CNC Machining: Custom CNC Machining Services in China

Precision Parts, Rapid Turnaround, From Prototypes to Production.

- ISO 9001 Certified

- AS9100 Compliant

- 24-Hour Response

Your Trusted Partner for High Precision CNC Machining

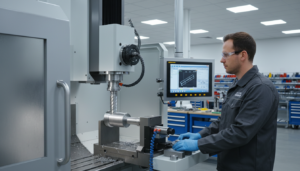

Celerity Precision is a top Chinese company that makes custom CNC machined parts. We are experts at turning your most complicated digital ideas into high-quality physical parts with unmatched speed and accuracy. We are your strategic partner for projects that need the best quality by using the latest technology and a team of skilled engineers. Our main goal is to make manufacturing as easy as possible by always delivering high-quality parts on schedule and providing fast, helpful customer support.

Our Core CNC Machining Services

Our state-of-the-art facility is based on cutting-edge CNC milling and CNC turning technologies that let us make a wide range of shapes with amazing accuracy. We can make everything from simple prismatic blocks to complex, multi-faceted parts, which is what makes us such a good manufacturer.

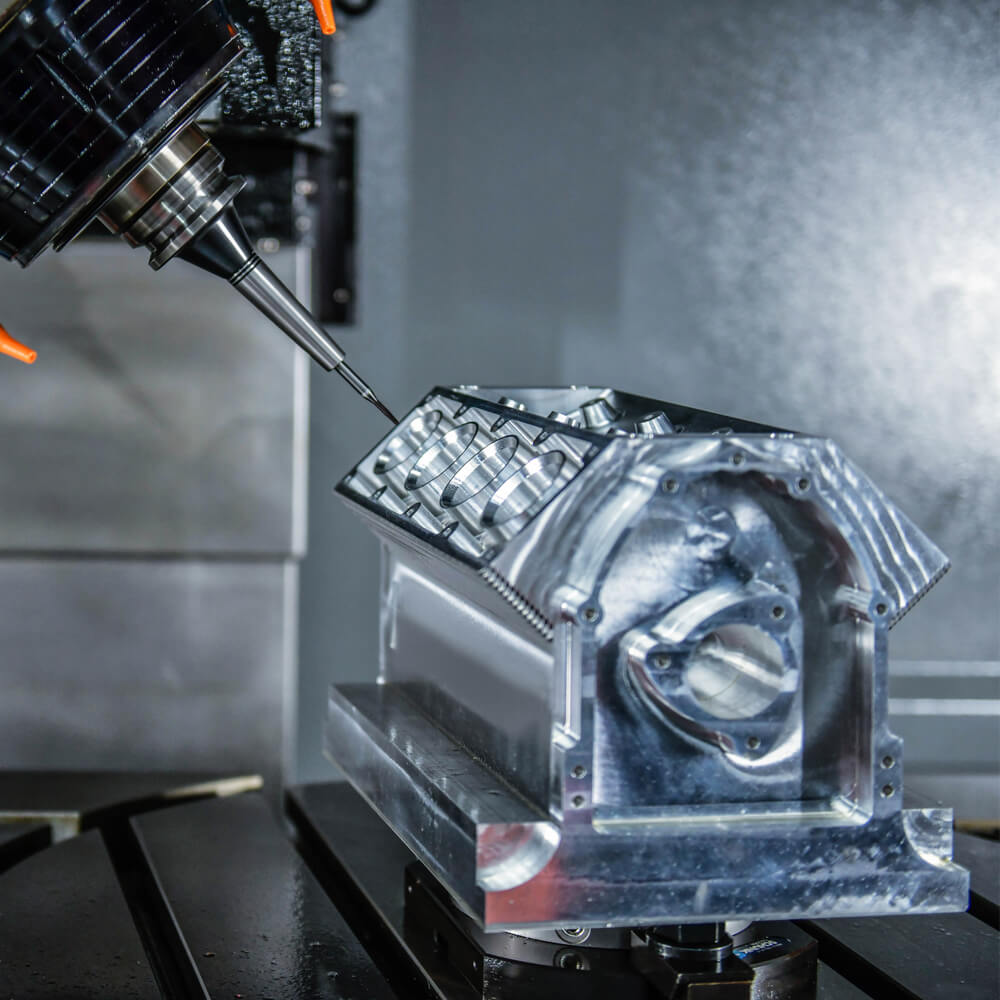

Custom CNC Milling

Our CNC milling centers with 3, 4, and 5 axes can make items with complicated shapes and contours. We machine everything from simple brackets to intricate housings and molds with tight tolerances and superior surface finishes.

Custom CNC Turning

We use modern CNC lathes to make cylindrical parts with very high accuracy. We can do multi-axis turning with live tooling, which means we can do secondary milling and drilling in the same setup for the best precision and efficiency.

CNC Machining Materials

Metal

Aluminum is strong, light metal that can be used for many things and doesn’t rust easily.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

Copper

Copper has great electrical and thermal conductivity, which makes it the best choice for heat sinks and electrical parts.

- Available Grades: C101 (OFHC), C110 (ETP)

- Common Finishes: As Machined, Electropolishing, Plating, Clear Coat

Brass

Brass is great for making fittings and decorative elements since it is easy to work with and looks like gold.

- Available Grades: C360

- Common Finishes: As Machined, Polishing, Plating, Brushing

Bronze

Bronze is durable and has minimal friction, it is widely used for naval hardware, bushings, and bearings.

- Available Grades: C932, C954

- Common Finishes: As Machined, Tumbling

Steel

Steel is a robust, long-lasting, and cheap material that works well in high-stress and industrial settings.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Stainless Steel

Stainless steel is very strong and doesn’t rust easily, so it’s great for use in food, medical, and maritime settings.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Magnesium

Magnesium is a very light metal that is great for uses where every gram matters.

- Available Grades: AZ31, AZ91

- Common Finishes: Chromate Conversion Coating

Titanium

Titanium is a high-performance metal that is quite strong for its weight and is also very biocompatible.

