Sheet Metal Fabrication: Custom Fabrication Services in China

Precision Brackets, Enclosures, and Assemblies. From Flat Sheet to Finished Product.

- ISO 9001 Certified

- Rapid Prototyping

- High-Volume Production

Your Expert Partner for Sheet Metal Fabrication

Celerity Precision is one of the best sheet metal fabrication companies in China that makes things to order. This flexible way of making things uses a variety of methods to cut, bend, and put together parts from flat sheets of metal. It is the best way to make strong and cheap parts like enclosures, brackets, chassis, and panels. Our modern facility has the latest machines and is run by a skilled team. This lets us quickly and accurately turn your designs into high-quality finished products, from single prototypes to large-scale production runs.

A Complete Fabrication and Assembly Solution

Our facility is set up to handle every step of the sheet metal fabrication process in one place, which helps with quality control and quick lead times. We have the tools and know-how to make your project a reality, from precise cutting to final assembly.

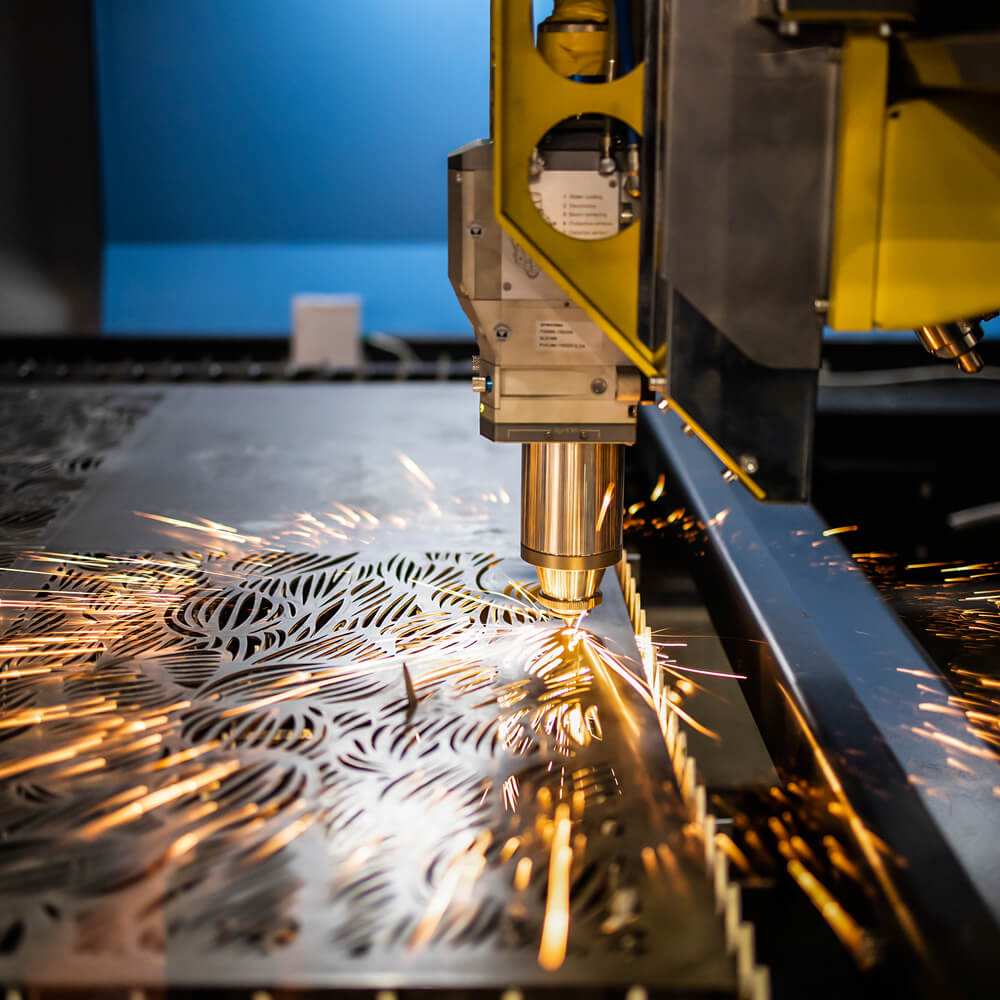

Laser Cutting

Our high-power fiber lasers can cut through a wide range of metals and thicknesses with amazing accuracy. This method is great for making clean edges, complex contours, and intricate patterns, which are all important for making your parts.

