Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Energy & Power

Precision Manufacturing for the Energy & Power Generation Industry

Forging the High-Strength, High-Temperature, and Mission-Critical Components that Power Our World—from Gas Turbine Blades to Subsurface Drilling Tools.

- ISO 9001 Certified

- Expertise in High-Temp Superalloys

- Full NDT & Material Traceability

Your Strategic Manufacturing Partner for Energy Systems

The energy and power generation industry is the bedrock of global infrastructure, operating under extreme conditions of high temperature, immense pressure, and the relentless demand for 24/7 reliability. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, dedicated to producing the mission-critical mechanical components that perform under these extraordinary stresses. From intricate turbine blades made from superalloys and massive generator shafts to durable downhole drilling tools and precision valve bodies for nuclear applications, we have the advanced technology and deep process expertise to meet the stringent demands of this vital sector.

We understand that components in the energy sector have a long lifecycle where failure is not an option. Our services are engineered to provide absolute confidence, from initial prototyping for harsh-environment validation to scalable, repeatable production. As your designs are finalized, we provide a seamless path to manufacturing, ensuring the material integrity, dimensional accuracy, and flawless performance of every component. We are more than a supplier; we are a precision partner committed to helping you build the future of reliable energy.

The Celerity Precision Advantage for Energy Applications

Expertise in High-Temperature Superalloys

We specialize in the complex machining of high-performance, heat-resistant superalloys like Inconel®, Hastelloy®, and precipitation-hardened stainless steels, which are essential for components in combustion and exhaust zones.

Large & Heavy Component Machining

Our facility is equipped with large-envelope CNC mills and high-capacity turning centers, enabling us to produce massive components like generator rotors, turbine casings, and large-scale valve bodies.

Uncompromising Precision for Rotating Systems

We excel at holding the extremely tight tolerances and geometric controls required for high-speed rotating assemblies, ensuring perfect balance, minimal vibration, and maximum operational efficiency.

Full Traceability & Nondestructive Testing (NDT)

We provide complete material traceability (MTRs) and can manage a full suite of NDT services (UT, MPI, FPI) through certified partners to validate the internal and external integrity of every critical part.

Prototyping for Extreme Validation

We produce production-quality prototypes from specified alloys, allowing your teams to perform rigorous real-world testing under extreme temperature, pressure, and load conditions before committing to full production.

Integrated Supply Chain

We offer a one-stop solution for complex energy components, managing everything from material sourcing and machining to heat treatment, specialized coatings, and final inspection to simplify your logistics.

From Certified Alloy to Power-Ready Component: Our Process

RFQ & Engineering Review

Submit your CAD files and technical specifications. Our engineers provide a comprehensive quote and DFM feedback focused on manufacturability with challenging alloys and performance under extreme stress.

Process Planning & Risk Mitigation

We develop a robust manufacturing strategy, including specialized tooling and multi-stage machining processes to manage the stresses and unique properties of high-performance materials.

Certified Material Sourcing & Verification

We procure certified superalloys and other materials from globally approved mills, providing full documentation to ensure compliance with the highest industry and safety standards.