- Available Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Common Finishes: As Machined, Anodizing (for color), Sand Blasting

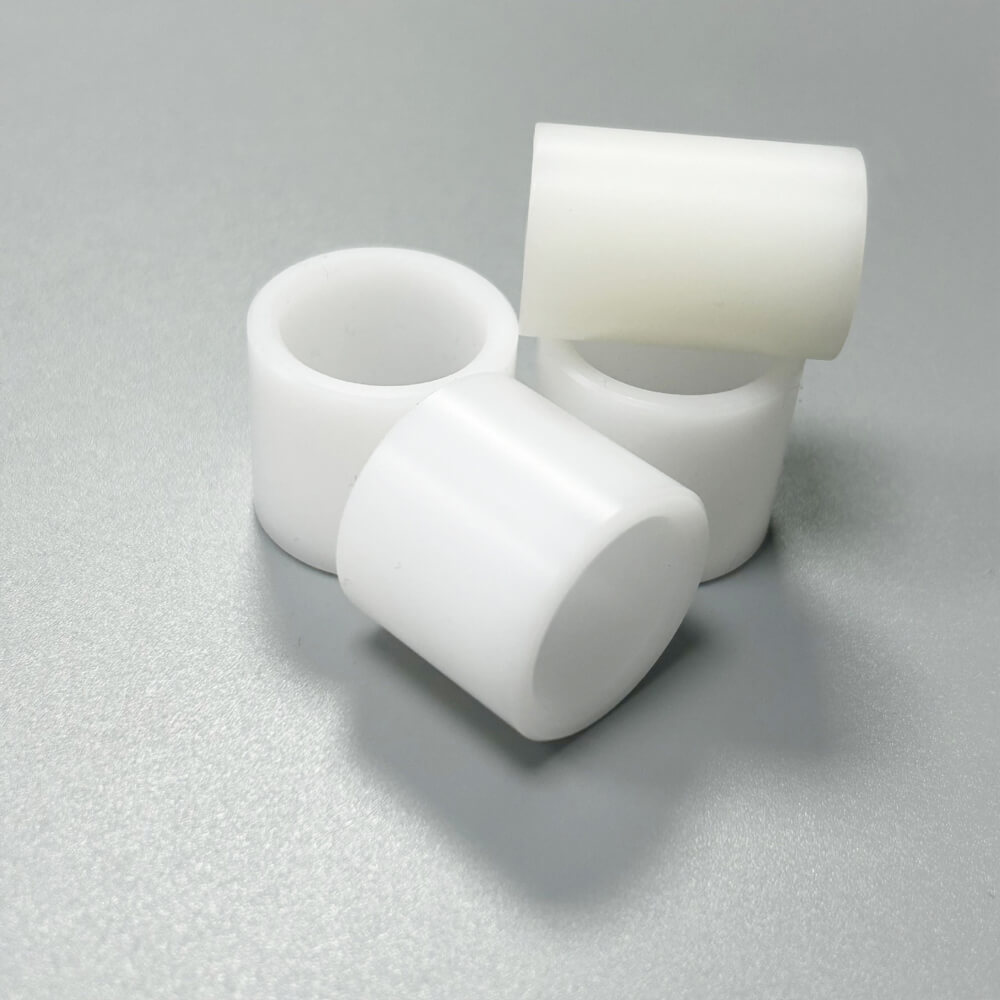

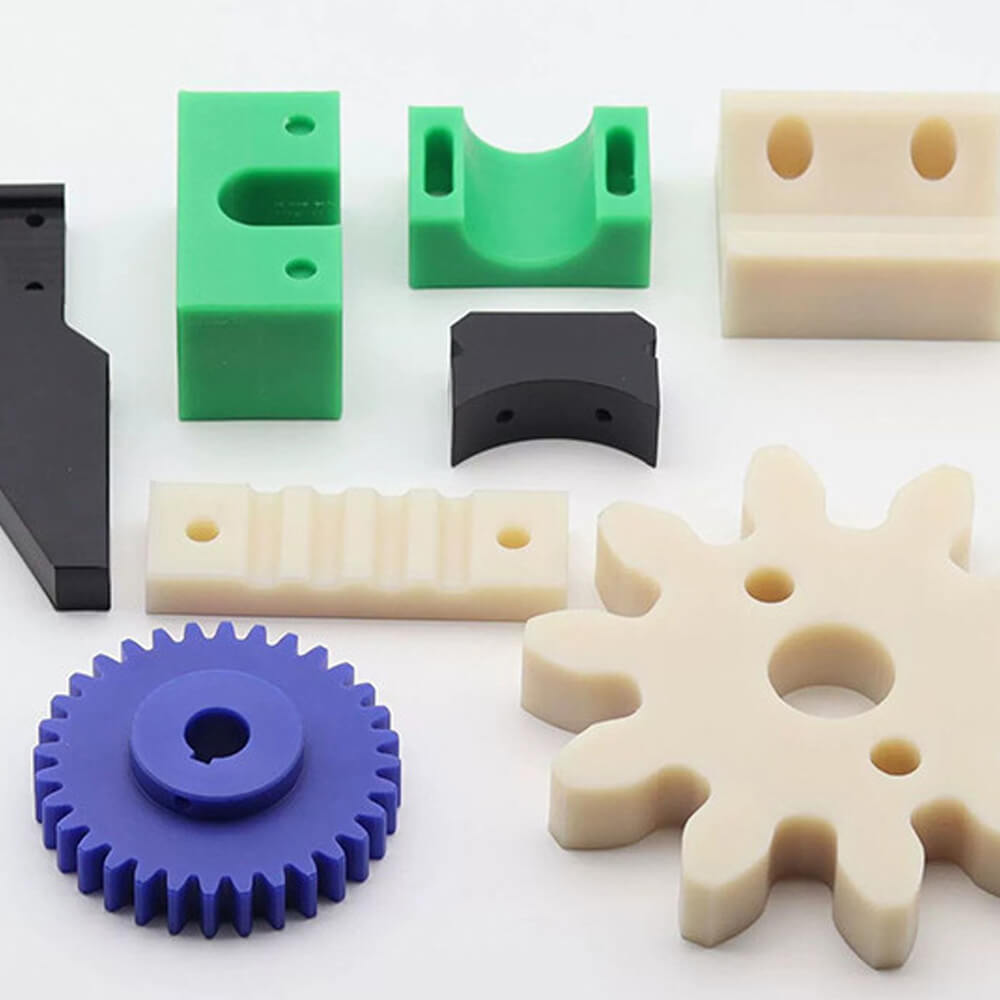

Plastic

ABS

ABS is a strong, impact-resistant, and cost-effective thermoplastic that works well for housings, enclosures, and prototypes.

