Home » CNC Machining Materials: Metals and Plastics » POM: Custom POM CNC Machining Material Supplier in China

Custom POM (Delrin/Acetal) CNC Machining Services in China

High-Stiffness, Low-Friction, and Dimensionally Stable Components for Precision Engineering.

- ISO 9001 Certified

- High-Precision Mechanical Parts

- Delrin® & Acetal Copolymer

Your Expert Partner for POM Machining

Celerity Precision is a leading manufacturer in China specializing in the high-precision CNC machining of POM (Polyoxymethylene), commonly known by its trade names Delrin® (homopolymer) or Acetal (copolymer). POM is a high-performance engineering thermoplastic renowned for its unique combination of high stiffness, excellent dimensional stability, low friction, and outstanding wear resistance. It is the go-to material for creating durable and precise mechanical parts that can replace metal in many applications, such as gears, bearings, jigs, and fixtures. Our facility is expertly equipped to machine POM to extremely tight tolerances, delivering parts that perform reliably in the most demanding mechanical systems.

Why Choose POM for Your Machined Parts

POM bridges the gap between high-performance plastics and metals. Its high crystallinity gives it a natural lubricity and exceptional resistance to wear, making it an ideal choice for moving or sliding components. Crucially, it has very low moisture absorption, ensuring that parts remain dimensionally stable and hold their tolerances even in humid or wet environments. At Celerity Precision, we leverage POM’s outstanding machinability—it cuts cleanly, producing excellent surface finishes and burr-free details—to create high-precision components for a wide range of industries.

High Stiffness & Tensile Strength

A very rigid material that resists bending and deformation under load.

Excellent Dimensional Stability

Very low moisture absorption means parts won't swell or change size.

Low Coefficient of Friction

Naturally slippery and self-lubricating, perfect for high-wear applications.

Outstanding Machinability

One of the easiest engineering plastics to machine, allowing for tight tolerances and fine features.

Good Chemical Resistance

Resistant to a wide range of solvents, fuels, and industrial chemicals.

High Fatigue Endurance

Resists failure under repeated cyclic loading, making it great for parts like snap-fits and gears.

POM-H (Homopolymer / Delrin®)

This grade offers slightly higher mechanical properties, including better tensile strength, stiffness, and a lower coefficient of friction. It is the premium choice for applications demanding the highest performance.

| Tensile Strength, Yield (MPa) | 70 MPa |

| Elongation at Break (%) | 25-75% |

| Hardness (Brinnell) | 94 |

| Density (g/cm³) | 1.42 |

POM-C (Copolymer / Acetal)

This grade offers better chemical resistance, lower outgassing, and better dimensional stability, especially in hot water. It is a more economical, general-purpose choice with excellent all-around properties.

| Tensile Strength, Yield (MPa) | 65 MPa |

| Elongation at Break (%) | 25-60% |

| Hardness (Brinnell) | 80 |

| Density (g/cm³) | 1.41 |

Surface Finishing Options for POM

Due to its chemical resistance and low-friction surface, POM is not suitable for most secondary finishing processes like painting or gluing.