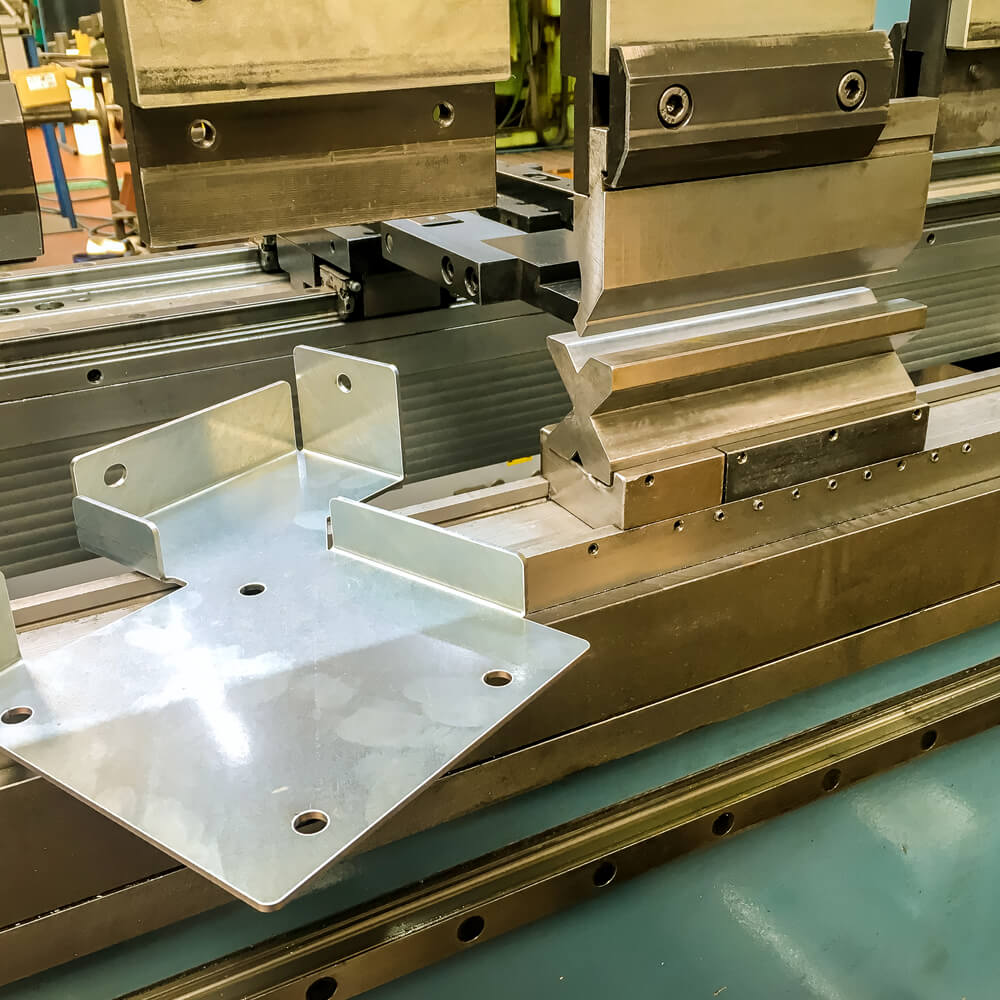

Precision & Heavy-Duty Machining

Your parts are expertly machined on our advanced 5-axis and large-format CNC centers. Complex features like turbine blade airfoils and fir-tree slots are machined with exceptional accuracy.

Heat Treatment & Specialized Coatings

Components undergo critical post-processing, such as vacuum heat treating, solution annealing, and the application of thermal barrier or anti-galling coatings to achieve final performance characteristics.

CMM Inspection & NDT Validation

All critical dimensions are verified using our large-format CMMs. We then coordinate any required NDT to provide a final report certifying the component's integrity before shipment.

Powering the Next Generation of Energy?

Let’s collaborate on the mission-critical components that will deliver reliable performance.

Key Manufacturing Services for the Energy Sector

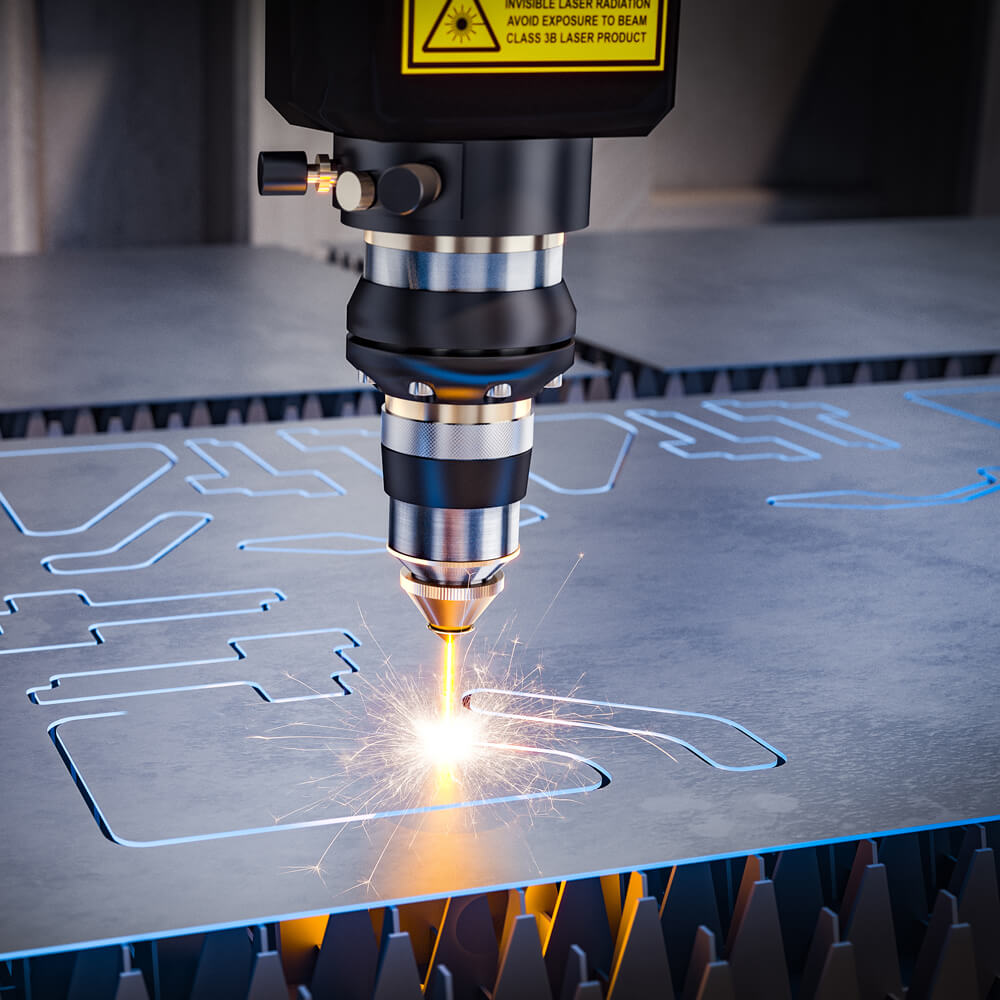

5-Axis CNC Milling

The only way to accurately produce complex geometries like turbine blades, blisks (bladed disks), and impellers from a single piece of high-strength superalloy.