Common Finishes: As Machined, Sand Blasting, Painting

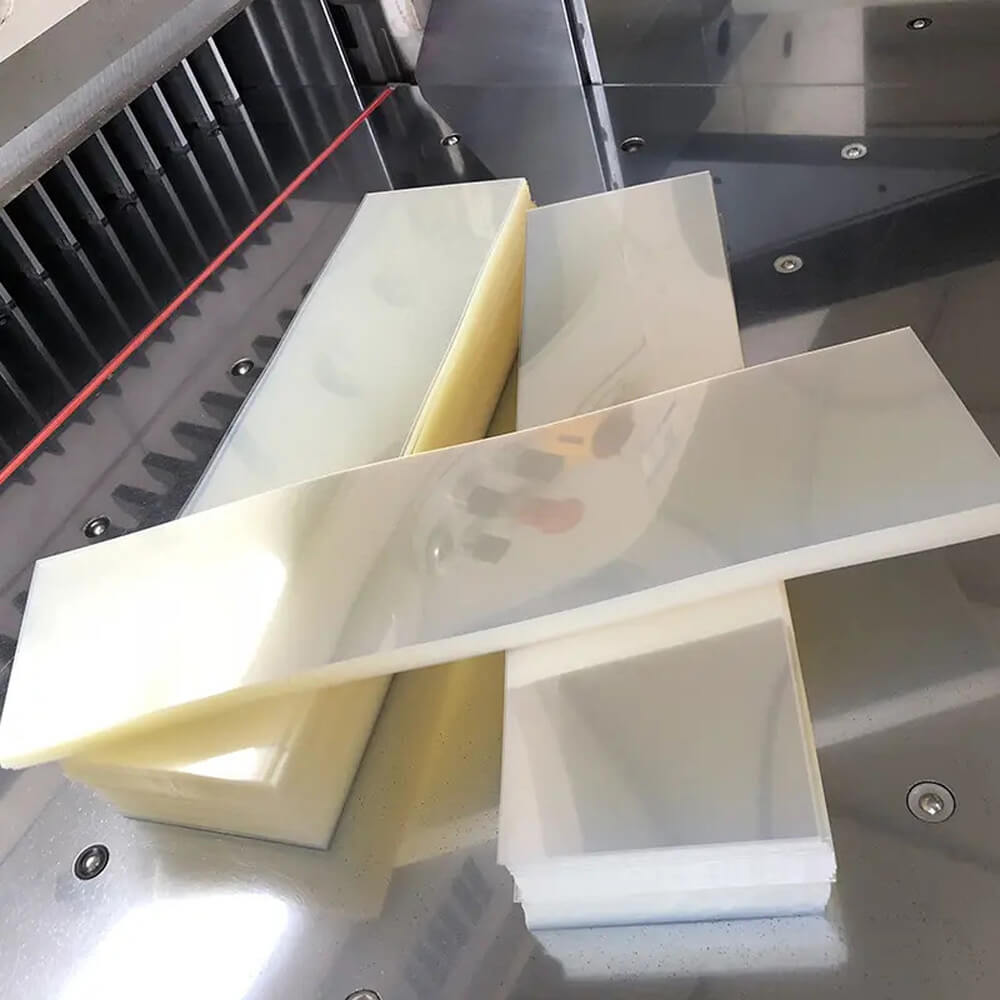

PC (Polycarbonate)

PC is a sturdy, clear material that can handle heat and impact very well.

- Common Finishes: As Machined, Vapor Polishing, Painting

PLA

PLA is a thermoplastic that breaks down naturally and comes from renewable resources. It is often used for quick prototyping.

Common Finishes: As Machined, Painting

PMMA (Acrylic)

PMMA is a clear, hard plastic with great optical clarity. It is widely used as a light-weight substitute to glass.

Common Finishes: As Machined, Vapor Polishing, Flame Polishing

POM (Delrin/Acetal)

POM is an engineering plastic that is low-friction and high-stiffness, making it great for gears and bearings.

Common Finishes: As Machined

PA (Nylon)

PA is a strong and flexible plastic that can stand up to chemicals and wear.

- Available Grades: PA6, PA66

- Common Finishes: As Machined

PE (Polyethylene)

PE is a typical type of plastic that can withstand chemicals and comes in varying densities for different uses.

Common Finishes: As Machined

PEEK

PEEK is a high-performance polymer that is very strong, resistant to chemicals, and stable at high temperatures.

Common Finishes: As Machined

PP (Polypropylene)

PP is a light plastic that is very elastic and resistant to chemicals. It is widely used for living hinges.

Common Finishes: As Machined

HIPS

HIPS is a cheap, stiff plastic that is easy to work with and is typically used to make prototypes before production.

Common Finishes: As Machined, Painting

PBT

PBT is a type of engineering thermoplastic that is stiff, stable in size, and can handle chemicals and heat.

Common Finishes: As Machined

PPA

PPA is a high-performance polyamide that is stronger, stiffer, and more heat-resistant than regular nylon.

Common Finishes: As Machined

PAI (Torlon)

PAI is high-performance plastic that is exceedingly strong and rigid and keeps its qualities even at very high temperatures.

Common Finishes: As Machined

PET

PET is a tough, rigid plastic used in engineering that resists chemicals well and wears well.

Common Finishes: As Machined

PPS

PPS is a high-performance thermoplastic that can withstand chemicals and high temperatures without changing shape.

Common Finishes: As Machined

PS (Polystyrene)

PS is a clear, rigid, and brittle plastic that doesn’t cost much and is typically used for prototypes.

Common Finishes: As Machined, Painting

PVC

PVC is a strong, long-lasting, and cheap plastic that doesn’t easily get damaged by chemicals or water.