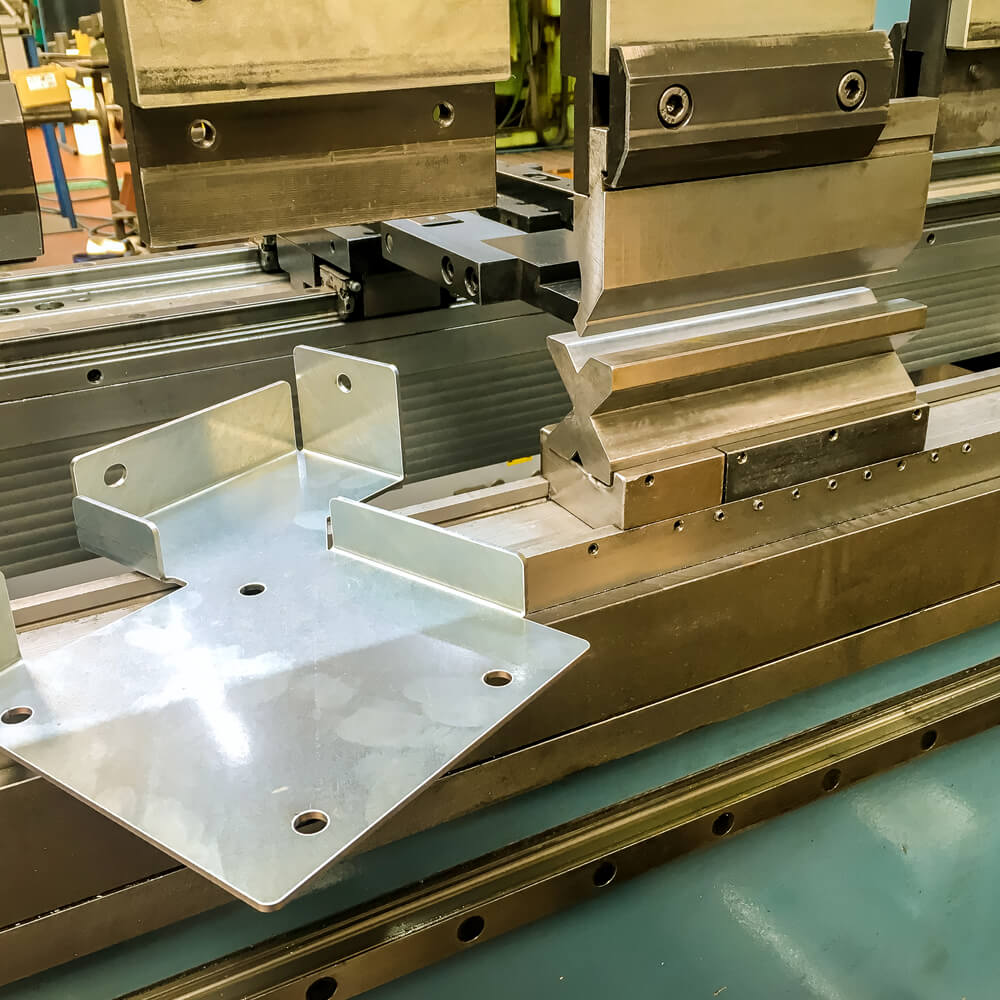

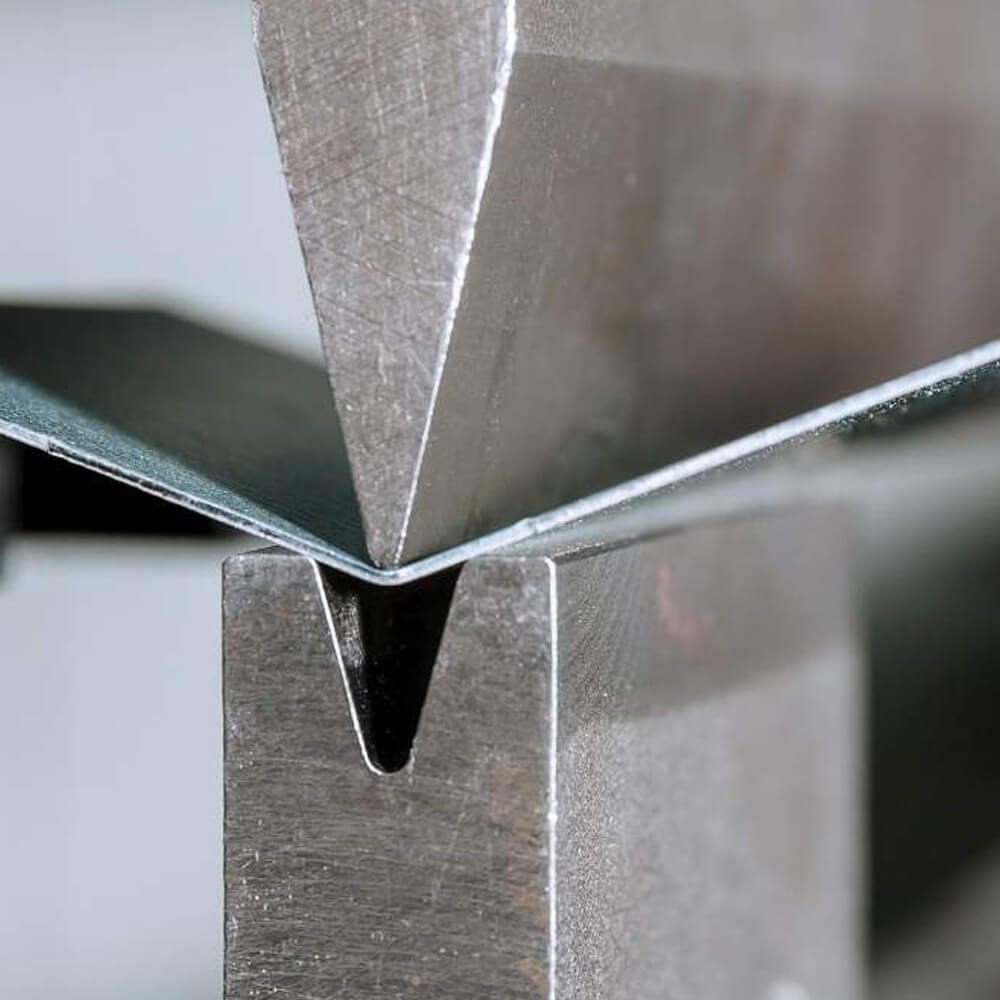

CNC Bending & Forming

We use multi-axis CNC press brakes to bend and shape sheet metal parts with great accuracy and consistency. Our skilled operators can make complicated geometries with multiple bends, making sure that every angle and dimension is exactly what you need.

