Home » CNC Machining Materials: Metals and Plastics » PC: Custom PC (Polycarbonate) CNC Machining Material Supplier in China

Custom PC (Polycarbonate) CNC Machining Services in China

Machining Strong, Transparent, and Impact-Resistant Components for Demanding Applications.

- ISO 9001 Certified

- Optically Clear Grades

- Expert Vapor Polishing

Your Expert Partner for Polycarbonate Machining

Celerity Precision is a trusted manufacturing partner in China specializing in the CNC machining of Polycarbonate (PC). Polycarbonate is a high-performance amorphous thermoplastic renowned for its unique and powerful combination of properties: outstanding impact strength, high stiffness, and excellent optical clarity. It is the material of choice for applications that demand transparency and extreme durability, from rugged machine guards and clear electronic housings to automotive lenses and medical manifolds. Machining PC to a high standard requires specific techniques to avoid stress and maintain clarity. Our facility is expertly equipped to machine Polycarbonate, delivering parts that are both functionally robust and aesthetically flawless.

Why Choose Polycarbonate for Your Machined Parts

Polycarbonate is an engineering powerhouse, often chosen when other transparent plastics like acrylic are not tough enough. Its ability to withstand massive impacts without fracturing makes it a premier choice for safety-critical applications. Furthermore, its inherent transparency can be enhanced with post-processing to achieve a near-optical, glass-like finish. At Celerity Precision, we employ specialized tooling, optimized coolants, and stress-relieving techniques to machine Polycarbonate parts that are free from crazing and maintain their exceptional structural integrity and clarity.

Exceptional Impact Strength

Extremely tough and shatter-resistant, often described as "bulletproof."

Excellent Optical Clarity

Naturally transparent with high light transmittance, which can be enhanced by polishing.

High Strength and Stiffness

A strong, rigid material that holds its shape well under load.

Good Temperature Resistance

Maintains its properties at higher temperatures than many other thermoplastics.

Good Dimensional Stability

Low moisture absorption and good creep resistance ensure parts remain dimensionally accurate.

Flame Retardant

Inherently flame-retardant, with special grades available that meet UL94 V-0 standards.

Machine Grade Polycarbonate

This is the standard, general-purpose grade, offering a superb balance of toughness, stiffness, and clarity. It is available in clear, black, and white.

| Tensile Strength, Yield (MPa) | 65 MPa |

| Elongation at Break (%) | 110% |

| Hardness (Brinnell) | 118 |

| Density (g/cm³) | 1.20 |

Surface Finishing Options for Polycarbonate

Post-processing is key to unlocking the full aesthetic potential of machined Polycarbonate.

As Machined

The standard finish, which is typically a very smooth, translucent, or frosted surface due to the fine tool marks.

Polishing

The premier method for creating a perfectly smooth, glossy, and optically clear surface. The process uses a solvent vapor to reflow the outer surface of the part, removing all tool marks.

Painting

Polycarbonate can be painted to achieve custom colors, often applied to the inside surface of a clear part ("second surface painting") for a durable, high-gloss look.

Sand Blasting

Creates a uniform, frosted, or diffused matte finish, which is excellent for light-diffusing applications or hiding fingerprints.

Pros and Cons of Polycarbonate CNC Machining

Pros

- Extreme Toughness: Unmatched impact resistance makes it ideal for protective covers, lenses, and guards.

- Optical Clarity: Can be post-processed to be as clear as glass but with far greater durability.

- High Strength: A rigid and strong material suitable for structural components.

- Good Heat Resistance: Can be used in applications with higher operating temperatures than ABS or Acrylic.

Cons

- Susceptible to Stress Cracking: Can be prone to "crazing" or cracking if exposed to certain chemicals or machined with improper techniques (e.g., wrong coolants, dull tools).

- Poor Scratch Resistance: The surface is relatively soft and can be easily scratched without a protective hard coat.

- Higher Cost: More expensive than general-purpose plastics like ABS and Acrylic.

- Poor Chemical Resistance: Not resistant to hydrocarbons and can be attacked by certain solvents and cleaning agents.

Applications of CNC Machined Polycarbonate Parts

Industrial Machinery

Safety guards, sight glasses, and transparent covers for machines.