Common Finishes: As Machined

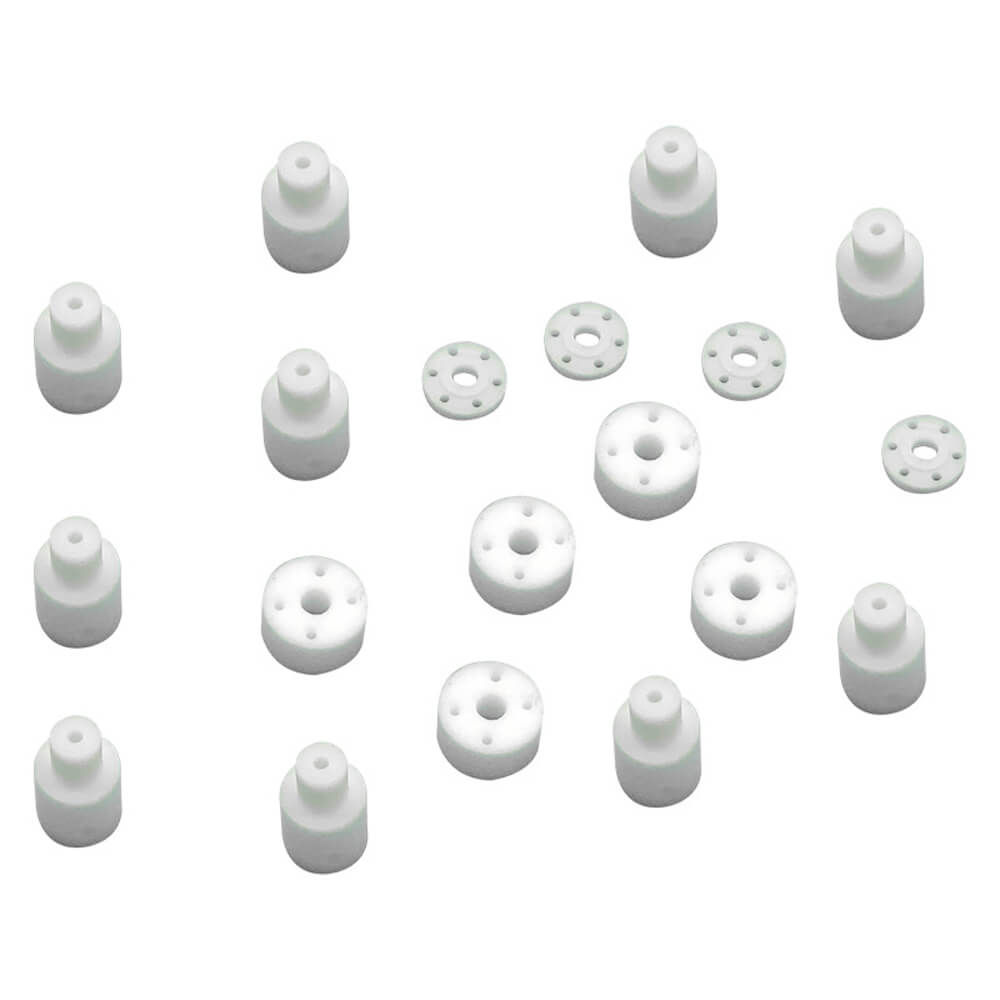

PTFE (Teflon™)

PTEE is known for having a very low coefficient of friction, being chemically inert, and being able to handle high temperatures.

Common Finishes: As Machined

Bakelite

Bakelite is a thermoset plastic that is hard, thick, and resistant to heat. It also has good electrical insulating qualities.

Common Finishes: As Machined

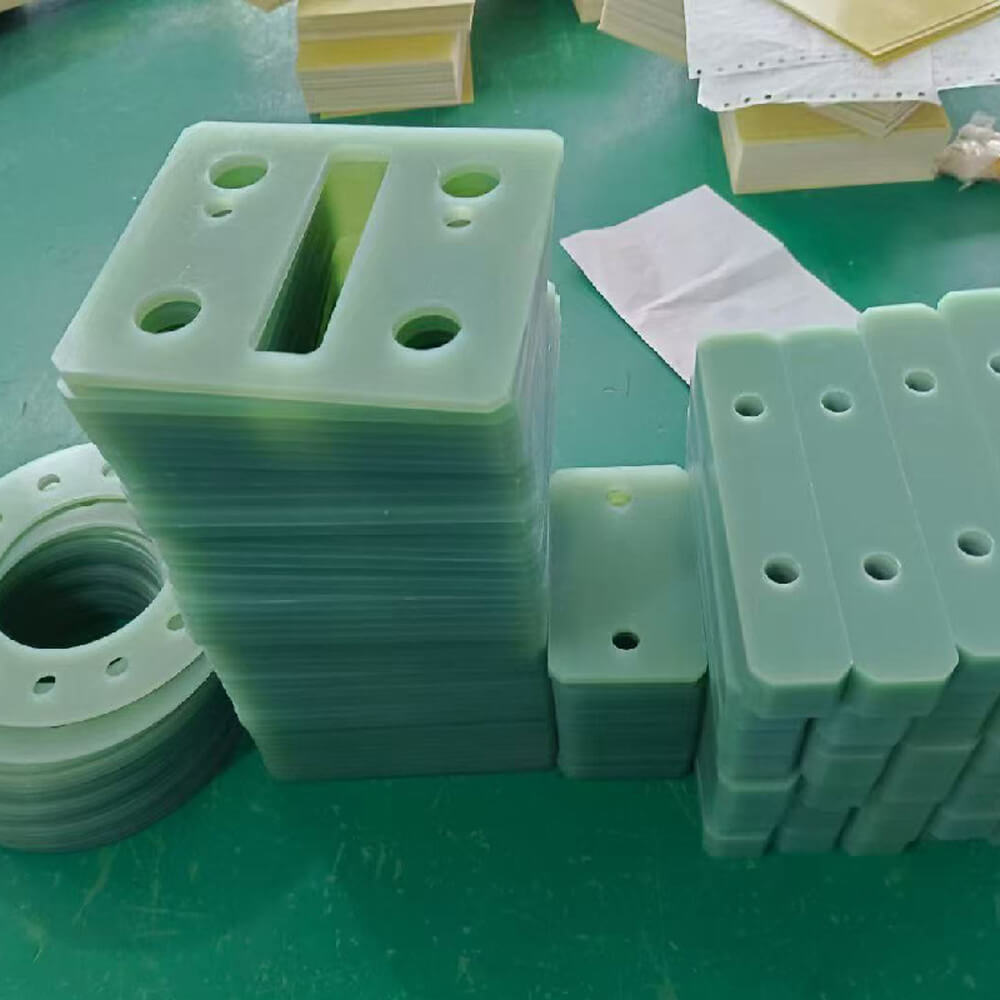

FR-4

FR-4 is a glass-reinforced epoxy laminate that is very strong and has great electrical insulation qualities.

Common Finishes: As Machined

CNC Surface Finish Enhance and Protect Your Parts

As Machined

The basic finish, which is the cheapest and most common, has obvious tool marks right from the machine.

Sand Blasting

Makes a smooth, non-reflective matte surface that looks good and helps paint stick better.

Tumbling

A mass-finishing method that quickly removes burrs and smooths off groups of parts.

Electropolishing

Makes metals like stainless steel have a finish that is super smooth, bright, and clean down to the smallest details.

Heat Treatment

A thermal procedure that changes mechanical qualities like strength and hardness (not only for looks).

Alodine

A chemical coating for aluminum that protects it from rust while yet letting electricity flow through it.

Anodizing

Makes a colored surface on metal and titanium that is sturdy, long-lasting, and attractive.

Teflon™ Coating

A fluoropolymer coating that doesn't stick and has low friction. It also resists chemicals very well.

Black Oxide

A conversion coating for steel that gives it a deep black finish without changing its size.

Electroless Plating

A uniform chemical plating procedure (like nickel) that makes all surfaces very hard and resistant to rust.

Electroplating

An electrochemical procedure that puts down a metal layer (such zinc, nickel, or chrome) for decorative or protective purposes.

Painting

A liquid coating that may be sprayed on and comes in a wide range of colors for a decorative and protective finish.

Passivation

A chemical cleaning method that makes stainless steel as resistant to corrosion as possible.

Powder Coating

An electrostatically applied powder dried to provide a finish that is stronger than regular paint.

Electrophoresis

An E-coat procedure that dips items in a coating to cover them completely and evenly.

Brushed Finish

A high-end, refined style with a unidirectional satin grain finish.