Welding & Assembly

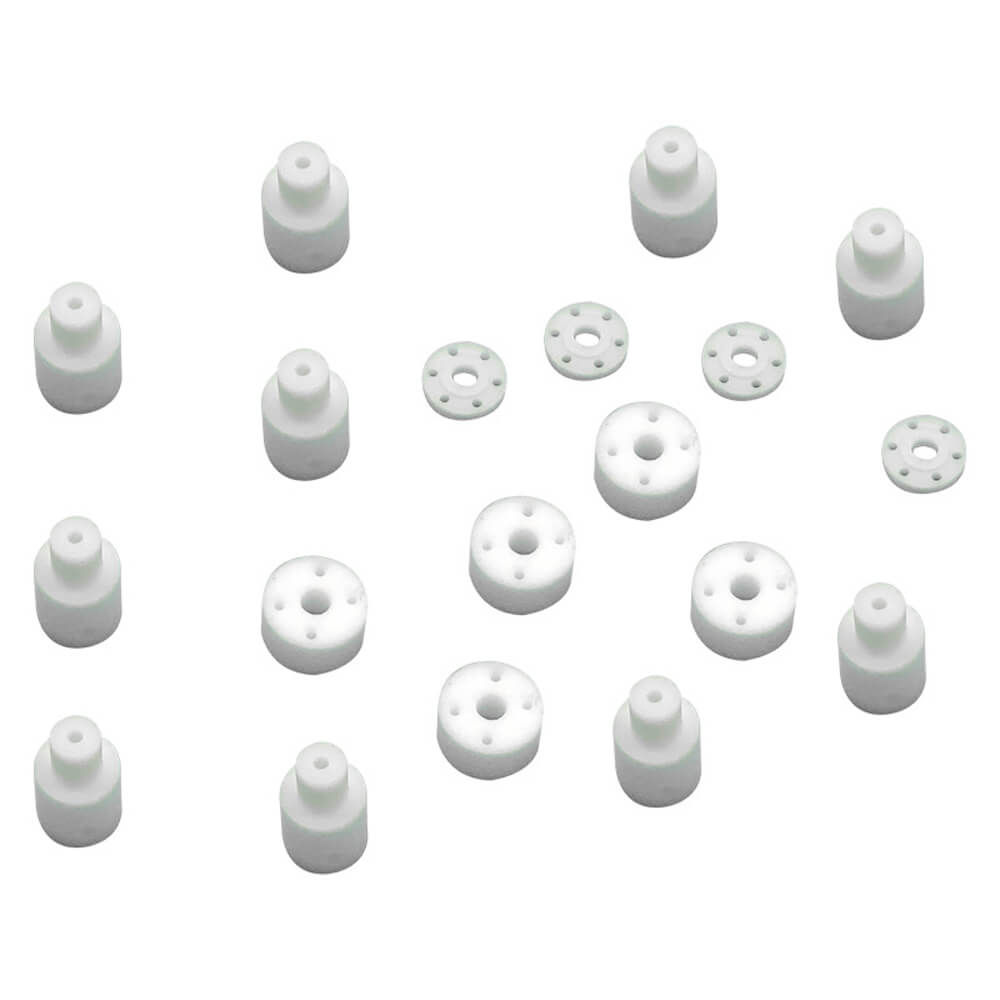

We do all kinds of welding, such as TIG, MIG, and spot welding, to make strong and clean assemblies. We also offer full assembly services, which include putting together things like PEM nuts, studs, and standoffs.

Sheet Metal Fabrication Materials

Metal

Aluminum is strong, light metal that can be used for many things and doesn’t rust easily.

- Available Grades: 6061, 7075, 5052, 2024, 6063, 6082, 5083

- Common Finishes: As Machined, Anodizing, Powder Coating, Sand Blasting, Chromate (Alodine)

Copper

Copper has great electrical and thermal conductivity, which makes it the best choice for heat sinks and electrical parts.

- Available Grades: C101 (OFHC), C110 (ETP)

- Common Finishes: As Machined, Electropolishing, Plating, Clear Coat

Brass

Brass is great for making fittings and decorative elements since it is easy to work with and looks like gold.

- Available Grades: C360

- Common Finishes: As Machined, Polishing, Plating, Brushing

Bronze

Bronze is durable and has minimal friction, it is widely used for naval hardware, bushings, and bearings.

- Available Grades: C932, C954

- Common Finishes: As Machined, Tumbling

Steel

Steel is a robust, long-lasting, and cheap material that works well in high-stress and industrial settings.

- Available Grades: Mild Steel (1018, 1020), Alloy Steel (4140, 4340), Tool Steel

- Common Finishes: Black Oxide, Zinc Plating, Powder Coating, Painting

Stainless Steel

Stainless steel is very strong and doesn’t rust easily, so it’s great for use in food, medical, and maritime settings.

- Available Grades: 303, 304/304L, 316/316L, 17-4 PH, 416, 420

- Common Finishes: Passivation, Electropolishing, Brushed Finish, As Machined

Magnesium

Magnesium is a very light metal that is great for uses where every gram matters.

- Available Grades: AZ31, AZ91

- Common Finishes: Chromate Conversion Coating

Titanium

Titanium is a high-performance metal that is quite strong for its weight and is also very biocompatible.

- Available Grades: Grade 2, Grade 5 (Ti-6Al-4V)

