Home » CNC Machining Materials: Metals and Plastics » PLA: Custom PLA CNC Machining Material Supplier in China

Custom PLA CNC Machining Services in China

Fast, Low-Cost, and Biodegradable Prototypes for Rapid Concept Validation.

- ISO 9001 Certified

- Ideal for Concept Models

- Rapid Turnaround

Your Expert Partner for PLA Prototyping

Celerity Precision offers rapid and affordable CNC machining services for PLA (Polylactic Acid) in China. PLA is a unique thermoplastic derived from renewable resources like corn starch, making it a biodegradable and eco-friendly choice. While widely known for its use in 3D printing, machined PLA is an outstanding material for creating early-stage concept models, non-functional prototypes, and fit-check parts with exceptional speed and at a very low cost. Our facility is expertly equipped to machine PLA, allowing you to quickly and affordably bring your initial ideas into the physical world for evaluation and iteration.

Why Choose PLA for Your Early-Stage Prototypes

PLA is the ideal material for the very first stages of product development. Its primary advantages are its low cost, ease of machining, and rapid turnaround time. It is a rigid and stiff material that machines cleanly, allowing for the creation of parts with good detail and a smooth surface finish. While it lacks the durability and temperature resistance of engineering plastics like ABS or PC, it is the perfect choice for quickly and inexpensively validating a design’s form and fit before moving on to more robust and costly materials.

Extremely Cost-Effective

Both the raw material and the machining process are very low-cost, making it perfect for iterative prototyping.

Rapid Machining & Turnaround

PLA machines very quickly and easily, enabling us to deliver your parts in the shortest possible timeframe.

Biodegradable & Eco-Friendly

Derived from renewable resources, it is a more sustainable choice for disposable or short-term-use prototypes.

Good Detail and Surface Finish

Machines cleanly, allowing for fine details and producing a smooth, semi-gloss surface.

High Stiffness

A relatively rigid material, making it good for creating models that hold their shape well.

Odorless and Non-Toxic

A safe and easy material to handle and work with.

Standard Machining Grade PLA

We use high-quality, industrial-grade PLA filament and stock specifically formulated for CNC machining. It offers higher rigidity and better thermal stability than standard 3D printing filaments, resulting in cleaner cuts and better dimensional accuracy. It is available in a variety of standard colors like white, black, and grey.

| Tensile Strength, Yield (MPa) | 65 MPa |

| Elongation at Break (%) | 3-6% |

| Hardness (Brinnell) | 88 |

| Density (g/cm³) | 1.24 |

Surface Finishing Options for PLA

Finishing options for PLA are primarily focused on improving its appearance for presentation models.

As Machined

The standard finish is a clean, smooth, semi-gloss surface. The quality of the machined finish is typically very good.

Sand Blasting

PLA can be easily sanded to remove any fine tool marks and create an even smoother, matte surface.

Painting

PLA provides an excellent surface for painting. With the use of a suitable primer, it can be painted in any color or finish to create high-fidelity appearance models.

Pros and Cons of PLA CNC Machining

Pros

- Low Cost: The most affordable way to get a high-quality physical model of your design.

- Speed: Extremely fast to machine, resulting in the quickest possible turnaround times.

- Good for Form & Fit: The perfect material for verifying the size, shape, and assembly of a design.

- Eco-Friendly: A biodegradable and sustainable option for prototyping.

- Safe and Easy to Process: No harsh fumes or chemicals involved in its processing.

Cons

- Low Temperature Resistance: Becomes soft and deforms at relatively low temperatures (above 60°C / 140°F). Not suitable for use in warm environments like the inside of a car.

- Brittle: PLA is stiff but also brittle, meaning it will crack or shatter under high impact rather than bend. Not suitable for functional, snap-fit parts.

- Poor Chemical Resistance: Can be degraded by moisture over long periods and is not resistant to many common chemicals.

- Not for Functional Testing: Due to its brittleness and low temperature resistance, it is generally not suitable for rigorous functional testing.

Applications of CNC Machined PLA Parts

Concept Models

Creating high-fidelity appearance models for design reviews, marketing photography, or investor presentations.

Form & Fit Prototypes

Producing parts to quickly check the size, shape, and how well they assemble with other components.

Ergonomic Studies

Machining models of handheld products to test their feel and ergonomics.

Jigs & Fixtures (Light Duty):

Creating simple, low-cost fixtures for holding parts during light-duty assembly or inspection.

Educational Models

Producing detailed models for educational and demonstration purposes.