Why Choose Celerity Precision For Online CNC Machining

Advanced Equipment

Our facility is built around cutting-edge 5-axis CNC machining centers and multi-axis turning lathes, which make it easy for us to work with complicated shapes.

Uncompromising Quality

We are an ISO 9001 accredited firm, which means we have strict quality control at every step, from checking the materials to the final CMM inspection. This makes sure that your parts match the highest requirements.

Engineering Expertise

With every quote, we give you a free Design for Manufacturability (DFM) analysis. This lets you get professional advise on how to improve your design for better performance and reduced costs.

Streamlined Process

We handle the whole manufacturing process to make sure that customers have a smooth and trustworthy experience, from our quick 24-hour quotes to our on-time global delivery.

One-Stop Solution

We are your only partner for the complete manufacturing process, and we offer a full range of in-house and certified finishing services.

Engineering Expertise

With every quote, we give you a free Design for Manufacturability (DFM) analysis. This lets you get professional advise on how to improve your design for better performance and reduced costs.

CNC Machining Online: From Digital File to Physical Part in 4 Simple Steps

Submit Design & Get Quote

Upload your CAD file and specifications in a safe way. Within 24 hours, our engineering team will look over your project and give you a full quote.

DFM Review & Order Confirmation

We give professional DFM feedback. As soon as you agree to the quote and timing, we set up the production of your project right away.

Precision Manufacturing

Our professional specialists use powerful CNC machines to carefully cut your parts, following stringent process controls to make sure they are accurate and of high quality.

Inspection & Global Delivery

A thorough final examination is done on each part. We then carefully pack and dispatch your parts to your door anywhere in the world.

How We've Helped Our CNC Machining Clients

Challenge

An aerospace client requested a structural part made of 7075 aluminum that was light, had complicated 5-axis characteristics, and had to be done right away.

Solution & Result

Using our 5-axis CNC milling skills and a streamlined workflow, we made the parts with a MIL-SPEC hardcoat anodized finish. We were able to supply completely compliant components 30% faster than the prior supplier.

Challenge

A startup in the medical device industry needed a series of complex prototypes of surgical instruments made of 316L stainless steel that were very clean and had no burrs.

Solution & Result

We machined the tools and gave them a professional electropolishing and passivation finish. Our method created a surface that was smooth on a microscopic level, which helped the client pass important biocompatibility tests and speed up their development schedule.

Challenge

A brand in the consumer electronics industry needed a lot of 6063 aluminum enclosures that looked excellent and had color that stayed the same.

Solution & Result

We built a unique manufacturing cell for the project that combined high-speed machining with a closely regulated Type II black anodizing process. This made over 10,000 units with a color consistency rate of 99.8%.

Custom CNC Machining Services - Celerity Precision

Are you looking for accuracy and dependability while creating custom parts? Industries are redefining how they create complicated products with custom CNC machining services.

In China, Celerity Precision provide excellent CNC machining services. We can work with a lot of different materials and needs. We can cut, drill, and shape anything with great accuracy. This makes sure that our outputs are of the best quality.

We can aid a lot of different businesses because we have superior technology and knowledge. We create parts that last a long time and work properly. We can match the needs of each client because we specialize in custom CNC machining.

Key Takeaways

- Making unique parts with high precision

- High-tech CNC machining

- A lot of different materials and services

- Solutions that are made just for each client’s needs

- Providing high-quality results to a variety of sectors

What is CNC Machining?

Computer-controlled machine tools are used in CNC machining. It manufactures parts and pieces with a high level of accuracy and repeatability.

Definition

Computer programs operate machines like lathes and mills in CNC machining. CAD software is used to design a part first. Then, a CNC program is made from this design to tell the machine what to do.

The most important things about CNC machining are accuracy and the capacity to do complicated operations over and over. Servo motors and stepper motors move the tools, which makes this possible.

History of CNC Technology

In the 1940s and 1950s, people made the first CNC machines. They utilized cards with holes in them or tapes to manage the operation.

CNC technology has come a long way since then. It now has superior software and computers. CNC machines today can do a lot of different things and work with a lot of different materials, such metals and plastics.

Additive vs. Subtractive Manufacturing

CNC machining is a subtractive process in which material is taken away to make pieces. This is not the same as additive manufacturing, like 3D printing, where material is added one layer at a time.

| Characteristics | Subtractive Manufacturing | Additive Manufacturing |

|---|---|---|

| Process | Material removal | Layer-by-layer addition |

| Complexity | High precision and complexity | High complexity with less material waste |

| Materials | Metals, plastics, composites | Variety of materials including metals, plastics, and ceramics |

Essential Components of CNC Machining Systems

When we know the main parts of CNC systems, we can realize how complicated and exact CNC machining is. We’ll talk about the key features of a CNC machine and how different coordinate systems help it make things right.

Main Parts of a CNC Machine

A CNC machine has a number of key parts that work together to make sure the work is done correctly. The spindle is important because it spins the cutting tool quickly. The controller is the brain of the machine. It reads G-code and tells the machine what to do.

Spindle and Controller Functions

The spindle holds the cutting tool and spins it. The controller tells the machine what to do, like moving the axes and changing tools. They work together to help the CNC machine conduct very precise work on complicated assignments.

Axes and Workholding Mechanisms

CNC machines move along axes, which might be 2 to 5 axes for different jobs. Workholding mechanisms maintain the workpiece stationary while it is being machined. For this, you can utilize vices, clamps, and chucks.

Coordinate Systems and Axes of Machines

Coordinate systems help CNC machines figure out where the workpiece and tool are. To use CNC machines successfully, you need to know how these systems work.

2-Axis, 3-Axis, and 5-Axis Settings

- 2-Axis CNC machines only work on two axes, which is suitable for simple turning.

- 3-Axis CNC machines have a third axis that lets them do more complicated machining.

- 5-Axis CNC machines are the most flexible because they can make complicated forms from numerous angles.

Knowing the key components of CNC systems and coordinate systems shows us how flexible and accurate CNC machining is.

CNC Programming and Operation

Programming and running CNC machines are very important in modern manufacturing. They help produce very accurate pieces that are very complicated. We focus on precise programming and operation to make sure that our CNC machining services are of the highest quality and efficiency.

Basics of G-code and Machine Language

G-code is a simple language used to program CNC machines. It informs machines what to do, like how fast to move. To program a CNC machine well, you need to know G-code because it affects how the machine works and what it does.

CAD/CAM Software Integration

For CNC programming, CAD/CAM software is very important. It allows designers develop comprehensive models and plan out how to use tools for milling. We employ modern CAD/CAM tools to connect design and manufacturing in a way that makes things more accurate and cuts down on production time.

