Home » Applications: Machining, Fabrication, Casting, and Surface Finish Services » Scientific Instruments Industry

Ultra-High Precision Manufacturing for the Scientific Instruments Industry

Building the Dimensionally Stable, Vacuum-Compatible, and Ultra-Precise Components that Drive Scientific Discovery—from Mass Spectrometer Ion Optics to Synchrotron Beamline Assemblies.

- ISO 9001 Certified

- Climate-Controlled Metrology

- Expertise in Low-Expansion Alloys

Your Collaborative Partner in Scientific Advancement

The world of scientific instrumentation is a realm of ultimate precision, where discoveries are enabled by components that are dimensionally stable to the nanometer and function flawlessly in ultra-high vacuum (UHV) environments. Celerity Precision is a specialized manufacturing partner in Shenzhen, China, built to serve the engineers and scientists at the forefront of research. We manufacture the foundational mechanical components for the world’s most advanced analytical and measurement instruments. From complex vacuum chambers and ion optical assemblies to low-expansion alloy optical benches and precisely aligned detector mounts, we have the specialized expertise and process controls to meet the extreme demands of this exacting field.

We understand that developing a new scientific instrument is a journey of iteration, experimentation, and perfection. Our services are designed to support this entire process, from providing rapid, high-fidelity prototypes for research labs to establishing a stable and repeatable production process for commercial instruments. We are more than a machine shop; we are a dedicated manufacturing partner committed to helping you build the tools that push the boundaries of human knowledge.

The Celerity Precision Advantage for Scientific Instruments

Extreme Precision & Stability

Our entire facility is climate-controlled, and we employ stress-relieving techniques to ensure that components made from materials like stainless steel and aluminum are dimensionally stable and free from internal stresses.

Expertise in Scientific-Grade Materials

We have deep experience machining the specific materials required for scientific applications, including UHV-grade 316L VIM/VAR stainless steel, low-expansion alloys like Invar and Kovar, PEEK, and machinable ceramics like Macor®.

Ultra-High Vacuum (UHV) Compatibility

Our manufacturing process, from material selection and handling to finishing and cleaning, is optimized to minimize outgassing, virtual leaks, and contamination, ensuring your components are UHV-ready.

Superior Surface Finishes

We can achieve the very low Ra surface finishes required for vacuum sealing surfaces, mirror substrates, and electro-optical components through precision machining, lapping, and electropolishing.

Rapid Prototyping for R&D

We partner with university labs and corporate R&D departments to deliver high-precision prototypes quickly, accelerating the development and validation of new instrument technologies.

Integrated Cleanroom Assembly

We go beyond the component, offering sub-assembly of sensitive optical and vacuum systems in a Class 1000 cleanroom environment, delivering pre-aligned and tested modules.

From Scientific Concept to Discovery-Ready Component: Our Process

RFQ & Collaborative Engineering Review

Submit your designs and specifications. Our engineers, experienced with scientific applications, provide a detailed quote and DFM feedback focused on stability, vacuum compatibility, and material selection.

Process Planning for Stability

We develop a robust manufacturing plan that often includes multi-stage machining with intermediate stress-relieving cycles to ensure the final component is stable and holds its form.

Sourcing Certified Materials

We procure certified materials from trusted suppliers, including UHV-grade stainless steel with low magnetic permeability and low-expansion alloys, providing full traceability documentation.