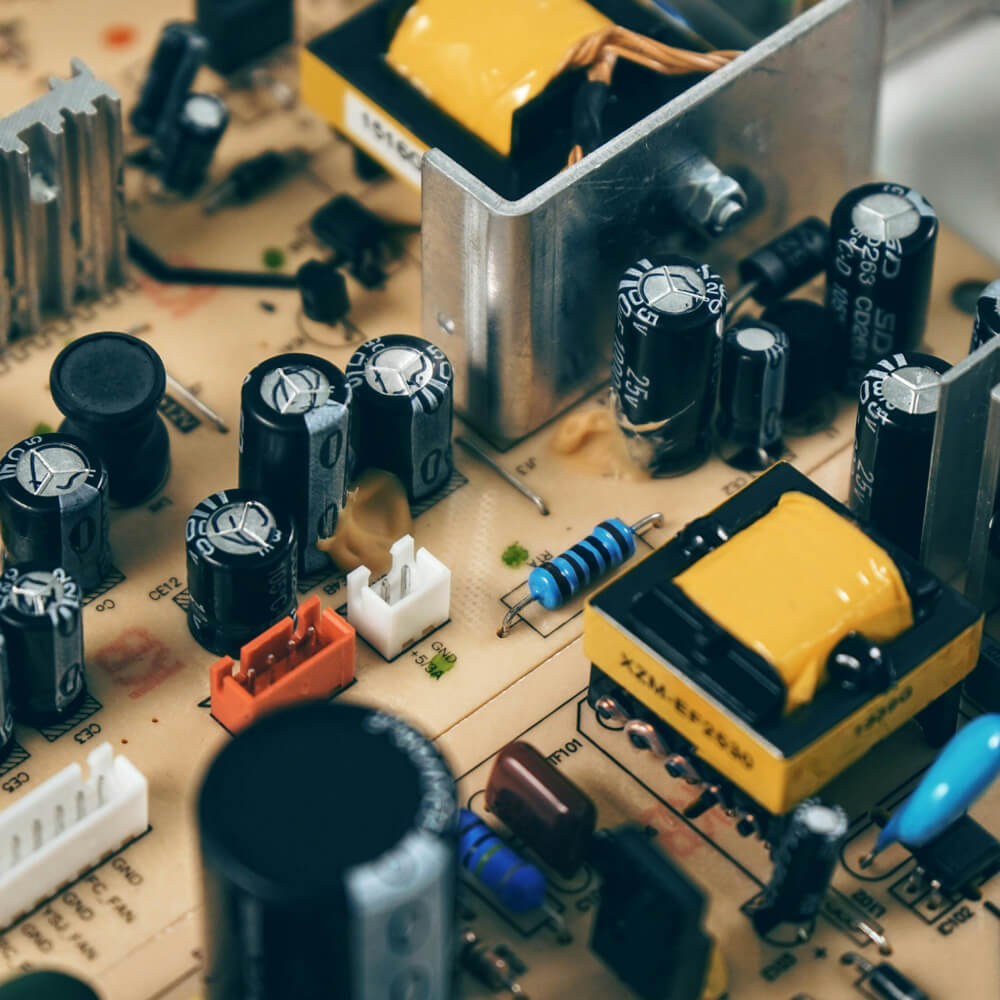

Electronics

Light pipes, LED lenses, clear housings, and touch screen displays.

Medical

Clear manifolds for fluidics, housings for diagnostic equipment, and surgical prototypes.

Automotive & Motorsport

Racing windshields, headlight lenses, and durable interior components.

Aerospace

Cockpit instrumentation panels and interior cabin components.

Robotics

Transparent chassis and protective housings for sensors and cameras.

Polycarbonate Machining FAQ

What is the main difference between Polycarbonate (PC) and Acrylic (PMMA)?

Both are clear plastics, but PC is dramatically tougher and more impact-resistant. Acrylic is more rigid, more scratch-resistant, and has better optical clarity than PC in its raw state, but it is much more brittle.

Why does my machined Polycarbonate part look frosted instead of clear?

The “as machined” finish will always be translucent or frosted due to the microscopic marks left by the cutting tool. To make it optically clear, a secondary process like vapor polishing or mechanical polishing is required.

What is "stress cracking" or "crazing"?

This refers to the formation of tiny cracks in the plastic, often caused by internal stresses from machining combined with exposure to a chemical agent (like an incompatible cutting fluid or cleaner). We use special techniques and compatible coolants to prevent this.

Can you tap threads directly into Polycarbonate?

Yes, PC is strong enough for direct tapping of threads, especially for light-duty applications. For repeated assembly/disassembly, installing threaded inserts is recommended for longer life.

Is Polycarbonate UV resistant?

Standard machine-grade PC has poor UV resistance and will yellow over time with prolonged sun exposure. Specific UV-stabilized grades are available for outdoor applications.

How do you polish machined Polycarbonate?

The best and most common method is vapor polishing, where a solvent vapor melts the outermost layer of the plastic, causing it to reflow into a perfectly smooth, glass-like surface.

Can Polycarbonate be glued or bonded?

Yes, it can be effectively bonded using specialized solvents or structural adhesives.

Is Polycarbonate a good electrical insulator?

Yes, it has excellent electrical insulating properties, making it a good choice for electronic housings and insulators.