Toolpath Generation and Optimization

Making toolpaths is an important part of programming a CNC machine. It depicts how the machine will cut and form the material. For speedier machining, less tool wear, and improved product quality, it’s vital to optimize toolpaths.

Machine Operation Parameters

For good machining results, it’s important to set the machine’s settings, such as spindle speed and feed rates. Getting these settings right maintains tools in good shape, makes sure the finish is right, and makes sure the parts are of good quality.

Spindle Speed and Feed Rates

You need to be very careful when changing the spindle speed and feed rates. This depends on the tool and material utilized. Getting these right can make machining more faster and better.

Cooling and Lubrication Systems

CNC machining needs cooling and lubrication systems to work. They lower the amount of heat, wear on tools, and improve the polish on the surface of the part.

We can create high-quality parts that match our clients’ particular needs by being experts in CNC programming and operation. This improves the quality of their products and manufacturing.

Types of CNC Machines and Processes

CNC technology has a lot of various machines that can meet a lot of different demands. These machines can conduct both simple cuts and more complicated jobs like milling and turning.

CNC Milling Machines and Applications

A lot of people use CNC milling machines. They take material off of a workpiece with instruments that spin. These devices can accomplish a lot of tasks, like drilling and tapping.

Uses for CNC milling:

- Making complicated pieces with a lot of accuracy

- Making dies and molds

- Making parts for cars and planes through machining

CNC Turning and Lathe Operations

Lathes, often called CNC turning centers, spin a workpiece around one axis. They’re great for producing parts that are round. They are widely utilized to make parts for cars and planes.

Uses for CNC Turning:

- Making axles and shafts

- Making bushings and bearings that fit perfectly

- Making pieces with complicated forms inside

Specialized CNC Equipment

There are CNC machines that can do more than just milling and turning.

EDM Systems and Routers

CNC routers cut and shape things like wood and plastic. EDM systems use electrical discharges to get rid of material. They work well for producing forms that are hard to make.

Laser, Waterjet, and Plasma Cutting

Laser cutting machines employ a strong laser to make very precise cuts. Waterjet cutting machines use high-pressure water to cut through things. Plasma cutting machines use a plasma flame to cut through materials that conduct electricity.

| Machine Type | Primary Function | Common Applications |

|---|---|---|

| CNC Milling | Removing material using rotating tools | Aerospace, automotive, mold making |

| CNC Turning | Rotating workpiece around a single axis | Producing cylindrical parts, shafts, axles |

| CNC Routers | Cutting and shaping various materials | Woodworking, sign making, plastic fabrication |

| EDM Systems | Removing material using electrical discharges | Producing complex shapes, cavities, and molds |

| Laser Cutting | Cutting materials with a high-powered laser | Precision cutting of metals, plastics, and wood |

| Waterjet Cutting | Cutting materials with a high-pressure water jet | Cutting thick or hard materials, including metals and stone |

| Plasma Cutting | Cutting electrically conductive materials with a plasma torch | Cutting steel, aluminum, and other metals |

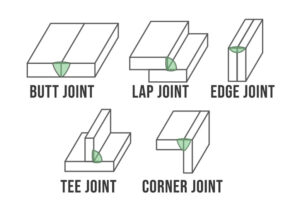

Review all our manufacturing capabilities like CNC machining, CNC milling, CNC turning, laser cutting, bending, welding, sheet metal fabrication, die casting and precision casting.

Materials Processed Through CNC Machining

CNC machining can work with a wide range of materials, including metals and sophisticated composites. Because of this, it is a top pick in many fields. One of its best features is how flexible it is.

Metal Machining Capabilities

CNC machining is wonderful for metals because it is accurate and can work with shapes that are hard to make. It works nicely with aluminum, titanium, and steel.

Processing of Steel, Aluminum, and Titanium

Steel is tough and long-lasting, making it great for heavy-duty use. Aluminum is a good choice for cars and planes since it is light and does not rust. Titanium is robust and can endure high temperatures. It is utilized in medical devices and planes.

| Metal | Properties | Common Applications |

|---|---|---|

| Steel | High strength, durability | Industrial machinery, construction |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, automotive |

| Titanium | High strength-to-weight ratio, resistant to extreme temperatures | Aerospace, medical implants |

Bronze and Other Special Alloys

CNC machines bronze and exotic alloys. Bronze is strong and can be used in bearings. Specialty alloys offer special qualities that make them good for certain jobs.

Plastics and Composites Fabrication

CNC machining can be used on more than just metals; it can also be used on polymers and composites. These are utilized for parts that need particular finishes and mechanical qualities.

Ceramic and Exotic Material Machining

Special CNC tools are used to machine ceramics and other rare materials. They are chosen because they have certain features, such as being able to withstand extreme temperatures and insulate electricity.

CNC machining lets producers make complicated pieces out of a wide range of materials. This works for a lot of different types of businesses.

The Complete CNC Machining Workflow

Knowing the full workflow is the key to getting CNC machining to be accurate and quick. We’ll show you the whole process, from design to quality check. It uses design, engineering, and manufacture to make items of the highest quality.

The Design and Engineering Phase

The design and engineering phase is the first step in the CNC machining process. This is where the design of the product is made and improved. This is an important phase since it determines if the part can be created and how.

We work with our clients to make sure the design meets their needs. We also check that it is ready for CNC machining.

CAD modeling and CAM programming

CAD modeling makes a digital model of a part when the design is done. Then, CAM programming uses this model to figure out what the CNC machine will do. We employ the best CAD/CAM software to make machining more accurate and faster.

Machine Setup and Operation

You need to set up the CNC machine correctly before you start. This includes ways to hold the workpiece, like fixturing and workholding. Also, for the best finish and precision, it’s important to choose the correct equipment and settings.

Fixturing and Workholding Techniques

When machining, good fixturing keeps the workpiece steady and safe. We employ clamps, vise jaws, and bespoke fittings for varied parts and materials.

Tool Selection and Cutting Parameters

The tools and settings you employ have a big effect on how you machine. We choose tools depending on the type of material, the finish we want, and what the machine can do. It’s also vital to change things like feed rates and spindle speeds to make machining more efficient.

Quality Control and Finishing Processes

Parts may need extra finishing steps like deburring or surface treatment after machining. We have stringent quality control to make sure that all parts match the standards of both our clients and the industry.

By learning about and optimizing each step of the CNC machining process, we can create high-quality, precise parts quickly and cheaply. We can make anything from prototypes to large-scale production with our CNC machining service.

Industry Applications of CNC Machining

Because it is so precise and flexible, CNC machining is important in many fields. It’s utilized in a lot of different fields to produce complicated parts that fit together perfectly. Here are the applications of CNC machine in manufacturing industries:

Parts for Cars and Planes

CNC machining makes very precise parts for cars and planes that are very important. This is how they make parts for engines, transmissions, and airplanes. Experts argue that CNC machining is important for manufacturing parts that are safe.