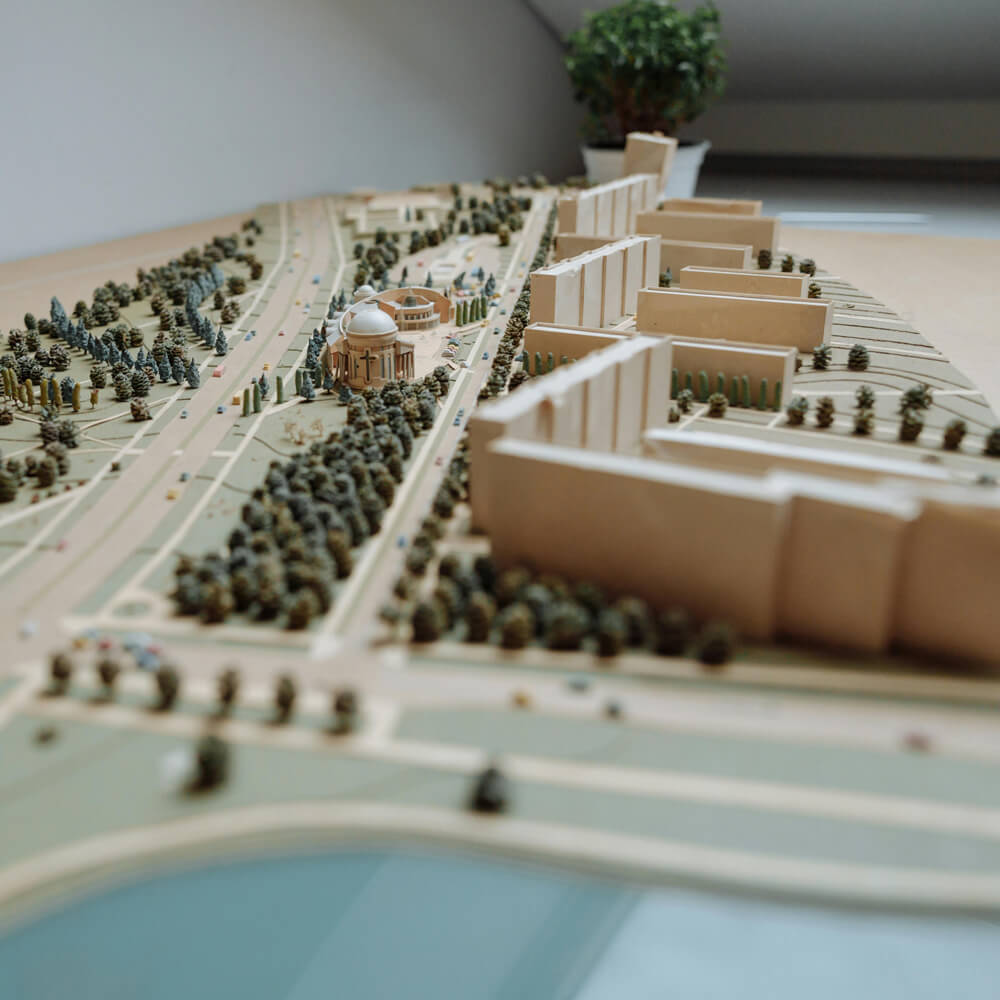

Architectural Models

Machining scale models of buildings and structures with fine detail.

PLA Machining FAQ

Isn't PLA a 3D printing material? Why would I machine it?

While famous for 3D printing, machining PLA from a solid block offers superior dimensional accuracy, a much smoother surface finish (with no layer lines), and creates a fully dense, stronger part compared to its 3D printed equivalent.

What is the main difference between PLA and ABS?

ABS is a petroleum-based plastic that is much tougher, more durable, and has a higher temperature resistance, making it suitable for functional parts. PLA is a plant-based plastic that is more brittle and less durable, making it best for non-functional models.

Is machined PLA strong?

It is stiff and has good tensile strength, but it is brittle. This means it can hold a static load well but will likely break if dropped or impacted.

How long will a PLA part last?

In a normal indoor environment, a PLA part will last for years. However, it is biodegradable and will break down over time if left outdoors or in a high-moisture environment.

What is the best way to paint a PLA part?

The best method is to first lightly sand the surface, apply a high-quality plastic primer (spray can is fine), and then apply your desired color coats.

Is PLA waterproof?

A solid machined part is water-resistant, but PLA will absorb moisture over time, which can cause it to swell and degrade. It is not recommended for long-term wet applications.

What colors is PLA available in?

Standard machining stock is typically available in neutral colors like white, black, and natural. A wide variety of colors can be achieved through painting.

Why should I choose machined PLA over 3D printed PLA?

Choose machined PLA when you need better dimensional accuracy, a perfectly smooth surface finish without layer lines, and a fully solid, non-porous part.