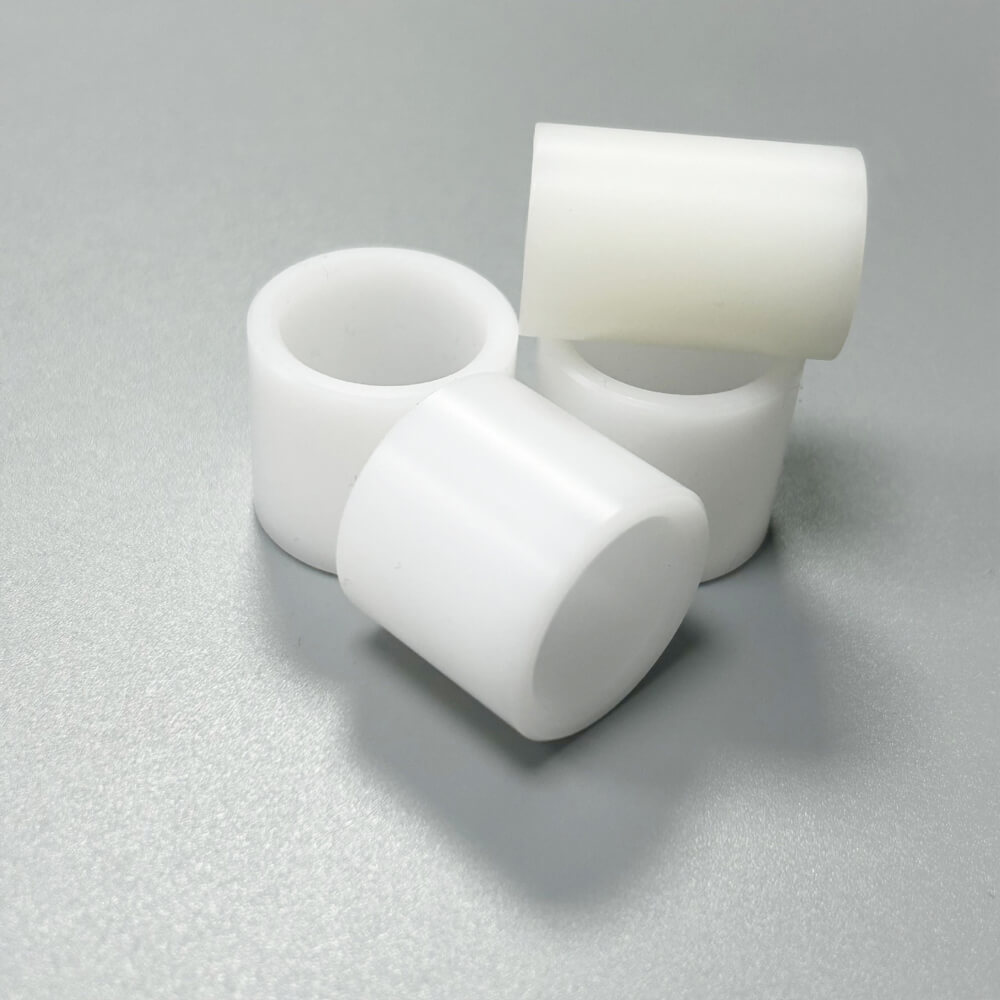

As Machined

This is the most common and almost always the final finish. POM machines to an excellent, smooth, semi-gloss surface with a naturally slippery feel. Colors are typically limited to natural white and black.

Polishing

While not common, the surface can be lightly buffed to enhance its natural sheen.

Pros and Cons of POM CNC Machining

Pros

- Excellent for Mechanical Parts: The best choice for gears, bearings, bushings, and other low-friction, high-wear components.

- Holds Tight Tolerances: Its rigidity and stability allow us to machine it to very high levels of precision.

- Great Metal Replacement: Can often replace aluminum or brass in mechanical applications, offering weight savings and lower cost.

- Performs in Wet Environments: Low moisture absorption ensures it will not swell or lose its properties.

- Superb Machinability: Easy to machine, resulting in fast cycle times and a beautiful as-machined finish.

Cons

- Difficult to Bond: Its low-friction, chemically resistant surface makes it very difficult to glue with common adhesives. Mechanical fastening is required.

- Poor UV Resistance: Not suitable for long-term outdoor use, as it can degrade when exposed to sunlight (black grades perform better).

- Limited Finishing Options: Cannot be effectively painted or coated.

- Not Flame Retardant: POM is flammable and will burn cleanly without smoke.

Applications of CNC Machined POM Parts

Industrial Machinery

Gears, bearings, bushings, rollers, wear pads, and valve bodies.

Automotive

Fuel system components, speaker grilles, and interior mechanical parts.