- Common Finishes: As Machined, Anodizing (for color), Sand Blasting

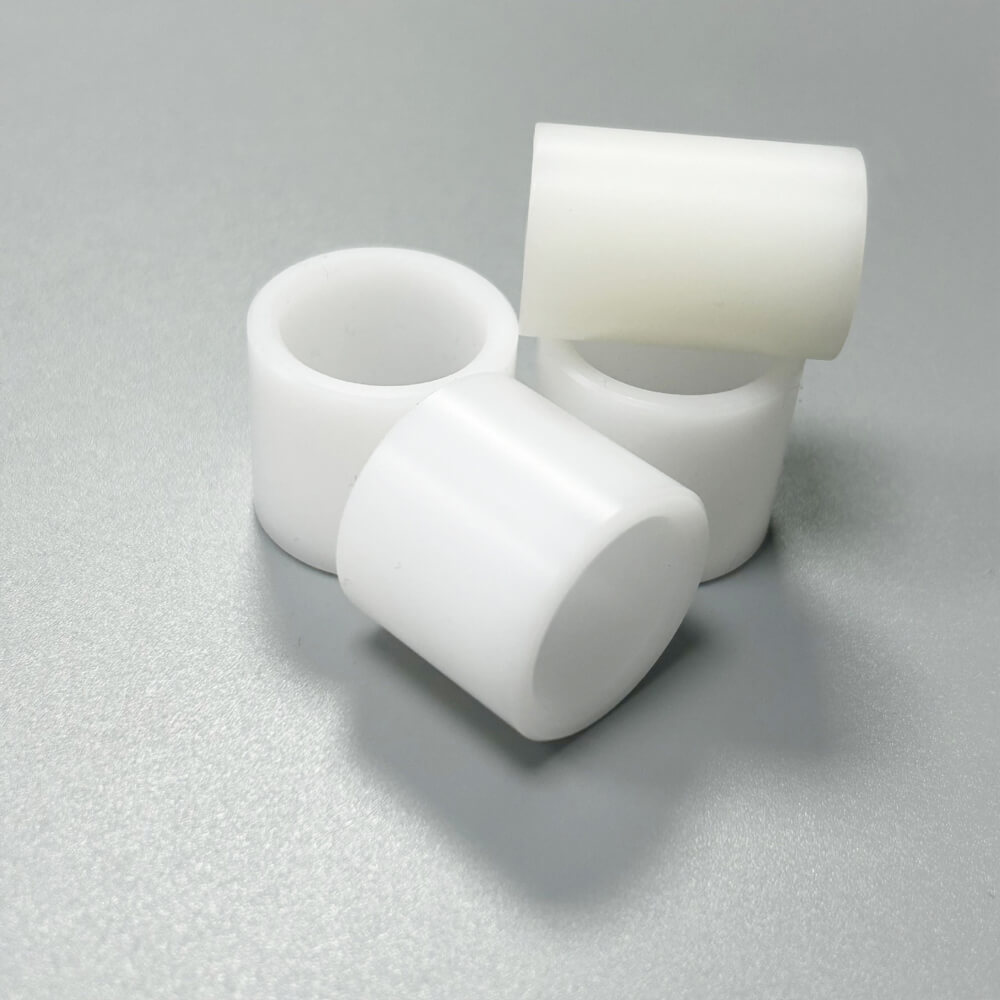

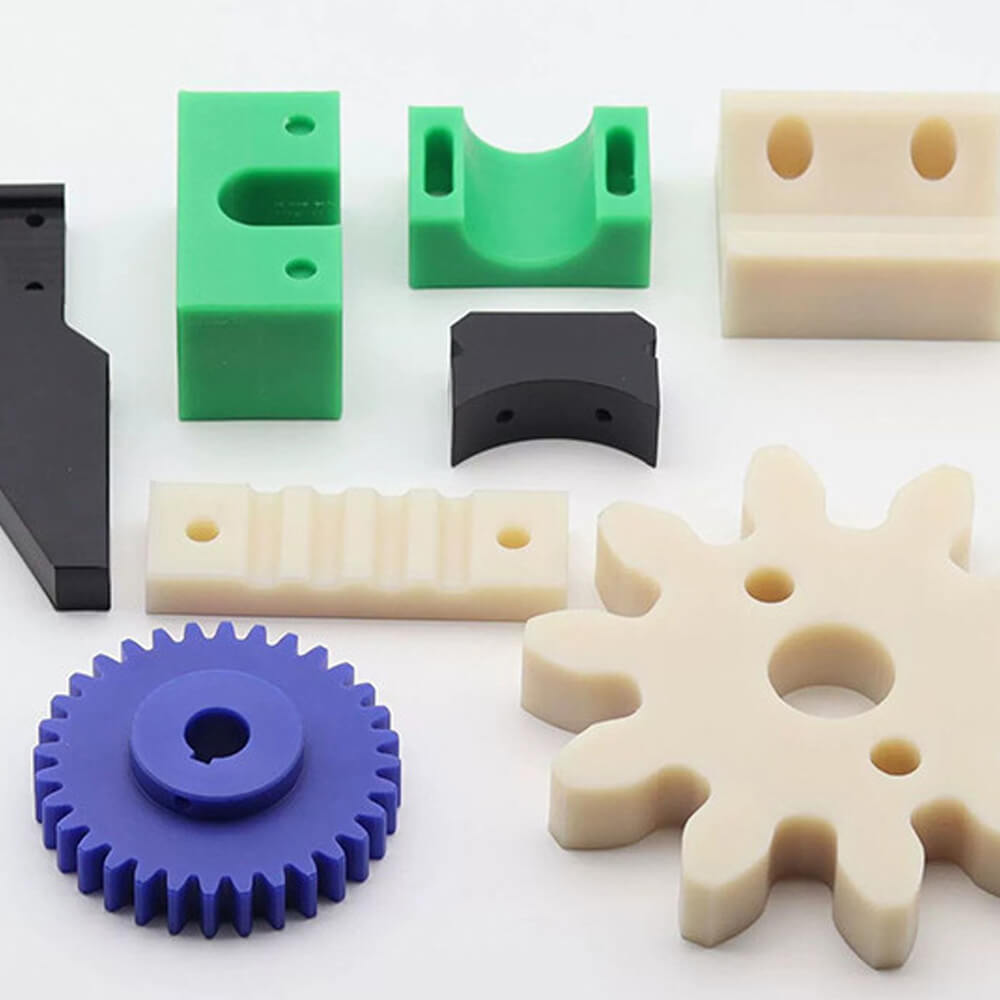

Plastic

ABS

ABS is a strong, impact-resistant, and cost-effective thermoplastic that works well for housings, enclosures, and prototypes.

Common Finishes: As Machined, Sand Blasting, Painting

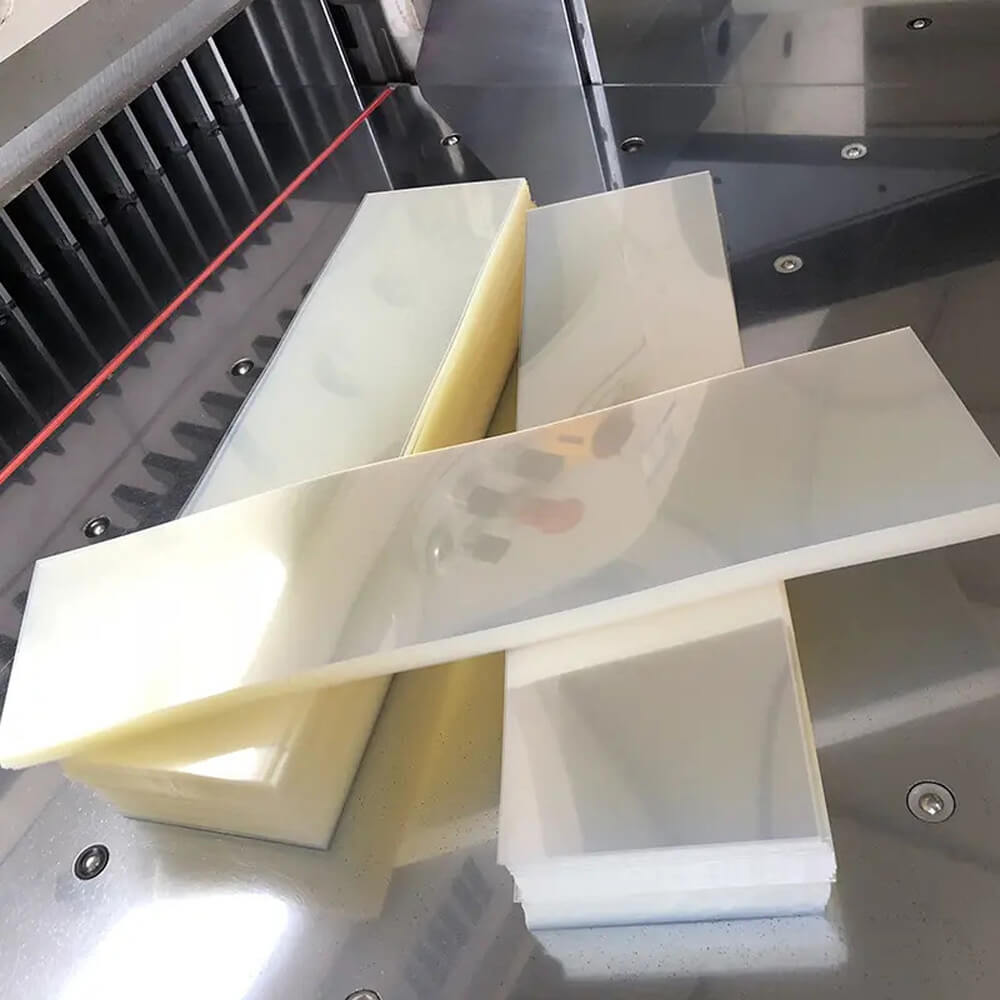

PC (Polycarbonate)

PC is a sturdy, clear material that can handle heat and impact very well.