Medical Devices and High-Precision Tools

CNC machining is very helpful in the medical field. It is used to produce precision tools and medical gadgets. This comprises implants and tools used in surgery.

Products and Electronics for Consumers

CNC machining is also used to make parts for phones, computers, and other electronic devices. It helps with product design by letting you make complicated forms and fine details.

Machinery and Tools for Industry

CNC machining is also crucial for creating tools and machines for use in factories. It makes items like molds, shafts, and gears with a lot of accuracy. This makes machines used in industry work better and last longer.

Making Prototypes and Custom Parts

People also utilize CNC machining to make prototypes and custom parts. Its ability to change quickly makes it easy to make unique parts and change designs. This is for making automotive prototypes and personalized medical implants.

It’s apparent that CNC machining will grow in new areas as we learn more about what it can do. This will make it even more vital in today’s factories.

Advantages of Custom CNC Machining

There are several benefits to custom CNC machining in the manufacturing industry. It makes things more accurate, repeatable, and flexible in terms of design. Because of this, it works well in a lot of different fields and uses.

Accuracy and Precision in Dimensions

People know that CNC machining is very accurate and precise. CNC machines make sure that things satisfy tight requirements by following accurate designs. This is very important in sectors like aerospace and medical devices, where accuracy is very important.

Repeatability for Production Runs

CNC machining is great for making big batches since it can do the same thing over and over again. Once a program is set up, the CNC machine can create a lot of parts that are all the same quality. This is a good way to save time and money on big orders.

Flexibility and Complexity in Design

CNC machining gives you the most freedom when it comes to design. It can make forms and designs that are too complicated for other approaches. This is perfect for making prototypes and parts that need to be made just for you.

Cost-Effectiveness at All Levels of Production

CNC machining is a good way to save money on production of all sizes. It cuts expenses for huge orders and saves money on tools for small batches. This makes it a viable option for both small and large production demands.

Why Choose China for CNC Machining Services?

China has a lot of experience and a well-developed industrial system. It is known for creating CNC parts that are both high-quality and cheap. Because of this, businesses all around the world choose it.

Infrastructure and Knowledge for Manufacturing

China has a lot of factories that can handle massive CNC projects. It offers a lot of great CNC shops with the newest machines and competent personnel. This configuration helps speed up production and improve quality.

Cost-Effectiveness and Competitive Prices

It costs less to have CNC work done in China. The country has fantastic prices and good parts. This is great for businesses that want to save money without losing quality.

| Factor | China | Other Countries |

|---|---|---|

| Manufacturing Infrastructure | Extensive and well-developed | Limited in some areas |

| Cost-Efficiency | Highly competitive | Variable |

| Technology Investment | Significant investment in CNC technology | Limited investment in some regions |

Investing in and Coming Up with New Technologies

China has invested a lot in CNC technology, which keeps its production at the cutting edge of new ideas. Chinese manufacturers can construct complicated parts with remarkable accuracy because they focus on new technology.

Logistics and Supply Chain Integration

China’s supply chain and logistics are built up so that production goes smoothly. It takes care of everything, from collecting the raw materials to bringing the finished products. This makes CNC machining in China quick and cheap.

Companies can acquire the best CNC machining services by taking use of China’s capabilities in production, cost, technology, and the supply chain. China’s CNC services are dependable and quick, whether you require specific parts or want to make more of them.

Celerity Precision Custom Online CNC Machining Services in China

In China, we provide CNC machining services that are tailored to your needs. We use cutting-edge technology and our knowledge to manufacture parts that are accurate and of high quality for many different sectors. We can handle a wide range of manufacturing needs thanks to our many skills. This means quick production and happy customers.

Full Range of Manufacturing Skills

We can do a lot of different CNC machining jobs at our facility, from simple to complex shapes. We can help with both making prototypes and making a lot of things. Our professional staff works with customers to figure out what they need and then comes up with solutions that meet those needs exactly.

High-Tech Tools and Equipment

For accuracy and speed, we use the newest CNC equipment and software. Our machines can manufacture parts that are very complicated with a lot of accuracy. We continually improving our technology so that we can be the best at CNC machining.

Material Selection and Sourcing

We have a lot of materials for CNC machining, such as plastics and metals. We can get nice goods at good prices because we have a lot of suppliers. This makes sure that our customers get the greatest goods.

Specialized Services

We provide specialized CNC machining services to meet your needs. This includes:

Plastic and acrylic CNC Machining

We employ precision machining on acrylic and plastics for a lot of different things. Our knowledge makes sure that items are created to the correct specs and finishes.

Metal CNC Services (Steel, Aluminum, Bronze, and Titanium)

We can work with a lot of different metals, like steel, aluminum, bronze, and titanium. We create parts for difficult jobs in the aerospace, automotive, and medical areas. These parts have to be sturdy, long-lasting, and exact.

To suit the needs of our clients, we use innovative technology, a wide range of manufacturing processes, and a lot of different materials. We can make high-quality, exact parts quickly and easily, whether you need prototypes, small quantities, or large-scale manufacturing.

Celerity Precision Quality Assurance and Certification

Quality control is very important in our CNC machining services. We recognize that it’s important to make sure our items are of the highest quality. We need to follow the rules and meet the high requirements of our customers.

Standards for ISO and Specific Industries

We follow the norms and ISO certification that are specific to our area. We make sure our parts are reliable and work well by following these rules.

Tools and Methods for Inspection

We check our CNC components with the newest tools and methodologies for inspections. We check the size, surface polish, and material to make sure they are right.

Tolerance Verification and Documentation

A key part of our quality job is checking tolerances. We keep complete records of all the checks. This helps us keep up with what our customers want.

Safety and Good Practices

The most important thing to us in CNC machining is safety. We always work and play by the rules of safety. This makes our work safe and of the highest quality.

We make sure our CNC parts are the best by following these quality measures. They meet the highest requirements.