CNC Turning with Live Tooling

Essential for manufacturing large generator shafts, rotor components, custom high-pressure flanges, and downhole tool bodies with high precision.

Wire & Sinker EDM

Used to create intricate features in hardened materials that are impossible to machine conventionally, such as internal splines and fir-tree slots for turbine blades.

Precision Grinding

Critical for achieving the final, ultra-tight tolerances and fine surface finishes on rotating shafts, bearing journals, and sealing surfaces.

Nondestructive Testing (NDT)

Coordinating services like Ultrasonic Testing (UT), Magnetic Particle Inspection (MPI), and Fluorescent Penetrant Inspection (FPI) to guarantee components are free of subsurface and surface defects.

Complex Assembly & Balancing

Performing mechanical assembly of rotating components and managing dynamic balancing services to ensure smooth, vibration-free operation at high speeds.

High-Performance Materials and Finishes for Energy Applications

Common Energy Sector Materials:

- Nickel Alloys (Inconel® 625, 718)

- Stainless Steel (17-4 PH, 316L)

- Titanium (Grade 5)

- Alloy Steel (4140, 4340)

- Super Duplex Stainless Steel

- Hastelloy®

Functional Surface Finishes:

- Thermal Barrier Coatings (TBC)

- Anti-Galling Coatings (e.g., Molybdenum Disulfide)

- Hard Chrome Plating

- Electroless Nickel Plating (for corrosion and wear)

- Passivation (for stainless steels)

- Shot Peening (to improve fatigue life)

Gallery of Energy & Power Generation Components

- Turbine and Compressor Blades (Blades & Vanes)

- Generator and Rotor Shafts

- Downhole Drilling Tools (e.g., MWD/LWD components)

- High-Pressure Valve Bodies and Components

- Impellers and Diffusers for Pumps and Compressors

- Large Bearing Housings

- Nuclear-Grade Flanges and Fittings

- Heat Exchanger Components

- Wind Turbine Gearbox and Hub Components

- Components for Geothermal and Hydroelectric Systems

Frequently Asked Questions

What is the best material for high-temperature turbine components?

Nickel-based superalloys like Inconel® 718 are the industry standard. They are specifically designed to retain exceptional strength and creep resistance at the extreme operating temperatures found inside gas turbines and jet engines.

Why is 5-axis machining essential for turbine blades?

Turbine blades have complex “airfoil” surfaces with constantly changing curves in multiple directions. 5-axis machining is the only practical way to create these aerodynamic profiles accurately and efficiently from a solid block of material.

What is Nondestructive Testing (NDT) and why is it critical?

NDT is a group of analysis techniques (like ultrasonic or magnetic particle) used to evaluate the properties of a component for defects without causing damage. In the energy sector, it is critical for ensuring that mission-critical parts have no hidden internal flaws that could lead to catastrophic failure.

How do you machine difficult materials like Inconel?

Machining superalloys is challenging as they rapidly work-harden and generate extreme heat. We overcome this with specialized carbide tooling, rigid machine setups, optimized low-speed/high-torque toolpaths, and high-pressure coolant systems.

Can you hold the tolerances required for high-speed generator shafts?

Yes. We use a combination of precision turning, finish grinding, and dynamic balancing to meet the strict requirements for straightness, roundness, and balance necessary for high-RPM rotating equipment.

Do you provide full material traceability for your components?

Absolutely. Full traceability from the original mill to the final component is standard procedure for us. We provide Mill Test Reports (MTRs) and certificates of conformance for all energy sector projects.

What are thermal barrier coatings (TBCs)?

TBCs are advanced ceramic coatings applied to metallic surfaces, such as on turbine blades. They act as thermal insulation, protecting the underlying superalloy from extreme temperatures and thereby extending the component’s life and performance.

Can you manufacture components for the nuclear power industry?

Yes. While we do not hold an “N-stamp”, we can manufacture components to nuclear industry specifications, which requires the highest levels of process control, documentation, material traceability, and quality assurance.

What are "downhole tools" for the oil & gas industry?

These are sophisticated electronic and mechanical instruments used deep inside a wellbore for drilling and evaluation (e.g., MWD/LWD systems). We machine the high-strength, pressure-resistant housings and internal components that protect the sensitive electronics from the extreme heat and pressure thousands of feet underground.

How do you guarantee the quality of a part that is several meters long?

We use large-format Coordinate Measuring Machines (CMMs), laser trackers, and robust in-process controls to ensure dimensional accuracy is maintained over the entire length of the component. For very long shafts, we also perform detailed straightness checks.

Related High-Reliability Applications

Defense & Military

Applying our mission-critical manufacturing expertise to components for land, sea, and air defense systems.

Industrial Machinery

Building robust, heavy-duty components for machinery that must operate continuously under heavy loads.

Marine Industry

Engineering components from corrosion-resistant alloys designed to survive in extremely harsh environments.