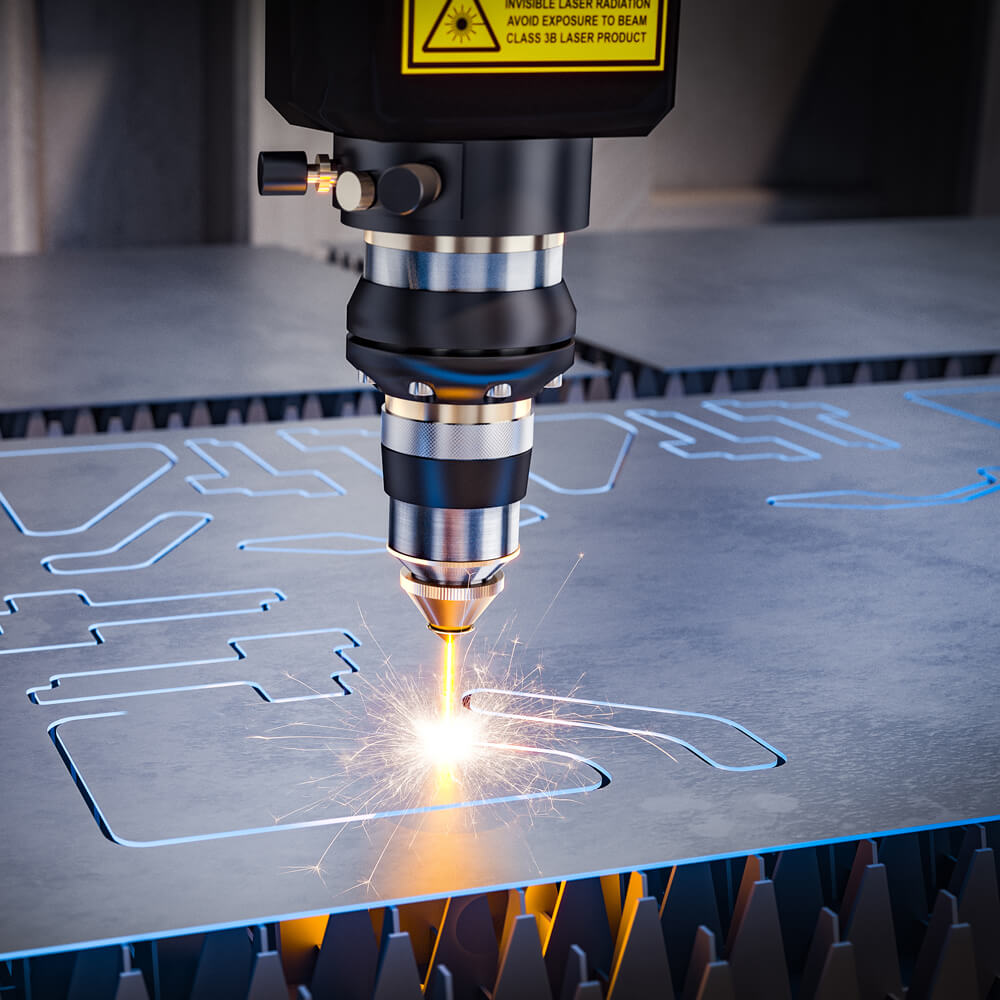

Precision Machining in a Controlled Environment

Your parts are expertly machined on our high-performance CNC centers in a temperature-controlled environment to minimize thermal variation and maximize accuracy.

UHV Cleaning & Finishing

Components undergo a multi-stage ultrasonic UHV cleaning process. Specified finishes like electropolishing or low-reflectivity coatings are applied by certified partners.

High-Accuracy CMM & Optical Inspection

All critical dimensions, geometric tolerances, and surface finishes are verified in our metrology lab using high-accuracy CMMs, profilometers, and optical inspection equipment.

Building the Tools for the Next Great Discovery?

Let’s collaborate on the ultra-precise components that will make your instrument a reality.