- Common Finishes: As Machined, Vapor Polishing, Painting

PLA

PLA is a thermoplastic that breaks down naturally and comes from renewable resources. It is often used for quick prototyping.

Common Finishes: As Machined, Painting

PMMA (Acrylic)

PMMA is a clear, hard plastic with great optical clarity. It is widely used as a light-weight substitute to glass.

Common Finishes: As Machined, Vapor Polishing, Flame Polishing

POM (Delrin/Acetal)

POM is an engineering plastic that is low-friction and high-stiffness, making it great for gears and bearings.

Common Finishes: As Machined

PA (Nylon)

PA is a strong and flexible plastic that can stand up to chemicals and wear.

- Available Grades: PA6, PA66

- Common Finishes: As Machined

PE (Polyethylene)

PE is a typical type of plastic that can withstand chemicals and comes in varying densities for different uses.

Common Finishes: As Machined

PEEK

PEEK is a high-performance polymer that is very strong, resistant to chemicals, and stable at high temperatures.

Common Finishes: As Machined

PP (Polypropylene)

PP is a light plastic that is very elastic and resistant to chemicals. It is widely used for living hinges.

Common Finishes: As Machined

HIPS

HIPS is a cheap, stiff plastic that is easy to work with and is typically used to make prototypes before production.

Common Finishes: As Machined, Painting

PBT

PBT is a type of engineering thermoplastic that is stiff, stable in size, and can handle chemicals and heat.

Common Finishes: As Machined

PPA

PPA is a high-performance polyamide that is stronger, stiffer, and more heat-resistant than regular nylon.

Common Finishes: As Machined

PAI (Torlon)

PAI is high-performance plastic that is exceedingly strong and rigid and keeps its qualities even at very high temperatures.

Common Finishes: As Machined

PET

PET is a tough, rigid plastic used in engineering that resists chemicals well and wears well.

Common Finishes: As Machined

PPS

PPS is a high-performance thermoplastic that can withstand chemicals and high temperatures without changing shape.

Common Finishes: As Machined

PS (Polystyrene)

PS is a clear, rigid, and brittle plastic that doesn’t cost much and is typically used for prototypes.

Common Finishes: As Machined, Painting

PVC

PVC is a strong, long-lasting, and cheap plastic that doesn’t easily get damaged by chemicals or water.

Common Finishes: As Machined

PTFE (Teflon™)

PTEE is known for having a very low coefficient of friction, being chemically inert, and being able to handle high temperatures.

Common Finishes: As Machined

Bakelite

Bakelite is a thermoset plastic that is hard, thick, and resistant to heat. It also has good electrical insulating qualities.

Common Finishes: As Machined

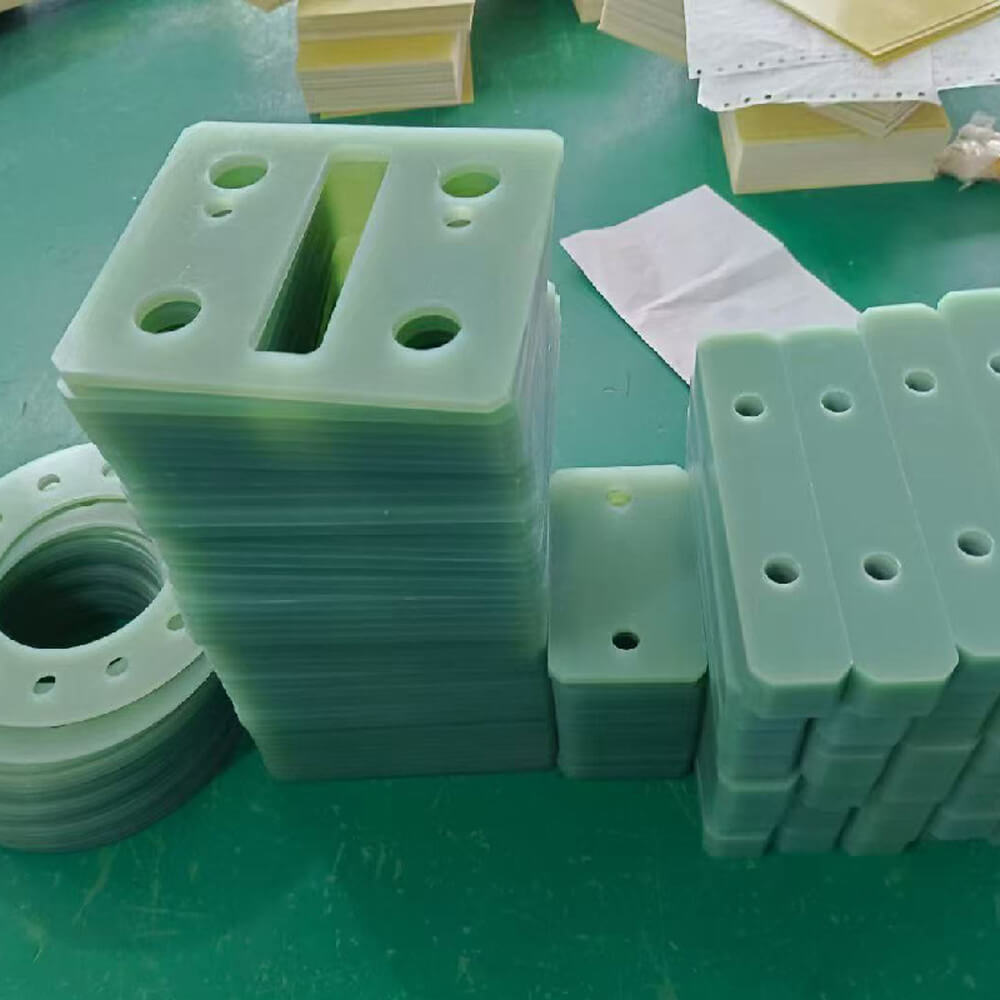

FR-4

FR-4 is a glass-reinforced epoxy laminate that is very strong and has great electrical insulation qualities.

Common Finishes: As Machined

CNC Surface Finish Enhance and Protect Your Parts

As Machined

The basic finish, which is the cheapest and most common, has obvious tool marks right from the machine.

Sand Blasting

Makes a smooth, non-reflective matte surface that looks good and helps paint stick better.

Tumbling

A mass-finishing method that quickly removes burrs and smooths off groups of parts.

Electropolishing

Makes metals like stainless steel have a finish that is super smooth, bright, and clean down to the smallest details.

Heat Treatment

A thermal procedure that changes mechanical qualities like strength and hardness (not only for looks).

