Home » CNC Machining Materials: Metals and Plastics » Stainless Steel: Custom Stainless Steel CNC Machining Material Supplier in China

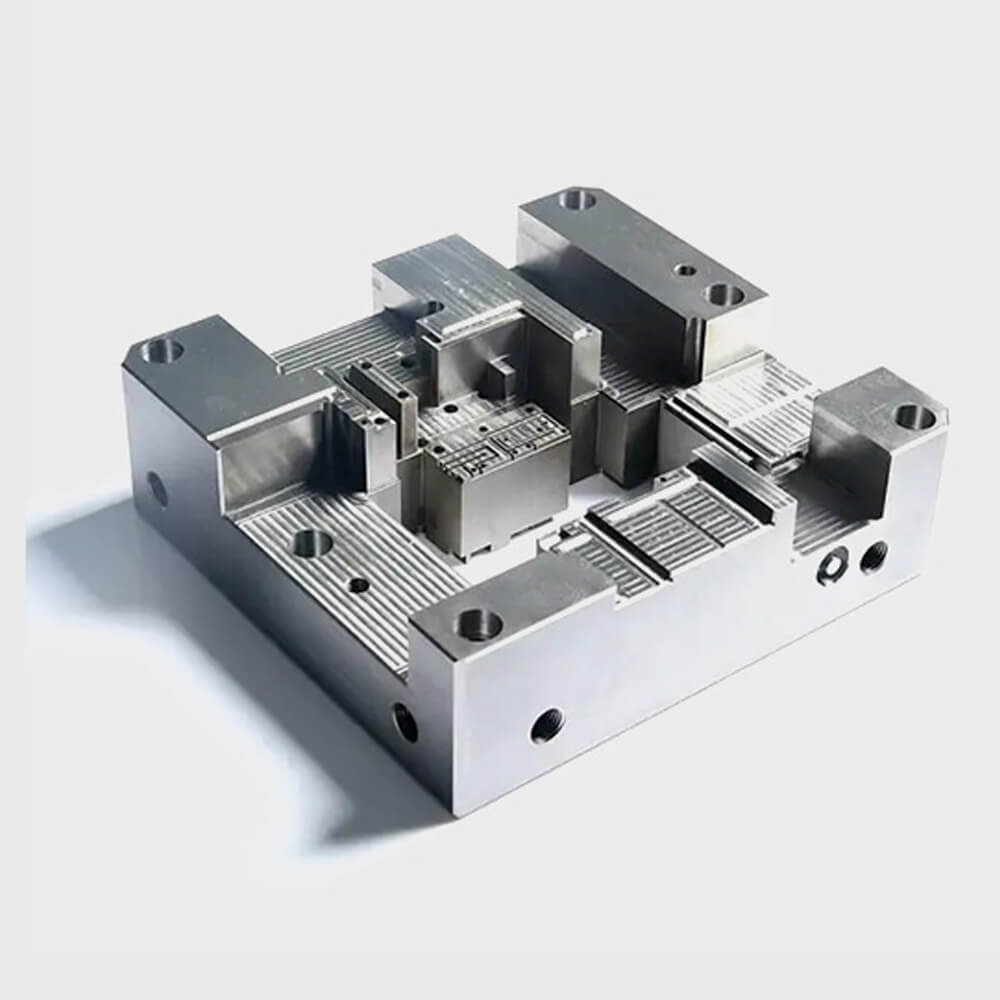

Custom Stainless Steel CNC Machining Services in China

Precision Machining of Stainless Steel for Corrosion Resistance, Strength, and a Premium Finish.

- ISO 9001 Certified

- Medical, Marine & Food Grade

- Expert Passivation Services

Your Expert Partner for Stainless Steel Machining

Celerity Precision is a premier manufacturer in China specializing in the CNC machining of stainless steel alloys. Renowned for its exceptional corrosion resistance, high strength, and clean, aesthetic appearance, stainless steel is the definitive material for parts used in harsh environments and applications demanding high purity. From critical medical instruments and marine hardware to food processing equipment, we have the expertise and technology to machine this tough material to exacting specifications. Our advanced CNC centers and rigorous quality processes ensure every stainless steel component we produce is durable, reliable, and perfectly finished.

Why Choose Stainless Steel for Your Machined Parts?

Stainless steel is an iron-based alloy containing a minimum of 10.5% chromium, which creates a passive, self-repairing oxide layer that provides its signature “stainless” quality. While more challenging to machine than carbon steel or aluminum, its combination of strength, corrosion resistance, and heat resistance is unmatched. At Celerity Precision, we have perfected the techniques for machining stainless steel. We use powerful, rigid CNC machines, specialized cutting tools, and optimized speeds and feeds to overcome work hardening and ensure a superior surface finish and tight tolerance adherence.

Exceptional Corrosion Resistance

The primary advantage, offering outstanding protection against rust, water, and many chemicals.

High Strength & Durability

Offers excellent mechanical properties, maintaining its strength at both high and low temperatures.

Aesthetic Appeal & Hygienic

Provides a clean, bright, and premium finish that is easy to sterilize and does not impart flavor, making it ideal for medical and food-grade use.

Heat Resistance

Maintains its strength and resists oxidation at elevated temperatures better than carbon steel.

Material Versatility

Available in a wide range of grades (Austenitic, Martensitic, etc.) to tailor properties for specific needs.

Long-Term Value

While the initial cost is higher, its long service life and low maintenance requirements often make it the most economical choice over time.

