Home » CNC Machining Materials: Metals and Plastics » PET: Custom PET CNC Machining Material Supplier in China

Custom PET CNC Machining Services in China

Machining Strong, Stable, and Wear-Resistant Components for Industrial and Food-Grade Applications.

- ISO 9001 Certified

- Excellent Dimensional Stability

- FDA Compliant Grades Available

Your Expert Partner for PET Machining

Celerity Precision is a leading manufacturing partner in China for the high-precision CNC machining of PET (Polyethylene Terephthalate). While widely known for its use in beverage bottles and fibers, in its solid, semi-crystalline form, PET is a high-performance engineering thermoplastic. It is renowned for its excellent mechanical strength, high stiffness, superior wear resistance, and outstanding dimensional stability due to very low moisture absorption. PET is an ideal material for complex, precision-machined parts used in the food processing, industrial, and electronics industries. Our facility is expertly equipped to machine PET to tight tolerances, delivering components with a superior surface finish and reliable, long-term performance.

Why Choose PET for Your Machined Parts?

PET is an excellent all-around engineering plastic that offers a performance profile similar to POM (Acetal) and PBT, but with superior wear characteristics and a harder, more scratch-resistant surface. Its key advantage is its extremely low moisture absorption, which ensures that precision-machined parts will not swell or change shape in humid or wet environments. At Celerity Precision, we leverage PET’s excellent machinability to produce intricate parts with a beautiful, high-gloss finish, making it a top choice for components that require both performance and a clean, aesthetic appearance.

High Strength & Stiffness

A strong, rigid material that resists deformation under load, making it great for structural parts.

Outstanding Dimensional Stability

Extremely low moisture absorption and a low coefficient of thermal expansion ensure it holds tolerances exceptionally well.

Superior Wear & Abrasion Resistance

One of the best plastics for wear resistance, especially in dry sliding applications.

Excellent Surface Hardness

Has a hard, scratch-resistant surface, which is ideal for aesthetic and functional parts.

Good Chemical Resistance

Resistant to a wide range of solvents, oils, and weak acids.

FDA Compliant

Many grades are compliant with FDA, USDA, and 3A-Dairy standards for food and pharmaceutical contact.

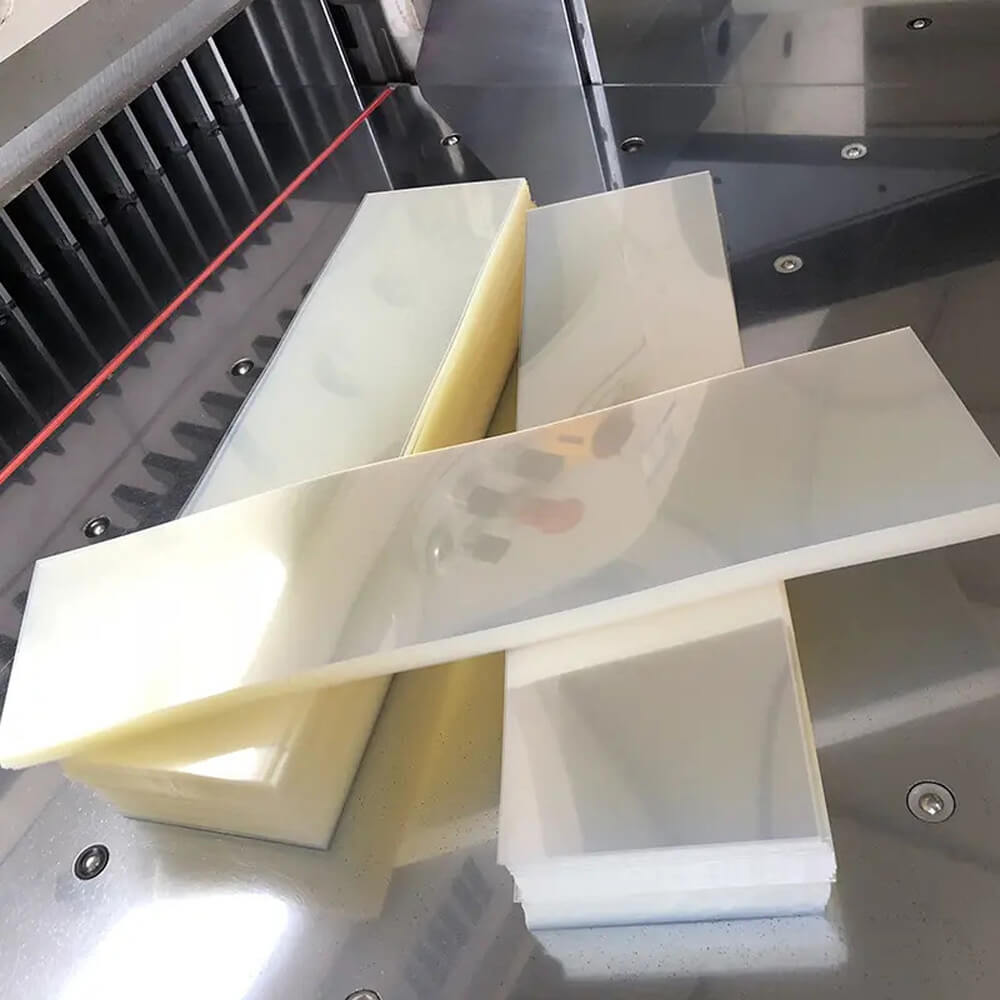

Unfilled PET (Natural / White, Black)