Here is the list for ISO standards followed by Celerity Precision for CNC machining services:

| ISO Standard | Title / Description |

|---|---|

| ISO 9001 | Quality Management Systems – Defines requirements for consistent quality in production and continuous improvement across all processes, including CNC machining. |

| ISO 2768-1 / ISO 2768-2 | General Tolerances for Linear and Angular Dimensions – Specifies standard machining tolerances for features without individual tolerance indications (Part 1: linear/angular dimensions; Part 2: geometrical tolerances). |

| ISO 1101 | Geometrical Product Specifications (GPS) — Geometrical Tolerancing – Defines symbols and rules for geometric dimensioning and tolerancing (GD&T) used in CNC machining drawings. |

| ISO 1302 | Surface Texture — Indication of Surface Texture in Technical Product Documentation – Specifies how to denote surface roughness and finishes on CNC machined parts. |

| ISO 4287 | Surface Texture — Profile Method: Terms, Definitions, and Parameters – Defines parameters (Ra, Rz, etc.) used to measure and specify machined surface quality. |

| ISO 8015 | Fundamentals of Geometrical Product Specification (GPS) – Establishes fundamental rules for how dimensions and tolerances are interpreted and applied in machining. |

| ISO 230 series | Test Code for Machine Tools – Specifies methods for testing the accuracy and performance of CNC machine tools (e.g., positioning accuracy, repeatability). |

| ISO 10791 series | Test Conditions for Machining Centres – Provides specific test procedures and tolerances for evaluating CNC machining centers. |

| ISO 14649 (STEP-NC) | Data Model for CNC Control – A modern standard for computer-controlled machining, replacing traditional G-code with feature-based data for smart manufacturing. |

| ISO 10360 | Geometrical Product Specifications (GPS) — Acceptance and Reverification Tests for Coordinate Measuring Machines (CMMs) – Defines how to test and verify accuracy of CMMs used to inspect machined parts. |

| ISO 15530 | CMM Measurement — Uncertainty Determination – Outlines methods to assess and calculate measurement uncertainty for machined parts inspection. |

| ISO 23125 | Machine Tools — Safety — Turning Machines – Sets safety requirements for CNC lathes and turning centers. |

| ISO 16090-1 | Machine Tools Safety — Machining Centres, Milling Machines, Transfer Machines – Defines safety requirements for CNC milling and machining centers. |

| ISO 14978 | General Concepts and Requirements for GPS Standards – Provides common definitions and requirements used across all geometrical product specification standards. |

| ISO 13399 | Cutting Tool Data Representation and Exchange – Defines digital data representation for cutting tools used in CNC machining for better interoperability in CAM systems. |

How Our CNC Machining Services Works?

We’re proud to make sure that everything goes smoothly from start to finish. We take care to do every part of your job with attention and accuracy.

Consultation and design help for projects

We begin with a thorough project consultation to learn what you require. We help you plan your project so that it may be CNC machined. This makes sure that your design will work and can be made.

The process of Quoting and the Structure of Prices

We give quotes that are easy to understand and rapid. We give you a full quote that lists all the charges. This covers the cost of materials, machining time, and any added services.

| Service | Description | Cost Factor |

|---|---|---|

| CNC Milling | Precision milling for complex geometries | Machine time, material |

| CNC Turning | Turning operations for cylindrical parts | Machine time, material |

| Surface Finishing | Various finishing options for enhanced surface quality | Process complexity, material |

Timeline for Production and Communication

As your project moves along, we keep you updated. We understand how vital it is to meet deadlines. So, we put in a lot of effort to get things done on time.

Shipping and Logistics for International Orders

We take care of shipping and logistics after we’re done. We work with trustworthy partners to make sure your parts get to you securely and on schedule, no matter where in the globe they are.

When you choose our CNC machining service, you work with a staff that cares about quality and service. From start to finish, we’re here to help your project succeed.

Final thoughts

CNC machining is a great way to make things. It adds accuracy, adaptability, and speed to the mix. We use the most up-to-date technology and talents for our custom CNC machining services in China. This makes sure that the parts and products are of excellent quality and meet tight criteria.

There are several benefits to CNC machining. It can create accurate pieces and complicated shapes. It’s also cheap, no matter how many you make. We employ CAD/CAM software, multi-axis machining, and thorough quality inspections. This makes sure that our CNC machining services are correct and dependable.

We can help if you work in aerospace, automotive, medical, or consumer electronics. We can help you with your production needs with our CNC machining services. Check out our bespoke CNC machining services to see how we can help you reach your goals. You can trust us with your online CNC machining needs because we have the knowledge and tools to do the job right.

CNC Machining FAQs

What does CNC machining mean?

CNC machining cuts and shapes materials with equipment that are controlled by computers. This comprises metals, polymers, and mixtures of the two. It makes parts or products that are very accurate.

What are the advantages of CNC machining?

CNC machining is accurate and can be done again and over again. It is cost-effective and gives you a lot of design options. This is true for all amounts of production.

What kinds of things can be cut and shaped with CNC machining?

You can use CNC machining on a lot of different materials. This covers metals, polymers, composites, ceramics, and even some very rare materials.

What is the difference between additive and subtractive manufacturing?

Like CNC machining, subtractive manufacturing makes things by taking away material. Additive manufacturing makes parts by adding material one layer at a time.

What is G-code, and how do you utilize it in CNC machining?

CNC machines use G-code as a programming language. It teaches machines how to drill, cut, or mill. It gives step-by-step directions on how to use tools and machines.

What kinds of CNC machines are there?

There are a lot of CNC machines. These include cutting technology, EDM systems, routers, turning and lathe machines, and milling machines. Each one has its own uses and advantages.

Why do so many people go to China for CNC machining services?

China is regarded for having a good manufacturing infrastructure and being cost-effective. It also puts money into technologies and has a robust supply chain. This is why it is one of the best places to get CNC machining services.

What steps are taken to make sure that CNC machining is of high quality?

CNC machining meets ISO and industry standards. It checks things, makes sure they are within tolerances, and follows safety rules. These make sure that the outputs are of excellent quality.

How can I begin using your CNC machining service?

To get started, call us to set up a meeting about your project. We will help you with the bidding process, the production schedule, and the shipping and logistics.

What will CNC machining look like in the future?

Automation and multi-axis systems are part of CNC machining’s future. It will also use technologies from Industry 4.0 and practices that are good for the environment. These improvements will make CNC machining more powerful and efficient.

Learn more about us. Are you need any more information? Contact us!

FAQs

What are your standard tolerances?

We can hold tolerances as tight as ±0.005mm (±0.0002″), though our standard tolerance for most features is ±0.05mm (±0.002″) unless otherwise specified.

What is your typical lead time?

Our lead times vary depending on complexity and quantity, but we can often deliver simple prototypes in as fast as 3-5 business days.

What CAD file formats do you accept?

We accept most common 3D formats, including STEP (.stp), IGES (.igs), Parasolid (.x_t), and SolidWorks (.sldprt). We also accept 2D drawings in PDF or DXF format.

Do you offer DFM analysis?

Yes, every quote we provide includes a free Design for Manufacturability (DFM) analysis where our engineers will highlight any potential issues or suggest optimizations for cost and quality.

What is your minimum order quantity (MOQ)?

We have no minimum order quantity. We are happy to produce a single prototype or tens of thousands of production parts.

Can you handle both prototypes and large production runs?

Absolutely. Our facility and processes are designed to be flexible, allowing us to provide the same high level of quality and service for one-off prototypes as we do for high-volume production.