Home » CNC Machining Materials: Metals and Plastics » PE: Custom PE (Polyethylene) CNC Machining Material Supplier in China

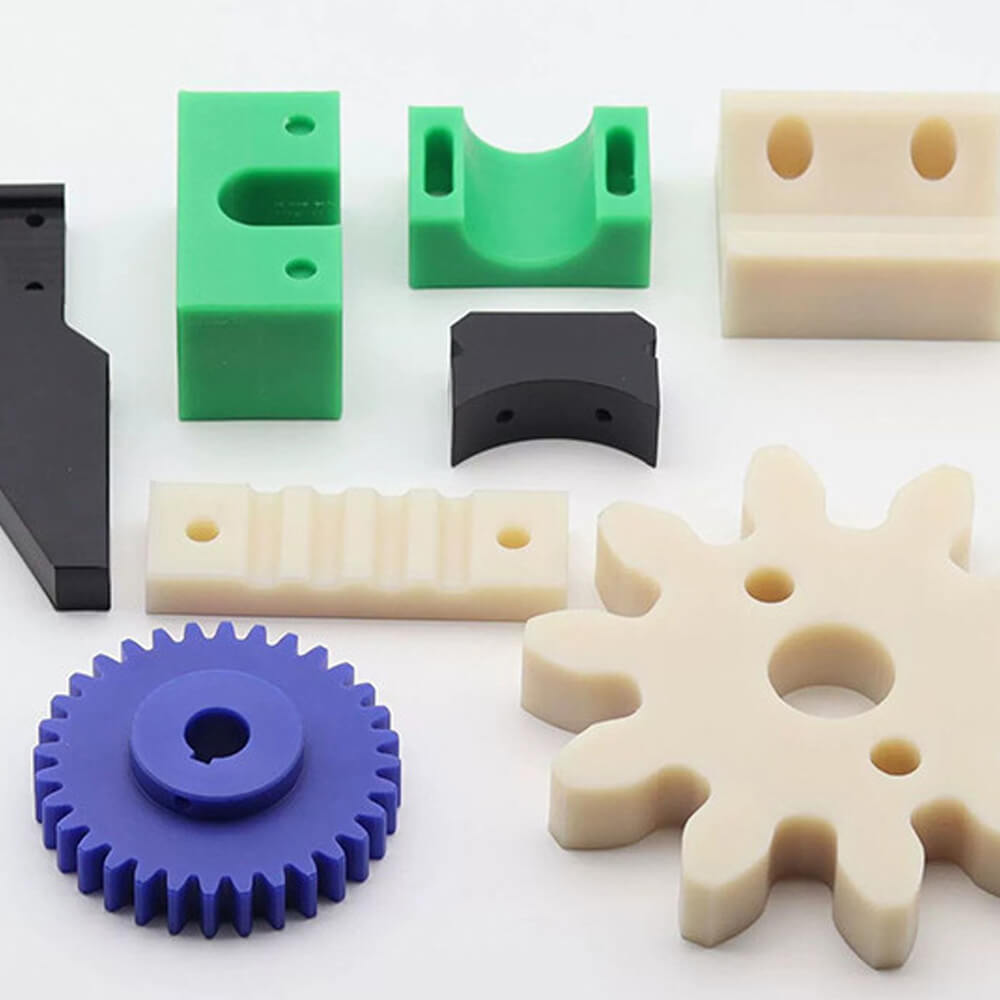

Custom PE (Polyethylene) CNC Machining Services in China

Machining Durable, Chemically Resistant, and Impact-Tough Components from a Versatile Plastic Family.

- ISO 9001 Certified

- HDPE, LDPE & UHMW Grades

- Food-Safe & Industrial Applications

Your Expert Partner for Polyethylene Machining

Celerity Precision is a leading manufacturing service provider in China specializing in the CNC machining of Polyethylene (PE). Polyethylene is one of the most widely used plastics in the world, available in a spectrum of densities and formulations, each offering a unique combination of properties. From the flexible and tough LDPE to the rigid and strong HDPE, and the ultra-durable UHMWPE, this material is celebrated for its exceptional chemical resistance, high impact strength, and low coefficient of friction. Machining PE requires specific expertise to manage its thermal expansion and flexible nature. Our facility is expertly equipped to machine all grades of Polyethylene, delivering high-quality parts for a vast range of industrial, commercial, and food-safe applications.

Why Choose Polyethylene for Your Machined Parts

Polyethylene is a tough, versatile, and cost-effective material choice for applications where chemical resistance and durability are key. Its waxy, self-lubricating surface makes it an excellent material for low-friction wear components, while its near-zero moisture absorption ensures it remains dimensionally stable in wet environments. While its softness can present machining challenges, Celerity Precision utilizes specialized sharp tooling, high machine speeds, and effective cooling methods to produce clean, precise, and burr-free Polyethylene parts.

Outstanding Chemical Resistance

Highly resistant to a wide range of acids, bases, and organic solvents.

