequent coatings like paint or powder coating.

Anodizing

Specialized anodizing processes for magnesium (like Dow 17 or HAE) create a very hard, thick, and highly protective ceramic-like coating.

Teflon™ Coating

Can be applied over a suitable primer to provide a low-friction and chemically resistant surface.

Electroless Plating

Electroless nickel can be applied over a special initial layer (like zincate) to provide a very hard, wear-resistant, and corrosion-resistant metallic coating.

Painting

A very common topcoat, almost always applied over a conversion coating or primer to provide the primary layer of cosmetic and environmental protection.

Powder Coating

A durable and tough finish that can be applied over a suitable primer to give excellent protection and a decorative look.

Pros and Cons of Magnesium CNC Machining

Pros

- Ultimate Weight Savings: The number one advantage, enabling lighter and more efficient designs.

- High Stiffness & Strength-to-Weight: Delivers rigid, strong performance without the weight penalty of other metals.

- Fastest Machining Speeds: Can be machined very quickly, which helps to offset the higher material cost with reduced cycle times.

- Excellent Vibration Damping: Ideal for high-performance machinery and sensitive electronic housings.

Cons

- High Cost: Magnesium alloys are more expensive than aluminum and steel.

- Poor Corrosion Resistance: Highly reactive and requires a robust protective coating to prevent rapid corrosion.

- Flammability Risk: Magnesium chips and dust are flammable and require special handling, coolants, and safety protocols during machining, which adds complexity.

- Lower Strength than High-Grade Aluminum/Steel: While the strength-to-weight ratio is excellent, the absolute strength is lower than high-performance aluminum or steel alloys.

Applications of CNC Machined Magnesium Parts

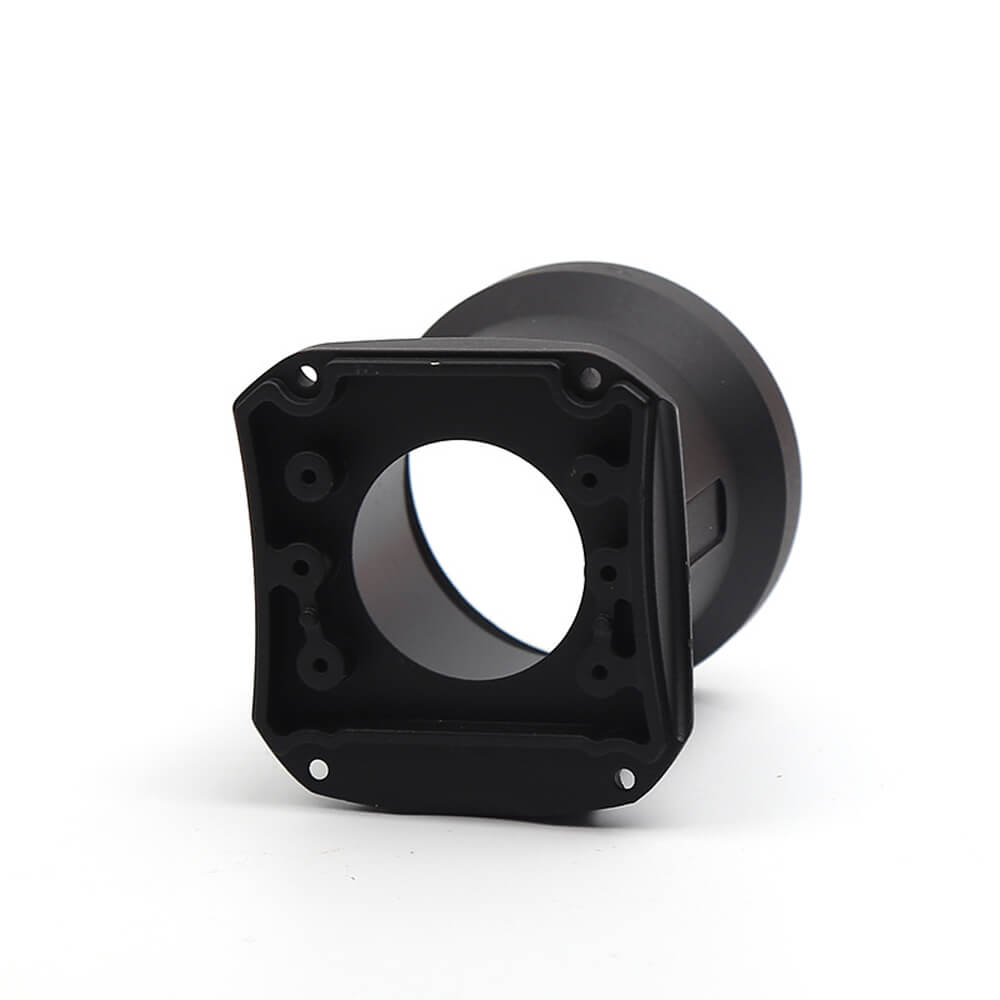

Aerospace & Defense

Drone components, aircraft gearbox casings, missile parts, and satellite components.

Automotive (High-Performance)

Racing wheel rims, intake manifolds, and transmission cases.

Electronics

Laptop and camera bodies, mobile phone frames, and other lightweight portable device housings.

Robotics

Lightweight robotic arms and end-effectors to improve speed and reduce motor load.

Medical

Components for lightweight mobility aids and portable medical devices.

Vibration Damping

Housings and mounts for sensitive optical and electronic equipment.

Magnesium Machining FAQ

How much lighter is magnesium than aluminum?

Magnesium is approximately 33% (one-third) lighter than aluminum by volume.

Is machining magnesium dangerous?

It can be if not handled correctly. Magnesium chips and dust are flammable. Celerity Precision uses stringent, industry-standard safety protocols, including specialized coolants, sharp tooling, excellent chip evacuation, and fire suppression systems, to machine magnesium safely.

Does magnesium need a protective coating?

Yes, absolutely. Unprotected magnesium will corrode very quickly, especially in humid environments. A finish like a conversion coating or anodizing is mandatory for all applications.

What is the best finish for magnesium?

A chromate conversion coating (like Dow 7) is the most common and effective base layer. For maximum protection, this is often followed by a high-quality paint or powder coat.

Is magnesium a strong material?

It has an excellent strength-to-weight ratio. While not as strong in absolute terms as a high-strength steel, a well-designed magnesium part can be just as strong as an aluminum part while being significantly lighter.

Can magnesium be welded?

Yes, magnesium alloys can be welded, but it requires a high level of skill and a completely inert gas shielding environment (like TIG welding) to prevent oxidation.

Is machining magnesium expensive?

The raw material is more costly than aluminum. However, magnesium’s excellent machinability allows for much faster cutting speeds, which can help to reduce the overall machining time and offset some of the material cost.

How do you handle the chips and dust safely?

We use high-volume coolant to prevent ignition, maintain excellent housekeeping to prevent dust accumulation, and store all magnesium chips in clearly labeled, sealed, dry steel containers away from our main production area.