Alodine

A chemical coating for aluminum that protects it from rust while yet letting electricity flow through it.

Anodizing

Makes a colored surface on metal and titanium that is sturdy, long-lasting, and attractive.

Teflon™ Coating

A fluoropolymer coating that doesn't stick and has low friction. It also resists chemicals very well.

Black Oxide

A conversion coating for steel that gives it a deep black finish without changing its size.

Electroless Plating

A uniform chemical plating procedure (like nickel) that makes all surfaces very hard and resistant to rust.

Electroplating

An electrochemical procedure that puts down a metal layer (such zinc, nickel, or chrome) for decorative or protective purposes.

Painting

A liquid coating that may be sprayed on and comes in a wide range of colors for a decorative and protective finish.

Passivation

A chemical cleaning method that makes stainless steel as resistant to corrosion as possible.

Powder Coating

An electrostatically applied powder dried to provide a finish that is stronger than regular paint.

Electrophoresis

An E-coat procedure that dips items in a coating to cover them completely and evenly.

Brushed Finish

A high-end, refined style with a unidirectional satin grain finish.

Ready to Fabricate Your Custom Parts?

From a simple bracket to a complex assembly, we’re ready to build it.

Why Choose Celerity Precision

Integrated In-House Capabilities

We manage every step of the process—from high-precision laser cutting and CNC bending to TIG/MIG welding and hardware insertion—ensuring seamless quality control and faster lead times.

Design for Manufacturability (DFM) Expertise

Our engineers review every design to ensure it is optimized for fabrication, providing feedback on bend radii, material selection, and feature placement to reduce cost and improve quality.

Precision and Repeatability

Our modern CNC press brakes and laser cutters guarantee that every part, from the first to the thousandth, is bent and cut with exceptional accuracy and consistency.

Complete Assembly Services

We are more than just a parts supplier; we are a solutions partner. We can deliver fully assembled products, complete with installed hardware, welding, and finishing.

From Prototype to Production Scale

We have the flexibility to produce a single, complex prototype enclosure or scale up to a full production run of thousands of brackets, all with the same commitment to quality.

Durable, High-Quality Finishes

We offer a complete range of finishing options, including durable powder coating and cosmetic anodizing, to ensure your fabricated parts look professional and withstand their end-use environment.

From Digital File to Finished Assembly in 4 Simple Steps

Submit Design & Get Quote

Securely upload your CAD files (STEP, DXF). Our team provides a detailed quote and DFM feedback within 24 hours.

DFM Review & Order Confirmation

We help optimize your design for fabrication. Once you approve, we program the machines.

Precision Fabrication & Assembly

Your parts are expertly cut, bent, welded, and assembled by our skilled technicians according to your exact specifications.

Inspection & Global Delivery

Every part and assembly is rigorously inspected before being securely packaged and shipped to your door.

Sheet Metal Fabrication in Action

Challenge

An electronics company needed a custom 1U server chassis in aluminum with complex ventilation patterns and precise locations for inserted hardware.

Solution & Result

We used laser cutting for the intricate vents, CNC bending for perfect angles, and automated hardware insertion for the PEM standoffs. We delivered 1,000 finished assemblies ready for the production line, saving the client significant assembly time.

Challenge

A manufacturer of industrial machinery required heavy-duty steel safety guards that were durable and highly visible.

Solution & Result

We fabricated the guards from 3mm thick steel sheet, using MIG welding for strong joints. A durable "safety yellow" powder coat finish provided both high visibility and long-term protection against wear and corrosion in a factory environment.

Challenge

A medical equipment company needed a sleek, easy-to-clean enclosure for a diagnostic device, made from 304 stainless steel with a premium look.

Solution & Result

We laser cut the components, used TIG welding for clean, non-porous seams, and then applied a #4 brushed finish with a specific grain direction. The final product was both aesthetically pleasing and met the hygienic standards of the medical industry.

Custom Sheet Metal Fabrication Services - Celerity Precision

“Innovation is what makes a leader different from a follower.” What Steve Jobs said is true in the field of custom sheet metal production.

Celerity Precision is the best custom metal sheet fabrication services provider in China. Here, accuracy and new ideas come together to build complicated parts.

We provide high-quality sheet metal fabrication services to a wide range of businesses. Our high-tech facilities in China use the newest technology. This makes sure that we create sheet metal parts quickly and with great accuracy.

We are proud of how stringent our quality control is. This guarantees that each item meets the highest requirements. They are quite good at making precise sheet metal parts.

Important Points

- Making complicated parts requires custom sheet metal fabrication.

- Advanced technology means accuracy and speed.

- Strict quality control is necessary for the best goods.

- China is one of the best places to get sheet metal work done.

- Many businesses use precision sheet metal fabrication.

Introduction

Making items like panels and brackets out of sheet metal is very important. Our team in China provides personalized services for a wide range of sectors. We put a lot of emphasis on accuracy and flexibility.

What is Sheet Metal Fabrication

Sheet metal fabrication makes pieces and structures out of metal sheets. It shapes metal by cutting, bending, and putting things together. Experts believe it’s about turning raw metal into functional shapes.

Uses and Benefits

Making things out of sheet metal makes them strong and accurate. It’s utilized in autos, electronics, construction, and space travel. It works well for both simple and complicated pieces.

The key advantages are:

- Very high accuracy and precision

- The parts are strong and last a long time.

- Design and manufacture that can be changed

- Affordable for projects of all sizes

Limitations and Trade-offs

There are certain problems with making something out of sheet metal. There are problems with the tools, the design, and the materials. Some materials are tougher to work with than others.

Knowing about these problems helps the process get better. We focus on design for manufacturability to make sure that projects go smoothly.

Common Materials

There are many different kinds of metals used in sheet metal manufacturing, and each has its own pros and cons. We have a vast warehouse full of high-quality metals at our site. This makes sure we have everything we need for any job.

Different Kinds of Metals Used

We work with metals like aluminum, brass, copper, stainless steel, and titanium. We pick each metal because of its unique properties. This is what makes them great for a variety of tasks.

- Steel is strong and lasts a long time, therefore it’s perfect for making things.

- Aluminum is a great material for saving weight because it is light and doesn’t rust.

- Stainless steel doesn’t rust, therefore it’s appropriate for areas where there are chemicals or water.

- Copper is a good conductor of heat and electricity, hence it is utilized in many electrical and heating systems.

- Brass is a robust metal that doesn’t rust and looks attractive. It is made of copper and zinc.

- Titanium is incredibly robust, doesn’t rust, and is utilized in planes and medical equipment.