Key Manufacturing Services for Scientific Instruments

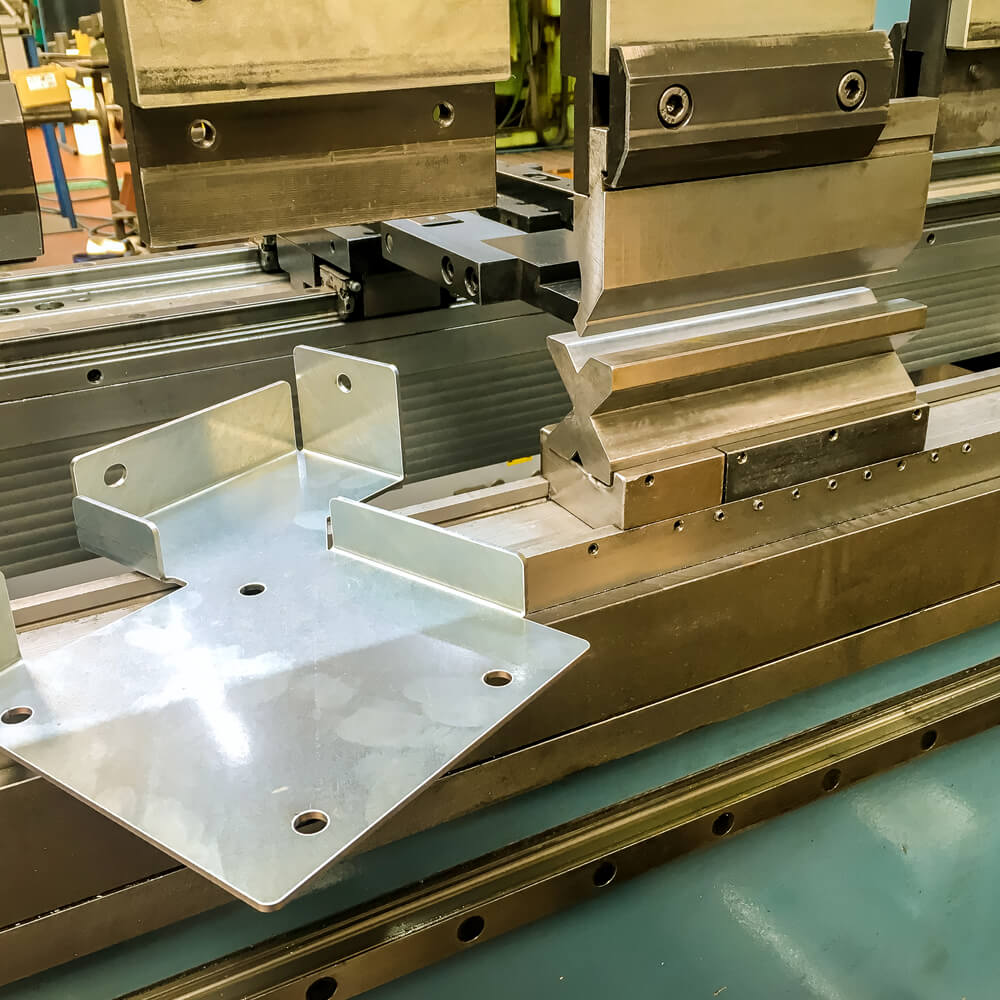

5-Axis CNC Milling

The essential capability for creating monolithic optical benches, complex vacuum chambers, and detector housings with intricate internal features and minimal weight.

CNC Turning with Live Tooling

Perfect for producing high-precision lens barrels, sample holders, manipulators, vacuum flanges, and electrical feedthrough bodies.

Wire EDM & Sinker EDM

Used for creating delicate flexure mounts, thin-walled features, and intricate internal geometries in conductive materials without inducing mechanical stress.

Precision Lapping & Polishing

Providing ultra-flat surfaces (down to λ/10) and mirror-like finishes (<0.1 µm Ra) on metals and ceramics for sealing and optical applications.

UHV Cleaning & Preparation

A multi-stage cleaning and baking process designed to remove all surface contaminants and ensure components are ready for ultra-high vacuum service.

Cleanroom Assembly

A Class 1000 environment for the particle-free assembly of sensitive optical mounts, detector arrays, and vacuum sub-systems.