This is the standard grade, offering an excellent balance of strength, stiffness, and wear resistance. It machines to a very smooth, high-gloss finish and is FDA compliant in its natural form.

| Tensile Strength, Yield (MPa) | 85 MPa |

| Elongation at Break (%) | 20-50% |

| Hardness (Rockwell M) | 94 |

| Density (g/cm³) | 1.39 |

PTFE-Filled PET (Bearing Grade)

This grade has solid PTFE lubricant added to the polymer. This significantly reduces the coefficient of friction and enhances the wear properties, making it a premier material for high-speed, dry-running bearing and bushing applications.

| Tensile Strength, Yield (MPa) | 65 MPa |

| Elongation at Break (%) | 10% |

| Hardness (Rockwell M) | 85 |

| Density (g/cm³) | 1.44 |

Surface Finishing Options for PET

Due to its high chemical resistance and excellent as-machined finish, PET is almost always used without a secondary finish.

As Machined

This is the standard and final finish. PET machines to an exceptionally smooth, hard, and high-gloss surface. Standard colors are natural (bright white) and black.

Polishing

he already glossy surface can be further buffed to a mirror-like shine for applications requiring the highest level of cosmetic appeal.

Pros and Cons of PET CNC Machining

Pros

- Excellent for Precision Parts: Its superior dimensional stability makes it one of the best plastics for holding very tight tolerances.

- Great for Food Processing: FDA compliant grades and excellent resistance to cleaning chemicals make it a top choice.

- Superior Wear Properties: Harder and more wear-resistant than other common plastics like Nylon or POM.

- Aesthetically Pleasing Finish: Machines to a beautiful, hard, high-gloss finish naturally.

Cons

- Lower Impact Strength: Not as tough as materials like Polycarbonate or Nylon. It is more rigid and can be brittle, especially at low temperatures.

- Poor Resistance to Hot Water/Steam: Can be degraded by continuous exposure to hot water or steam above 60°C (140°F).

- Sensitive to Machining Heat: Can be prone to melting or creating burrs if not machined with very sharp tools and proper cooling.

- Higher Cost: A premium engineering plastic that is more expensive than materials like ABS or HDPE.

Applications of CNC Machined PET Parts

Food Processing & Packaging

Manifolds, pistons, gears, and conveyor components for food handling machinery.

Industrial Machinery

Precision gears, bearings, bushings, and rollers, especially in high-wear applications.

Electronics

Insulators, switch components, and high-precision structural parts for testing equipment.

Medical & Pharmaceutical

Components for diagnostic and analysis equipment, and parts requiring chemical resistance.

Prototyping

Creating dimensionally accurate, functional prototypes for parts that will be injection molded in PET.

Automotive

Components for fuel systems and other parts requiring good chemical resistance and dimensional stability.

PET Machining FAQ

What is the main difference between PET and PBT?

They are both polyesters and have similar properties. PET is generally stronger, stiffer, and has better wear resistance. PBT is tougher (less brittle) and has better electrical insulating properties.

When should I choose PET over POM (Delrin)?

Choose PET when you need better wear resistance, a harder surface, or superior dimensional stability, especially for food-grade applications. Choose POM when you need higher impact toughness and a slightly lower cost.

What is the difference between PET and the plastic used for water bottles?

They are chemically the same. However, the PET used for machining is a semi-crystalline, high-molecular-weight version that is solid, hard, and opaque, while the PET for bottles is an amorphous, lower-molecular-weight version that is transparent and flexible.

Why is PET a good material for food-grade parts?

It is FDA compliant, has virtually no moisture absorption (preventing bacteria growth), and is highly resistant to the acidic and alkaline cleaning agents used in the food industry.

Is PET difficult to machine?

It is not overly difficult, but it requires care. It has a low melting point, so sharp tools, high speeds, and coolant are necessary to achieve a clean, burr-free finish and prevent heat buildup.

Can PET be used in hot water?

It is not recommended for continuous use in water above 60°C (140°F), as it can be susceptible to hydrolysis, which degrades the material.

Is PET a good electrical insulator?

Yes, it is a very good electrical insulator with good dielectric properties.

What colors is PET available in?

The standard stock colors for machining are natural (a very bright, opaque white) and black.