304 Stainless Steel (A2)

The most common and versatile stainless steel grade. It offers excellent corrosion resistance and good formability, making it a “workhorse” for a huge range of applications.

| Tensile Strength, Yield (MPa) | 515 MPa |

| Elongation at Break (%) | 40% |

| Hardness (Brinnell) | 201 |

| Density (g/cm³) | 8.00 |

316 Stainless Steel (A4)

Contains molybdenum, which provides superior corrosion resistance, especially against chlorides and industrial solvents. It is the preferred choice for marine, medical, and chemical applications.

| Tensile Strength, Yield (MPa) | 515 MPa |

| Elongation at Break (%) | 40% |

| Hardness (Brinnell) | 217 |

| Density (g/cm³) | 8.00 |

303 Stainless Steel

A free-machining grade of stainless steel due to the addition of sulfur. It is the easiest to machine, making it a cost-effective choice for high-volume parts, but has slightly lower corrosion resistance than 304.

| Tensile Strength, Yield (MPa) | 620 MPa |

| Elongation at Break (%) | 40% |

| Hardness (Brinnell) | 262 |

| Density (g/cm³) | 8.03 |

17-4 PH Stainless Steel

A precipitation-hardening alloy that can be heat-treated to extremely high strength and hardness levels, comparable to alloy steels, while still maintaining good corrosion resistance.

| Tensile Strength, Yield (MPa) | 1000-1310 MPa (Heat Treated) |

| Elongation at Break (%) | 10-14% |

| Hardness (Brinnell) | 360-420 |

| Density (g/cm³) | 7.80 |

Surface Finishing Options for Stainless Steel

While stainless steel is naturally corrosion-resistant, we offer several finishes to enhance its appearance and maximize its performance.

As Machined

The standard finish with visible tool marks. Passivation is highly recommended after machining.

Passivation

A critical chemical cleaning process that removes free iron from the surface and maximizes the natural corrosion resistance of the alloy.

Electropolishing

An electrochemical process that creates an ultra-smooth, bright, mirror-like, and microscopically clean surface.

Brushed Finish

Creates an elegant, linear satin grain for a sophisticated, high-end decorative appearance on parts like panels and enclosures.

Sand Blasting

Produces a uniform, non-reflective matte finish for a clean, industrial look.

Tumbling

An effective method for deburring and creating a smooth, uniform, semi-lustrous finish on batches of small parts.

Heat Treatment

Used on hardenable grades like 17-4 PH to significantly increase their strength and hardness.

Pros and Cons of Stainless Steel CNC Machining

Pros

- Superior Corrosion Resistance: The defining characteristic, making it essential for harsh environments.

- Hygienic and Easy to Clean: The non-porous surface is easy to sterilize, which is critical for medical and food-grade applications.

- High Strength and Toughness: Maintains excellent mechanical properties across a wide temperature range.

- Premium Aesthetic: The clean, bright finish provides a high-end look and feel.

Cons

- Difficult to Machine: Stainless steel is tough and prone to "work hardening," which requires slower cutting speeds, more robust tooling, and more powerful machines, increasing machining cost.

- Higher Material Cost: More expensive than carbon steel and aluminum.

- Poor Thermal Conductivity: Does not dissipate heat well, which can be a challenge during machining and a disadvantage in thermal management applications.

- Heavy Weight: A dense material, similar in weight to regular steel.

Applications of CNC Machined Stainless Steel Parts

Medical & Surgical

Surgical instruments, bone screws, medical implants, and diagnostic equipment components.

Food & Beverage

Processing equipment, nozzles, manifolds, and sanitary fittings.

Marine

Shafts, valves, fasteners, and hardware for use in saltwater environments.

Aerospace

High-strength fittings, fasteners, and components for engines and exhaust systems.

Energy & Chemical

Valve bodies, pump components, and fixtures for corrosive processing environments.

Architecture

Custom decorative hardware, brackets, and structural elements.

Stainless Steel Machining FAQ

What is the difference between 304 and 316 stainless steel?

316 stainless steel contains molybdenum, which gives it significantly better resistance to corrosion from chlorides (like salt water and de-icing salts). 316 is the preferred choice for marine and medical applications.

I thought stainless steel doesn't rust. Why does it need passivation?

During machining, microscopic iron particles from the cutting tools can become embedded in the surface. These particles can rust. Passivation is a chemical process that removes this “free iron” and allows the stainless steel’s natural protective layer to form properly.

Which stainless steel is the easiest to machine?

Grade 303 is specifically designed for machinability. The addition of sulfur acts as a chip breaker, allowing for faster and more efficient machining.

Is stainless steel magnetic?

It depends on the grade. Austenitic grades like 304 and 316 are generally non-magnetic in their raw state but can become slightly magnetic after machining (work hardening). Martensitic grades like the 400 series are magnetic.

Can stainless steel be hardened by heat treatment?

Austenitic grades (304, 316) cannot be hardened by heat treatment. However, martensitic (400 series) and precipitation-hardening (17-4 PH) grades are designed to be heat-treated to very high strength and hardness levels.

What is the best finish for a medical part?

For medical instruments and implants, a combination of electropolishing and passivation is often the best choice. This creates an ultra-smooth, clean, and highly corrosion-resistant surface.

Is stainless steel difficult to weld?

Most common stainless steels (like 304 and 316) are readily weldable, especially with the TIG welding process, which produces very clean and strong joints.

How do I specify a stainless steel grade on my drawing?

Be specific, for example, “Material: Stainless Steel, 316L” or “Material: Stainless Steel, 17-4 PH, Condition H900.”