High-Performance Materials and Finishes for Scientific Instruments

Common Scientific Materials:

- Stainless Steel (316L VIM/VAR, 304L)

- Aluminum (6061-T6)

- Titanium (Grade 2, Grade 5)

- Low-Expansion Alloys (Invar 36, Kovar)

- PEEK & Vespel® (for insulators and sample handling)

- Macor® & Alumina (machinable ceramics)

- Oxygen-Free Copper (OFC)

Functional Surface Finishes:

- Electropolishing (for the lowest outgassing on steel)

- Black Anodizing (Type II, low outgassing)

- Chemical Conversion Coating (Alodine)

- Passivation (essential for UHV stainless steel)

- Bead Blasting (with glass bead for a uniform matte finish)

- Optical Black Coatings (for stray light control)

Gallery of Scientific Instrument Components

- Mass Spectrometer Components (Ion Sources, Quadrupoles, Flight Tubes)

- Optical Benches, Breadboards, and Mirror Mounts

- Ultra-High Vacuum (UHV) Chamber Bodies and Flanges

- Electron Microscope Column Components

- Sample Stages, Holders, and Manipulators

- Laser Housings and Optical Chassis

- Particle Accelerator Beamline Components

- X-Ray and Neutron Detector Housings

- Collimators and Slit Assemblies

- Cryostat and Dewar Components

Frequently Asked Questions

What is the best material for a dimensionally stable optical bench?

For ultimate thermal stability, low-expansion alloys like Invar 36 are ideal. For applications where weight is also a concern, stress-relieved 6061-T6 aluminum with a ribbed, lightweighted design is an excellent and more cost-effective choice.

What makes a component "UHV compatible"?

UHV compatibility means the component has very low outgassing rates (it doesn’t release trapped gases/vapors into the vacuum). This is achieved by using low-vapor-pressure materials (like 316L SS), avoiding porous finishes, eliminating “virtual leaks” (trapped air volumes), and performing specialized UHV cleaning.

Can you achieve the flatness required for a vacuum seal?

Yes. We routinely machine and lap ConFlat (CF) and other vacuum sealing surfaces to the high degree of flatness and fine surface finish required to create a reliable, metal-to-metal seal.

What is stress relieving and why is it important?

Stress relieving is a heat treatment process that removes internal stresses induced during material manufacturing and machining. For scientific instruments, it is critical to ensure that a component will not warp or change shape over time or with temperature changes, which would ruin instrument alignment and calibration.

What is the best finish for reducing stray light in an optical system?

For aluminum, Type II black anodizing is a common choice. For ultimate performance, specialized optical black paints or coatings can be applied over a bead-blasted surface to create a highly absorptive, low-reflectivity finish.

Can you machine non-magnetic materials?

Yes, we frequently work with non-magnetic materials like 316L stainless steel, titanium, and aluminum, which are essential for instruments involving electron beams, magnetic fields, or sensitive detectors.

What is Macor® and when is it used?

Macor® is a machinable glass-ceramic. It is an excellent electrical insulator and is vacuum stable, so it’s often used for insulators and sample holders inside vacuum chambers where complex shapes are needed that would be too expensive to produce in a traditional ceramic like Alumina.

How do you guarantee the precision of your components?

We use a combination of in-process controls, a temperature-controlled environment, and final inspection in our metrology lab using high-accuracy CMMs and other advanced instruments. We provide full inspection reports with every shipment.

Can you help with the design of a component for manufacturability?

Absolutely. We encourage collaboration. Our engineers can provide DFM feedback to help you reduce cost and improve the stability and performance of your component designs without compromising their scientific function.

How do you handle and package sensitive UHV components?

After UHV cleaning, all parts are handled with powder-free nitrile gloves in a clean environment. They are then wrapped in UHV-grade foil or cleanroom bags, nitrogen-purged, and double-bagged to prevent any contamination during shipping.

Related Ultra-Precision Applications

Semiconductor Industry

Manufacturing components for wafer fabrication equipment that operate in pristine, high-vacuum environments.

Medical & Healthcare

Building ultra-precise components for diagnostic equipment, surgical robots, and medical laser systems.

Defense & Military

Creating the high-precision optical chassis, targeting systems, and sensor housings for advanced defense applications.