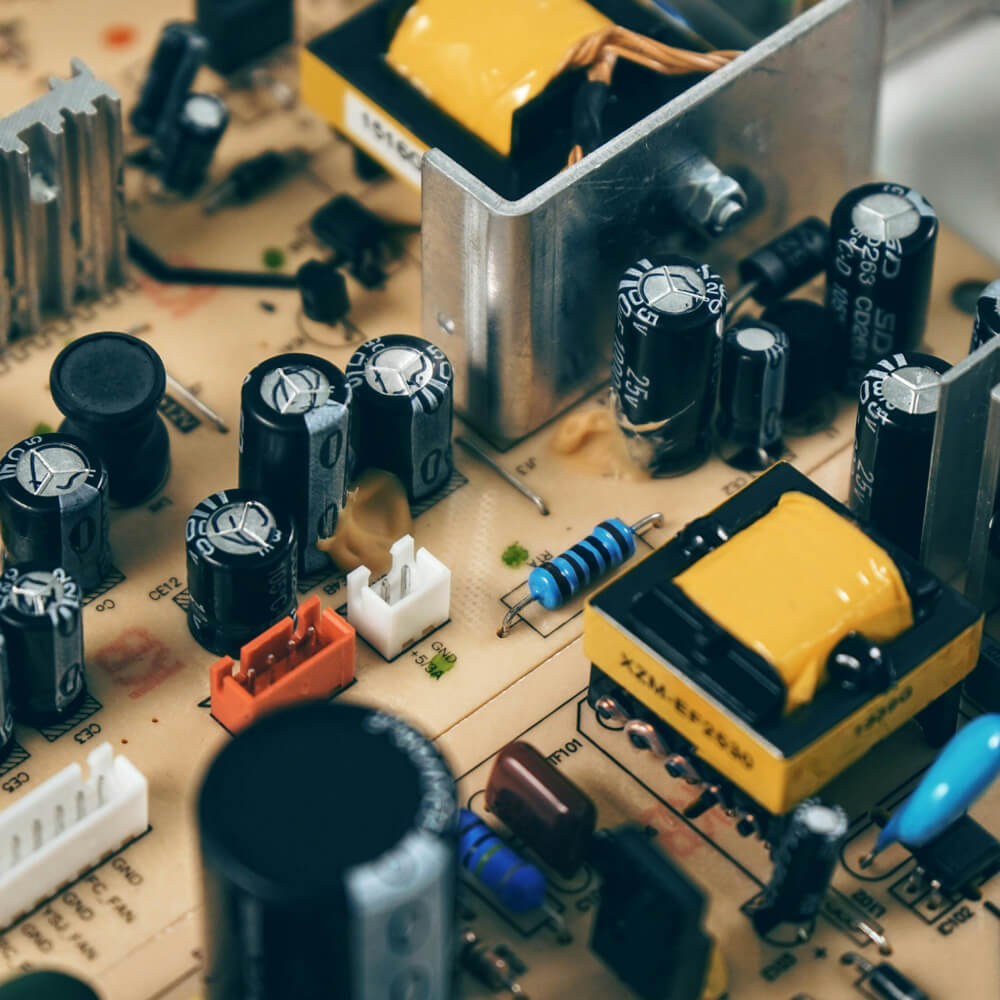

Consumer Electronics

Sliding mechanisms, structural frames, and precision internal components.

Medical

Instrument handles, and components for medical devices that require high stiffness and sterilization resistance (specific grades).