Properties of the Material

The metals we utilize are very important. They choose the proper metal for a project. Strength, how well it can be formed, how well steel resists rust, and how much it costs are all important factors.

| Material | Strength | Formability | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Steel | High | Good | Low | Moderate |

| Aluminum | Moderate | Excellent | High | Moderate |

| Stainless Steel | High | Good | Excellent | High |

| Copper | Moderate | Good | High | High |

| Brass | High | Good | High | Moderate |

| Titanium | High | Fair | Excellent | Very High |

Differences Between Sheet and Plate Thickness

When working with sheet metal, the thickness of the material is quite important. Plates are thicker than sheets.

We can work with various kinds of thicknesses. There are thin sheets for accurate work and hefty plates for heavy-duty operations.

Fabrication Processes / Techniques

Our team uses welding, laser cutting, stamping, and CNC machining. This makes sure that we make parts that are both accurate and useful. We at Celerity Precision work hard to make high-quality sheet metal parts.

Cutting Methods

For precise cuts, we use plasma cutting, laser cutting, and water jet cutting. Each method is good for a distinct purpose, such speed or precision. They go nicely with a lot of different things.

- Laser cutting is great for making precise cuts and detailed designs.

- Plasma cutting: A great way to quickly cut through heavy materials.

- Water jet cutting is great for cutting out complicated shapes without damaging them with heat.

Punching, Notching, and Blanking

Punching, notching, and blanking are very important in working with sheet metal. They form the metal with a die. Notching cuts edges, punching makes holes, and blanking cuts out shapes.

Bending and Forming

Bending and shaping the metal into the shapes you need. We employ deep drawing, press brake bending, and roll shaping. These technologies allow us construct shapes that are very complicated with accuracy.

- Press brake bending is a great way to bend metal at angles.

- Roll shaping is the best way to make shapes that are always the same.

- Deep drawing works well for designs that are cup-shaped or have a lot of detail.

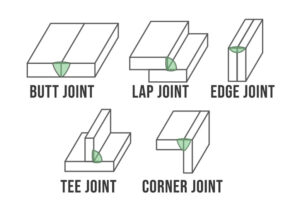

Joining Methods: Welding, Riveting, Brazing, and Adhesives

It’s very important to put parts together while working with sheet metal. We employ adhesives, welding, riveting, and brazing. Each method has its own merits, such as strength and beauty.

Step-by-Step Fabrication Workflow

We have a precise step-by-step process for creating high-quality items at Celerity Precision. Our team of qualified engineers and technicians works closely together. They make sure that every step is done exactly right.

Design and Blueprint: CAD, Flat Pattern Design, and DFM

The first thing to do is design. We utilize CAD software to produce comprehensive plans and flat patterns. This step is very important for design for manufacturability (DFM). It helps us uncover and fix flaws with the way things are made early on.

Our technical staff makes sure that the design is easy to make. They use the newest technology to make the process of making things easier.

Material Selection & Preparation

We choose the suitable materials after the design is finished. We chose based on what the project needs, such as strength and how well it resists corrosion.

After that, we prepare the stuff for production. We cut it to the correct size and tried to use as little waste as possible.

Cutting and Profiling

The next step is to cut and shape the material. We use high-tech tools like plasma cutters and laser cutters. This makes it easy for us to make accurate cuts and forms that are hard to make.

We can cut a lot of different materials precisely using our high-quality tools. We address the exact needs of each project.

Bending and Shaping

We bend and shape the material after cutting it. Depending on the bend and the material, we employ either press brakes or roll forming equipment.

Our trained specialists keep an eye on the bending process. They check that the finished product meets all the specifications and is perfect.

Design Considerations & Best Practices

Following best practices is the most important thing to do to acquire the greatest results in sheet metal manufacturing. Celerity Precision’s team does design for manufacturability analysis. This helps make the design of the product better and less expensive.

When you design with care, your sheet metal projects will work better and cost less. Designers may build goods that are helpful and cheap to make if they know how fabrication works.

Grain Direction, Reliefs, and Bending Radii

When creating items out of sheet metal, you should think about the bending radii, the grain direction, and the reliefs. To avoid damage, the bending radius must match the thickness of the material. The direction of the grain impacts how the metal bends, therefore it’s important to keep this in mind when designing. Adding reliefs can also make the part stronger and less stressful.

Tolerances, Bend Allowance, Flat Pattern Accuracy

When working with sheet metal, it’s important to know how to set tolerances, allow for bends, and make sure the flat pattern is correct. Tolerances tell you how big or little a part can be. Knowing how much bend to allow helps you figure out how to lay out bent parts. Getting the flat pattern properly is critical for the final shape of the part.

Minimize Welding / Optimize for Joining

Making pieces that need less welding and better ways to link them saves money and speeds up production. Designers can make pieces easier and cheaper to put together by choosing the correct way to join them, such welding or riveting.

Cost, Material Waste, Lead Time Trade-offs

Designers need to think about the cost, waste of materials, and lead time. You can save money by making designs that utilize less material and are easier to create. Our team helps clients find methods to cut costs and make things run more smoothly.

Applications / Industries

We work with a lot of different industries, such as commercial, industrial, and consumer goods. We also do work in the domains of architecture and aerospace. We offer a lot of different services, from storing energy to making medical cabinets.

Commercial and Industrial Applications

Sheet metal is very important for business and industrial purposes. It is used for ductwork, roofing, and frames. We create parts that are just right for your needs.

- HVAC systems are one of the main uses.

- Enclosures for electrical equipment

- Framing the structure

Consumer Products, Appliances, Enclosures etc.

Making things for people to use requires sheet metal. We pay attention to pieces that operate well and look well. This makes them stand out in the market.

We make things like:

- Appliances for the home

- Cases for electronics

- Parts for cars

Specialized Uses (Architectural, Aerospace, Medical)

In addition to its many uses in everyday life, sheet metal is also employed in architecture, aircraft, and medical. These sections need to be exact and follow rigorous guidelines.

Some well-known instances are:

- Architectural details like railings and decorative facades

- Parts for aerospace that need to be very precise and last a long time

- Medical instruments and equipment that need tight quality control

At Celerity Precision, we are happy to work with a lot of different businesses. We provide high-quality sheet metal fabrication services that are customized to meet the needs of each industry.

Design Guide: Sheet Metal Fabrication

Following a design guide is very important if you want to get the best outcomes while working with sheet metal. Our guide will help you understand how to make things and come up with designs that are straightforward to follow.

Overview

Cutting, bending, and connecting are all parts of sheet metal fabrication. For efficient manufacture and quality, a good design must take these phases into account. The material, tolerances, and design of bends and holes are all important items to think about.