Excellent Impact Strength

Very tough and durable, especially at low temperatures.

Near-Zero Moisture Absorption

Does not swell or change dimension in wet or humid environments.

Low Coefficient of Friction

A naturally slippery surface, making it ideal for wear and sliding applications.

FDA Compliant Grades

Many grades are available that are certified as safe for direct food contact.

Cost-Effective

A very affordable material, especially for its level of performance and durability.

HDPE (High-Density Polyethylene)

A rigid, strong, and durable grade with a high strength-to-density ratio. It is the most common grade for machining structural components, tanks, and fixtures.

| Tensile Strength, Yield (MPa) | 30 MPa |

| Elongation at Break (%) | 600% |

| Hardness (Brinnell) | 65 |

| Density (g/cm³) | 0.95 |

LDPE (Low-Density Polyethylene)

A softer and much more flexible grade than HDPE. It is known for its exceptional toughness and flexibility, making it ideal for parts that need to bend or deform.

| Tensile Strength, Yield (MPa) | 10 MPa |

| Elongation at Break (%) | 500% |

| Hardness (Brinnell) | 45 |

| Density (g/cm³) | 0.92 |

UHMW / UPE (Ultra-High-Molecular-Weight Polyethylene)

An extremely dense and tough grade with exceptional abrasion and impact resistance, far exceeding that of HDPE. It is a premier material for high-wear applications like wear strips and chain guides.

| Tensile Strength, Yield (MPa) | 40 MPa |

| Elongation at Break (%) | 350% |

| Hardness (Brinnell) | 66 |

| Density (g/cm³) | 0.93 |

Surface Finishing Options for Polyethylene

Due to its extremely high chemical resistance and waxy surface, PE is very difficult to finish, paint, or glue. It is almost always used with an as-machined finish.

As Machined

This is the standard and typically the only finish. PE machines to a clean, smooth, waxy surface. The color is usually natural (a milky white) or black.

Pros and Cons of Polyethylene CNC Machining

Pros

- Superb Chemical Resistance: The best choice for tanks, liners, and components in corrosive chemical environments.

- Very Tough and Durable: High impact strength means it will not crack or shatter easily.

- Excellent for Wear Applications (UHMW): UHMW is a top-tier material for wear strips and sliding components.

- Dimensionally Stable in Water: Will not change size or properties when submerged.

- Low Cost: A very affordable and high-value material.

Cons

- Difficult to Bond or Paint: The low-energy, waxy surface makes it nearly impossible to glue or paint without specialized surface treatments.

- Low Stiffness and Strength: Not a good material for structural parts that require high rigidity or tensile strength.

- "Gummy" to Machine: Can be difficult to machine cleanly without producing burrs if incorrect tools or parameters are used.

- High Thermal Expansion: Has a high coefficient of thermal expansion, meaning it will change size significantly with temperature changes. This must be considered for tight-tolerance parts.

Applications of CNC Machined Polyethylene Parts

Food Processing & Handling

Cutting boards, food-grade chutes, conveyor components, and augers (FDA-grade HDPE & UHMW).

Chemical Industry

Tanks, liners, flanges, and pump components for handling corrosive chemicals.

Industrial Machinery

Wear strips, chain guides, sprockets, and bumpers (UHMW).

Marine Applications

Starboard, dock bumpers, and components for use in water.

Medical

Components for prosthetic devices and custom supports (specific grades).

Prototyping

Creating durable, low-cost functional prototypes for testing.

Polyethylene Machining FAQ

What is the main difference between HDPE, LDPE, and UHMW?

In simple terms: LDPE is soft and flexible. HDPE is hard and rigid. UHMW is extremely hard, dense, and has the best wear resistance.

Why is it called "waxy"?

PE has a low coefficient of friction, which gives it a distinctively slippery or waxy feel. This property is what makes it a good material for sliding applications.

Can you glue Polyethylene parts together?

It is extremely difficult. It requires specialized surface preparation (like flame or plasma treatment) and industrial-grade structural adhesives. For most applications, mechanical fastening is the only reliable method.

Is Polyethylene food safe?

Many natural (unpigmented) grades of HDPE and UHMW are FDA compliant and widely used in the food industry. Black and other colored grades are typically not food safe.

How do you machine PE without it melting or creating burrs?

The key is to use extremely sharp cutting tools (often with geometries specifically for plastics), high machine speeds, and effective cooling to remove heat and chips from the cutting zone quickly.

Does PE have good UV resistance?

Natural PE has poor UV resistance and can become brittle with prolonged sun exposure. Black grades contain carbon black, which acts as a UV inhibitor, making them suitable for outdoor use.

Is PE a strong material?

It is very tough (resists impact), but it is not very strong or stiff (resists bending). It is not suitable for applications that require high tensile or flexural strength.

How do I choose between HDPE and UHMW?

Choose HDPE for general-purpose structural parts, tanks, and fixtures. Choose UHMW when your application involves high levels of abrasion or sliding wear, such as a conveyor chain guide or a scraper blade.