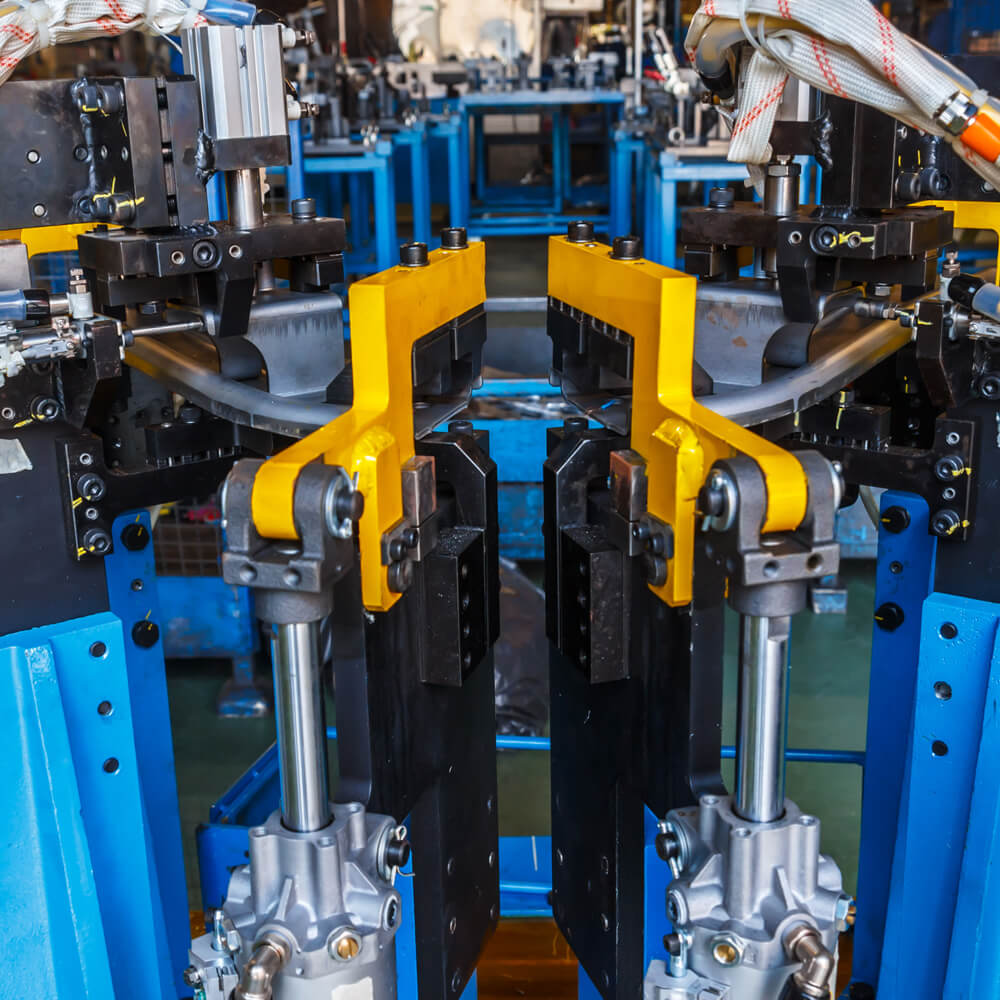

Jigs & Fixtures

Creating durable, non-marring jigs, nests, and fixtures for manufacturing and assembly lines.

Food Processing

Components for food processing equipment that require low friction and chemical resistance (FDA-compliant grades).

POM Machining FAQ

What is the main difference between Delrin® (POM-H) and Acetal (POM-C)?

Delrin® (homopolymer) is slightly stronger, stiffer, and has a lower coefficient of friction, making it better for high-performance mechanical parts. Acetal (copolymer) has better chemical and hot water resistance, making it more stable in certain environments. For most applications, they are largely interchangeable.

Why can't I glue Delrin?

Its chemical resistance and low surface energy prevent most adhesives from forming a strong bond. The surface needs to be heavily prepared (e.g., plasma or chemical etching) before bonding is possible. Mechanical fastening is the recommended joining method.

What colors is POM available in?

The standard stock colors for machining are natural (a bright, opaque white) and black.

Is POM a good material for bearings?

It is one of the best plastic materials for bearings. Its low friction, high wear resistance, and high strength make it a top choice for replacing metal bearings in many applications.

Is POM safe for food contact?

Standard grades are not. However, specific FDA, NSF, and 3A-Dairy compliant grades of both POM-H and POM-C are available for food processing and medical applications.

Does POM absorb water?

It has one of the lowest moisture absorption rates of any engineering plastic, which is why it is so dimensionally stable.

How do you machine POM to tight tolerances?

POM’s excellent machinability and stability are key. We use very sharp tools, high cutting speeds, and stress-relieving techniques (annealing) for the most critical-tolerance parts to ensure they remain accurate.

Is POM resistant to gasoline and oils?

Yes, it has excellent resistance to hydrocarbons, solvents, and automotive fluids, which is why it’s a popular choice for fuel system components.