Tolerances

In sheet metal fabrication, tolerances are very important. They show how much you can change while making pieces. To make sure parts fit well and fulfill requirements, you need to know and specify the right tolerances.

Depending on the method and material, common tolerances are between 0.1 mm and 0.5 mm. Always ask the fabricator what tolerances are possible for your project.

Sheet Stock Sizes & Gauge Lookup Chart

There are many sizes and thicknesses of sheet metal, which are measured in gauges. A gauge lookup chart shows how thick a material is based on its gauge number.

| Gauge | Thickness (mm) | Thickness (in) |

|---|---|---|

| 18 | 1.2 | 0.0478 |

| 20 | 0.9 | 0.0359 |

| 22 | 0.7 | 0.0279 |

Quoting Formats: 3D CAD & DXF Files

If you want accurate quotations and a seamless production process, send 3D CAD or DXF files with your design. These formats let fabricators look at your design and offer you specific prices.

Check that your design files are clean, proper, and free of mistakes. This keeps everything clear and makes sure your parts are manufactured perfectly.

Standards, Safety & Environmental Aspects

At Celerity Precision, we make sure our work is safe and green by following the standards and checking for quality. We want to make the best products, keep our people safe, and have a little impact on the environment.

Safety in Fabrication

Our number one goal is to keep our crew safe. We have tight standards for how to handle materials, use machinery, and weld. We train and practice our staff regularly to prepare for any threats.

- How to safely handle and store materials

- Correct usage of personal protection equipment (PPE)

- Taking care of machinery and equipment on a regular basis

Standards for Materials and Regulations

We make sure that our items meet all the rules and standards. This means that we use materials that meet the technical standards and follow the rules of the industry.

Material standards are very important for how well our product works and how good it is. We get materials from sources we trust who meet these requirements. This makes sure that our work is dependable.

Environmental effects, Recycling, and Sustainability

We at Celerity Precision want to have less of an effect on the environment. We do this by reusing metal wastes and making our fabrication process more efficient to reduce waste.

Some of the things we do to help the environment are:

- Putting in place recycling initiatives for scrap metal

- Making the most of fabrication processes to cut down on waste

- Using materials and coatings that are good for the environment when you can

These steps help us safeguard the environment and do our jobs more quickly and cheaply.

Innovative Perspectives and Trends for the Future

There is going to be a huge change in the sheet metal fabrication business. New technology and better ways of making things are behind this change. There is a huge shift toward CNC, automation, and smart fabrication. These developments are affecting how sheet metal goods are created and sent out.

Automated and Smart Fabrication

We are all about new ideas at Celerity Precision. Our factory keeps getting smarter and more advanced. This is very important for automation and CNC machining. They help us be more accurate, work faster, and get more done.

Smart fabrication can help us make production better. We can address consumer needs faster and cut down on waste. We can’t wait to see what the future holds with these new tools.

Final Thoughts

Sheet metal fabrication is the most important part of modern production. It combines precision, flexibility, and new ideas to make complicated designs come to reality. Every stage, from picking the correct materials to using advanced techniques like laser cutting, bending, and welding, needs skill and careful attention to detail. China is still the best place in the world for custom sheet metal fabrication because it has cutting-edge technology, talented workers, and affordable solutions for many different industries.

We at Celerity Precision are committed to making sheet metal parts that are high-quality, long-lasting, and dependable, and that meet tight industry standards. We make sure our clients get the best solutions that are both efficient and ready for the future by using automation, smart fabrication, and eco-friendly methods. Our goal is to turn ideas into precision-engineered products that push innovation forward, whether they are for aerospace, medical, construction, or consumer use.

Sheet Metal Fabrication FAQs

What is the process of making sheet metal?

Making anything out of sheet metal is called sheet metal fabrication. We make them by cutting, punching, bending, and connecting. We want to make bespoke parts that can be used in a lot of different ways.

What are the advantages of making custom sheet metal?

Custom sheet metal production gives you accuracy, speed, and adaptability. We can create intricate patterns that meet certain needs. This makes it great for fields like medicine and aerospace.

What kinds of materials are often used to make sheet metal?

We use metals like steel, aluminum, and titanium. The proper material will rely on the project’s needs and budget. Our team helps you pick the right materials for your project.

What kinds of fabrication are used to make sheet metal?

We cut with lasers, plasmas, and bends. We also use welding and brazing to put parts together. Our advanced facilities make sure that the parts are of high quality.

How can you make sure that the sheet metal parts you make are of good quality?

Our quality staff makes sure that products meet technical criteria. We also respect rules on the environment and materials. Our work is guided by quality and sustainability.

What are some essential design factors to think about when making sheet metal?

The direction of the grain and the bending radius are very important. Our engineers help make things that are worth more. They provide you ideas about how to make your designs better.

What kinds of businesses do you make custom sheet metal for?

We make things for a lot of different fields. This includes cupboards for batteries and medical supplies. We also offer services that fulfill the needs of architecture and aerospace.

How do you make sure that safety and the environment are taken into account when working with sheet metal?

Safety is our number one goal. We follow rules and safe practices. We also want to lessen the damage our job does to the environment. We want a safe workplace and a smaller impact on the environment.

What do you think will happen in the future with sheet metal fabrication?

The future is all about smart fabrication and automation. We are dedicated to using modern technology. This lets us give our customers new ways to solve their problems.

FAQs - Celerity Precision

What is the difference between laser cutting and CNC punching?

Laser cutting is ideal for intricate contours, complex shapes, and cutting thicker materials with a smooth edge. CNC punching is extremely fast and cost-effective for parts with many standard-sized holes or simple shapes.

What is the maximum material thickness you can process?

We can laser cut steel up to [e.g., 20mm], stainless steel up to [e.g., 15mm], and aluminum up to [e.g., 12mm]. Bending capabilities depend on the material and thickness. Please contact us with your specific needs.

What are your standard tolerances for sheet metal parts?

Our standard tolerances for sheet metal features are typically ±0.2mm (±0.008″). Tighter tolerances are achievable but depend on the material, thickness, and geometry.

What file formats are best for sheet metal?

For a complete part, a STEP file is best. For flat patterns, a DXF or DWG file is ideal. Providing both is a great way to ensure accuracy.

Can you install hardware like PEM nuts and studs?

Yes, absolutely. We have dedicated hardware insertion presses and can install a wide variety of self-clinching nuts, studs, and standoffs as part of our assembly service.

What is a "bend radius," and why is it important?

The bend radius is the inside radius of a bend. It’s important because bending metal too sharply can cause it to crack. Our standard inside bend radius is typically equal to the material thickness, but we can accommodate other requirements.